Further Interpretation of the Volatile, Microbial Community and Edible Quality of Fresh Fermented Rice Noodles with Different Selected Strains

Abstract

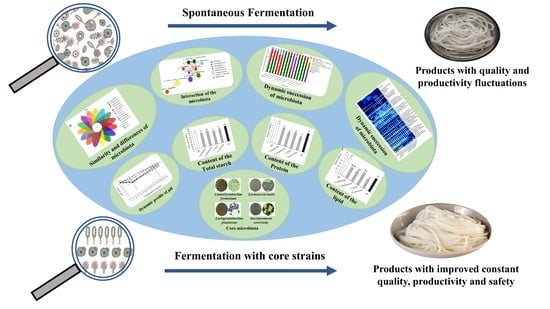

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Activation of Strains

2.3. Preparation of FFRNs

2.4. The pH Value and Proximate Composition Analysis

2.5. Cooking Qualities and Textural Properties Analysis

2.6. Volatile Components Analysis

2.7. Microbial Composition Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. The pH Value

3.2. The Content of the Total Starch, Protein and Lipid

3.3. The Cooking Qualities and Textural Profiles

3.4. Dynamic Analysis of Microbial Community

3.4.1. Dynamic Analysis of Bacterial Community

3.4.2. Dynamic Analysis of Fungal Community

3.4.3. Differences and Similarities in Fermentation

3.4.4. Correlation of Occurrence Patterns between the Microbiological Communities

3.5. Changes of Volatile Components

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Keatkrai, J.; Jirapakkul, W. Volatile profile of khanom jeen, Thai fermented rice noodles, and the changes during the fermentation process. Sci. Asia J. Sci. Soc. Thail. 2010, 36, 46–51. [Google Scholar] [CrossRef]

- Li, M.; Yang, R.; Zhang, H.; Wang, S.; Chen, D.; Lin, S. Development of a flavor fingerprint by HS-GC–IMS with PCA for volatile compounds of Tricholoma matsutake Singer. Food Chem. 2019, 290, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Zhu, Y.; Fang, C.; Wijffels, R.H.; Xu, Y. Can we control microbiota in spontaneous food fermentation–Chinese liquor as a case example. Trends Food Sci. Technol. 2021, 110, 321–331. [Google Scholar] [CrossRef]

- Li, N.; Zhang, B.; Zhao, S.; Niu, M.; Jia, C.; Huang, Q.; Lin, Q. Influence of lactobacillus/candida fermentation on the starch structure of rice and the related noodle features. Int. J. Biol. Macromol. 2018, 121, 882–888. [Google Scholar] [CrossRef]

- Yi, C.; Zhu, H.; Yang, R.; Bao, J.; He, H.; Niu, M. Links between microbial compositions and volatile profiles of rice noodle fermentation liquid evaluated by 16S rRNA sequencing and GC-MS. LWT-Food Sci. Technol. 2020, 118, 108774. [Google Scholar] [CrossRef]

- Wang, A.; Xiao, T.; Xi, H.; Qin, W.; He, Y.; Nie, M.; Chen, Z.; Wang, L.; Liu, L.; Wang, F.; et al. Edible qualities, microbial compositions and volatile compounds in fresh fermented rice noodles fermented with different starter cultures. Food Res. Int. 2022, 156, 111184. [Google Scholar] [CrossRef]

- Heitmann, M.; Zannini, E.; Arendt, E. Impact of Saccharomyces cerevisiae metabolites produced during fermentation on bread quality parameters: A review. Crit. Rev. Food Sci. Nutr. 2017, 58, 1152–1164. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Arneborg, N.; Hansen, A.S. Influence of commercial baker’s yeasts on bread aroma profiles. Food Res. Int. 2013, 52, 160–166. [Google Scholar] [CrossRef]

- Wang, A.; Yi, C.; Xiao, T.; Qin, W.; Chen, Z.; He, Y. Volatile compounds, bacteria compositions and physicochemical properties of 10 fresh fermented rice noodles from southern China. Food Res. Int. 2021, 150, 110787. [Google Scholar] [CrossRef]

- Imm, B.; Heo, Y.; Imm, J. Effects of plant-based content, flavor and texture information on consumer satisfaction with non-fried ramen. Food Qual. Prefer. 2021, 92, 104221. [Google Scholar] [CrossRef]

- Meng, Y.; Chen, X.; Sun, Z.; Li, Y.; Chen, D.; Fang, S.; Chen, J. Exploring core microbiota responsible for the production of volatile flavor compounds during the traditional fermentation of Koumiss. LWT-Food Sci. Technol. 2021, 135, 110049. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, K.; Guo, H.; Geng, Y.; Ren, G. Characterization of volatile compounds in differently coloured Chenopodium quinoa seeds before and after cooking by headspace-gas chromatography-ion mobility spectrometry. Food Chem. 2021, 348, 129086. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zeng, X.; Song, H.; Xi, Y.; Li, Y.; Hui, B.; Li, H.; Li, J. Characterization of the aroma profiles of cold and hot break tomato pastes by GC-O-MS, GC x GC-O-TOF-MS, and GC-IMS. Food Chem. 2023, 405, 134823. [Google Scholar] [CrossRef]

- Cavanna, D.; Zanardi, S.; Dall’Asta, C.; Suman, M. Ion mobility spectrometry coupled to gas chromatography: A rapid tool to assess eggs freshness. Food Chem. 2018, 271, 691–696. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Qian, M.; Deng, Y.; Yuan, H.; Jiang, Y. Insight into aroma dynamic changes during the whole manufacturing process of chestnut-like aroma green tea by combining GC-E-Nose, GC-IMS, and GC × GC-TOFMS. Food Chem. 2022, 387, 132813. [Google Scholar] [CrossRef] [PubMed]

- Geng, D.-H.; Liang, T.; Yang, M.; Wang, L.; Zhou, X.; Sun, X.; Liu, L.; Zhou, S.; Tong, L.-T. Effects of Lactobacillus combined with semidry flour milling on the quality and flavor of fermented rice noodles. Food Res. Int. 2019, 126, 108612. [Google Scholar] [CrossRef] [PubMed]

- Tong, L.T.; Gao, X.; Lin, L.; Liu, Y.; Zhong, K.; Liu, L.; Zhou, S. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. J. Cereal Sci. 2015, 62, 45–49. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, D.; Pu, D.; Zhang, Y.; Ren, F. Multivariate relationships among sensory attributes and volatile components in commercial dry porcini mushrooms (boletus edulis). Food Res. Int. 2020, 133, 109112. [Google Scholar] [CrossRef]

- Zang, J.H.; Xu, Y.S.; Xia, W.S.; Yu, D.W.; Gao, P.; Jiang, Q.X.; Yang, F. Dynamics and diversity of microbial communitysuccession during fermentation of Suan yu, a Chinese traditional fermented fish, determined by high throughput sequencing. Food Res. Int. 2018, 111, 565–573. [Google Scholar] [CrossRef]

- Amato, K.R.; Yeoman, C.J.; Kent, A.; Righini, N.; Carbonero, F.; Estrada, A.; Leigh, S.R. Habitat degradation impacts black howler monkey (Alouatta pigra) gastrointestinal microbiomes. ISME J. 2013, 7, 1344–1353. [Google Scholar] [CrossRef]

- Jiang, L.; Song, J.; Qi, M.; Suo, W.; Deng, Y.; Liu, Y.; Li, H. Modification mechanism of protein in rice adjuncts upon extrusion and its effects on nitrogen conversion during mashing. Food Chem. 2022, 407, 135150. [Google Scholar] [CrossRef]

- Shang, J.Y.; Zhao, B.; Li, L.M.; Liu, M.; Hong, J.; Fan, X.Q.; Wu, T.F.; Liu, C.; Zheng, X.L. Impact of A/B-type wheat starch granule ratio on rehydration behavior and cooking quality of noodles and the underlying mechanisms. Food Chem. 2022, 405, 134896. [Google Scholar] [CrossRef]

- Kang, M.J.; Bae, I.Y.; Lee, H.G. Rice noodle enriched with okara: Cooking property, texture, and in vitro starch digestibility. Food Biosci. 2018, 22, 178–183. [Google Scholar] [CrossRef]

- Hu, A.; Gao, C.; Lu, Z.; Lu, F.; Bie, X. Detection of Exiguo-bacterium spp. and E. acetylicum on fresh-cut leafy vegetables by a multiplex PCR assay. J. Microbiol. Methods 2020, 180, 106100. [Google Scholar] [CrossRef]

- Ling, N.; Jiang, X.; Forsythe, S.; Zhang, D.; Shen, Y.; Ding, Y.; Ye, Y. Food safety risks and contributing factors of Cronobacter spp. Engineering 2021, 12, 128–138. [Google Scholar] [CrossRef]

- Samaddar, A.; Shrimali, T.; Tiwari, S.; Sharma, A. First report of human infection caused by Curvularia warraberensis, manifesting as invasive sinusitis with intracranial involvement. J. Med. Mycol. 2022, 33, 101337. [Google Scholar] [CrossRef]

- Jung, K.U.; Yoon, K.W.; Do, I.G.; Lee, D. Aspergillus appendicitis complicating chemotherapy of leukemia: A case report and review of the literature. Int. J. Surg. Case Rep. 2022, 100, 107738. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Z.; Sun, L.; Dong, L.; Du, M. Dynamics of microbial communities, texture and flavor in suan zuo yu during fermentation. Food Chem. 2020, 332, 127364. [Google Scholar] [CrossRef]

- Lu, Z.H.; Cao, W.; Peng, H.H.; Wang, F.; Tatsumi, E.; Kohyama, K.; Li, L.T. Effect of fermentation metabolites on rheological and sensory properties of fermented rice noodles. J. Sci. Food Agric. 2008, 88, 2134–2141. [Google Scholar] [CrossRef]

- Aisala, H.; Sola, J.; Hopia, A.; Linderborg, K.M.; Sandell, M. Odor-contributing volatile compounds of wild edible Nordic mushrooms analyzed with HS-SPME-GCMS and HS-SPME-GC-O/FID. Food Chem. 2019, 283, 566–578. [Google Scholar] [CrossRef]

- Marušić, N.; Vidaček, S.; Janči, T.; Petrak, T.; Medić, H. Determination of volatile compounds and quality parameters of traditional Istrian dry-cured ham. Meat Sci. 2014, 96, 1409–1416. [Google Scholar] [CrossRef]

- Zhuang, K.; Wu, N.; Wang, X.; Wu, X.; Wang, S.; Long, X.; Wei, X. Effects of 3 feeding modes on the volatile and nonvolatile compounds in the edible tissues of female chinese mitten crab (Eriocheir sinensis). J. Food Sci. 2016, 81, S968–S981. [Google Scholar] [CrossRef]

- Niu, Y.; Yao, Z.; Xiao, Q.; Xiao, Z.; Ma, N.; Zhu, J. Characterization of the key aroma compounds in different light aroma type Chinese liquors by GC-olfactometry, GC-FPD, quantitative measurements, and aroma recombination. Food Chem. 2017, 233, 204–215. [Google Scholar] [CrossRef]

| L. plantarum | L. fermentum | L. lactis | S. cerevisiae | NF | |

|---|---|---|---|---|---|

| Cooking Properties | |||||

| Water absorption rate (%) | 14.25 ± 1.03 cd | 15.22 ± 1.05 c | 13.37 ± 1.35 d | 19.16 ± 0.89 a | 16.63 ± 1.32 b |

| Cooking loss (%) | 2.73 ± 0.33 c | 2.92 ± 0.19 b | 2.66 ± 0.13 d | 3.05 ± 0.16 ab | 3.11 ± 0.11 a |

| Turbidity (at 675 nm) | 0.29 ± 0.07 b | 0.31 ± 0.02 b | 0.28 ± 0.05 a | 0.34 ± 0.02 b | 0.36 ± 0.04 b |

| TPA | |||||

| Hardness (g) | 1827 ± 219 b | 1616 ± 147 c | 1980 ± 207 a | 1555 ± 232 c | 1186 ± 178 d |

| Adhesiveness (g. s) | −28.46 ± 4.16 cd | −29.53 ± 3.36 bc | −28.84 ± 3.24 d | −39.13 ± 4.67 ab | −28.08 ± 2.82 a |

| Resilience (%) | 50.86 ± 2.32 c | 52.28 ± 2.29 b | 49.16 ± 3.59 c | 57.31 ± 3.69 a | 40.21 ± 2.43 d |

| Springiness (%) | 94.23 ± 1.18 ab | 94.52 ± 1.66 ab | 94.61 ± 1.62 ab | 93.29 ± 0.64 c | 95.67 ± 2.13 a |

| Cohesion | 0.84 ± 0.01 ab | 0.83 ± 0.01 bc | 0.86 ± 0.01 a | 0.83 ± 0.01 bc | 0.84 ± 0.02 ab |

| Chewiness | 1421 ± 129 b | 1244 ± 113 c | 1619 ± 134 a | 1017 ± 121 d | 1036 ± 136 d |

| Relative Odor Activity Value (ROAV) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 h | 6 h | Rice Noodle | |||||||||||||||

| Compounds | Describe | L. plantarum | L. fermentum | L. lactis | S. cerevisiae | NF | L. plantarum | L. fermentum | L. lactis | S. cerevisiae | NF | L. plantarum | L. fermentum | L. lactis | S. cerevisiae | NF | |

| E-2-Nonenal dimer | Orris-like a | 0.0009 b | 26.93 | 29.12 | 23.26 | 35.59 | 21.82 | - | - | - | - | - | 47.21 | 42.66 | 42.49 | 59.16 | 29.88 |

| E-2-Nonenal monomer | Orris-like a | 0.0009 b | 100 | 100 | 100 | 100 | 100 | - | - | - | - | - | 100 | 100 | 100 | 100 | 100 |

| 2-Methyl butanal | Chocolate-like a | 0.001 b | 16.96 | 14.23 | 13.58 | 13.27 | 13.12 | 100 | 100 | 100 | 100 | 100 | 16.01 | 12.53 | 19.72 | 16.33 | 16.24 |

| Heptanal dimer | Fatty a | 0.0028 b | 6.01 | 6.53 | 6.72 | 6.33 | 6.24 | 41.38 | 35.04 | 30.64 | 41.43 | 50.12 | 22.37 | 29.01 | 31.37 | 15.13 | 23.70 |

| Heptanal monomer | Fatty a | 0.0028 b | 1.35 | 1.31 | 1.98 | 2.19 | 0.96 | 22.27 | 29.00 | 21.37 | 35.13 | 23.70 | - | - | - | - | - |

| n-Nonanal dimer | Orange, rose a | 0.0031 b | 7.24 | 9.31 | 6.77 | 7.96 | 5.39 | 13.11 | 12.13 | 16.35 | 17.26 | 16.61 | - | - | - | - | - |

| n-Nonanal monomer | Orange, rose a | 0.0031 b | 3.21 | 2.52 | 3.01 | 2.44 | 2.36 | 1.87 | 1.67 | 1.04 | 1.39 | 0.80 | - | - | - | - | - |

| 3-Methyl butanal | Almond a | 0.029 b | 0.21 | 0.37 | 0.41 | 0.41 | <0.1 | 0.59 | 1.46 | 0.83 | 0.39 | 0.11 | 0.19 | 0.15 | 0.21 | 0.14 | 0.13 |

| 2-Hexenal monomer | Sweet a | 0.03 b | 0.64 | 0.52 | 0.59 | 0.78 | 0.14 | - | - | - | - | - | 5.9 | 5.41 | 6.77 | 6.63 | 4.61 |

| 2-Hexenal dimer | Sweet a | 0.03 b | 0.11 | <0.10 | 0.11 | 0.12 | 0.11 | 0.1 | 0.11 | 0.22 | 0.24 | 0.11 | 0.12 | 0.12 | 0.14 | 0.13 | 0.09 |

| Hexanal | Grassy, fruity a | 0.0615 b | 0.62 | 0.52 | 0.33 | 0.93 | 0.65 | 0.47 | 0.39 | 0.32 | 0.70 | 0.09 | 2.80 | 5.45 | 3.21 | 7.21 | 0.19 |

| E-2-Octenal monomer | Green-leafy a | 0.25 b | <0.10 | 0.10 | <0.10 | <0.10 | <0.10 | - | - | - | - | - | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| E-2-Octenal dimer | Green-leafy a | 0.25 b | <0.10 | <0.10 | 0.11 | 0.13 | <0.10 | - | - | - | - | - | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| Ethyl acetate dimer | Pineapple-like a | 0.005 b | 2.04 | 2.33 | 2.32 | 5.23 | 2.95 | 8.91 | 8.13 | 9.29 | 11.45 | 8.74 | 11.14 | 15.27 | 14.52 | 13.10 | 5.37 |

| Ethyl acetate monomer | Pineapple-like a | 0.005 b | - | - | - | - | - | 2.50 | 2.74 | 2.71 | 3.02 | 5.13 | - | - | - | - | - |

| Ethyl hexanoate | Banana-like a | 0.005 b | 4.95 | 4.23 | 3.40 | 3.53 | 3.12 | 4.65 | 3.81 | 4.94 | 4.84 | 4.79 | - | - | - | - | - |

| Ethyl octanoate dimer | Floral a | 0.0193 b | - | - | - | - | - | 0.13 | 0.12 | 0.33 | 2.98 | 0.15 | - | - | - | - | - |

| Ethyl propanoate | Rum a | 0.01 b | - | - | - | - | - | - | - | - | - | - | 9.64 | 10.29 | 12.91 | 13.93 | 2.91 |

| Ethyl octanoate monomer | Floral a | 0.0193 b | - | - | - | - | - | - | - | - | - | - | 6.12 | 9.12 | 7.17 | ||

| Ethyl octanoate dimer | Floral a | 0.0193 b | - | - | - | - | - | - | - | - | - | - | 5.36 | 4.50 | 1.37 | ||

| Hexyl acetate monomer | Cherry, pear, floral a | 0.115 b | 0.11 | 0.17 | 0.37 | 1.90 | 0.12 | 0.10 | <0.10 | <0.10 | <0.10 | <0.10 | 0 | 0 | 0 | ||

| Hexyl acetate dimer | Cherry, pear, floral a | 0.115 b | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | 0.13 | 0.18 | 0.10 | ||

| 6-Methyl-5-hepten-2-one | Citrus-like a | 0.068 b | 0.12 | 0.10 | 0.13 | 0.14 | 0.12 | 0.1 | <0.1 | 0.16 | 0.17 | 0.10 | 0.12 | 0.11 | 0.14 | ||

| 2-Heptanone dimer | Fruity a | 0.14 b | <0.10 | <0.10 | 0.11 | 0.13 | <0.10 | <0.10 | <0.10 | <0.10 | <0.1 | <0.1 | <0.10 | <0.10 | 0.11 | ||

| 2-Heptanone monomer | Fruity a | 0.14 b | <0.10 | <0.10 | <0.10 | 0.33 | <0.1 | 0.29 | 0.45 | 0.31 | 0.56 | 0.17 | 0.19 | 0.36 | 19.78 | ||

| Acetoin | Woody a | 0.014 b | 1.18 | 1.18 | 1.17 | 1.77 | 1.12 | 1.48 | 1.52 | 0.38 | 2.24 | 0.56 | 3.24 | 5.76 | 4.43 | ||

| 1-Heptanol | Fragrant a | 0.023 b | <0.10 | <0.10 | <0.10 | <0.10 | 0.10 | <0.10 | <0.10 | 0.15 | 1.27 | 0.55 | 0.36 | 0.97 | 0.12 | ||

| 1-Hexanol dimer | Aromatic a | 0.04 b | 0.79 | 0.73 | 0.60 | 0.69 | 0.62 | 0.26 | 0.17 | 0.30 | 0.36 | <0.10 | 0.18 | 0.21 | 0.26 | ||

| 2-Pentylfuran | Vegetable a | 0.0058 b | 1.42 | 1.37 | 2.01 | 1.67 | 1.25 | 1.07 | 1.10 | 2.12 | 2.09 | 1.62 | 3.00 | 2.79 | 2.90 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Xie, S.; Xia, Z.; Wang, F.; Tong, L. Further Interpretation of the Volatile, Microbial Community and Edible Quality of Fresh Fermented Rice Noodles with Different Selected Strains. Foods 2023, 12, 961. https://doi.org/10.3390/foods12050961

Wang A, Xie S, Xia Z, Wang F, Tong L. Further Interpretation of the Volatile, Microbial Community and Edible Quality of Fresh Fermented Rice Noodles with Different Selected Strains. Foods. 2023; 12(5):961. https://doi.org/10.3390/foods12050961

Chicago/Turabian StyleWang, Aixia, Songfeng Xie, Zengrun Xia, Fengzhong Wang, and Litao Tong. 2023. "Further Interpretation of the Volatile, Microbial Community and Edible Quality of Fresh Fermented Rice Noodles with Different Selected Strains" Foods 12, no. 5: 961. https://doi.org/10.3390/foods12050961