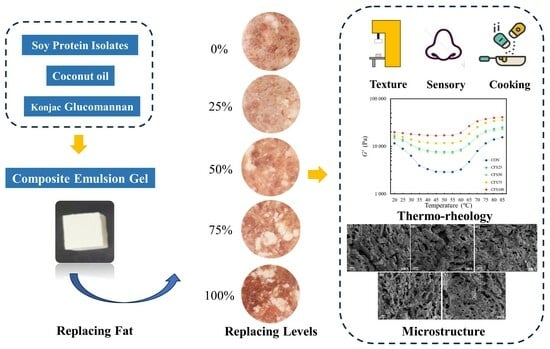

Quality, Thermo-Rheology, and Microstructure Characteristics of Cubic Fat Substituted Pork Patties with Composite Emulsion Gel Composed of Konjac Glucomannan and Soy Protein Isolate

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effects of CFS Containing Different Concentrations of KGM on Lean Meat Patties

2.1.1. Sensory Attributes

2.1.2. Texture Profile

2.2. Effect of Replacing Pork Back Fat with CFS

2.2.1. Proximate Composition

2.2.2. Lipid Oxidation

2.2.3. Color

2.2.4. Technological Characteristics

2.2.5. Texture Profile

2.2.6. Sensory Attributes

2.2.7. Thermo-Rheology Properties

2.2.8. Microstructure

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Preparation of CFS

4.3. Preparation of Pork Patties

4.4. Sensory Evaluation

4.5. Texture Profile Analysis

4.6. Proximate Composition, Color, and Technological Characteristics

4.7. Lipid Oxidation Stability

4.8. Thermo-Rheology Analysis

4.9. Microstructure Observation

4.10. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alves, L.A.A.d.S.; Lorenzo, J.M.; Gonçalves, C.A.A.; Santos, B.A.d.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna type sausages using pork skin and green banana flour as a fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Global Initiative on Diet, Physical Activity and Health; WHO: Geneva, Switzerland, 2013. [Google Scholar]

- Ren, Y.; Huang, L.; Zhang, Y.; Li, H.; Zhao, D.; Cao, J.; Liu, X. Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods 2022, 11, 1950. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Munekata, P.E.S.; Pateiro, M.; López-Fernández, O.; Lorenzo, J.M. Immobilization of oils using hydrogels as strategy to replace animal fats and improve the healthiness of meat products. Curr. Opin. Food Sci. 2021, 37, 135–144. [Google Scholar] [CrossRef]

- Dreher, J.; Weißmüller, M.; Herrmann, K.; Terjung, N.; Gibis, M.; Weiss, J. Influence of protein and solid fat content on mechanical properties and comminution behavior of structured plant-based lipids. Food Res. Int. 2021, 145, 110416. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Cui, L.; Meng, Z. Oleogels/emulsion gels as novel saturated fat replacers in meat products: A review. Food Hydrocoll. 2023, 137, 108313. [Google Scholar] [CrossRef]

- Alejandre, M.; Passarini, D.; Astiasarán, I.; Ansorena, D. The effect of low-fat beef patties formulated with a low-energy fat analogue enriched in long-chain polyunsaturated fatty acids on lipid oxidation and sensory attributes. Meat Sci. 2017, 134, 7–13. [Google Scholar] [CrossRef]

- Huang, L.; Zhao, D.; Wang, Y.; Li, H.; Zhou, H.; Liu, X. Transglutaminase treatment and pH shifting to manipulate physicochemical properties and formation mechanism of cubic fat substitutes. Food Chem. X 2022, 16, 110508. [Google Scholar] [CrossRef]

- Ran, X.; Yang, H. Promoted strain-hardening and crystallinity of a soy protein-konjac glucomannan complex gel by konjac glucomannan. Food Hydrocoll. 2022, 133, 107959. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, J.; Li, X.; Liu, Q.; Kong, B. Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages. Foods 2021, 10, 1460. [Google Scholar] [CrossRef]

- Huang, L.; Ren, Y.; Li, H.; Zhang, Q.; Wang, Y.; Cao, J.; Liu, X. Create Fat Substitute from Soybean Protein Isolate/Konjac Glucomannan: The Impact of the Protein and Polysaccharide Concentrations Formulations. Front. Nutr. 2022, 9, 843832. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, W.; Zhou, G. Effects of glutinous rice flour on the physiochemical and sensory qualities of ground pork patties. LWT—Food Sci. Technol. 2014, 58, 135–141. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, H.; Xu, W.; Jia, C.; Peng, Y.; Zhuang, X.; Qi, J.; Xiong, G.; Mei, L.; Xu, X. The effect of water-insoluble dietary fiber from star anise on water retention of minced meat gels. Food Res. Int. 2022, 157, 111425. [Google Scholar] [CrossRef]

- Huang, L.; Liu, S.; Wang, Y.; Li, H.; Cao, J.; Liu, X. Effect of cooking methods and polysaccharide addition on the cooking performance of cubic fat substitutes. LWT 2023, 181, 114741. [Google Scholar] [CrossRef]

- Pan, N.; Dong, C.; Du, X.; Kong, B.; Sun, J.; Xia, X. Effect of freeze-thaw cycles on the quality of quick-frozen pork patty with different fat content by consumer assessment and instrument-based detection. Meat Sci. 2021, 172, 108313. [Google Scholar] [CrossRef]

- Cîrstea, N.; Nour, V.; Corbu, A.R.; Muntean, C.; Codină, G.G. Reformulation of Bologna Sausage by Total Pork Backfat Replacement with an Emulsion Gel Based on Olive, Walnut, and Chia Oils, and Stabilized with Chitosan. Foods 2023, 12, 3455. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef]

- Zheng, B.; Li, X.; Hao, J.; Xu, D. Meat systems produced with Monascus pigment water-in-oil-in-water multiple emulsion as pork fat replacers. Food Chem. 2023, 402, 134080. [Google Scholar] [CrossRef]

- Salcedo-Sandoval, L.; Cofrades, S.; Ruiz-Capillas, C.; Carballo, J.; Jiménez-Colmenero, F. Konjac-based oil bulking system for development of improved-lipid pork patties: Technological, microbiological and sensory assessment. Meat Sci. 2015, 101, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Cîrstea, N.; Nour, V.; Boruzi, A.I. Effects of Pork Backfat Replacement with Emulsion Gels Formulated with a Mixture of Olive, Chia and Algae Oils on the Quality Attributes of Pork Patties. Foods 2023, 12, 519. [Google Scholar] [CrossRef] [PubMed]

- Poyato, C.; Astiasarán, I.; Barriuso, B.; Ansorena, D. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT—Food Sci. Technol. 2015, 62, 1069–1075. [Google Scholar] [CrossRef]

- Carvalho Barros, J.; Munekata, P.E.S.; de Carvalho, F.A.L.; Pateiro, M.; Barba, F.J.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Use of Tiger Nut (Cyperus esculentus L.) Oil Emulsion as Animal Fat Replacement in Beef Burgers. Foods 2020, 9, 44. [Google Scholar] [CrossRef]

- Holman, B.W.B.; van de Ven, R.J.; Mao, Y.; Coombs, C.E.O.; Hopkins, D.L. Using instrumental (CIE and reflectance) measures to predict consumers’ acceptance of beef colour. Meat Sci. 2017, 127, 57–62. [Google Scholar] [CrossRef]

- Badar, I.H.; Li, Y.; Liu, H.; Chen, Q.; Liu, Q.; Kong, B. Effect of vegetable oil hydrogel emulsion as a fat substitute on the physicochemical properties, fatty acid profile, and color stability of modified atmospheric packaged buffalo burgers. Meat Sci. 2023, 199, 109143. [Google Scholar] [CrossRef] [PubMed]

- Ran, X.; Lou, X.; Zheng, H.; Gu, Q.; Yang, H. Improving the texture and rheological qualities of a plant-based fishball analogue by using konjac glucomannan to enhance crosslinks with soy protein. Innov. Food Sci. Emerg. Technol. 2022, 75, 102910. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Effect of preformed konjac gels, with and without olive oil, on the technological attributes and storage stability of merguez sausage. Meat Sci. 2013, 93, 351–360. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Choi, M.-J.; Cho, Y. Improved Physicochemical Properties of Pork Patty Supplemented with Oil-in-Water Nanoemulsion. Food Sci. Anim. Resour. 2020, 40, 262–273. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Liu, J.-Y.; Fu, L.; Zhao, Y.-Y.; Zhu, H.; Zhang, Y.-Y.; Zhang, H.; Bai, Y.-H. Effect of bamboo shoot dietary fiber on gel properties, microstructure and water distribution of pork meat batters. Asian-Australas. J. Anim. Sci. 2020, 33, 1180–1190. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; de Carvalho, F.A.L.; Domínguez, R.; Trindade, M.A.; Pateiro, M.; Lorenzo, J.M. Healthy beef burgers: Effect of animal fat replacement by algal and wheat germ oil emulsions. Meat Sci. 2021, 173, 108396. [Google Scholar] [CrossRef]

- Shao, L.; Bi, J.; Dai, R.; Li, X. Effects of fat/oil type and ethylcellulose on the gel characteristic of pork batter. Food Res. Int. 2020, 138, 109788. [Google Scholar] [CrossRef] [PubMed]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jimenez, M.J.; Jimenez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Technol. 2017, 54, 3959–3968. [Google Scholar] [CrossRef]

- Dias, M.F.; Guimarães, A.S.; Benevenuto Júnior, A.A.; Silva, V.R.O.; Fontes, P.R.; Ramos, A.d.L.S.; Ramos, E.M. Canola and olive oil gelled emulsions as pork fat replacers in beef burgers. Br. Food J. 2021, 124, 50–60. [Google Scholar] [CrossRef]

- Lucas-González, R.; Roldán-Verdu, A.; Sayas-Barberá, E.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Assessment of emulsion gels formulated with chestnut (Castanea sativa M.) flour and chia (Salvia hispanica L) oil as partial fat replacers in pork burger formulation. J. Sci. Food Agric. 2019, 100, 1265–1273. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Kong, B.; Zhao, J.; Liu, Q.; Diao, X. Contributions of Fat Content and Oxidation to the Changes in Physicochemical and Sensory Attributes of Pork Dumpling Filler during Frozen Storage. J. Agric. Food Chem. 2014, 62, 6390–6399. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, W.; Zhou, G. Emulsion stability, thermo-rheology and quality characteristics of ground pork patties prepared with soy protein isolate and carrageenan. J. Sci. Food Agric. 2014, 95, 2832–2837. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.L. A Comparison of the Rheological Characteristics of Different Fractions of Chicken Myofibrillar Proteins. J. Food Biochem. 1992, 16, 217–227. [Google Scholar] [CrossRef]

- Yoon, W.B.; Gunasekaran, S.; Park, J.W. Characterization of Thermorheological Behavior of Alaska Pollock and Pacific Whiting Surimi. J. Food Sci. 2006, 69, 338–343. [Google Scholar] [CrossRef]

- Pan, N.; Wan, W.; Du, X.; Kong, B.; Liu, Q.; Lv, H.; Xia, X.; Li, F. Mechanisms of Change in Emulsifying Capacity Induced by Protein Denaturation and Aggregation in Quick-Frozen Pork Patties with Different Fat Levels and Freeze–Thaw Cycles. Foods 2021, 11, 44. [Google Scholar] [CrossRef]

- Zhang, T.; Xue, Y.; Li, Z.; Wang, Y.; Xue, C. Effects of deacetylation of konjac glucomannan on Alaska Pollock surimi gels subjected to high-temperature (120 °C) treatment. Food Hydrocoll. 2015, 43, 125–131. [Google Scholar] [CrossRef]

- Hermansson, A.M.; Langton, M. Filamentous structures of bovine myosin in diluted suspensions and gels. J. Sci. Food Agric. 1988, 42, 355–369. [Google Scholar] [CrossRef]

- Campo-Deaño, L.; Tovar, C.A.; Jesús Pombo, M.; Teresa Solas, M.; Javier Borderías, A. Rheological study of giant squid surimi (Dosidicus gigas) made by two methods with different cryoprotectants added. J. Food Eng. 2009, 94, 26–33. [Google Scholar] [CrossRef]

- Yan, W.; Yin, T.; Xiong, S.; You, J.; Hu, Y.; Huang, Q. Gelling properties of silver carp surimi incorporated with konjac glucomannan: Effects of deacetylation degree. Int. J. Biol. Macromol. 2021, 191, 925–933. [Google Scholar] [CrossRef] [PubMed]

- National Health Comission of China. National Food Safety Standard; National Health Comission of China: Beijing, China, 2016.

- Shahiri Tabarestani, P.; Kashiri, M.; Maghsoudlou, Y.; Shahiri Tabarestani, H.; Ghorbani, M. Effect of Opuntia pulp as a clean label ingredient on techno-functional properties of meat-free burger. Int. J. Food Sci. Technol. 2022, 57, 3982–3989. [Google Scholar] [CrossRef]

- John, L.; Cornforth, D.; Carpenter, C.E.; Sorheim, O.; Pettee, B.C.; Whittier, D.R. Color and thiobarbituric acid values of cooked top sirloin steaks packaged in modified atmospheres of 80% oxygen, or 0.4% carbon monoxide, or vacuum. Meat Sci. 2005, 69, 441–449. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, T.; Xue, Y.; Xue, C. Changes of structural and physical properties of semi-gel from Alaska pollock surimi during 4 °C storage. Food Hydrocoll. 2019, 87, 772–782. [Google Scholar] [CrossRef]

| Parameters | TLP | KEG0 | KEG3.5 | KEG7 | KEG10.5 |

| Sensory characteristics | |||||

| Appearance | 6.0 ± 0.6 a | 4.5 ± 0.8 b | 6.0 ± 0.7 a | 6.2 ± 0.8 a | 4.0 ± 0.9 b |

| Aroma | 5.3 ± 0.8 b | 6.3 ± 0.8 a | 6.5± 0.5 a | 6.3 ± 0.5 a | 5.3 ± 0.8 b |

| Juiciness | 6.0 ± 0.7 b | 7.1 ± 0.5 a | 6.1 ± 0.3 b | 6.5 ± 1.1 ab | 6.0 ± 0.7 b |

| Tenderness | 5.7 ± 0.5 c | 6.7 ± 0.5 ab | 6.5 ± 0.5 b | 7.1 ± 0.6 a | 5.7 ± 0.8 c |

| Overall acceptability | 5.5 ± 0.5 c | 6.4 ± 0.5 b | 6.7 ± 0.5 ab | 7.25 ± 0.5 a | 4.4 ± 0.5 d |

| Texture parameters | |||||

| Hardness (N) | 89.23 ± 3.32 a | 50.20 ± 3.53 b | 40.34 ± 3.80 c | 25.00 ± 1.99 e | 32.82 ± 1.83 d |

| Springiness | 0.79 ± 0.04 ab | 0.80 ± 0.04 a | 0.72 ± 0.03 bc | 0.73 ± 0.05 abc | 0.71 ± 0.03 c |

| Cohesiveness | 0.54 ± 0.06 a | 0.54 ± 0.03 a | 0.40 ± 0.02 bc | 0.45 ± 0.02 abc | 0.43 ± 0.03 b |

| Chewiness (N) | 36.15 ± 1.78 a | 19.24 ± 1.07 b | 12.31 ± 0.43 c | 13.13 ± 0.30 c | 10.24 ± 0.97 c |

| Parameters | CON | CFS25 | CFS50 | CFS75 | CFS100 |

|---|---|---|---|---|---|

| Proximate composition (g/100 g) | |||||

| Moisture | 58.33 ± 0.82 e | 63.05 ± 0.48 d | 66.74 ± 0.65 c | 70.29 ± 0.13 b | 73.13 ± 0.11 a |

| Protein | 17.78 ± 0.12 b | 17.79 ± 0.15 b | 17.83 ± 0.13 b | 18.35 ± 0.10 a | 18.41 ± 0.11 a |

| Fat | 21.04 ± 0.46 a | 15.62 ± 0.77 b | 13.09 ± 0.71 c | 6.97 ± 0.09 d | 3.65 ± 0.12 e |

| Fat reduction (%) | - | 25.76 | 37.78 | 66.87 | 82.65 |

| Technological characteristics | |||||

| pH value | 5.89 ± 0.02 b | 5.88 ± 0.02 b | 5.89 ± 0.00 b | 5.93 ± 0.00 a | 5.99 ± 0.02 a |

| Cooking loss (%) | 11.75 ± 1.10 b | 10.92 ± 1.38 b | 8.53 ± 1.50 ab | 6.89 ± 1.98 a | 6.24 ± 0.29 a |

| Shrinkage (%) | 19.75 ± 1.77 a | 14.47 ± 0.37 b | 11.50 ± 1.41 bc | 8.55 ± 0.60 cd | 6.84 ± 0.74 d |

| Water retention (%) | 83.26 ± 1.96 c | 84.25 ± 0.59 c | 85.59 ± 1.02 bc | 88.71 ± 2.02 ba | 90.35 ± 0.54 a |

| TBARS value (mg MDA/kg sample) | |||||

| 0 d | 0.06 ± 0.01 a | 0.06 ± 0.01 a | 0.07 ± 0.01 a | 0.07 ± 0.02 a | 0.05 ± 0.01 a |

| 7 d | 0.38 ± 0.02 a | 0.25 ± 0.01 b | 0.21 ± 0.01 c | 0.16 ± 0.01 d | 0.13 ± 0.01 d |

| Color parameters | |||||

| L* | 68.93 ± 0.12 a | 65.92 ± 1.69 a | 61.12 ± 1.04 b | 58.89 ± 1.37 b | 59.51 ± 1.14 b |

| a* | 9.53 ± 0.03 b | 9.36 ± 0.63 b | 10.48 ± 0.35 ab | 11.82 ± 0.86 a | 12.23 ± 0.88 a |

| b* | 22.07 ± 0.30 bc | 20.65 ± 0.94 c | 22.84 ± 1.15 abc | 24.44 ± 1.18 ab | 25.91 ± 0.92 a |

| Parameters | CON | CFS25 | CFS50 | CFS75 | CFS100 |

|---|---|---|---|---|---|

| Sensory characteristics | |||||

| Appearance | 5.4 ± 1.1 b | 6.5 ± 0.8 a | 6.7 ± 0.5 a | 5.4 ± 0.7 b | 5.4 ± 0.8 b |

| Aroma | 5.3 ± 0.7 a | 5.4 ± 0.5 a | 5.5 ± 0.7 a | 5.3 ± 0.9 a | 5.2 ± 0.6 a |

| Juiciness | 7.0 ± 1.1 a | 7.2 ± 0.6 a | 6.6 ± 0.8 ab | 6.2 ± 0.6 ab | 5.7 ± 0.7 b |

| Tenderness | 6.3 ± 0.8 a | 7.0 ± 0.5 a | 6.4 ± 0.7 a | 6.7 ± 1.1 a | 6.6 ± 1.1 a |

| Overall acceptability | 6.6 ± 1.0 a | 6.9 ± 0.9 a | 6.9 ± 1.0 a | 6.5 ± 0.7 a | 6.4 ± 0.7 a |

| Texture parameters | |||||

| Hardness (N) | 13.97± 0.82 c | 18.39 ± 0.08 b | 17.70 ± 0.55 b | 18.81 ± 0.47 b | 23.67 ± 1.94 a |

| Springiness | 0.44 ± 0.01 d | 0.53 ± 0.02 c | 0.56 ± 0.04 bc | 0.61 ± 0.03 b | 0.69 ± 0.03 a |

| Cohesiveness | 0.24 ± 0.02 c | 0.28 ± 0.01 b | 0.27 ± 0.00 b | 0.29 ± 0.02 b | 0.34 ± 0.02 a |

| Chewiness (N) | 1.16 ± 0.04 d | 2.94 ± 0.18 c | 2.81 ± 0.16 c | 3.40 ± 0.31 b | 6.17 ± 0.14 a |

| Ingredients (g/100 g) | Lean Meat Patties | Fat-Replaced Patties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TLP | KEG0 | KEG3.5 | KEG7 | KEG10 | CON | CFS25 | CFS50 | CFS75 | CFS100 | |

| CFS | ||||||||||

| SPI | - | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Coconut oil | - | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| KGM | - | 0 | 3.5 | 7 | 10.5 | 7 | 7 | 7 | 7 | 7 |

| Water | - | 85 | 81.5 | 78 | 74.5 | 78 | 78 | 78 | 78 | 78 |

| Meat patties | ||||||||||

| Lean meat | 94 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Pork back fat | - | - | - | - | - | 24 | 18 | 12 | 6 | 0 |

| CFS | 0 | 24 | 24 | 24 | 24 | 0 | 6 | 12 | 18 | 24 |

| Egg white | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Salt | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Ren, Y.; Huang, L.; Ye, X.; Li, H.; Li, J.; Cao, J.; Liu, X. Quality, Thermo-Rheology, and Microstructure Characteristics of Cubic Fat Substituted Pork Patties with Composite Emulsion Gel Composed of Konjac Glucomannan and Soy Protein Isolate. Gels 2024, 10, 111. https://doi.org/10.3390/gels10020111

Wei L, Ren Y, Huang L, Ye X, Li H, Li J, Cao J, Liu X. Quality, Thermo-Rheology, and Microstructure Characteristics of Cubic Fat Substituted Pork Patties with Composite Emulsion Gel Composed of Konjac Glucomannan and Soy Protein Isolate. Gels. 2024; 10(2):111. https://doi.org/10.3390/gels10020111

Chicago/Turabian StyleWei, Lai, Yuqing Ren, Lu Huang, Xinnan Ye, He Li, Jian Li, Jinnuo Cao, and Xinqi Liu. 2024. "Quality, Thermo-Rheology, and Microstructure Characteristics of Cubic Fat Substituted Pork Patties with Composite Emulsion Gel Composed of Konjac Glucomannan and Soy Protein Isolate" Gels 10, no. 2: 111. https://doi.org/10.3390/gels10020111