Physicochemical and Functional Characteristics of RD43 Rice Flour and Its Food Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Flour Preparation

2.3. Scanning Electron Microscopy

2.4. Particle Size Distributions Analysis

2.5. Color

2.6. Determination of Amylose Content

2.7. X-ray Diffraction Analysis

2.8. Fourier Transforms Infrared (FTIR) Spectroscopy

2.9. Water Absorption Index (WAI), Swelling Power (SP), and Water Solubility Index (WSI)

2.10. Thermal Properties

2.11. Pasting Properties

2.12. In Vitro Starch Digestion of Flour and Steamed Muffin

2.13. Bile Acid Binding

2.14. Cholesterol Micellization

2.15. Steamed Muffin Preparation

2.16. Sensory Evaluation of Steamed Muffin

2.17. Statistical Analysis

3. Results and Discussion

3.1. Morphology Observation

3.2. Particle Size Distribution

3.3. Color of Rice Flour

3.4. The Amylose Content of Rice Flour

3.5. X-ray Diffraction

3.6. FTIR Spectroscopy

3.7. Hydration Properties of Rice Flour

3.8. Thermal Properties of Rice Flour

3.9. Pasting Properties of Rice Flour

3.10. In Vitro Starch Digestion

3.11. Bile Binding Acid and Cholesterol Micellization

3.12. Starch Digestibility and Sensory Evaluation of Steamed Muffins

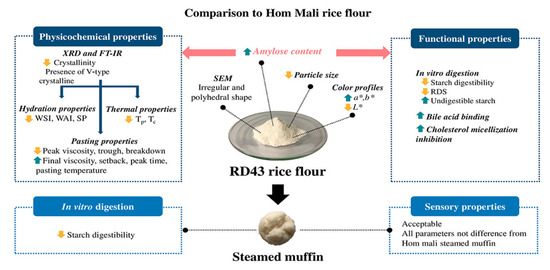

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kaur, B.; Ranawana, V.; Henry, J. The glycemic index of rice and rice products: A review, and table of GI values. Crit. Rev. Food Sci. Nutr. 2016, 56, 215–236. [Google Scholar] [CrossRef] [Green Version]

- Priya, T.R.; Nelson, A.R.L.E.; Ravichandran, K.; Antony, U. Nutritional and functional properties of coloured rice varieties of South India: A review. J. Ethn. Foods 2019, 6, 11. [Google Scholar] [CrossRef] [Green Version]

- Koh, L.W.; Kasapis, S.; Lim, K.M.; Foo, C.W. Structural enhancement leading to retardation of in vitro digestion of rice dough in the presence of alginate. Food Hydrocoll. 2009, 23, 1458–1464. [Google Scholar] [CrossRef]

- Thiranusornkij, L.; Thamnarathip, P.; Chandrachai, A.; Kuakpetoon, D.; Adisakwattana, S. Comparative studies on physicochemical properties, starch hydrolysis, predicted glycemic index of Hom Mali rice and Riceberry rice flour and their applications in bread. Food Chem. 2019, 283, 224–231. [Google Scholar] [CrossRef] [PubMed]

- Kraithong, S.; Lee, S.; Rawdkuen, S. Physicochemical and functional properties of Thai organic rice flour. J. Cereal Sci. 2018, 79, 259–266. [Google Scholar] [CrossRef]

- Cai, J.; Man, J.; Huang, J.; Liu, Q.; Wei, W.; Wei, C. Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohydr. Polym. 2015, 125, 35–44. [Google Scholar] [CrossRef]

- Yousif, A.; Nhepera, D.; Johnson, S. Influence of sorghum flour addition on flat bread in vitro starch digestibility, antioxidant capacity and consumer acceptability. Food Chem. 2012, 134, 880–887. [Google Scholar] [CrossRef]

- Falade, K.O.; Christopher, A.S. Physical, functional, pasting and thermal properties of flours and starches of six Nigerian rice cultivars. Food Hydrocoll. 2015, 44, 478–490. [Google Scholar] [CrossRef]

- Vanavichit, A.; Kamolsukyeunyong, W.; Siangliw, M.; Siangliw, J.L.; Traprab, S.; Ruengphayak, S.; Chaichoompu, E.; Saensuk, C.; Phuvanartnarubal, E.; Toojinda, T. Thai Hom Mali Rice: Origin and breeding for subsistence rainfed lowland rice system. Rice 2018, 11, 20. [Google Scholar] [CrossRef] [Green Version]

- Jiamjariyatam, R. Use of riceberry bran to reduce oil absorption in puffed cracker. Int. Food Res. J. 2019, 26, 441–450. [Google Scholar]

- Hu, E.A.; Pan, A.; Malik, V.; Sun, Q. White rice consumption and risk of type 2 diabetes: Meta-analysis and systematic review. Br. Med. J. 2012, 344, e1454. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wasusun, A.; Wongpiyachon, S.; Songchitsomboon, S.; Sukviwat, W.; Maneenin, P.; Pakkethati, S. Rice variety RD43: Medium glycemic index rice for niche market. Thai Rice Res. J. 2017, 8, 45–53. [Google Scholar]

- AOAC. Official Methods of Analysis of Association of Official Analytical Chemist, 17th ed.; AOAC: Gaithersburg, MD, USA, 2003. [Google Scholar]

- Cheetham, N.W.; Tao, L. Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study. Carbohydr. Polym. 1998, 36, 277–284. [Google Scholar] [CrossRef]

- De la hera, E.; Gomez, M.; Rosell, C.M. Particle size distribution of rice flour affecting the starch enzymatic hydrolysis and hydration properties. Carbohydr. Polym. 2013, 98, 421–427. [Google Scholar] [CrossRef] [Green Version]

- Englyst, H.N.; Kingman, S.; Cummings, J. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, 33–50. [Google Scholar]

- Goñi, I.; Garcia-Alonso, A.; Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Mäkynen, K.; Jitsaardkul, S.; Tachasamran, P.; Sakai, N.; Puranachoti, S.; Nirojsinlapachai, N.; Chattapat, V.; Caengprasath, N.; Ngamukote, S.; Adisakwattana, S. Cultivar variations in antioxidant and antihyperlipidemic properties of pomelo pulp (Citrus grandis [L.] Osbeck) in Thailand. Food Chem. 2013, 139, 735–743. [Google Scholar] [CrossRef]

- Curtis, P.C. Untrained Sensory Panels. The Science of Meat Quality, 1st ed.; Kerth, C.H., Ed.; Wiley-Blackwell: Ames, IA, USA, 2013; pp. 215–231. [Google Scholar]

- Wani, A.A.; Singh, P.; Shah, M.A.; Wani, I.A.; Götz, A.; Schott, M.; Zacherl, C. Physico-chemical, thermal and rheological properties of starches isolated from newly released rice cultivars grown in Indian temperate climates. LWT-Food Sci. Technol. 2013, 53, 176–183. [Google Scholar] [CrossRef]

- Leewatchararongjaroen, J.; Anuntagool, J. Effects of dry-milling and wet-milling on chemical, physical and gelatinization properties of rice flour. Rice Sci. 2016, 23, 274–281. [Google Scholar] [CrossRef] [Green Version]

- Keeratipibul, S.; Luangsakul, N.; Lertsatchayarn, T. The effect of Thai glutinous rice cultivars, grain length and cultivating locations on the quality of rice cracker (arare). LWT-Food Sci. Technol. 2008, 41, 1934–1943. [Google Scholar] [CrossRef]

- Chrastil, J. Chemical and physicochemical changes of rice during storage at different temperatures. J. Cereal Sci. 1990, 11, 71–85. [Google Scholar] [CrossRef]

- Juliano, B. Structure, chemistry, and function of the rice grain and its fractions. Ceral Foods World 1992, 37, 772. [Google Scholar]

- Chung, H.J.; Liu, Q.; Lee, L.; Wei, D. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents. Food Hydrocoll. 2011, 25, 968–975. [Google Scholar] [CrossRef]

- Wang, L.; Guo, J.; Wang, R.; Shen, C.; Li, Y.; Luo, X.; Li, Y.; Chen, Z. Studies on quality of potato flour blends with rice flour for making extruded noodles. Cereal Chem. 2016, 93, 593–598. [Google Scholar] [CrossRef]

- Ye, J.; Hu, X.; Luo, S.; McClements, D.J.; Liang, L.; Liu, C. Effect of endogenous proteins and lipids on starch digestibility in rice flour. Int. Food Res. J. 2018, 106, 404–409. [Google Scholar] [CrossRef]

- Colussi, R.; Pinto, V.Z.; El Halal, S.L.M.; Vanier, N.L.; Villanova, F.A.; e Silva, R.M.; da Rosa Zavareze, E.; Dias, A.R.G. Structural, morphological, and physicochemical properties of acetylated high-, medium-, and low-amylose rice starches. Carbohydr. Polym. 2014, 103, 405–413. [Google Scholar] [CrossRef] [Green Version]

- Fang, J.; Fowler, P.; Tomkinson, J.; Hill, C. Preparation and characterisation of methylated hemicelluloses from wheat straw. Carbohydr. Polym. 2002, 47, 285–293. [Google Scholar] [CrossRef]

- Ratnaningsih, N.; Harmayani, E.; Marsono, Y. Physicochemical properties, in vitro starch digestibility, and estimated glycemic index of resistant starch from cowpea (Vigna unguiculata) starch by autoclaving-cooling cycles. Int. J. Biol. Macromol. 2020, 142, 191–200. [Google Scholar] [CrossRef]

- Castillo, L.A.; López, O.V.; García, M.A.; Barbosa, S.E.; Villar, M.A. Crystalline morphology of thermoplastic starch/talc nanocomposites induced by thermal processing. Heliyon 2019, 5, e01877. [Google Scholar] [CrossRef] [Green Version]

- Ren, N.; Ma, Z.; Xu, J.; Hu, X. Insights into the supramolecular structure and techno-functional properties of starch isolated from oat rice kernels subjected to different processing treatments. Food Chem. 2020, 317, 126464. [Google Scholar] [CrossRef]

- Awuchi, C.G.; Igwe, V.S.; Echeta, C.K. The functional properties of foods and flours. Int. J. Curr. Adv. Res. 2019, 5, 139–160. [Google Scholar]

- Nakorn, K.N.; Tongdang, T.; Sirivongpaisal, P. Crystallinity and rheological properties of pregelatinized rice starches differing in amylose content. Starch Stärke 2009, 61, 101–108. [Google Scholar] [CrossRef]

- Wijaya, C.; Do, Q.D.; Ju, Y.H.; Santoso, S.P.; Putro, J.N.; Laysandra, L.; Soetaredjo, F.E.; Ismadji, S. Isolation and characterization of starch from Limnophila aromatica. Heliyon 2019, 5, e01622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Int. J. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef] [Green Version]

- Van Hung, P.; Maeda, T.; Miskelly, D.; Tsumori, R.; Morita, N. Physicochemical characteristics and fine structure of high-amylose wheat starches isolated from Australian wheat cultivars. Carbohydr. Polym. 2008, 71, 656–663. [Google Scholar] [CrossRef]

- Ye, L.; Wang, C.; Wang, S.; Zhou, S.; Liu, X. Thermal and rheological properties of brown flour from Indica rice. J. Cereal Sci. 2016, 70, 270–274. [Google Scholar] [CrossRef]

- Yang, C.; Shu, Y.; Zhang, L.; Wang, X.; Zhao, H.J.; Ma, C.; Wu, D. Starch properties of mutant rice high in resistant starch. J. Agric. Food Chem. 2006, 54, 523–528. [Google Scholar] [CrossRef]

- Dang, J.M.C.; Copeland, L. Genotype and environmental influences on pasting properties of rice flour. Cereal Chem. 2004, 81, 486–489. [Google Scholar] [CrossRef]

- Saleh, M.; Meullenet, J.-F. Cooked rice texture and rice flour pasting properties; impacted by rice temperature during milling. J. Food Sci. Technol. 2015, 52, 1602–1609. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.-C.; Lai, H.-M. Characteristics of the starch fine structure and pasting properties of waxy rice during storage. Food Chem. 2014, 152, 432–439. [Google Scholar] [CrossRef]

- Gourineni, V.; Stewart, M.L.; Skorge, R.; Sekula, B.C. Slowly digestible carbohydrate for balanced energy: In vitro and in vivo evidence. Nutrients 2017, 9, 1230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panlasigui, L.N.; Thompson, L.U. Blood glucose lowering effects of brown rice in normal and diabetic subjects. Int. J. Food Sci. Nutr. 2006, 57, 151–158. [Google Scholar] [CrossRef]

- Takahama, U.; Hirota, S. Inhibition of buckwheat starch digestion by the formation of starch/bile salt complexes: Possibility of its occurrence in the intestine. J. Agric. Food Chem. 2011, 59, 6277–6283. [Google Scholar] [CrossRef] [PubMed]

- Villwock, V.K.; Eliasson, A.C.; Silverio, J.; BeMiller, J.N. Starch-lipid interactions in common, waxy, ae du, and ae su2 maize starches examined by differential scanning calorimetry. Cereal Chem. 1999, 76, 292–298. [Google Scholar] [CrossRef]

| Physicochemical Properties | Rice Flour | |

|---|---|---|

| Hom Mali | RD43 | |

| Particle size distribution (µm) | ||

| Volume mean diameter (D4,3) | 130.00 ± 0.58 | 103.00 ± 0.15 * |

| Equivalent diameters at 10% cumulative volume (D10) | 23.33 ± 0.13 | 5.41 ± 0.33 * |

| Average particle size (D50) | 115.67 ± 0.33 | 73.07 ± 0.17 * |

| Equivalent diameters at 90% cumulative volume (D90) | 259.67 ± 1.73 | 257.00 ± 2.52 |

| Color | ||

| Lightness (L*) | 91.09 ± 0.06 | 89.4 ± 0.02 * |

| Redness (a*) | 0.01 ± 0.02 | 0.16 ± 0.02 * |

| Yellowness (b*) | 5.38 ± 0.07 | 6.29 ± 0.07 * |

| Amylose content (%) a | 16.05 ± 0.39 | 19.04 ± 0.30 * |

| Hydration properties a | ||

| WSI (g/g sample) | 9.33 ± 0.13 | 7.33 ± 0.13 * |

| WAI (g/g sample) | 13.06 ± 0.13 | 12.41 ± 0.07 * |

| SP (g/100g sample) | 13.68 ± 0.11 | 12.35 ± 0.16 * |

| Thermal properties | ||

| To (°C) | 65.63 ± 0.07 | 65.07 ± 0.26 |

| Tp (°C) | 71.20 ± 0.15 | 70.23 ± 0.22 * |

| Tc (°C) | 76.6 ± 0.10 | 75.20 ± 0.31 * |

| Gelatinization enthalpy (J/g) | 7.85 ± 0.28 | 6.89 ± 0.31 |

| Pasting properties | ||

| Peak viscosity (RVU) | 310.38 ± 3.71 | 223.50 ± 0.35 * |

| Trough (RVU) | 173.33 ± 0.94 | 156.17 ± 0.94 * |

| Breakdown (RVU) | 137.04 ± 2.77 | 67.33 ± 1.30 * |

| Final viscosity (RVU) | 302.71 ± 2.77 | 342.08 ± 3.30 * |

| Setback (RVU) | 129.38 ± 1.38 | 185.92 ± 2.36 * |

| Peak time (min) | 5.43 ± 0.05 | 5.70 ± 0.05 * |

| Pasting temperature (°C) | 84.05 ± 0.07 | 89.73 ± 0.04 * |

| Total starch (%) | 81.43 ± 0.58 | 80.72 ± 0.34 |

| Rice Flour | % Bile Acid Binding | % Cholesterol Micellization Inhibition | ||

|---|---|---|---|---|

| Taurocholic Acid | Taurodeoxycholic Acid | Glycodeoxycholic Acid | ||

| Hom mali | 2.51 ± 0.23 | NA | NA | 9.22 ± 0.48 |

| RD43 | 7.45 ± 0.36 * | 36.35 ± 0.19 * | 11.61 ± 0.12 * | 12.95 ± 0.52 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suklaew, P.o.; Chusak, C.; Adisakwattana, S. Physicochemical and Functional Characteristics of RD43 Rice Flour and Its Food Application. Foods 2020, 9, 1912. https://doi.org/10.3390/foods9121912

Suklaew Po, Chusak C, Adisakwattana S. Physicochemical and Functional Characteristics of RD43 Rice Flour and Its Food Application. Foods. 2020; 9(12):1912. https://doi.org/10.3390/foods9121912

Chicago/Turabian StyleSuklaew, Phim on, Charoonsri Chusak, and Sirichai Adisakwattana. 2020. "Physicochemical and Functional Characteristics of RD43 Rice Flour and Its Food Application" Foods 9, no. 12: 1912. https://doi.org/10.3390/foods9121912