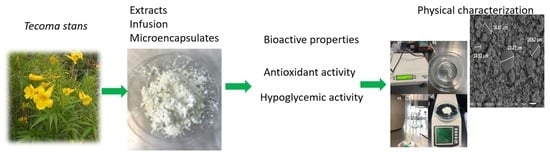

Microencapsulation of Tecoma stans Extracts: Bioactive Properties Preservation and Physical Characterization Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Sample Preparation

2.3. Extraction

2.3.1. Factorial Design

2.3.2. Infusion Preparation

2.4. Antioxidant Activity

2.4.1. ABTS

2.4.2. DPPH

2.4.3. Standard Curve

2.5. Hypoglycemic Activity

2.6. Spray Drying Microencapsulation

2.6.1. Mixture Preparation

2.6.2. Spray Drying Process

2.7. Physicochemical Characterization

2.7.1. Yield

2.7.2. Moisture

2.7.3. Water Activity (Aw)

2.7.4. Wettability

2.7.5. Bulk and Tapped Density

2.7.6. Color

2.8. Compound Identification

2.9. Micrographs

2.10. Data Analysis

3. Results and Discussion

3.1. Antioxidant Activity of Extracts Based on Factorial Design

3.2. Microencapsulates Bioactive Properties

3.2.1. Antioxidant Activity

3.2.2. Hypoglycemic Activity

3.3. Microencapsulates Characterization

3.3.1. Physicochemical Characterization

3.3.2. Compound Identification

3.4. Micrographs of Microencapsulates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pelton, J. A survey of the ecology of Tecoma Stans. Butl. Univ. Bot. Stud. 1964, 14, 53–88. [Google Scholar]

- Argueta, A.; Cano Asseleih, L.M.; Rodarte García, M.E. Atlas de las Plantas de la Medicina Tradicional Mexicana; Biblioteca Digital de la Medicina Tradicional Mexicana Tronadora: Mexico City, México, 2009. [Google Scholar]

- Costantino, L.; Raimondi, L.; Pirisino, R.; Brunetti, T.; Pessotto, P.; Giannessi, F.; Lins, A.P.; Barlocco, D.; Antolini, L.; El-Abady, S.A. Isolation and Pharmacological Activities of the Tecoma Stans Alkaloids. Il Farm. 2003, 58, 781–785. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Santamaría, L.; Ramírez, G.; Nicasio, P.; Alegría-Reyes, C.; Herrera-Arellano, A. Antidiabetic Activities of Tecoma Stans (L.) Juss. Ex Kunth. J. Ethnopharmacol. 2009, 124, 284–288. [Google Scholar] [CrossRef]

- Al-Azzawi, A.; Al-Sameraei, K.; Al-Khateeb, E.; Al-Juboori, A. Antibacterial Activity and the Histopathological Study of Crude Extracts and Isolated Tecomine from Tecoma Stans Bignoniaceae in Iraq. Pharmacogn. Res. 2012, 4, 37. [Google Scholar] [CrossRef] [PubMed]

- Salem, M.Z.; Gohar, Y.M.; Camacho, L.M.; El-Shanhorey, N.A.; Salem, A.Z.M. Antioxidant and Antibacterial Activities of Leaves and Branches Extracts of Tecoma stans (L.) Juss. Ex Kunth against Nine Species of Pathogenic Bacteria. Afr. J. Microbiol. Res. 2013, 7, 418–426. [Google Scholar] [CrossRef]

- Rajamurugan, R.; Thirunavukkarasu, C.; Sakthivel, V.; Sivashanmugam, M.; Raghavan, C.M. Phytochemical Screening, Antioxidant and Antimicrobial Activities of Ethanolic Extract of Tecoma Stans Flowers. Int. J. Pharma Bio Sci. 2013, 4, 124–130. [Google Scholar]

- Evangeline, R.M.; Murugan, N.; Kumar, P.P.; Christhudas, I.N. In Vitro Studies on α-Glucosidase Inhibition, Antioxidant and Free Radical Scavenging Properties of Tecoma Stans. Int. J. Pharm. Pharm. Sci. 2015, 7, 44–49. [Google Scholar]

- Senthilkumar, C.S.; Kumar, M.S.; Pandian, M.R. In Vitro Antibacterial Activity of Crude Leaf Extracts from Tecoma stans (L) Juss. et Kunth, Coleus Forskohlii and Pogostemon Patchouli against Human Pathogenic Bacteria. Int. J. Pharmtech. Res. 2010, 2, 439–442. [Google Scholar]

- Jethinlalkhosh, J.P.; Lathika, V. Screening of Phytochemical Constituents and Antimicrobial Activity of Traditional Medicinal Plants. Int. J. Res. Pharm. Sci. 2012, 3, 361–365. [Google Scholar]

- Al-Judaibi, A.; Al-Yousef, F. Antifungal Effect of Ethanol Plant Extracton candida Sp. Am. J. Agric. Biol. Sci. 2014, 9, 277–283. [Google Scholar] [CrossRef]

- Bakr, R.O.; Fayed, M.A.A.; Salem, M.A.; Hussein, A.S. Tecoma Stans: Alkaloid Profile and Antimicrobial Activity. J. Pharm. Bioallied Sci. 2019, 11, 341. [Google Scholar] [CrossRef] [PubMed]

- Govindappa, M.; Sadananda, T.; Channabasava, R.; Raghavendra, V.B. In Vitro Anti-Inflammatory, Lipoxygenase, Xanthine Oxidase and Acetycholinesterase Inhibitory Activity of Tecoma stans (L.) Juss. Ex Kunth. Int. J. Pharma Bio Sci. 2011, 2, 275–285. [Google Scholar]

- Swarna, S.K.; Nivedhitha, M.S.; Priya, V.V.; Gayathri, R.G.; Selvaraj, J.S.; Madhan, K.M.; Devi, B.S. Comparative Evaluation of Anti-Inflammatory Potential of Ethanolic Extract of Leaf, Bark and Flower of Tecoma Stans with Ibuprofen- An In Vitro Analysis. Pharmacogn. J. 2019, 11, 1088–1092. [Google Scholar] [CrossRef]

- Ittagi, S.; Merugumolu, V.K.; Siddamsetty, R.S. Cardioprotective Effect of Hydroalcoholic Extract of Tecoma Stans Flowers against Isoproterenol Induced Myocardial Infarction in Rats. Asian Pac. J. Trop. Dis. 2014, 4, S378–S384. [Google Scholar] [CrossRef]

- Larbie, C.; Emikpe, B.O.; Akpor, S.A.; Adams, E.; Adjei, C.O.; Oyagbemi, A.A.; Jarikre, T.A. Ameliorative Effect of Extract of Tecoma stans (L.) Juss. Ex Kunth Leaves against CCl4—and Acetaminophen—Induced Liver Damage in Rats. Adv. Tradit. Med. 2020, 20, 555–562. [Google Scholar] [CrossRef]

- Shanmukha, I.; Vijay Kumar, M.; Ramachandra, S.S. Protective Effect of Tecoma Stans Leaf Extract on Experimentally Induced Gastric Ulcers in Rats. Int. J. Drug Dev. Res. 2013, 5, 231–236. [Google Scholar]

- Sridharan, G.; Sarvanan, R.; Brindha, P. Evaluation of Anticancer Potentials of Tecoma stans (L). Juss. Ex. Kunth against EAC Cell Lines. Int. J. Pharm. Pharm. Sci. 2014, 6, 88–92. [Google Scholar]

- Martín Ortega, A.M.; Segura Campos, M.R. Bioactive Compounds as Therapeutic Alternatives. In Bioactive Compounds; Elsevier: Amsterdam, The Netherlands, 2019; pp. 247–264. [Google Scholar]

- Da Silva, R.F.; Carneiro, C.N.; de Sousa, C.B.D.C.; Gomez, F.J.V.; Espino, M.; Boiteux, J.; Fernández, M.D.L.; Silva, M.F.; Dias, F.D.S. Sustainable Extraction Bioactive Compounds Procedures in Medicinal Plants Based on the Principles of Green Analytical Chemistry: A Review. Microchem. J. 2022, 175, 107184. [Google Scholar] [CrossRef]

- Prakash, B.; Kujur, A.; Singh, P.P.; Kumar, A.; Yadav, A. Plants-Derived Bioactive Compounds as Functional Food Ingredients and Food Preservative. J. Nutr. Food Sci. 2017, 1, 100005. [Google Scholar]

- Corrêa-Filho, L.; Moldão-Martins, M.; Alves, V. Advances in the Application of Microcapsules as Carriers of Functional Compounds for Food Products. Appl. Sci. 2019, 9, 571. [Google Scholar] [CrossRef]

- Manousi, N.; Sarakatsianos, I.; Samanidou, V. Extraction Techniques of Phenolic Compounds and Other Bioactive Compounds from Medicinal and Aromatic Plants. In Engineering Tools in the Beverage Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 283–314. [Google Scholar]

- Jha, A.K.; Sit, N. Extraction of Bioactive Compounds from Plant Materials Using Combination of Various Novel Methods: A Review. Trends Food Sci. Technol. 2022, 119, 579–591. [Google Scholar] [CrossRef]

- Belščak-Cvitanović, A.; Komes, D. Extraction and Formulation of Bioactive Compounds. In Handbook of Coffee Processing By-Products; Elsevier: Amsterdam, The Netherlands, 2017; pp. 93–140. [Google Scholar]

- Abdul Mudalip, S.K.; Khatiman, M.N.; Hashim, N.A.; Che Man, R.; Arshad, Z.I.M. A Short Review on Encapsulation of Bioactive Compounds Using Different Drying Techniques. Mater. Today Proc. 2021, 42, 288–296. [Google Scholar] [CrossRef]

- Guía-García, J.L.; Charles-Rodríguez, A.V.; Reyes-Valdés, M.H.; Ramírez-Godina, F.; Robledo-Olivo, A.; García-Osuna, H.T.; Cerqueira, M.A.; Flores-López, M.L. Micro and Nanoencapsulation of Bioactive Compounds for Agri-Food Applications: A Review. Ind. Crops Prod. 2022, 186, 115198. [Google Scholar] [CrossRef]

- Jafari, S.; Jafari, S.M.; Ebrahimi, M.; Kijpatanasilp, I.; Assatarakul, K. A Decade Overview and Prospect of Spray Drying Encapsulation of Bioactives from Fruit Products: Characterization, Food Application and in Vitro Gastrointestinal Digestion. Food Hydrocoll. 2023, 134, 108068. [Google Scholar] [CrossRef]

- Smaoui, S.; Ben Hlima, H.; Ben Braïek, O.; Ennouri, K.; Mellouli, L.; Mousavi Khaneghah, A. Recent Advancements in Encapsulation of Bioactive Compounds as a Promising Technique for Meat Preservation. Meat Sci. 2021, 181, 108585. [Google Scholar] [CrossRef]

- Đorđević, V.; Balanč, B.; Belščak-Cvitanović, A.; Lević, S.; Trifković, K.; Kalušević, A.; Kostić, I.; Komes, D.; Bugarski, B.; Nedović, V. Trends in Encapsulation Technologies for Delivery of Food Bioactive Compounds. Food Eng. Rev. 2015, 7, 452–490. [Google Scholar] [CrossRef]

- Sharma, R.; Rashidinejad, A.; Jafari, S.M. Application of Spray Dried Encapsulated Probiotics in Functional Food Formulations. Food Bioprocess Technol. 2022, 15, 2135–2154. [Google Scholar] [CrossRef]

- Alu’datt, M.H.; Alrosan, M.; Gammoh, S.; Tranchant, C.C.; Alhamad, M.N.; Rababah, T.; Zghoul, R.; Alzoubi, H.; Ghatasheh, S.; Ghozlan, K.; et al. Encapsulation-Based Technologies for Bioactive Compounds and Their Application in the Food Industry: A Roadmap for Food-Derived Functional and Health-Promoting Ingredients. Food Biosci. 2022, 50, 101971. [Google Scholar] [CrossRef]

- Conde-Hernández, L.A.; Guerrero-Beltrán, J.Á. Total Phenolics and Antioxidant Activity of Piper Auritum and Porophyllum Ruderale. Food Chem. 2014, 142, 455–460. [Google Scholar] [CrossRef]

- Bajalan, I.; Rouzbahani, R.; Pirbalouti, A.G.; Maggi, F. Antioxidant and Antibacterial Activities of the Essential Oils Obtained from Seven Iranian Populations of Rosmarinus Officinalis. Ind. Crops Prod. 2017, 107, 305–311. [Google Scholar] [CrossRef]

- Jenkins, D.J.; Wolever, T.M.; Jenkins, A.L. Starchy foods and glycemic index. Diabetes Care 1988, 11, 149–159. [Google Scholar] [CrossRef] [PubMed]

- ISO 266642:2010; Determination of Glycemic Index (GI) and Recommendation for Food Classification. International Organization for Standardization Food Products: Geneva, Switzerland, 2010.

- Fang, Z.; Bhandari, B. Comparing the Efficiency of Protein and Maltodextrin on Spray Drying of Bayberry Juice. Food Res. Int. 2012, 48, 478–483. [Google Scholar] [CrossRef]

- Horwitz, W.; Latimer, G.W. AOAC Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Vissotto, F.Z.; Jorge, L.C.; Makita, G.T.; Rodrigues, M.I.; Menegalli, F.C. Influence of the Process Parameters and Sugar Granulometry on Cocoa Beverage Powder Steam Agglomeration. J. Food Eng. 2010, 97, 283–291. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin Stability and Antioxidant Activity of Spray-Dried Açai (Euterpe Oleracea Mart.) Juice Produced with Different Carrier Agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- Jangam, S.V.; Thorat, B.N. Optimization of Spray Drying of Ginger Extract. Dry. Technol. 2010, 28, 1426–1434. [Google Scholar] [CrossRef]

- Vega, A.J.D.; Ruiz, H.; Luna, J.J.; Luna, M.L.; Hernández, P.; Ávila-Sosa, R.; Ochoa, C.E. Effect of solvents and extraction methods on total anthocyanins, phenolic compounds and antioxidant capacity of Renealmia alpinia (Rottb.) Maas peel. Czech J. Food Sci. 2017, 5, 456–465. [Google Scholar] [CrossRef]

- Aarland, R.C.; Peralta-Gómez, S.; Morales Sanchéz, C.; Parra-Bustamante, F.; Villa-Hernández, J.M.; de León-Sánchez, F.D.; Pérez-Flores, L.J.; Rivera-Cabrera, F.; Mendoza-Espinoza, J.A. A Pharmacological and Phytochemical Study of Medicinal Plants Used in Mexican Folk Medicine. Indian J. Tradit. Knowl. 2015, 14, 550–557. [Google Scholar]

- Li, H.-B.; Wong, C.-C.; Cheng, K.-W.; Chen, F. Antioxidant Properties in Vitro and Total Phenolic Contents in Methanol Extracts from Medicinal Plants. LWT Food Sci. Technol. 2008, 41, 385–390. [Google Scholar] [CrossRef]

- Silva, E.M.; Souza, J.N.S.; Rogez, H.; Rees, J.F.; Larondelle, Y. Antioxidant Activities and Polyphenolic Contents of Fifteen Selected Plant Species from the Amazonian Region. Food Chem. 2007, 101, 1012–1018. [Google Scholar] [CrossRef]

- Elfalleh, W.; Kirkan, B.; Sarikurkcu, C. Antioxidant Potential and Phenolic Composition of Extracts from Stachys Tmolea: An Endemic Plant from Turkey. Ind. Crops Prod. 2019, 127, 212–216. [Google Scholar] [CrossRef]

- Saleem, H.; Khurshid, U.; Sarfraz, M.; Tousif, M.I.; Alamri, A.; Anwar, S.; Alamri, A.; Ahmad, I.; Abdallah, H.H.; Mahomoodally, F.M.; et al. A Comprehensive Phytochemical, Biological, Toxicological and Molecular Docking Evaluation of Suaeda fruticosa (L.) Forssk.: An Edible Halophyte Medicinal Plant. Food Chem. Toxicol. 2021, 154, 112348. [Google Scholar] [CrossRef] [PubMed]

- Conde-Hernández, L.A.; Luna-Guevara, M.L.; Luna-Guevara, J.J.; Pérez-Vázquez, J.; Aranda-García, R.J. Mexican Sage (Salvia Officinalis) Extraction Using Factorial Design and Its Effect on Chemical and Antibacterial Properties. J. Chem. 2021, 2021, 5594278. [Google Scholar] [CrossRef]

- Li, S.; Li, S.-K.; Gan, R.-Y.; Song, F.-L.; Kuang, L.; Li, H.-B. Antioxidant Capacities and Total Phenolic Contents of Infusions from 223 Medicinal Plants. Ind. Crops Prod. 2013, 51, 289–298. [Google Scholar] [CrossRef]

- Lizcano, L.J.; Bakkali, F.; Begoña Ruiz-Larrea, M.; Ignacio Ruiz-Sanz, J. Antioxidant Activity and Polyphenol Content of Aqueous Extracts from Colombian Amazonian Plants with Medicinal Use. Food Chem. 2010, 119, 1566–1570. [Google Scholar] [CrossRef]

- Szwajgier, D.; Baranowska-Wójcik, E.; Kukula-Koch, W.; Kowalik, K.; Polak-Berecka, M.; Waśko, A. Evolution of the Anticholinesterase, Antioxidant, and Anti-Inflammatory Activity of Epilobium Angustifolium L. Infusion during in Vitro Digestion. J. Funct. Foods 2021, 85, 104645. [Google Scholar] [CrossRef]

- Esmaeili, F.; Hashemiravan, M.; Eshaghi, M.R.; Gandomi, H. Encapsulation of Arctium Lappa L. Root Extracts by Spray-Drying and Freeze-Drying Using Maltodextrin and Gum Arabic as Coating Agents and It’s Application in Synbiotic Orange-Carrot Juice. J. Food Meas. Charact. 2022, 16, 2908–2921. [Google Scholar] [CrossRef]

- Sarabandi, K.; Jafari, S.M.; Mahoonak, A.S.; Mohammadi, A. Application of Gum Arabic and Maltodextrin for Encapsulation of Eggplant Peel Extract as a Natural Antioxidant and Color Source. Int. J. Biol. Macromol. 2019, 140, 59–68. [Google Scholar] [CrossRef]

- Abdel-Aty, A.M.; Barakat, A.Z.; Mohamed, S.A. Garden cress gum and maltodextrin as microencapsulation coats for entrapment of garden cress phenolic-rich extract: Improved thermal stability, storage stability, antioxidant and antibacterial activities. Food Sci. Biotechnol. 2023, 32, 47–58. [Google Scholar] [CrossRef]

- Xiao, Z.; Xia, J.; Zhao, Q.; Niu, Y.; Zhao, D. Maltodextrin as Wall Material for Microcapsules: A Review. Carbohydr. Polym. 2022, 298, 120113. [Google Scholar] [CrossRef]

- Visvanathan, R.; Jayathilake, C.; Liyanage, R.; Sivakanesan, R. Applicability and Reliability of the Glucose Oxidase Method in Assessing α-Amylase Activity. Food Chem. 2019, 275, 265–272. [Google Scholar] [CrossRef]

- Lu, W.; Yang, X.; Shen, J.; Li, Z.; Tan, S.; Liu, W.; Cheng, Z. Choosing the Appropriate Wall Materials for Spray-Drying Microencapsulation of Natural Bioactive Ingredients: Taking Phenolic Compounds as Examples. Powder Technol. 2021, 394, 562–574. [Google Scholar] [CrossRef]

- Khalifa, I.; Li, M.; Mamet, T.; Li, C. Maltodextrin or Gum Arabic with Whey Proteins as Wall-Material Blends Increased the Stability and Physiochemical Characteristics of Mulberry Microparticles. Food Biosci. 2019, 31, 100445. [Google Scholar] [CrossRef]

- Jimenez-Gonzalez, O.; Luna-Guevara, J.J.; Ramírez-Rodrigues, M.M.; Luna-Vital, D.; Luna-Guevara, M.L. Microencapsulation of Renealmia alpinia (Rottb.) Maas Pulp Pigment and Antioxidant Compounds by Spray-Drying and Its Incorporation in Yogurt. J. Food Sci. Technol. 2022, 59, 1162–1172. [Google Scholar] [CrossRef] [PubMed]

- Salehi, B.; Ata, A.; Anil Kumar, N.V.; Sharopov, F.; Ramírez-Alarcón, K.; Ruiz-Ortega, A.; Ayatollahi, S.A.; Fokou, P.V.T.; Kobarfard, F.; Zakaria, Z.A.; et al. Antidiabetic Potential of Medicinal Plants and Their Active Components. Biomolecules 2019, 9, 551. [Google Scholar] [CrossRef]

- Mahdi, A.A.; Mohammed, J.K.; Al-Ansi, W.; Ghaleb, A.D.S.; Al-Maqtari, Q.A.; Ma, M.; Ahmed, M.I.; Wang, H. Microencapsulation of Fingered Citron Extract with Gum Arabic, Modified Starch, Whey Protein, and Maltodextrin Using Spray Drying. Int. J. Biol. Macromol. 2020, 152, 1125–1134. [Google Scholar] [CrossRef]

- Caliskan, G.; Nur Dirim, S. The Effects of the Different Drying Conditions and the Amounts of Maltodextrin Addition during Spray Drying of Sumac Extract. Food Bioprod. Process. 2013, 91, 539–548. [Google Scholar] [CrossRef]

- George, S.; Thomas, A.; Kumar, M.V.P.; Kamdod, A.S.; Rajput, A.; Abdullah, S. Impact of Processing Parameters on the Quality Attributes of Spray-Dried Powders: A Review. Eur. Food Res. Technol. 2023, 249, 241–257. [Google Scholar] [CrossRef]

- Arumugham, T.; Krishnamoorthy, R.; AlYammahi, J.; Hasan, S.W.; Banat, F. Spray Dried Date Fruit Extract with a Maltodextrin/Gum Arabic Binary Blend Carrier Agent System: Process Optimization and Product Quality. Int. J. Biol. Macromol. 2023, 238, 124340. [Google Scholar] [CrossRef]

- Jimenez-Gonzalez, O.; Ruiz-Espinosa, H.; Luna-Guevara, J.J.; Ochoa-Velasco, C.E.; Luna Vital, D.; Luna-Guevara, M.L. A Potential Natural Coloring Agent with Antioxidant Properties: Microencapsulates of Renealmia alpinia (Rottb.) Maas Fruit Pericarp. NFS J. 2018, 13, 1–9. [Google Scholar] [CrossRef]

- Schwechheimer, C. Understanding Gibberellic Acid Signaling—Are We There Yet? Curr. Opin. Plant Biol. 2008, 11, 9–15. [Google Scholar] [CrossRef]

- Mukherjee, A.; Gaurav, A.K.; Singh, S.; Yadav, S.; Bhowmick, S.; Abeysinghe, S.; Verma, J.P. The Bioactive Potential of Phytohormones: A Review. Biotechnol. Rep. 2022, 35, e00748. [Google Scholar] [CrossRef]

- Sharma, R.; Martins, N.; Chaudhary, A.; Garg, N.; Sharma, V.; Kuca, K.; Nepovimova, E.; Tuli, H.S.; Bishayee, A.; Chaudhary, A.; et al. Adjunct Use of Honey in Diabetes Mellitus: A Consensus or Conundrum? Trends Food Sci. Technol. 2020, 106, 254–274. [Google Scholar] [CrossRef]

- Osada, Y.; Shibamoto, T. Antioxidative Activity of Volatile Extracts from Maillard Model Systems. Food Chem. 2006, 98, 522–528. [Google Scholar] [CrossRef]

- Yang, F.; Chen, L.; Zhao, D.; Guo, T.; Yu, D.; Zhang, X.; Li, P.; Chen, J. A Novel Water-Soluble Chitosan Grafted with Nerol: Synthesis, Characterization and Biological Activity. Int. J. Biol. Macromol. 2023, 232, 123498. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lu, X.; El-Seedi, H.; Teng, H. Recent Advances in the Development of Sesquiterpenoids in the Treatment of Type 2 Diabetes. Trends Food Sci. Technol. 2019, 88, 46–56. [Google Scholar] [CrossRef]

- Senevirathne, B.S.; Jayasinghe, M.A.; Pavalakumar, D.; Siriwardhana, C.G. Ceylon Cinnamon: A Versatile Ingredient for Futuristic Diabetes Management. J. Future Foods 2022, 2, 125–142. [Google Scholar] [CrossRef]

| Factor | Level 1 (−1) | Level 2 (1) |

|---|---|---|

| Method | Ultrasound | Stirring |

| Solvent | Ethanol | Water |

| Time (min) | 5 | 15 |

| Antioxidant Activity (mg Trolox/g d.s.) | ||||

|---|---|---|---|---|

| Method | Solvent | Time | ABTS | DPPH |

| −1 | −1 | −1 | 18.34 ± 1.19 | 1.65 ± 0.14 |

| 1 | −1 | −1 | 13.23 ± 0.38 | 1.47 ± 0.03 |

| −1 | 1 | −1 | 30.49 ± 1.02 | 2.21 ± 0.03 |

| 1 | 1 | −1 | 36.51 ± 0.51 | 3.21 ± 0.06 |

| −1 | −1 | 1 | 18.72 ± 0.44 | 2.24 ± 0.08 |

| 1 | −1 | 1 | 16.36 ± 0.99 | 1.44 ± 0.05 |

| −1 | 1 | 1 | 29.55 ± 1.22 | 2.33 ± 0.10 |

| 1 | 1 | 1 | 35.64 ± 1.25 | 2.77 ± 0.01 |

| Area under the Curve | GI | ||

|---|---|---|---|

| mg/dL | mmol/L | ||

| White bread | 12,379.80 ± 33.8 a | 688.38 ± 1.9 a | 71 a |

| Extract | 12,407.40 ± 39.5 a | 689.95 ± 2.3 a | 71 a |

| Infusion | 9949.80 ± 32.3 d | 553.48 ± 1.4 d | 57 e |

| ET1 | 11,001.20 ± 40.9 b | 613.67 ± 4.0 b | 63 b |

| ET2 | 11,081.20 ± 18.5 b | 616.28 ± 1.0 b | 64 d |

| ET3 | 10,676.50 ± 51.9 c | 593.37 ± 2.3 c | 61 c |

| IT1 | 8825.20 ± 53.2 f | 490.78 ± 3.0 f | 51 f |

| IT2 | 9001.90 ± 62.3 e | 501.33 ± 2.9 e | 52 f |

| IT3 | 8218.40 ± 28.8 g | 456.95 ± 1.6 g | 47 g |

| ET1 | IT3 | |

|---|---|---|

| Yield (%) | 18.34 ± 3.13 a | 21.98 ± 10.47 a |

| Moisture (%) | 4.04 ± 0.4 a | 4.75 ± 0.63 a |

| Aw | 0.298 ± 0.001 a | 0.231 ± 0.003 b |

| Wettability (s) | 297.33 ± 14.29 b | 460 ± 2 a |

| Bulk density (g/mL) | 0.261 ± 0.003 a | 0.257 ± 0.006 a |

| Tapped density (g/mL) | 0.375 ± 0.008 a | 0.371 ± 0.013 a |

| Color | ||

| L* | 88.627 ± 0.006 b | 90.61 ± 0.017 a |

| a* | 0.453 ± 0.025 a | −8.3 ± 0.01 b |

| b* | 9.007 ± 0.015 b | 18.427 ± 0.025 a |

| Microencapsulate | Solvent | Chemical Compounds | Area (%) |

|---|---|---|---|

| Extract T1 | Ethanol | Gibberellic acid | 30.32 |

| Cyclobutane, 1,1-dimethyl-2-octyl | 11.89 | ||

| 2-Furanmethanol | 27.68 | ||

| Hexane | Butane, 2,2-dimethyl | 9.58 | |

| 1-Hexene,3,4-dimethyl | 13.56 | ||

| Cyclopentane, methyl | 6.73 | ||

| Infusion T3 | Ethanol | Gibberellic acid | 29.86 |

| 2-Furanmethanol | 14.25 | ||

| Hexane | Butane, 2,2-dimethyl | 23.63 | |

| Ethyl acetate | Benzene, 1,3-bis (3-phenoxyphenoxy) | 13.37 | |

| Nerol | 5.05 | ||

| Propanoic acid, 2-(3-acetoxy-4,4-14-trimethylandrost-8-en-17-yl- | 7.37 | ||

| (2,3-diphenyl-cyclopropyl) methyl phenyl sulfoxide, trans) | 12.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Jiménez, J.R.; Luna-Guevara, M.L.; Luna-Guevara, J.J.; Conde-Hernández, L.A.; Ramos-Cassellis, M.E.; Hernández-Cocoletzi, H. Microencapsulation of Tecoma stans Extracts: Bioactive Properties Preservation and Physical Characterization Analysis. Foods 2024, 13, 1001. https://doi.org/10.3390/foods13071001

García-Jiménez JR, Luna-Guevara ML, Luna-Guevara JJ, Conde-Hernández LA, Ramos-Cassellis ME, Hernández-Cocoletzi H. Microencapsulation of Tecoma stans Extracts: Bioactive Properties Preservation and Physical Characterization Analysis. Foods. 2024; 13(7):1001. https://doi.org/10.3390/foods13071001

Chicago/Turabian StyleGarcía-Jiménez, Jair R., María L. Luna-Guevara, Juan J. Luna-Guevara, Lilia A. Conde-Hernández, María E. Ramos-Cassellis, and Heriberto Hernández-Cocoletzi. 2024. "Microencapsulation of Tecoma stans Extracts: Bioactive Properties Preservation and Physical Characterization Analysis" Foods 13, no. 7: 1001. https://doi.org/10.3390/foods13071001