Physically, pizza baking can be described as a process of simultaneous heat and liquid and vapor water transport within the product itself and within the gaseous environment inside the oven chamber. Conduction raises the temperature of the lower pizza surface, which is in contact with the hot oven floor, and then transfers heat from the lower surface to the upward layers of the crust, while radiation and convection transmit heat from the oven vault to the exposed upper surface of the pizza. Hence, these heat transfer mechanisms produce different localized heating effects, which will be monitored as reported below.

3.1. Assessment of the Different Area Sections of Baked Pizza Samples

By using the open-source image processing software ImageJ, it was possible to assess the surface area occupied by the ingredients used to top several pizza samples cooked in the pilot-scale wood-fired oven, as shown in

Table 2.

Whatever the ingredient type and number used, there was no statistically significant difference among the overall surface areas of all the pizza samples tested at the 95% confidence level, this amounting to 623 ± 18 cm2, equivalent to an average diameter of 28.2 ± 0.4 cm. In addition, the surface area of the raised rim was independent of the garnishment used, with the average thickness of this annular section being equal to 2.2 ± 0.1 cm.

From

Table 2, it can be noted that when using no ingredient (pizza A) or just one ingredient (tomato puree or sunflower oil), as in the case of pizza B and C, the internal surface area was practically constant (440 cm

2), this representing about 71% of the overall pizza surface area. When using both these ingredients, the surface area covered by tomato puree or sunflower oil amounted to 48 or 23%, respectively. When the mozzarella cheese was further put in, the surface areas covered by sunflower oil, tomato puree, or mozzarella cheese totaled 7, 28, or 37% of the overall pizza surface area.

3.2. Monitoring of the Raised Rim Growth

During pizza baking, the heat received by the rim makes it expand because of local water evaporation. A thermal imaging camera was used to monitor the time course of its height (h) when baking different pizza samples of A–D type (

Table 1), as shown for instance for the pizza sample D in

Figure 1. An initial rapid growth of the edge occurred during the first 40 s, followed by a slower one in the following 40 s.

Table S1 in the electronic supplement shows the effect of baking time (t

B) on the average value and standard deviation of the instantaneous height (h) of the raised rim of 15 different pizza samples of type A–D (cf.

Table 1) during their baking in a pilot-scale wood-fired oven. The rim growth in white pizza samples (A) was not statistically different from that of tomato pizza samples (C) at a probability level of 0.05. This was also observed for the raised rims of white and tomato pizza samples both enriched with sunflower oil (B and D); however, these being statistically different from those of pizza samples of types A and C (

Table S1). Taken together and accounting for an average data variability of 12%, the dimensionless ratio between the current (h) and initial (h0) heights of the raised rim appeared to be approximately independent of the garnishment ingredients used (

Figure 2). Altogether, such a ratio increased from 1 to about 3 in as short as 80 s, while the rim height grew from 0.78 ± 0.09 cm to 2.33 ± 0.34 cm (

Table S1). For this reason, its growth was assumed to be unrelated to the addition of a third ingredient (i.e., mozzarella cheese) in the internal pizza shell, and thus no further measurements were carried out for pizza E. As shown in

Figure 2, the first exponential growth of the raised rim lasting about 20 s was followed by a linear growth during the subsequent 20–30 s, and then by declining growth during the remaining 30–40 s.

3.3. Mapping of the Thermal Profile of Pizza during Baking

Table S2 in the electronic supplement shows the mean values and standard deviations of the experimental temperatures of the oven floor exposed to fire and oven vault (T

FL) or shielded by the pizza sample undergoing baking (T

FLbp), and of different sectors of five pizza types (cf.

Table 1), such as the raised rim (T

SR), and upper (T

SU) and lower (T

SL) central areas, as baked in a wood-fired pizza oven operating in quasi steady-state conditions.

Table S2 also shows the temperatures of the areas covered with tomato puree (TP) or sunflower oil (SO), with or without mozzarella cheese (MC), when 2 or 3 ingredients were distributed over the central area of the pizza shell. Each measurement was repeated 12 times for any of the five pizza types listed in

Table 1.

Figure 3 shows the time course of the average temperatures of the oven floor as exposed to fire (T

FL) or shielded by the pizza sample itself (T

FLbp) throughout all the baking tests performed.

First, the oven floor temperature (TFL) exhibited no statistically significant variation around 439 ± 3 °C at the probability level p = 0.05, this confirming further that the oven was operating in quasi steady-state conditions. Second, the temperature of the oven floor at direct contact of each pizza showed a decreasing trend, that was accurately simulated by using a quadratic regression equation with coefficients of determination (r2) ranging from 0.98 to 0.99. The first derivate of TFLbp with respect to tB for tB = 0 was expressed by a negative number, its modulus apparently increasing with the pizza mass. The greater the pizza mass per unit surface, the more rapid the cooling of the oven floor surface area over which the raw pizza was laid.

Figure 4 shows the time course of the average temperatures of the raised rim (T

SR) and lower area (T

SL) of all the pizza samples fed into the wood-fired oven.

As shown in

Figure 4a, after 80 s, the raised rim in all the pizza types under study increased to an average temperature (T

SR) of 150 ± 13 °C, except for the margherita pizza (E) that reached such a temperature after 100 s owing to its greater mass (

Table 1). All these thermal profiles were fitted using quadratic regression equations, their coefficients of determination (r

2) ranging from 0.996 to 0.998 (see broken lines in

Figure 4a). Moreover, in the case of pizza types A–D, for t

B = 0, (dT

SR/dt

B) and (d

2T

SR/dt

B2) were approximately constant and equal to 3.2 ± 0.1 °C/s and −0.041 ± 0006 °C/s

2, respectively. The final temperature of the raised rim was thus independent of the topping ingredients used and gave rise to quite a crispy area of the pizza crust.

The lower area of any pizza sample did not uniformly contact the hot oven floor owing to the presence of a laminar layer made of stagnant air and/or evaporated water. Thus, its temperature (T

SL) increased up to an average value of 100 ± 9 °C in as short as 80 s, except for the pizza type E that reached such a temperature after 100 s (

Figure 4b). By using the least squares method, quadratic regression equations were used to reconstruct the T

SL profiles, their coefficients of determination (r

2) varying from 0.988 to 0.998 (see broken lines in

Figure 4b). For the pizza types A–D, for t

B = 0, (dT

SL/dt

B) and (d

2T

SL/dt

B2) were found to be approximately constant and equal to 2.7 ± 0.2 °C/s and −0.044 ± 0005 °C/s

2, respectively. Probably, because of the pizzaiuolo’s ability at lifting and rotating the pizza toward the fire by means of a metal peel, not only was the pizza baked uniformly around its whole circumference, but the final temperature of the lower pizza area was also not so high as to burn it. This aspect will be further discussed below.

Figure 5 shows the time course of the average temperature (T

SU) of the upper area of the pizza samples examined in this work. This temperature was related to the area devoid of any ingredient in the case of white pizza (A) or spread with sunflower oil (B) or tomato puree (C) only. In the case of pizza D, its central area having been spread with SO and TP, the thermal imaging camera was able to determine the average temperatures T

SO and T

TP of both areas. In the case of pizza E, the average temperatures of the areas covered with TP, SO, or mozzarella cheese pieces were measured.

At the end of baking, the temperature of the central upper side of white pizza (A) approached 182 ± 9 °C, probably because the formation of large dark brown colored areas increased the local emissivity and enhanced the absorption of the radiative heat from the oven vault. When the central upper area of white pizza was spread with sunflower oil (B), the increase in the pizza mass from 250 to 280 g limited its temperature increase to 156 ± 4 °C. For the pizzas D and E, the area covered with SO reached a lower temperature of 108 ± 3 °C, probably because of its smaller area exposed to the irradiating oven vault. When the whole central area of pizza C was garnished with tomato puree at 7 °Bx, its high moisture content limited the temperature growth to 81 ± 2 °C. Such a temperature was not statistically significantly different from that of the area equally topped with TP in pizza D or E, their average temperatures being equal to 84 ± 3 °C (

Figure 5). Finally, the temperature of the area topped with white or pale ivory colored mozzarella cheese was definitively smaller (67 ± 2 °C), for its initial temperature (15 °C) was smaller than that (21 °C) of dough, TP, and SO, and emissivity lower than that of tomato puree.

3.4. Time Course of the Pizza Weight Loss

Table S2 lists the instantaneous mean mass (m

S) of any pizza sample studied.

Such data were used to estimate the instantaneous amount of water evaporated during baking and thus calculate the current moisture mass fraction on an oil-free basis (x

W) of the overall pizza sample (

Table S2). It can be noted that the moisture content of white pizza such as (A) or topped with sunflower oil (B) reduced from 0.45 g/g to 0.43 or 0.42 g/g, respectively. On the contrary, x

W for the tomato pizza such as (C) or topped with SO (D) reduced from 0.555 to 0.542 g/g. The addition of MC in pizza sample E slightly affected x

W, which lessened from 0.554 to 0.536 g/g.

The amount of water evaporated (m

e) during the baking tests carried out here was found to be a complex function of the average temperature of the sample, as well as its composition and water activity. When using no or just one topping ingredient, such a temperature was assumed as coincident with that of the upper side of the pizza crust (T

SU). When the pizza was garnished with two or three ingredients, it was assumed as coincident with that of the surface area topped with tomato puree (T

TP), this representing as much as 48 and 28% of the overall surface area of pizza types D and E, respectively. Thus, by plotting the m

e data collected during the water-heating [

9] and pizza-baking tests against the sample temperature (T

S) as specified above (i.e., T

SU or T

TP) using a semi-logarithmic plot (

Figure 6), it was possible to describe m

e via the following empirical relationship:

where a and b are empirical coefficients that can be determined by using the least squares method, as shown in

Table S3.

Obviously, water heating in aluminum trays having a diameter near to that of the pizza samples under study gave rise to greater water evaporation whatever the sample temperature. The samples C, D, and E, being all garnished with TP and having a greater moisture content around 0.55 g/g, exhibited a slower moisture evaporation. In pizza sample B, garnished with sunflower oil, water evaporation was even smaller. Nevertheless, at the end of their baking, such samples exhibited a higher temperature than that of samples C–E, this resulting in an overall weight loss greater than that of all the other pizza samples. Since the heat transferred by radiation and convection was almost constant [

10], the low specific heat of sunflower oil allowed the pizza sample B to reach higher temperatures than that of the tomato puree area during baking, this enhancing the overall water vapor formation. Finally, the evaporation of sample A, being ungarnished, was exclusively related to the physical properties of the dough itself, which has a specific heat greater than sunflower oil but lower than tomato puree and mozzarella cheese. Altogether, at the end of baking, the overall amount of water evaporated was near to 10 g in spite of the different temperature of the upper side of the pizza types examined (

Figure 6).

3.5. Color Visual Assessment of Baked Pizzas

The formation of brown or black colored areas in pizza during its baking in the wood-fired oven, due to the appearance of brown or black pigments, was previously monitored using computerized image analysis techniques and related to the available lysine content [

13]. By using the IRIS electronic eye, any digital image was processed as a color spectrum on a maximum scale of 4096 colors, each of these corresponding to a unique set of three values in the RGB space. The black color was represented by the decimal code (0, 0, 0), while the brown one by (165, 42, 42), as derived from

https://www.rapidtables.com/web/color/RGB_Color.html (accessed on 14 February 2023).

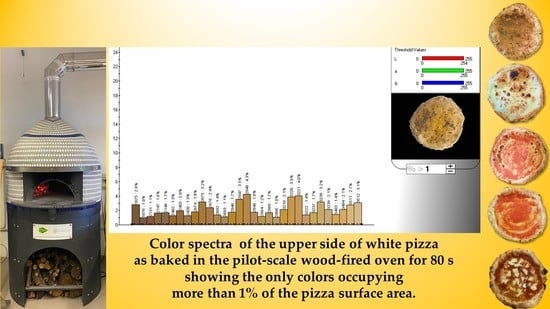

As an example,

Figure 7 shows the color spectra of the pizza sample A as such and after 80 s baking in the pilot-scale wood-fired oven. By comparing such spectra, it was quite easy to highlight the color differences between these samples, as well as to quantify the area of each significant color and mark it as a percentage.

The effect of the browning or blackening process during the pizza baking was characterized by accounting for the color decimal codes seen as dark brown or black by the human eye. In particular, the browned areas of the pizza were characterized by 41 different decimal codes, while the blackened ones by 16 ones, as shown in

Table 3. By associating such individual colors in two clusters, it was possible to derive the percentage of the pizza surface area denoted as browned (Br) or blackened (Bl).

Figure S2 in the electronic supplement shows the color spectra of the upper and lower sides of pizza samples A–E, as they were extracted from the oven after a baking time of 80 s for samples A–D or 100 s for the margherita pizza E; while

Table S4 shows how the proportion of the browned or blackened area in both sides of such pizza samples increased as baking progressed.

As shown in

Table S3, the percentage degree of browning or blackening in the lower pizza shell was smaller than that observed in the upper one. At the end of baking (t

B = 80 s), the central upper side of the white pizza sample (A) reached a temperature as high as 182 °C (

Table S2), and thus exhibited the greatest Y

Br and Y

Bl values. Since the T

SU in pizza samples B was around 156 °C, its degree of browning was just near to 9%. In pizza samples C and D, the presence of tomato puree limited the temperature of the upper area to 81–84 °C, this resulting in a percentage of browning of about 11%, a value not statistically different from the above one at

p = 0.05. Finally, pizza sample E was characterized by the smaller degree of browning (7.3%), probably because of the higher reflectivity of the mozzarella cheese pieces.

Concerning the degree of burning, its highest value was observed on the upper side of white pizza A (7.9%), even if the corresponding deviation standard, as high as 6%, made it not statistically different from those observed (1.4–3.9%) in the other pizza samples.

The degrees of browning and blackening on the lower side of all the pizza samples under study appeared to be unrelated not only to the use or not of topping ingredients, but also to the increase in the overall mass of each pizza. In principle, the greater the overall mass of the pizza, the more effective the contact between the pizza base and the hot oven floor will be. This should enhance the heat transfer through conduction from the bottom of the pizza and thus yield a more extensive blackening. This was in all probability counterbalanced by the pizzaiuolo’s ability at turning the pizza in almost the same area of the hot oven floor to limit or avoid burning the pizza bottom.

Although color formation in bakery products is caused by numerous parallel and consecutive reactions with various components, the appearance of brown pigments was generally simulated by assuming either zero order or first order kinetics [

5,

14,

15]. To discriminate the mechanism of browning or blackening, the percentage degree Y

Br or Y

Bl versus the upper or lower pizza side temperature was plotted on a semilogarithmic scale, as shown in

Figure 8 and

Figure 9.

From

Figure 8, it was observed that the curves of browning and burning on the upper surface area of all pizza samples might be described by straight lines on a semilogarithmic scale. Actually, two distinct straight lines were identified, the first one fitting the color change of white pizzas such as (A) or topped with sunflower oil (B), and the second one that of tomato pizzas such as (C) or garnished with SO only (D) or with mozzarella cheese also (E). From

Figure 9, the browning and burning yields for all the pizza samples under study were scattered, so were roughly fitted using a single straight line.

In the circumstances, the experimental Y

Br and Y

Bl data were reconstructed according to Bigelow et al. [

16]:

where Y

i is the percentage degree of browning (Br) or blackening (Bl) corresponding to the actual (T

Sj) and reference (T

SjR) temperatures of the upper or lower side of any pizza sample, and z

i is the temperature increment needed for a ten-fold acceleration of the rate of pizza browning or blackening (i.e., for increasing Y

i by a factor of 10).

By using the least squares method, it was possible to fit the experimental Y

i values, as shown by the continuous and broken lines plotted in

Figure 8 and

Figure 9.

Table 4 lists the empirical coefficients (z

i and T

SjR) of the least-squares regressions.

In the literature, such a first-order kinetic model has been generally used to describe the death rate of free cells and spores, as well as the inactivation or degradation rate of enzymes, vitamins, and pigments [

17]. Whereas the z values characterizing microbial death ranged from 5 to 11 °C, those related to enzyme inactivation varied from 15 to 20 °C [

18], and those concerning typical chemical reactions, such as vitamin B1 and chlorophyll destruction [

17], or the optimal cooking time of different pasta formats [

19], were found to fluctuate from 25 to 111 °C.

In this case, the formation rate of browned or blackened areas in baked pizza was increased 10-fold as the temperature of the upper side of pizza was increased by 19 or 16 °C in the case of white pizzas A and B, or by about 9 °C in the case of any tomato pizza (C–E). This might be the result of the inertial effect exerted by the addition of an aqueous-rich tomato puree. In fact, the moisture content of white pizzas was definitely smaller than that of tomato pizzas (

Table S2). On the contrary, there was no statistically significant difference between the z values characterizing the temperature-sensitivity of the lower side of any white or tomato pizzas to browning and burning, probably because of the highly scattered data collected.

In the circumstances, whatever the pizza type baked, the percentage of burning of its bottom was generally far smaller than that observed on its upper side. This definitively contradicts the general belief that the bottom of pizza baked in wood-fired ovens is more burnt than that cooked in gas or electric ovens. Since the blackened areas observed in tomato pizzas covered up to 4% of total pizza surface areas (

Table S4), their wastage would be lower than the amount (~6%) of pizza averagely discarded at the end of a meal in a typical Neapolitan pizzeria [

20]. This would avoid the health risk of ingesting charred pizza pieces with high levels of acrylamide, its accumulation in starchy foods baked, fried, or roasted at 120–150 °C increasing the risk of developing cancer for consumers in all age groups [

21]. In fact, despite the Food Safety Authority (EFSA) recommendation to not exceed the dose of 0.17 mg of acrylamide per kg of body weight and day [

22], the concentration of acrylamide in pizzas baked in a wood-fired oven was found to range from 0.8 to 2.4 mg/kg [

23].