Strategies for Exploiting Milk Protein Properties in Making Films and Coatings for Food Packaging: A Review

Abstract

:1. Introduction

2. Milk Proteins: Native Structures and Properties

2.1. Caseins: Characteristics and Properties

2.2. Whey Proteins

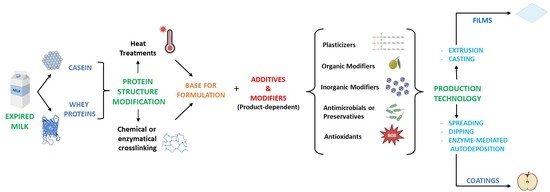

3. Approaches and Methodologies for Modifying the Properties of Milk Proteins

3.1. Thermal Treatments

3.2. Protein–Protein Crosslinking

4. Films and Coatings from Milk Proteins

4.1. Films from Casein and Whey Proteins: Formulation and Production Methodologies

Casein and Whey Protein Pre-Treatments

4.2. Additives and Modifiers

4.2.1. Plasticizers

4.2.2. Organic Modifiers

4.2.3. Inorganic Modifiers

4.2.4. Antimicrobial Agents and Preservatives

| Type of Material | Aims | Formulation | Production Conditions | Main Results | Reference |

|---|---|---|---|---|---|

| Edible Casein Sheets | Develop films from different casein types. Evaluation of glycerol (Gly) concentration on the extrusion process |

| Extrusion + conditioning at 23 °C/50% relative humidity (RH) for 48 h | Gly concentration, RH, and type of casein are relevant parameters. The higher the Gly concentration, the higher the susceptibility to water on the film. | [68] |

| Edible Casein Film | Study of properties of films obtained using different casein concentrations |

| Casting + drying (oven) at 50 °C for 5 h + conditioning at 27 °C for 2 days | Higher casein concentration (9.5%) showed higher yield, increased thickness, and tensile strength (TS). | [63] |

| Edible Casein Film | Use of dielectric barrier discharge (DBD) cold plasma technology for improving casein film properties |

| Casting on polyacrylic plates + drying at 35 °C/50% RH for 48 h Films loaded onto quartz reaction device, treated with DBD-50 Plasma Reactor at different conditions of voltage and time | DBD cold plasma improved mechanical and barrier performances: increased TS, elongation at break (EAB); decreased water vapor permeability (WVP). | [67] |

| Casein Film | Develop a NaCas-based film added with linseed oil resin (LOR) |

| Casting on Teflon Petri dish + drying at 35 °C for 10 h + conditioning at 23 °C-50% RH for 3 days | LOR decreased film WVP; minimum was reached with 10–15% addition. Decrease in tensile modulus (TM) and TS; EAB remained stable. | [81] |

| Casein Film | Casein crosslinking with tannic acid (TA) to obtain a film with better physico-chemical properties for food packaging |

| Casting on silicon molds + drying at room temperature (RT) for 7 days | TA was a good crosslinker for casein, as confirmed by FTIR. Protein network was modified by concentration of phenolic acid. Increased TS and decreased EAB; TA improved water resistance of the film. | [71] |

| Active Casein Film | Develop a NaCas-based film including microencapsulated citral as antimicrobial |

| Casting + drying at 25 °C-55% RH for 24 h | Best film resistance at NaCas:Sor = 1:0.91 and NaCas:CM = 1:0.95. Mechanical properties were acceptable, but SEM revealed surface discontinuity. | [93] |

| Active Casein-CMC film | Develop a carboxymethyl cellulose (CMC)-NaCas-based film containing 5 probiotic bacterial strains and application on trout fillets. |

| Casting on Petri dish + drying at ambient conditions for 48 h | During 14-day refrigerated storage, delay in both spoilage bacteria growth and formation of biogenic amines compared to the control. Films containing L. acidophilus were most effective. | [96] |

| Active Casein Film | Develop casein active films reinforced with ZnO nanoparticles and rosemary essential oil (REO) and properties investigation |

| Casting on Petri dish + drying in oven at 30 °C-50% RH for 24 h + conditioning at 25 °C-50% RH | ZnO + REO increased barrier, mechanical properties, and humidity resistance. WVP reduction, strength and flexibility increase. Good antimicrobial activity against tested bacteria. | [82] |

| Active Casein Film | Develop a NaCas film added with cinnamon essential oil nanoemulsion (CEO-NE) as antimicrobial and cellulose nanofibers (CNF) as mechanical reinforcement |

| Casting on polystyrene Petri dish + drying at 25 °C-50% RH for 48 h | Presence of CNF increased film crystallinity, SEM revealed decreased surface roughness. Decrease in both WVP and adsorption of humidity. Improved mechanical properties and controlled release CEO-NE due to CNF; CEO-NE showed a little antimicrobial activity. | [83] |

| Active Casein Film | Study of effects derived from type of plasticizer and lipid concentration included in NaCas-based films. Investigation of quercetin (QC) antioxidant effect |

| Casting on Petri dish + drying at 23 °C-40% RH for 3 days | Water vapor transmission rate (WVTR) was significantly lower in Sor-plasticized films. Adding 10% BW strongly decreased WVTR in the presence of Gly. Sor improved TS and Young’s modulus (YM) but worsened EAB. QC extracts showed an effective radical scavenging activity. | [65] |

| Edible WP film | Investigating and testing properties of WP edible films |

| Casting on petri dishes + drying at 25°-50% RH × 24 h + conditioning at 25°-53% RH × 48 h before testing | Increasing protein concentration leads to lower opacity and moisture adsorption of films and increased TS and EAB. Films with higher glycerol concentration showed weakened mechanical resistance and higher moisture adsorption rates. | [79] |

| WP Edible Film | Improve the physical characteristics of whey protein isolate (WPI)-based film using γ-aminobutyric acid (GABA) |

| Pouring on perspex sheet + drying overnight | Films made with GABA had an increased EAB and WVP and decreased TS and light transmittance. Lowest concentrations of GABA enhanced hydration and thermal properties. | [86] |

| Active WP Edible Film | Develop antifungal films from WPI added with low quantities of a water-soluble derivative of chitosan (WSCh) |

| Casting on polystyrene Petri dish + drying at 60 °C for 3 h in oven + conditioning at 20 °C-58% RH for 48 h | WSCh acts as a crosslinking agent through H bonds, causing a decrease in EAB and solubility. WPI/WSCh films had excellent fungistatic activity and barrier effects. Aspergillus niger was 100% inhibited, while Penicillium roqueforti was more resistant. | [95] |

| WP Edible film | Develop an edible film using WPC previously treated with heat, high-power ultrasound (US) and/or crosslinked with microbial TGase |

| Casting on Plexiglass Petri dish + drying in oven at 35 °C for 18 h + conditioning at 50% RH for 96 h before peeling + 20 °C-50% RH for 48 h | US treatment slightly decreased WVP and increased puncture strength and TS of the films. TGase crosslinking increased puncture deformation values and affected film color. Heat-treated films had the best mechanical properties and thus were tested as separation material for cheese slices. | [74] |

| Active WP film | Develop a film based on WPC added with natamycin (Nat) and/or α-tocopherol (αTOC) nanoemulsion |

| Solvent casting on polystyrene Petri dishes + drying in oven at 30 °C for 12 h + conditioning at 25 °C-58% RH for 7 days | Addition of αTOC and Nat significantly decreased TS and EM and increased EAB. Opacity, UV light barrier, and WVP of composite film also increased. Antioxidant activity and antimicrobial effect against C. albicans, P. chrysogenum, and S. cerevisiae were evidenced. | [94] |

| Active WP film | Develop a WPI film carrying a controlled release system for lysozyme (LYZ) based on pH-responsive polyacrylic acid (PAA)/LYZ complex incorporated within the matrix |

| Casting on polypropylene substrate + drying overnight at 25 °C-40% RH | PAA molecular weight affected the surface charge and hydrophilicity of the films. Incorporating PAA/LYZ complex into film extended its release time up to 500 h due to a low diffusivity. A 5.7 log reduction in bacterial population within 72 h was observed. Free LYZ was hardly effective against Listeria innocua. | [91] |

| WP film reinforced with CNCs | Develop a WPI film reinforced through addition of cellulose nanocrystals (CNC) extracted from sugar bagasse |

| Casting on Teflon mold + drying in incubator at 50 °C for 15 h + conditioning 25 °C- 50% RH for 48 h | Lightness and transparency of the films decreased with increasing WPI content. CNC increased film hydrophilicity (lower water contact angle values), increased TS and YM, and reduced the WVP. Oxygen permeability did not change. | [84] |

| WP film added with Sodium Solfite, SDS and Urea | Evaluate effects of reactive additives sodium sulfite (SS), sodium dodecyl sulfate (SDS), and urea on properties of WP films |

| Casting on Petri dish + conditioning at 23 °C-50% RH for 9 days at least | SS led to increased number of hydrophobic interactions and H bonds and slightly decreased number of disulfide bonds. O2 permeability decreased from 68 to 46 cm3 with 1% SDS addition. WVTR decreased with 20% SDS addition. | [89] |

| WP edible films modified with UV radiation | Evaluate effects of UV radiation on WPC treating either the film-forming solution or the film |

| UV exposure in a stainless-steel exposure chamber of a microprocessor-controlled UV radiation system | UV radiation of solutions increased free-SH groups and induced formation of aggregates. Derived films showed significantly higher TS, puncture strength and puncture deformation. Solubility was lower than for finished films exposed to UV. When UV was applied to solutions, films were more tinted. | [75] |

| WP edible film added with rapeseed oil | Develop WPI films added with rapeseed oil (RSO) |

| Casting on Petri dish + drying at 25 °C-50% RH for 24 h + conditioning at 25 °C-50% RH for 48 h before testing | Presence of RSO decreased film WVP and water hydrophilicity, increased permeability to O2 and CO2. WVP and diffusion coefficient values were higher for films stored at 5° C than at 25° C. | [85] |

| WP film produced under alkaline conditions | Develop WP-derived materials obtained under alkaline conditions and with no heat-treatment |

| Casting on Petri dish + drying at 25 °C-45% RH for 48 h | Casting films containing either 40 or 50% of Gly at pH 12 led to the production of more resistant and flexible materials than at pH 7. Opacity was also higher for films obtained at a pH of 12. | [73] |

| Active WP film | Develop a WPC active coating, incorporated with seaweed (Fucus vesiculosus) extract (SWE) as antioxidant |

| Casting on aluminum foil surface + drying at room temperature (RT) for 3–4 days. Chicken breasts were vacuum packaged with the films. | Presence of SWE improved thickness, TS, and EM of the film. The active film also inhibited lipid oxidation at the surface of chicken breast for up to 25 days of storage. | [99] |

| Active edible WP film | Study viability and antimicrobial activity of bacteriocin-producing lactic acid bacteria (LAB) incorporated in a WP film in presence or absence of nutrients |

| Casting into Petri dishes + drying at 30 °C-50% RH for 24 h | The presence of LAB reduced viscosity of film-forming solutions and improved elasticity and EAB of film. WP-based films ensured high viability of LAB strains during 28-day storage at 4 °C. Adding MRS broth slightly affected the viability but was needed to achieve a good antimicrobial activity against L. innocua. | [97] |

| WP film added with XOS and GOS | Develop a WP film added with xylooligosaccharide (XOS) and galactooligosaccharide (GOS). |

| Casting onto Petri plates + drying at 27 °C for 24 h + conditioning (vacuum) at 75% RH for 48 h before testing | XOS and GOS addition resulted in films with similar structure (cross-sectional SEM), with lower TS and higher EAB than control films. Prebiotics reduced WVP, despite the higher hydrophobicity evidenced by contact angle reduction. | [61] |

| WP film added with probiotics | Develop a composite film made with WP and carrageenan (CA) as a carrier of probiotic strains |

| Casting onto Teflon-coated plates + drying at RT + conditioning at 25 or 4 °C-53% RH, before testing | Significant decrease in cell counts observed for all strains in both WPI and CA films during storage at 25 °C, whereas counts were stable in blended films. Multi-strain cultures presented the same behavior. Incorporation of probiotic bacteria influenced WVP and color values of films, decreasing TS and EAB. | [98] |

4.3. Coatings from Casein and Whey Protein: Formulation and Production Methodologies

4.3.1. Coating Application Methods

4.3.2. Additives and Modifiers

| Type of Material | Aims | Formulation | Production Technology | Application | Main Results | Reference |

|---|---|---|---|---|---|---|

| Antioxidant WP coating | Develop a WP coating incorporated with tea polyphenols (TP) for preserving fresh-cut apples |

| Dipping for 5 min + draining for 10 min + storing at 20 °C for 24 h | Fresh-cut apples | Antioxidant activity increased with increasing TP concentration. Coated slices showed lower browning during 24 h storage. | [108] |

| WP edible antioxidant coating | Develop WP edible coatings with incorporated lemon (LEO) and lemongrass (LGEO) essential oils for preserving fresh-cut pears |

| Dipping for 2 min + draining on a filter paper + packing under modified atmosphere + storing at 4 °C-80 % relative humidity (RH) for 28 days | Fresh-cut pears | Presence of LEO and LGEO reduced O2 and CO2 permeability of the film. Coating caused reduction in color changes and loss in hardness of pear slices. | [109] |

| Active casein coating | Develop an active casein coating by adding antioxidant substances. Investigate effects of NaCas concentration on coating properties |

| Dipping for 2 min + draining on metallic grids for 10 min | Fresh fennels | Thickness of dry coating was 0.6–7.2 µm, depending on NaCas concentration, with good antioxidant properties. Water vapor permeability (WVP) was highest for films with 4 and 14% NaCas. | [101] |

| Composite WP–pectin coatings | Develop WP–pectin complex coating enzymatically reticulated by TGase and applied to eggshells to increase egg shelf life and to roasted peanuts to prevent oxidation |

| Eggs: Dipping for 1 min in the solution + drying for 10 min at room temperature (RT) Peanuts: Dipping for 10 s + drying at RT for 10 min + packing in sealed low-density polyethylene bags | Eggshells, Roasted peanuts | Eggs: Coating maintained a higher yolk index and albumen CO2 content, reduced weight loss and increased albumen and yolk pH. Compared to uncoated eggs, eggshell strength was higher and post-wash bacterial penetration was lower. Peanuts: Coating reduced the peroxide value. TGase reticulation decreased WVP and thus seed water absorption. | [106,107] |

| Antimicrobial WP coating | Develop an edible active coating for improving shelf life of fresh-curd cheese |

| Dipping into coating solution for 3 s + drying on perforated metal trays at 12 °C for 30 min + vacuum packing | Fresh-curd cheese | After 31-day ripening, coating had no effects on cheese moisture, color, texture, flavor. Coating had strong antimicrobial effect, and thus efficiently extended cheese shelf life compared to uncoated control cheese. | [110] |

| Antimicrobial casein coating | Investigate the efficacy of a casein/natamycin (NTM) coating for the control of mold growth on cheese surface |

| Dipping cheese into the solution twice for 60 s + leaving to drip for 2 h + draining at 22 °C for 1 h | Kashar cheese | The casein/NTM coating suppressed mold growth during 90-day ripening without adverse effects on cheese quality but a slight decrease in ripening. | [111] |

| WP nanofibril-based antimicrobial and antioxidant coating | Develop a coating using WPI nanofibrils (WPNFs), incorporating carvacrol (CA) for preserving fresh-cut cheddar cheese |

| Dipping cheese pieces into the solution for 60 s + draining at RT for 30 min + storage at 4 °C for 10 days | Fresh-cut cheddar cheese | WPNFs-CA coating had smooth and continuous surface, promoting lower weight losses and better textural properties in cheese. Antimicrobial activity was higher than in traditional films due to CA. | [116] |

| Active antimicrobial WP edible coating | Develop WP coating incorporated with probiotics and investigate its antimicrobial activity on sliced ham preservation |

| Slice immersion for 2 min in the solution + draining for 30 sec + storage at 4°C for 45 days | Sliced ham | Coating decreased water loss of ham without changes in color. Probiotics incorporated in coating inhibited growth of Staphylococcus spp., Pseudomonas spp., Enterobacteriaceae and yeasts/molds during storage. | [115] |

| Active edible WP film/coating | Develop a coating containing a nanoemulsion of cocoa–liquor (nCL) for improving physical and functional properties and prolonging the shelf life of muffins |

| Dipping muffins into the solution for 5 s + drying at 40 °C for 15 min | Muffins | nCL modified the secondary structure of the WP (FTIR), decreasing mechanical properties, solubility and WVP of the film. Moisture loss during storage at 20–50% RH was lower for coated muffins compared to the uncoated control. | [117] |

4.4. Relevant Properties of Milk-Protein-Based Films and Coatings and Future Developments

| Type of Material | Formulation | Thickness | WVP | TS | EAB | Reference |

|---|---|---|---|---|---|---|

| Casein film | µm | (1010 g H2O Pa−1 s−1 m−1) (ASTM Method E96-95) | MPa (ASTM D1708-93) | % (ASTM D1708-93) | [81] | |

| 110 | 5.4 | 57.0 | 4.0 | ||

| 110 | 2.2–5.0 | 23.4–41.2 | 2.7–4.7 | ||

| 110 | / | 13.6 | 11.6 | ||

| 110 | / | 25.8 | 3.0 | ||

| Casein film | µm | (1010 g H2O Pa−1 s−1 m−1) (ASTM E96M-10) | MPa (23°C, 50%RH) | % (23°C, 50%RH) | [71] | |

| 800 | 11.0 | 2.6 | 458 | ||

| 800 | 4.6–5.7 | 2.6–5.8 | 294–458 | ||

| Active WP film | µm | (1010 g H2O Pa−1 s−1 m−1) (ASTM E96M-80) | MPa (ASTM D882-91) | % (ASTM D882-91) | [95] | |

| 149 | 2.1 | 5.4 | 19 | ||

| 139–141 | 1.9–2.3 | 3.9–5.0 | 7–13 | ||

| WP film reinforced with CNCs | MPa (ASTM D882) | % (ASTM D882) | [84] | |||

| / | / | 2.30 | 46.07 | ||

| / | / | 3.41–4.93 | 17.63–26.54 | ||

| Antimicrobial casein-based flexible coating |

| / | / | 0.49 | 55.23 | [113] |

| / | / | 0.97–1.65 | 52.51–64.77 | ||

| Casein-based TiO2 nanocomposite coating |

| / | / | 2.30 | 67.5 | [114] |

| / | / | 0.55–1.25 | 102–120 |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, T.; Aadil, R.M.; Ahmed, H.; Rahman, U.U.; Soares, B.C.; Souza, S.L.; Pimentel, T.C.; Scudino, H.; Guimarães, J.T.; Esmerino, E.A.; et al. Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol. 2019, 88, 361–372. [Google Scholar] [CrossRef]

- Limbo, S.; Pellegrino, L.; D’Incecco, P.; Gobbi, S.; Rosi, V.; Fracassetti, D. Storage of pasteurized milk in clear PET bottles com-bined with light exposure on a retail display case: A possible strategy to define the shelf life and support a recyclable packaging. Food Chem. 2020, 329, 127116. [Google Scholar] [CrossRef]

- Sar, T.; Harirchi, S.; Ramezani, M.; Bulkan, G.; Akbas, M.Y.; Pandey, A.; Taherzadeh, M.J. Potential utilization of dairy in-dustries by-products and wastes through microbial processes: A critical review. Sci. Total Environ. 2022, 810, 152253. [Google Scholar] [CrossRef] [PubMed]

- Kamal, H.; Ali, A.; Le, C.F. Green solvent processing: Effect of type of solvent on extraction and quality of protein from dairy and non-dairy expired milk products. Food Chem. 2023, 400. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yang, K.; Wang, J.; Wei, D.; Liu, Z.; Zhang, S.; Ye, W.; Zhang, C.; Wang, Z.; Yang, X. Expired milk powder emulsion-derived carbonaceous framework/Si composite as efficient anode for lithium-ion batteries. J. Colloid Interface Sci. 2023, 638, 99–108. [Google Scholar] [CrossRef] [PubMed]

- Group of Chief Scientific Advisors, towards a Sustainable Food System European Commission (2020), 10.2777/282386 Scientific Opinion no. 8. Available online: https://op.europa.eu/en/web/eu-law-and-publications/publication-detail/-/publication/ca8ffeda-99bb-11ea-aac4-01aa75ed71a1 (accessed on 9 January 2023).

- FAO—Food and Agriculture Organization of the United Nations. The State of Food and Agriculture 2019. Moving forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019; Available online: https://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 5 September 2020).

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2018, 109, 1095–1107. [Google Scholar] [CrossRef]

- Karaca, O.B.; Oluk, C.A.; Taşpinar, T.; Güven, M. New concepts in packaging: Milk Protein Edible Films. In Health and Safety Aspects of Food Processing Technologies; Malik, A., Erginkaya, Z., Eds.; Spinger: New York, NY, USA, 2019; pp. 537–565. [Google Scholar]

- Korycki, A.; Garnier, C.; Irusta, S.; Chabert, F. Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes. Polymers 2022, 14, 3466. [Google Scholar] [CrossRef] [PubMed]

- Mastropetros, S.G.; Pispas, K.; Zagklis, D.; Ali, S.S.; Kornaros, M. Biopolymers production from microalgae and cyanobacteria cultivated in wastewater: Recent advances. Biotechnol. Adv. 2022, 60. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Kumar, M.; Kumar, V.; Sarsaiya, S.; Anerao, P.; Ghosh, P.; Singh, L.; Liu, H.; Zhang, Z.; Awasthi, M.K. A comprehensive review on recent advancements in biodegradation and sustainable management of biopolymers. Environ. Pollut. 2022, 307. [Google Scholar] [CrossRef]

- Thulasisingh, A.; Kumar, K.; Yamunadevi, B.; Poojitha, N.; SuhailMadharHanif, S.; Kannaiyan, S. Biodegradable packaging materials. Polym. Bull. 2021, 79, 4467–4496. [Google Scholar] [CrossRef]

- Verma, S.; Manjubala, I.; Narendrakumar, U. Protein and carbohydrate biopolymers for biomedical applications. Int. J. Pharm. Tech. Res. 2016, 9, 408–421. [Google Scholar]

- Di Donato, P.; Taurisano, V.; Poli, A.; Gomez d’Ayala, G.; Nicolaus, B.; Malinconinco, M.; Santagata, G. Vegetable wastes derived polysaccharides as natural eco-friendly plasticizers of sodium alginate. Carbohydr. Polymers 2020, 2029, 115427. [Google Scholar]

- Gautam, K.; Vishvakarma, R.; Sharma, P.; Singh, A.; Gaur, V.K.; Varjani, S.; Srivastava, J.K. Production of biopolymers from food waste: Constrains and perspectives. Bioresour. Technol. 2022, 361. [Google Scholar] [CrossRef]

- Calva-Estrada, S.J.; Jimenez-Fernandez, M.; Lugo-Cervantes, E. Protein-based films: Advances in the development of bio-materials applicable to food packaging. Food Eng. Rev. 2019, 11, 78–92. [Google Scholar] [CrossRef]

- Swaisgood, H.E. Chemistry of the caseins. In Advanced Dairy Chemistry—1 Proteins, 3rd ed.; Fox, P.F., McSweeney, P.L.H., Eds.; Springer: Boston, MA, USA, 2003; Volume 1, pp. 139–201. [Google Scholar]

- Huppertz, T. Chemistry of the caseins. In Advanced Dairy Chemistry-Proteins: Basic Aspects, 4th ed.; McSweeney, P.L.H., Fox, P.F., Eds.; Springer: New York, NY, USA, 2013; Volume 1A, pp. 135–160. [Google Scholar]

- Huppertz, T.; Gazi, I.; Luyten, H.; Nieuwenhuijse, H.; Alting, A.; Schokker, E. Hydration of casein micelles and caseinates: Implications for casein micelle structure. Int. Dairy J. 2017, 74, 1–11. [Google Scholar] [CrossRef]

- McMahon, D.J.; Oommen, B.S. Casein Micelle Structure, Functions, and Interactions. In Advanced Dairy Chemistry—Proteins: Basic Aspects, 4th ed.; McSweeney, P.L.H., Fox, P.F., Eds.; Springer: New York, NY, USA, 2013; Volume 1A, pp. 185–209. [Google Scholar]

- Mirdha, L.; Chakraborty, H. Characterization of structural conformers of κ-casein utilizing fluorescence spectroscopy. Int. J. Biol. Macromol. 2019, 131, 89–96. [Google Scholar] [CrossRef] [PubMed]

- Wynn, P.C.; Sheehy, P.A. Minor Proteins, Including Growth Factors. In Advanced Dairy Chemistry—Proteins: Basic Aspects, 4th ed.; McSweeney, P.L.H., Fox, P.F., Eds.; Springer: New York, NY, USA, 2013; Volume 1A, pp. 317–335. [Google Scholar]

- O’Mahony, J.A.; Fox, P.F.; Kelly, A.L. Indigenous Enzymes of Milk. In Advanced Dairy Chemistry—Proteins: Basic Aspects, 4th ed.; McSweeney, P.L.H., Fox, P.F., Eds.; Springer: New York, NY, USA, 2013; Volume 1A, pp. 337–385. [Google Scholar]

- Sawyer, L. β-Lactoglobulin. In Advanced Dairy Chemistry—Proteins: Basic Aspects, 4th ed.; McSweeney, P.L.H., Fox, P.F., Eds.; Springer: New York, NY, USA, 2013; Volume 1A, pp. 211–259. [Google Scholar]

- Guyomarc’H, F.; Famelart, M.-H.; Henry, G.; Gulzar, M.; Leonil, J.; Hamon, P.; Bouhallab, S.; Croguennec, T. Current ways to modify the structure of whey proteins for specific functionalities—A review. Dairy Sci. Technol. 2014, 95, 795–814. [Google Scholar] [CrossRef]

- Madureira, A.R.; Pereira, C.I.; Gomes, A.M.P.; Pintado, M.E.; Xavier Malcata, F. Bovine whey proteins—Overview on their main biological properties. Food Res. Int. 2007, 40, 1197–1211. [Google Scholar] [CrossRef]

- Nunes, L.; Tavares, M. Thermal treatments and emerging technologies: Impacts on the structure and techno-functional properties of milk proteins. Trends Food Sci. Technol. 2019, 90, 88–99. [Google Scholar] [CrossRef]

- D’Incecco, P.; Limbo, S.; Hogenboom, J.A.; Pellegrino, L. Novel technologies for extending the shelf life of drinking milk: Concepts, research trends and current applications. LWT 2021, 148, 111746. [Google Scholar] [CrossRef]

- Considine, T.; Patel, H.A.; Anema, S.G.; Singh, H.; Creamer, L.K. Interactions of milk proteins during heat and high hydro-static pressure treatments—A Review. Innov. Food Sci. Emerg. Technol. 2007, 8, 1–23. [Google Scholar] [CrossRef]

- El-Salam, M.A.; El-Shibiny, S.; Salem, A. Factors Affecting the Functional Properties of Whey Protein Products: A Review. Food Rev. Int. 2009, 25, 251–270. [Google Scholar] [CrossRef]

- Anema, S.G. The whey proteins in milk: Thermal denaturation, physical interactions, and effects on the functional properties of milk. In Milk Proteins, 3rd ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 325–384. [Google Scholar] [CrossRef]

- Pellegrino, L.; Hogenboom, J.A.; Rosi, V.; Sindaco, M.; Gerna, S.; D’Incecco, P. Focus on the Protein Fraction of Sports Nutrition Supplements. Molecules 2022, 27, 3487. [Google Scholar] [CrossRef]

- Cattaneo, S.; Masotti, F.; Pellegrino, L.M. Chemical modifications of casein occurring during industrial manufacturing of milk protein powders. Eur. Food Res. Technol. 2012, 235, 315–323. [Google Scholar] [CrossRef]

- Beliciu, C.; Sauer, A.; Moraru, C. The effect of commercial sterilization regimens on micellar casein concentrates. J. Dairy Sci. 2012, 95, 5510–5526. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Salam, M.H.A.; El-Shibiny, S. Glycation of whey proteins: Technological and nutritional implications. Int. J. Biol. Macromol. 2018, 112, 83–92. [Google Scholar] [CrossRef]

- Cardoso, H.B.; Wierenga, P.A.; Gruppen, H.; Schols, H.A. Maillard induced glycation behavior of individual milk proteins. Food Chem. 2018, 252, 311–317. [Google Scholar] [CrossRef]

- Lund, M.N.; Ray, C.A. Control of Maillard Reactions in Foods: Strategies and Chemical Mechanisms. J. Agric. Food Chem. 2017, 65, 4537–4552. [Google Scholar] [CrossRef] [Green Version]

- Friedman, M. Chemistry, Biochemistry, Nutrition, and Microbiology of Lysinoalanine, Lanthionine, and Histidinoalanine in Food and Other Proteins. J. Agric. Food Chem. 1999, 47, 1295–1319. [Google Scholar] [CrossRef]

- McKerchar, H.J.; Clerens, S.; Dobson, R.C.; Dyer, J.M.; Maes, E.; Gerrard, J.A. Protein-protein crosslinking in food: Proteomic characterisation methods, consequences and applications. Trends Food Sci. Technol. 2019, 86, 217–229. [Google Scholar] [CrossRef]

- Buchert, J.; Cura, D.E.; Ma, H.; Gasparetti, C.; Monogioudi, E.; Faccio, G.; Mattinen, M.; Boer, H.; Partanen, R.; Selinheimo, E.; et al. Crosslinking Foo Proteins for Improved Functionality. Annu. Rev. Food Sci. Technol. 2010, 1, 113–138. [Google Scholar] [CrossRef] [PubMed]

- Al-Saadi, J.M.; Deeth, H.C. Cross-linking of proteins and other changes in UHT milk during storage at different tempera-tures. Aust. J. Dairy Technol. 2008, 63, 93. [Google Scholar]

- Nielsen, S.D.; Knudsen, L.J.; Bækgaard, L.T.; Rauh, V.; Larsen, L.B. Influence of Lactose on the Maillard Reaction and Dehy-droalanine-Mediated Protein Cross-Linking in Casein and Whey. Foods 2022, 11, 897. [Google Scholar] [CrossRef] [PubMed]

- Dalsgaard, T.K.; Otzen, D.; Nielsen, J.H.; Larsen, L.B. Changes in Structures of Milk Proteins upon Photo-oxidation. J. Agric. Food Chem. 2007, 55, 10968–10976. [Google Scholar] [CrossRef]

- Fuentes-Lemus, E.; Silva, E.; Barrias, P.; Aspee, A.; Escobar, E.; Lorentzen, L.G.; Carroll, L.; Leinisch, F.; Davies, M.J.; López-Alarcón, C. Aggregation of α- and β-caseins induced by peroxyl radicals involves secondary reactions of carbonyl compounds as well as di-tyrosine and di-tryptophan formation. Free. Radic. Biol. Med. 2018, 124, 176–188. [Google Scholar] [CrossRef]

- Hellwig, M. The Chemistry of Protein Oxidation in Food. Angew. Chem. Int. Ed. 2019, 58, 16742–16763. [Google Scholar] [CrossRef]

- Huang, H.; Yi, J.; Fan, Y. Influence of peroxyl radical-induced oxidation on structural characteristics, emulsifying, and foaming properties of α-lactalbumin. LWT 2022, 163, 113590. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Han, J.; Yuan, D.; Lu, Z.; Zhang, L. Influence of transglutaminase-induced modification of milk protein con-centrate (MPC) on yoghurt texture. Int. Dairy J. 2018, 78, 65–72. [Google Scholar] [CrossRef]

- Schorsch, C.; Carrie, H.; Clark, A.; Norton, I. Cross-linking casein micelles by a microbial transglutaminase conditions for formation of transglutaminase-induced gels. Int. Dairy J. 2000, 10, 519–528. [Google Scholar] [CrossRef]

- Raak, N.; Corredig, M. Kinetic aspects of casein micelle cross-linking by transglutaminase at different volume fractions. Food Hydrocoll. 2022, 128, 107603. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Chronakis, I.S. Crosslinking of milk proteins by microbial transglutaminase: Utilization in functional yogurt products. Food Chem. 2018, 245, 620–632. [Google Scholar] [CrossRef] [PubMed]

- Kouravand, F.; Jooyandeh, H.; Barzegar, H.; Hojjati, M. Mechanical, barrier and structural properties of whey protein isolate-based films treated by microbial transglutaminase. J. Microbiol. Biotechnol. Food Sci. 2020, 9, 960–964. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Liu, T.; Yang, C.; Liu, D.; Li, H.; Yu, J. Textural performance of Zea mays transglutaminase modified milk protein concentrate in stirred yoghurt. LWT 2021, 147, 111625. [Google Scholar] [CrossRef]

- Romeih, E.; Walker, G. Recent advances on microbial transglutaminase and dairy application. Trends Food Sci. Technol. 2017, 62, 133–140. [Google Scholar] [CrossRef]

- Liu, K.; Xu, X.; Liu, H.; Liu, Z.; Zhao, K.; Ma, Y.; Zhang, K. Mechanical properties and water sensitivity of soybean protein isolate film improved by incorporation of sodium caseinate and transglutaminase. Prog. Org. Coat. 2021, 153, 106154. [Google Scholar] [CrossRef]

- Díaz-Montes, E.; Castro-Muñoz, R. Edible films and coatings as food-quality preservers: An overview. Foods 2021, 10, 249. [Google Scholar] [CrossRef]

- Kandasamy, S.; Yoo, J.; Yun, J.; Kang, H.-B.; Seol, K.-H.; Kim, H.-W.; Ham, J.-S. Application of Whey Protein-Based Edible Films and Coatings in Food Industries: An Updated Overview. Coatings 2021, 11, 1056. [Google Scholar] [CrossRef]

- Cheng, L.; Ye, A.; Yang, Z.; Gilbert, E.P.; Knott, R.; de Campo, L.; Singh, H. Small-angle X-ray scattering (SAXS) and small-angle neutron scattering (SANS) study on the structure of sodium caseinate in dispersions and at the oil-water inter-face: Effect of calcium ions. Food Struct. 2022, 32, 100276. [Google Scholar] [CrossRef]

- Ramos, Ó.L.; Fernandes, J.C.; Silva, S.I.; Pintado, M.E.; Malcata, F.X. Edible Films and Coatings from Whey Proteins: A Review on Formulation, and on Mechanical and Bioactive Properties. Crit. Rev. Food Sci. Nutr. 2012, 52, 533–552. [Google Scholar] [CrossRef]

- Schmid, M.; Müller, K. Chapter 11-Whey Protein-Based Packaging Films and Coatings. In Whey Proteins—From Milk to Medicine; Deeth, C.H., Bansal, N., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 407–437. [Google Scholar]

- Fernandes, L.M.; Guimarães, J.T.; Silva, R.; Rocha, R.S.; Coutinho, N.M.; Balthazar, C.F.; Calvalcanti, R.N.; Piler, C.W.; Pimentel, T.C.; Neto, R.P.; et al. Whey protein films added with galactooligosaccharide and xylooligosaccharide. Food Hydrocoll. 2020, 104, 105755. [Google Scholar] [CrossRef]

- Fematt-Flores, G.E.; Aguiló-Aguayo, I.; Marcos, B.; Camargo-Olivas, B.A.; Sánchez-Vega, R.; Soto-Caballero, M.C.; Salas-Salazar, N.A.; Flores-Córdova, M.A.; Rodríguez-Roque, M.J. Milk Protein-Based Edible Films: Influence on Mechanical, Hydrodynamic, Optical and Antioxidant Properties. Coatings 2022, 12, 196. [Google Scholar] [CrossRef]

- Sabil, S.; Maruddin, F.; Wahyuni, T.; Taufik, M. Edible film characteristics at different casein concentrations. IOP Conf. Ser. Earth Environ. Sci. 2021, 788, 012115. [Google Scholar] [CrossRef]

- Picchio, M.L.; Paredes, A.J.; Palma, S.D.; Passeggi, M.C.G., Jr.; Gugliotta, L.M.; Minari, R.J.; Igarzabal Alvarez, C.I. pH-responsive casein-based films and their application as functional coatings in solid dosage formulations. Colloids Surf. 2018, 541, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Brzoska, N.; Müller, M.; Nasui, L.; Schmid, M. Effects of film constituents on packaging-relevant properties of sodium caseinate-based emulsion films. Prog. Org. Coat. 2018, 114, 250–258. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Rhim, J.W.; Azizi-Lalabadi, M.; Hemmati-Dinarvand, M.; Ehsani, A. Preparation and characterization of functional sodium caseinate/guar gum/TiO2/cumin essential oil composite film. Int. J. Biol. Macromol. 2020, 145, 835–844. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liu, Q.; Luo, Y.; Murad, M.S.; Zhu, L.; Mu, G. Improved packing performance and structure-stability of casein edible films by dielectric barrier discharges (DBD) cold plasma. Food Packag. Shelf Life 2020, 24, 100471. [Google Scholar] [CrossRef]

- Chevalier, E.; Assezat, G.; Prochazka, F.; Oulahal, N. Development and characterization of a novel edible extruded sheet based on different casein sources and influence of the glycerol concentration. Food Hydrocoll. 2018, 75, 182–191. [Google Scholar] [CrossRef]

- Pereda, M.; Aranguren, M.I.; Marcovich, N.E. Effect of crosslinking on the properties of sodium caseinate films. J. Appl. Polym. Sci. 2009, 116, 18–26. [Google Scholar] [CrossRef]

- Juvonen, H.; Smolander, M.; Boer, H.; Pere, J.; Buchert, J.; Peltonen, J. Film Formation and Surface Properties of Enzymatically Crosslinked Casein Films. J. Appl. Polym. Sci. 2011, 119, 2205–2213. [Google Scholar] [CrossRef]

- Picchio, M.L.; Linck, Y.G.; Monti, G.A.; Gugliotta, L.M.; Minari, R.J.; Igarzabal, C.I.A. Casein films crosslinked by tannic acid for food packaging applications. Food Hydrocoll. 2018, 84, 424–434. [Google Scholar] [CrossRef]

- Jahromi, M.; Niakousari, M.; Golmakani, M.T.; Ajalloueian, F.; Khalesi, M. Effect of dielectric barrier discharge atmospheric cold plasma treatment on structural, thermal and techno-functional characteristics of sodium caseinate. Innov. Food Sci. Emerg. Technol. 2020, 66, 102542. [Google Scholar] [CrossRef]

- Abdalrazeq, M.; Giosafatto, C.V.L.; Esposito, M.; Fenderico, M.; Di Pierro, P.; Porta, R. Glycerol-Plasticized Films Obtained from Whey Proteins Denatured at Alkaline pH. Coatings 2019, 9, 322. [Google Scholar] [CrossRef] [Green Version]

- Cruz-Diaz, K.; Cobos, A.; Fernández-Valle, M.E.; Díaz, O.; Cambero, M.I. Characterization of edible films from whey pro-teins treated with heat, ultrasounds and/or transglutaminase. Application in cheese slices packaging. Food Packag. Shelf Life 2019, 22, 100397. [Google Scholar] [CrossRef]

- Díaz, O.; Candia, D.; Cobos, Á. Effects of ultraviolet radiation on properties of films from whey protein concentrate treated before or after film formation. Food Hydrocoll. 2016, 55, 189–199. [Google Scholar] [CrossRef]

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Polysaccharides, protein and lipid-based natural edible films in food packaging: A review. Carbohydr. Polym. 2020, 238, 116178. [Google Scholar] [CrossRef]

- Khan, M.; Volpe, S.; Valentino, M.; Miele, N.; Cavella, S.; Torrieri, E. Active Casein Coatings and Films for Perishable Foods: Structural Properties and Shelf-Life Extension. Coatings 2021, 11, 899. [Google Scholar] [CrossRef]

- Hernandez-Izquierdo, V.; Krochta, J. Thermoplastic Processing of Proteins for Film Formation—A Review. J. Food Sci. 2008, 73, R30–R39. [Google Scholar] [CrossRef]

- Galus, S.; Lenart, A. Optical, mechanical, and moisture sorption properties of whey protein edible films. J. Food Process. Eng. 2019, 42, e13245. [Google Scholar] [CrossRef]

- Krochta, J.M.; Hudson, J.S.; Avena-Bustillos, R.J. Casein-acetylated monoglycerides coating for sliced apple products. In Proceedings of the Annual Meeting of the Institute of Food Technologists, Anaheim, CA, USA, 16–20 June 1990. [Google Scholar]

- Pereda, M.; Marcovich, N.E.; Mosiewicki, M.A. Sodium caseinate films containing linseed oil resin as oily modifier. Food Hydrocoll. 2015, 44, 407–415. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Kia, E.M.; Ghasempour, Z.; Ehsani, A. Preparation of Active Nanocomposite Film Consisting of Sodium Caseinate, ZnO Nanoparticles and Rosemary Essential Oil for Food Packaging Applications. J. Polym. Environ. 2020, 29, 588–598. [Google Scholar] [CrossRef]

- Ranjbaryan, S.; Pourfathi, B.; Almasi, H. Reinforcing and release controlling effect of cellulose nanofiber in sodium caseinate films activated by nanoemulsified cinnamon essential oil. Food Packag. Shelf Life 2019, 21, 100341. [Google Scholar] [CrossRef]

- Sukyai, P.; Anongjanya, P.; Bunyahwuthakul, N.; Kongsin, K.; Harnkarnsujarit, N.; Sukatta, U.; Chollakup, R.J.F.R.I. Effect of cellulose nanocrystals from sugarcane bagasse on whey protein isolate-based films. Food Res. Int. 2018, 107, 528–535. [Google Scholar] [CrossRef]

- Galus, S.; Kadzińska, J. Gas barrier and wetting properties of whey protein isolate-based emulsion films. Polym. Eng. Sci. 2018, 59, E375–E383. [Google Scholar] [CrossRef]

- He, Z.; Zhao, J.; Liu, C.; Li, W.; Wang, Y. Ameliorating effect of γ-aminobutyric acid on the physical performance of whey protein films. Food Hydrocoll. 2021, 124, 107207. [Google Scholar] [CrossRef]

- Kajthunyakarn, W.; Khlibsuwan, R.; Sakloetsakun, D.; Pongjanyakul, T. Sodium caseinate films modified using halloysite: Physicochemical characterization and drug permeability studies. J. Drug Deliv. Sci. Technol. 2019, 54, 101235. [Google Scholar] [CrossRef]

- Kajthunyakarn, W.; Sakloetsakun, D.; Pongjanyakul, T. Sodium caseinate-magnesium aluminum silicate nanocomposite films for modified-release tablets. Mater. Sci. Eng. C 2018, 92, 827–839. [Google Scholar] [CrossRef]

- Schmid, M.; Prinz, T.K.; Stäbler, A.; Sängerlaub, S. Effect of Sodium Sulfite, Sodium Dodecyl Sulfate, and Urea on the Molecular Interactions and Properties of Whey Protein Isolate-Based Films. Front. Chem. 2017, 4, 49. [Google Scholar] [CrossRef] [Green Version]

- Colak, B.Y.; Peynichou, P.; Galland, S.; Oulahal, N.; Assezat, G.; Prochazka, F.; Degraeve, P. Active biodegradable sodium caseinate films manufactured by blown-film extrusion: Effect of thermo-mechanical processing parameters and formulation on lysozyme stability. Ind. Crops Prod. 2015, 72, 142–151. [Google Scholar] [CrossRef]

- Ozer, B.B.P.; Uz, M.; Oymaci, P.; Altinkaya, S.A. Development of a novel strategy for controlled release of lysozyme from whey protein isolate based active food packaging films. Food Hydrocoll. 2016, 61, 877–886. [Google Scholar] [CrossRef] [Green Version]

- Chevalier, E.; Chaabani, A.; Assezat, G.; Prochazka, F.; Oulahal, N. Casein/wax blend extrusion for production of edible films as carriers of potassium sorbate—A comparative study of waxes and potassium sorbate effect. Food Packag. Shelf Life 2018, 16, 41–50. [Google Scholar] [CrossRef]

- Yoplac, I.; Hidalgo, A.; Vargas, L. Characterization, microstructure, and spectroscopic study of optimized sodium caseinate–sorbitol active biofilms with citral microencapsulate. Polym. Bull. 2022, 1–22. [Google Scholar] [CrossRef]

- Agudelo-Cuartas, C.; Granda-Restrepo, D.; Sobral, P.J.; Hernandez, H.; Castro, W. Characterization of whey protein-based films incorporated with natamycin and nanoemulsion of α-tocopherol. Heliyon 2020, 6, e03809. [Google Scholar] [CrossRef] [PubMed]

- Braber, N.L.V.; Di Giorgio, L.; Aminahuel, C.A.; Vergara, L.I.D.; Costa, A.O.M.; Montenegro, M.A.; Mauri, A.N. Antifungal whey protein films activated with low quantities of water soluble chitosan. Food Hydrocoll. 2020, 110, 106156. [Google Scholar] [CrossRef]

- Mozaffarzogh, M.; Misaghi, A.; Shahbazi, Y.; Kamkar, A. Evaluation of probiotic carboxymethyl cellulose-sodium caseinate films and their application in extending shelf life quality of fresh trout fillets. LWT 2020, 126, 109305. [Google Scholar] [CrossRef]

- La Storia, A.; Di Giuseppe, F.A.; Volpe, S.; Oliviero, V.; Villani, F.; Torrieri, E. Physical properties and antimicrobial activity of bioactive film based on whey protein and Lactobacillus curvatus 54M16 producer of bacteriocins. Food Hydrocoll. 2020, 108, 105959. [Google Scholar] [CrossRef]

- Sogut, E.; Ertekin Filiz, B.; Seydim, A.C. Whey protein isolate- and carrageenan-based edible films as carriers of different pro-biotic bacteria. J. Dairy Sci. 2022, 105, 4829–4842. [Google Scholar] [CrossRef]

- Andrade, M.A.; Barbosa Souza, V.G.L.; Coelhoso, I.M.; Reboleira, J.; Bernardino, S.; Ganhão, R.; Mendes, S.; Fernando, A.L.; Vilarinho, F.; Sanches Silva, A.; et al. Novel Active Food Packaging Films Based on Whey Protein Incorporated with Seaweed Extract: Development, and Application in Fresh Poultry Meat. Coatings 2021, 11, 229. [Google Scholar] [CrossRef]

- Jalilzadeh, A.; Hesari, J.; Peighambardoust, S.H.; Javidipour, I. The effect of whey protein-based edible coating containing natamycin and lysozyme-xanthan gum conjugate on the shelf life of ultrafiltrated white cheese. J. Food Bioprocess Eng. 2020, 3, 168–177. [Google Scholar]

- Valentino, M.; Volpe, S.; Di Giuseppe, F.A.; Cavella, S.; Torrieri, E. Active Biopolymer Coating Based on Sodium Caseinate: Physical Characterization and Antioxidant Activity. Coatings 2020, 10, 706. [Google Scholar] [CrossRef]

- Picchio, M.L.; Minari, R.J.; Gugliotta, L.M. Enhancing the coating properties of acrylic/casein latexes with high protein content. J. Coat. Technol. Res. 2017, 14, 543–553. [Google Scholar] [CrossRef]

- Nian, L.; Wang, M.; Sun, X.; Zeng, Y.; Xie, Y.; Cheng, S.; Cao, C. Biodegradable active packaging: Components, preparation, and applications in the preservation of postharvest perishable fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2022, 1–36. [Google Scholar] [CrossRef] [PubMed]

- Strube, O.I.; Rüdiger, A.A.; Bremser, W. Enzymatically controlled material design with casein—From defined films to local-ized deposition of particles. J. Biotechnol. 2015, 201, 69–74. [Google Scholar] [CrossRef]

- Ruediger, A.A.; Bremser, W.; Strube, O.I. Nanoscaled Biocoatings via Enzyme Mediated Autodeposition of Casein. Macromol. Mater. Eng. 2016, 301, 1181–1190. [Google Scholar] [CrossRef]

- Dávalos-Saucedo, C.A.; Rossi-Márquez, G.; Regalado-González, C.; Alonzo-Macías, M.; Di Pierro, P. Application of transglutaminase crosslinked whey protein–pectin coating improves egg quality and minimizes the breakage and porosity of eggshells. Coatings 2018, 8, 438. [Google Scholar] [CrossRef] [Green Version]

- Rossi-Márquez, G.; Helguera, M.; Briones, M.; Dávalos-Saucedo, C.A.; Di Pierro, P. Edible coating from enzymatically reticu-lated whey protein-pectin to improve shelf life of roasted peanuts. Coatings 2021, 11, 329. [Google Scholar] [CrossRef]

- Ming, Y.; Chen, L.; Khan, A.; Wang, H.; Wang, C. Effects of tea polyphenols on physicochemical and antioxidative properties of whey protein coating. Food Sci. Biotechnol. 2020, 29, 1655–1663. [Google Scholar] [CrossRef]

- Galus, S.; Mikus, M.; Ciurzyńska, A.; Domian, E.; Kowalska, J.; Marzec, A.; Kowalska, H. The effect of whey protein-based edible coatings incorporated with lemon and lemongrass essential oils on the quality attributes of fresh-cut pears during stor-age. Coatings 2021, 11, 745. [Google Scholar] [CrossRef]

- Mileriene, J.; Serniene, L.; Henriques, M.; Gomes, D.; Pereira, C.; Kondrotiene, K.; Malakauskas, M. Effect of liquid whey pro-tein concentrate-based edible coating enriched with cinnamon carbon dioxide extract on the quality and shelf life of Eastern European curd cheese. J. Dairy Sci. 2021, 104, 1504–1517. [Google Scholar] [CrossRef]

- Yangılar, F.; Yıldız, P.O. Casein/natamycin edible films efficiency for controlling mould growth and on microbiological, chemical and sensory properties during the ripening of Kashar cheese. J. Sci. Food Agric. 2015, 96, 2328–2336. [Google Scholar] [CrossRef]

- Liu, J.; Hui, A.; Ma, J.; Chen, Z.; Peng, Y. Fabrication and application of hollow ZnO nanospheres in antimicrobial casein-based coatings. Int. J. Appl. Ceram. Technol. 2017, 14, 128–134. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, J.; Xu, Q.; Zhang, J. Fabrication of antibacterial casein-based ZnO nanocomposite for flexible coatings. Mater. Des. 2017, 113, 240–245. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Fan, Q.; Ma, J.; Yan, Z. Facile synthesis of casein-based TiO2 nanocomposite for self-cleaning and high covering coat-ings: Insights from TiO2 dosage. Prog. Org. Coat. 2016, 99, 223–229. [Google Scholar] [CrossRef]

- Pereira, J.O.; Soares, J.; Monteiro, M.J.; Gomes, A.; Pintado, M. Impact of whey protein coating incorporated with Bifidobacterium and Lactobacillus on sliced ham properties. Meat Sci. 2018, 139, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, H.; Tian, B.; Jiang, B.; Xu, J.; Li, D.; Feng, Z.; Liu, C. Novel Edible Coating with Antioxidant and Antimicrobial Activities Based on Whey Protein Isolate Nanofibrils and Carvacrol and Its Application on Fresh-Cut Cheese. Coatings 2019, 9, 583. [Google Scholar] [CrossRef] [Green Version]

- Calva-Estrada, S.J.; Jimenez-Fernandez, M.; Vallejo-Cardona, A.A.; Castillo-Herrera, G.A.; Lugo-Cervantes, E.C. Cocoa Nanoparticles to Improve the Physicochemical and Functional Properties of Whey Protein-Based Films to Extend the Shelf Life of Muffins. Foods 2021, 10, 2672. [Google Scholar] [CrossRef]

- Fotie, G.; Gazzotti, S.; Ortenzi, M.A.; Limbo, S.; Piergiovanni, L. Performance comparison of coatings based on cellulose nanocrystals and microfibrillated cellulose for food packaging. Carbohydr. Polym. Technol. Appl. 2023, 5, 100264. [Google Scholar] [CrossRef]

- Fotie, G.; Limbo, S.; Piergiovanni, L. Manufacturing of Food Packaging Based on Nanocellulose: Current Advances and Challenges. Nanomaterials 2020, 10, 1726. [Google Scholar] [CrossRef]

- Guazzotti, V.; Marti, A.; Piergiovanni, L.; Limbo, S. Bio-based coatings as potential barriers to chemical contaminants from recycled paper and board for food packaging. Food Addit. Contam. Part A 2014, 31, 402–413. [Google Scholar] [CrossRef]

- Guazzotti, V.; Limbo, S.; Piergiovanni, L.; Fengler, R.; Fiedler, D.; Gruber, L. A study into the potential barrier properties against mineral oils of starch-based coatings on paperboard for food packaging. Food Packag. Shelf Life 2015, 3, 9–18. [Google Scholar] [CrossRef]

- Li, F.; Biagioni, P.; Bollani, M.; Maccagnan, A.; Piergiovanni, L. Multi-functional coating of cellulose nanocrystals for flexible packaging applications. Cellulose 2013, 20, 2491–2504. [Google Scholar] [CrossRef] [Green Version]

- Schmid, M.; Dallmann, K.; Bugnicourt, E.; Cordoni, D.; Wild, F.; Lazzeri, A.; Noller, K. Properties of Whey-Protein-Coated Films and Laminates as Novel Recyclable Food Packaging Materials with Excellent Barrier Properties. Int. J. Polym. Sci. 2012, 2012, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Joo, E.; Chang, Y.; Choi, I.; Lee, S.B.; Kim, D.H.; Choi, Y.J.; Yoon, C.S.; Han, J. Whey protein-coated high oxygen barrier multilayer films using surface pretreated PET substrate. Food Hydrocoll. 2018, 80, 1–7. [Google Scholar] [CrossRef]

- Weizman, O.; Dotan, A.; Nir, Y.; Ophir, A. Modified whey protein coatings for improved gas barrier properties of biode-gradable films. Polym. Adv. Technol. 2017, 28, 261–270. [Google Scholar] [CrossRef]

| αs1-Casein | αs2-Casein | β-Casein | κ-Casein | α-La | β-Lg | |

|---|---|---|---|---|---|---|

| Molecular mass (Da) | 23,614 | 25,230 | 23,983 | 19,023 | 14,174 | 18,362 |

| Concentration g L−1 | 10 | 2.6 | 9.3 | 3.3 | 1.2 | 3.2 |

| Pro | 17 | 10 | 35 | 20 | 2 | 8 |

| Cys | 0 | 2 | 0 | 2 | 8 | 5 |

| Glu | 24 | 25 | 18 | 13 | 8 | 16 |

| Asp | 8 | 11 | 5 | 1 | 9 | 11 |

| SerP | 8 | 11 | 5 | 1 | 0 | 0 |

| Glucidic residues | 0 | 0 | 0 | 0–5 | 0 | 0 |

| Hydrophobicity (kJ/res) | 4.9 | 4.7 | 5.6 | 5.1 | 4.7 | 5.1 |

| Isoelectric pH | 4.16–4.49 | 4.68–5.13 | 4.50–5.29 | 5.43–6.12 | 4.66–4.90 | 4.64–4.98 |

| Net charge/residue | −0.10 | −0.07 | −0.06 | −0.02 | −0.02 | −0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gerna, S.; D’Incecco, P.; Limbo, S.; Sindaco, M.; Pellegrino, L. Strategies for Exploiting Milk Protein Properties in Making Films and Coatings for Food Packaging: A Review. Foods 2023, 12, 1271. https://doi.org/10.3390/foods12061271

Gerna S, D’Incecco P, Limbo S, Sindaco M, Pellegrino L. Strategies for Exploiting Milk Protein Properties in Making Films and Coatings for Food Packaging: A Review. Foods. 2023; 12(6):1271. https://doi.org/10.3390/foods12061271

Chicago/Turabian StyleGerna, Stefano, Paolo D’Incecco, Sara Limbo, Marta Sindaco, and Luisa Pellegrino. 2023. "Strategies for Exploiting Milk Protein Properties in Making Films and Coatings for Food Packaging: A Review" Foods 12, no. 6: 1271. https://doi.org/10.3390/foods12061271