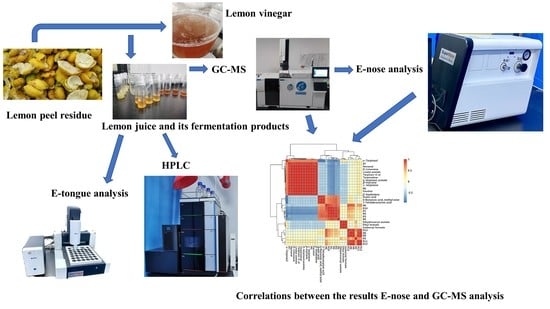

Utilization of Lemon Peel for the Production of Vinegar by a Combination of Alcoholic and Acetic Fermentations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Extraction of Juice from Lemon Peel

2.2. Alcoholic Fermentation of the Lemon Peel Juice

2.3. Making of Lemon Vinegar

2.3.1. Isolation and Identification of Acid Tolerant Acetobacter spp.

2.3.2. Acetic Fermentation of the Lemon Peel Wine

2.4. Determination of Quality Parameters of the Lemon Vinegar

2.5. Analysis of Organic Acids

2.6. HS-SPME-GC-MS Analysis of Volatile Components

2.7. E-Nose Analysis of the Lemon Vinegar

2.8. E-Tongue Analysis of the Lemon Vinegar

2.9. Statistical Analysis

3. Results and Discussion

3.1. Isolation and Identification of Acid Tolerant Acetobacter

3.2. Alcoholic and Acetic Acid Fermentations

3.3. Organic Acids

3.4. Volatile Components

3.5. E-Nose Analysis

3.6. Correlation between E-Nose and GC-MS Analyses

3.7. E-Tongue Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. 2020. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 12 May 2023).

- Gómez, B.; Gullón, B.; Yáñez, R.; Parajó, J.C.; Alonso, J.L. Pectic Oligosacharides from Lemon Peel Wastes: Production, Purification, and Chemical Characterization. J. Agric. Food Chem. 2013, 61, 10043–10053. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, W.; Xu, Y.; Chen, L.; Cao, J.; Jiang, W. An advance on nutritional profile, phytochemical profile, nutraceutical properties, and potential industrial applications of lemon peels: A comprehensive review. Trends Food Sci. Technol. 2022, 124, 219–236. [Google Scholar] [CrossRef]

- Adibelli, Z.; Dilek, M.; Akpolat, T. Lemon juice as an alternative therapy in hypertension in Turkey. Int. J. Cardiol. 2009, 135, E58–E59. [Google Scholar] [CrossRef] [PubMed]

- Di Matteo, A.; Di Rauso Simeone, G.; Cirillo, A.; Rao, M.A.; Di Vaio, C. Morphological characteristics, ascorbic acid and antioxidant activity during fruit ripening of four lemon (Citrus limon (L.) Burm. F.) cultivars. Sci. Hortic. 2021, 276, 109741. [Google Scholar] [CrossRef]

- Xia, T.; Zhang, B.; Duan, W.; Zhang, J.; Wang, M. Nutrients and bioactive components from vinegar: A fermented and functional food. J. Funct. Foods 2020, 64, 103681. [Google Scholar] [CrossRef]

- Chou, C.H.; Liu, C.W.; Yang, D.J.; Wu, Y.H.; Chen, Y.C. Amino acid, mineral, and polyphenolic profiles of black vinegar, and its lipid lowering and antioxidant effects in vivo. Food Chem. 2015, 168, 63–69. [Google Scholar] [CrossRef]

- Del Rio, J.A.; Fuster, M.D.; Gomez, P.; Porras, I.; Garcia-Lidon, A.; Ortuno, A. Citrus limon: A source of flavonoids of pharmaceutical interest. Food Chem. 2004, 84, 457–461. [Google Scholar] [CrossRef]

- Gil-Izquierdo, A.; Riquelme, M.T.; Porras, N.; Ferreres, F. Effect of the rootstock and interstock grafted in lemon tree (Citrus limon (L.) Burm.) on the flavonoid content of lemon juice. J. Agric. Food Chem. 2004, 52, 324–331. [Google Scholar] [CrossRef]

- Liu, S.; Li, S.; Ho, C.-T. Dietary bioactives and essential oils of lemon and lime fruits. Food Sci. Hum. Wellness 2022, 11, 753–764. [Google Scholar] [CrossRef]

- Scherer, R.; Rybka, A.C.P.; Ballus, C.A.; Meinhart, A.D.; Filho, J.T.; Godoy, H.T. Validation of a HPLC method for simultaneous determination of main organic acids in fruits and juices. Food Chem. 2012, 135, 150–154. [Google Scholar] [CrossRef] [Green Version]

- Sun, R.; Xing, R.; Zhang, J.; Wei, L.; Ge, Y.; Deng, T.; Chen, Y. Authentication and quality evaluation of not from concentrate and from concentrate orange juice by HS-SPME-GC-MS coupled with chemometrics. LWT 2022, 162, 113504. [Google Scholar] [CrossRef]

- Cai, W.; Tang, F.; Guo, Z.; Guo, X.; Zhang, Q.; Zhao, X.; Shan, C. Effects of pretreatment methods and leaching methods on jujube wine quality detected by electronic senses and HS-SPME-GC-MS. Food Chem. 2020, 330, 127330. [Google Scholar] [CrossRef]

- Chen, L.; Ning, F.; Zhao, L.; Ming, H.; Zhang, J.; Yu, W.; Luo, L. Quality assessment of royal jelly based on physicochemical properties and flavor profiles using HS-SPME-GC/MS combined with electronic nose and electronic tongue analyses. Food Chem. 2023, 403, 134392. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yang, Y.; Zhu, Y.; Ben, A.; Qi, J. A novel strategy for discriminating different cultivation and screening odor and taste flavor compounds in Xinhui tangerine peel using E-nose, E-tongue, and chemometrics. Food Chem. 2022, 384, 132519. [Google Scholar] [CrossRef]

- Cejudo-Bastante, C.; Castro-Mejias, R.; Natera-Marin, R.; Garcia-Barroso, C.; Duran-Guerrero, E. Chemical and sensory characteristics of orange based vinegar. J. Food Sci. Technol. 2016, 53, 3147–3156. [Google Scholar] [CrossRef] [Green Version]

- Roda, A.; Lucini, L.; Torchio, F.; Dordoni, R.; De Faveri, D.M.; Lambri, M. Metabolite profiling and volatiles of pineapple wine and vinegar obtained from pineapple waste. Food Chem. 2017, 229, 734–742. [Google Scholar] [CrossRef] [PubMed]

- Behera, B.C.; Mishra, R.; Mohapatra, S. Microbial citric acid: Production, properties, application, and future perspectives. Food Front. 2021, 2, 62–76. [Google Scholar] [CrossRef]

- Pandey, S.; Singh, N.K.; Yadav, T.C.; Bansal, A.K.; Thanki, A.; Yadav, M.; Nayak, J. Metabolic Products of Mixed Culture Fermentation. In Engineering of Microbial Biosynthetic Pathways; Springer: Berlin/Heidelberg, Germany, 2020; pp. 75–92. [Google Scholar] [CrossRef]

- Mamlouk, D.; Gullo, M. Acetic Acid bacteria: Physiology and carbon sources oxidation. Indian J. Microbiol. 2013, 53, 377–384. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, R.; Xiao, H.; Liu, C.; Wang, H.; Wu, Y.; Ben, A.; Wang, Y. Dynamic changes in volatile and non-volatile flavor compounds in lemon flavedo during freeze-drying and hot-air drying. LWT 2023, 175, 114510. [Google Scholar] [CrossRef]

- Perez-Cacho, P.R.; Rouseff, R.L. Fresh squeezed orange juice odor: A review. Crit. Rev. Food Sci. Nutr. 2008, 48, 681–695. [Google Scholar] [CrossRef]

- Galvan-Lima, A.; Cunha, S.C.; Martins, Z.E.; Soares, A.G.; Ferreira, I.; Farah, A. Headspace volatolome of peel flours from citrus fruits grown in Brazil. Food Res. Int. 2021, 150 Pt B, 110801. [Google Scholar] [CrossRef]

- Cuevas, F.J.; Pereira-Caro, G.; Moreno-Rojas, J.M.; Muñoz-Redondo, J.M.; Ruiz-Moreno, M.J. Assessment of premium organic orange juices authenticity using HPLC-HR-MS and HS-SPME-GC-MS combining data fusion and chemometrics. Food Control 2017, 82, 203–211. [Google Scholar] [CrossRef]

- Li, M.; Zhang, W.; Zhang, M.; Yin, Y.; Liu, Z.; Hu, X.; Yi, J. Effect of centrifugal pre-treatment on flavor change of cloudy orange juice: Interaction between pectin and aroma release. Food Chem. 2022, 374, 131705. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Huang, X.; Wang, C.; Aheto, J.H.; Chang, X.; Yu, S.; Zhang, X.; Wang, Y. Coupling electronic nose with GC–MS improves flavor recognition and grade differentiation of Zhenjiang aromatic vinegar. J. Food Process Eng. 2021, 44, e13806. [Google Scholar] [CrossRef]

- Jo, Y.; Chung, N.; Park, S.W.; Noh, B.S.; Jeong, Y.J.; Kwon, J.H. Application of E-tongue, E-nose, and MS-E-nose for discriminating aged vinegars based on taste and aroma profiles. Food Sci. Biotechnic. 2016, 25, 1313–1318. [Google Scholar] [CrossRef] [PubMed]

| Juice | Wine | Vinegar | |

|---|---|---|---|

| pH value | 2.78 ± 0.01 a | 2.46 ± 0.02 b | 2.01 ± 0.02 c |

| Titratable acidity (g/L) | 3.43 ± 0.00 c | 4.45 ± 0.01 b | 5.04 ± 0.01 a |

| Ethanol (%v/v) | n. a. c | 5.16 ± 0.02 a | <1.00 b |

| Chromaticity | L* = 0.23 ± 0.02 a a* = 1.83 ± 0.01 a b* = 0.40 ± 0.01 c | L* = 0.14 ± 0.01 b a* = 1.81 ± 0.02 a b* = 0.59 ± 0.01 b | L* = 0.11 ± 0.01 c a* = 1.25 ± 0.00 b b* = 0.90 ± 0.02 a |

| TSS (°Brix) | 15.0 ± 0.00 | 8.0 ± 0.00 | 6.5 ± 0.00 |

| Sample | ||||||||

|---|---|---|---|---|---|---|---|---|

| Organic Acids (g/L) a | ||||||||

| Oxalic | Tartaric | Lactic | Acetic | Citric | Succinic | Fumaric | Trans-Aconitic | |

| Lemon juice | 2.56 ± 0.28 a | 0.73 ± 0.12 b | n. a. c | n. a. b | 6.83 ± 0.02 b | 1.76 ± 0.10 a | 0.10 ± 0.01 a | 0.24 ± 0.01 a |

| Lemon wine | 0.93 ± 0.02 b | 3.74 ± 0.10 a | 5.19 ± 0.05 a | n. a. b | 7.19 ± 0.02 a | 0.36 ± 0.02 c | 0.11 ± 0.01 a | 0.09 ± 0.03 b |

| Lemon vinegar | 0.25 ± 0.01 c | 0.46 ± 0.01 c | 0.23 ± 0.02 b | 184.34 ± 2.73 a | n. a. c | 0.62 ± 0.04 b | 0.12 ± 0.01 a | 0.05 ± 0.01 b |

| Peak Number | Compounds | RT (min) | Concentration (mg/L) | ||

|---|---|---|---|---|---|

| Lemon Juice | Lemon Wine | Lemon Vinegar | |||

| Alcohols | - | ||||

| 1 | Ethanol | 3.615 | ND b | 42.46 ± 1.14 a | ND b |

| 2 | Dihydrocarveol | 8.213 | ND b | 1.98 ± 0.17 a | ND b |

| 3 | 2-methyl-5-(1-methylethenyl)-, (1.alpha.,2.alpha.,5.beta.)-cyclohexanol | 11.535 | ND b | 40.55 ± 0.96 a | ND b |

| 4 | trans-3-caren-2-ol | 13.956 | ND b | ND b | 0.55 ± 0.05 a |

| 5 | 2-hydroxy-2,2,4-trimethyl-3-cyclohexene-1-methanol | 16.202 | ND b | 1.54 ± 0.16 a | 1.65 ± 0.13 a |

| 6 | 2,6,6-trimethyl-bicyclo [3.1.1]heptan-2-ol | 17.965 | ND c | 0.10 ± 0.02 b | 0.33 ± 0.04 a |

| 7 | Carveol | 19.033 | 5.52 ± 0.10 a | ND b | ND b |

| 8 | 6-methyl-2-heptanol | 21.908 | 7.12 ± 0.14 a | ND b | ND b |

| 9 | 4-(1,1-dimethylethyl)-benzenemethanol | 24.443 | ND b | 0.19 ± 0.03 a | ND b |

| 10 | Linalool | 25.328 | 26.39 ± 2.28 a | 13.57 ± 0.72 b | 1.71 ± 0.10 c |

| 11 | Para-menth-3-en-1-ol | 26.571 | ND b | 319.50 ± 5.39 a | 306.12 ± 12.02 a |

| 12 | Fenchol | 26.612 | 169.69 ± 13.47 a | ND b | ND b |

| 13 | Terpinen-4-ol | 27.359 | 496.69 ± 7.66 a | 56.09 ± 2.94 b | 44.83 ± 5.78 c |

| 14 | 1-methyl-4-(1-methylethenyl)-cyclohexanol | 28.383 | ND c | 17.43 ± 2.50 b | 26.17 ± 2.18 a |

| 15 | 5-isopropyl-2-methylbicyclo [3.1.0]hexan-2-ol | 28.48 | 8.99 ± 0.16 a | ND b | ND b |

| 16 | Isoborneol | 29.528 | 0.92 ± 0.10 a | ND b | ND b |

| 17 | cis-verbenol | 30.308 | 0.95 ± 0.19 a | ND b | ND b |

| 18 | α-terpineol | 31.208 | 552.03 ± 7.42 a | 401.51 ± 10.04 b | 4.44 ± 0.12 c |

| 19 | p-mentha-1,5-dien-8-ol | 31.892 | 56.02 ± 8.12 a | ND b | ND b |

| 20 | cis-3,7-dimethyl-2,6-octadienol | 32.526 | 53.67 ± 3.35 a | ND b | ND b |

| 21 | Benzyl alcohol | 35.718 | 12.74 ± 0.09 a | ND b | ND b |

| 22 | m-methylbenzyl alcohol | 35.766 | ND c | 11.49 ± 0.64 a | 7.02 ± 0.70 b |

| 23 | Geraniol | 36.554 | 4.02 ± 0.06 a | ND b | ND b |

| 24 | Phenylethyl alcohol | 37.294 | ND b | ND b | 23.09 ± 0.96 a |

| 25 | 2-methyl-benzeneethanol | 37.302 | ND b | 4.77 ± 0.08 a | ND b |

| 26 | Caryophyllenyl alcohol | 43.512 | ND c | 3.30 ± 0.15 a | 2.91 ± 0.08 b |

| 27 | Globulol | 48.926 | ND c | 0.19 ± 0.01 b | 0.28 ± 0.03 a |

| 28 | α-bisabolol | 49.568 | 0.05 ± 0.03 a | ND b | ND b |

| 29 | Hydroxycitronellol | 53.174 | 0.13 ± 0.03 a | ND b | ND b |

| 30 | Heptaethylene glycol | 59.259 | 0.14 ± 0.02 a | ND b | ND b |

| Terpenes | - | ||||

| 1 | (E,E)-1,3,5-heptatriene | 4.208 | 5.19 ± 0.09 a | ND b | ND b |

| 2 | α-pinene | 5.557 | 24.66 ± 3.40 a | ND b | ND b |

| 3 | Camphene | 6.994 | 0.76 ± 0.12 a | ND b | ND b |

| 4 | β-myrcene | 10.682 | 75.96 ± 1.15 a | ND b | ND b |

| 5 | (+)-sabinene | 10.902 | 64.09 ± 0.83 a | 23.47 ± 3.50 b | 4.53 ± 0.15 c |

| 6 | D-limonene | 11.625 | 825.88 ± 41.61 a | ND b | ND b |

| 7 | (+)-4-carene | 13.225 | ND b | ND b | 7.37 ± 0.23 a |

| 8 | γ-terpinene | 13.33 | 416.00 ± 8.25 a | 7.00 ± 0.47 b | 5.93 ± 0.63 b |

| 9 | α-terpinene | 14.752 | ND b | ND b | 9.52 ± 0.11 a |

| 10 | Terpinolene | 14.769 | 95.58 ± 0.06 a | 10.57 ± 1.36 b | 8.21 ± 0.40 c |

| 11 | γ-elemene | 28.366 | 19.84 ± 0.77 a | ND b | ND b |

| 12 | Limonene oxide | 30.235 | ND b | 24.18 ± 0.41 a | ND b |

| 13 | β-bisabolene | 33.679 | 106.20 ± 4.10 a | ND b | ND b |

| 14 | 4-isopropenyl-1-methoxymethoxymethyl-cyclohexene | 34.426 | ND b | 1.71 ± 0.18 a | ND b |

| 15 | R-limonene | 34.678 | ND b | ND b | 0.53 ± 0.09 a |

| 16 | Dipentenedioxide | 41.814 | 0.34 ± 0.02 b | 0.80 ± 0.48 ab | 1.28 ± 0.06 a |

| Esters | - | ||||

| 1 | Ethyl acetate | 3.111 | ND b | 2.06 ± 0.06 a | ND b |

| 2 | Dihydrocarvyl acetate | 7.027 | ND b | 1.00 ± 0.19 a | ND b |

| 3 | Linalyl acetate | 8.294 | 2.02 ± 0.10 a | ND b | ND b |

| 4 | δ-terpineol acetate | 12.364 | 152.77 ± 2.28 a | ND b | ND b |

| 5 | Isobornyl formate | 29.455 | ND b | 10.56 ± 0.58 a | ND b |

| 6 | 6-nonynoic acid, methyl ester | 30.194 | ND b | ND b | 58.95 ± 2.95 a |

| 7 | 2,5-octadecadiynoic acid, methyl ester | 40.389 | ND b | ND b | 0.07 ± 0.01 a |

| 8 | Bicyclo [3.1.1]hept-2-en-4-ol, 2,6,6-trimethyl-, acetate | 41.355 | ND c | 0.08 ± 0.03 b | 0.21 ± 0.02 a |

| 9 | [1,1’-bicyclopropyl]-2-octanoic acid, 2’-hexyl-, methyl ester | 45.855 | ND b | 1.38 ± 0.06 a | ND b |

| Aldehydes | - | ||||

| 1 | Nonanal | 19.374 | 11.56 ± 1.64 a | ND b | ND b |

| 2 | 2-ethylidene-6-methyl-3,5-heptadienal | 38.333 | 0.08 ± 0.02 a | ND b | ND b |

| Ketones | - | ||||

| 1 | 6-camphenone | 6.613 | ND b | 0.53 ± 0.13 a | ND b |

| 2 | 6-methyl-5-hepten-2-one | 16.466 | 0.82 ± 0.05 a | ND b | ND b |

| 3 | Fenchone | 19.098 | ND b | 1.12 ± 0.15 a | ND b |

| 4 | (+)-2-bornanone | 23.647 | 5.74 ± 0.05 b | 7.14 ± 0.70 a | ND c |

| 5 | 3-methyl-6-(1-methylethyl)-2-cyclohexen-1-one | 31.892 | ND c | 6.57 ± 0.04 a | 4.54 ± 0.30 b |

| 6 | 1-(2-methylphenyl)-ethanone | 32.891 | ND c | 13.21 ± 0.43 a | 11.47 ± 0.99 b |

| 7 | 1-(4-methylphenyl)-ethanone | 32.94 | 18.97 ± 0.25 a | ND b | ND b |

| Acids | - | ||||

| 1 | Acetic acid | 31.762 | ND b | ND b | 0.62 ± 0.15 a |

| 2 | 3-Tetradecanynoic acid | 45.506 | ND b | ND b | 1.94 ± 1.40 a |

| Phenols | - | ||||

| 1 | Butylated hydroxytoluene | 39.048 | 2.27 ± 0.05 a | 2.77 ± 0.89 a | 3.26 ± 0.27 a |

| 2 | p-Cresol | 42.557 | ND c | 5.29 ± 0.16 b | 5.69 ± 0.28 a |

| 3 | 2-methyl-5-(1-methylethyl)-phenol | 46.473 | ND b | ND b | 3.30 ± 0.07 a |

| 4 | Thymol | 47.244 | 3.74 ± 0.13 b | 4.89 ± 0.03 a | 2.44 ± 0.22 c |

| 5 | 2,6-bis(1,1-dimethylethyl)-phenol | 51.493 | ND b | 0.65 ± 0.04 a | ND b |

| 6 | 2,4-Di-tert-butylphenol | 51.558 | ND b | ND b | 0.70 ± 0.07 a |

| Others | - | ||||

| 1 | Dimethyl ether | 3.501 | ND b | ND b | 73.46 ± 0.51 a |

| 2 | 1-chloro-2-methyl-propane | 7.019 | 1.70 ± 0.05 b | ND c | 2.13 ± 0.15 a |

| 3 | 6,6-bicyclo [3,1,1]heptane | 8.31 | 90.67 ± 10.45 a | ND b | ND b |

| 4 | 1-methyl-3-(1-methylethyl)-benzene | 13.964 | ND b | 2.45 ± 0.24 a | ND b |

| 5 | o-Cymene | 13.988 | 18.15 ± 0.22 a | ND b | ND b |

| 6 | Geranyl vinyl ether | 19.285 | 0.02 ± 0.00 c | 1.91 ± 0.04 a | 0.73 ± 0.01 b |

| 7 | 4-ethenyl-1,2-dimethyl-benzene | 20.511 | 172.93 ± 6.31 a | ND b | ND b |

| 8 | 2-benzoyl-1,3-dithiane | 22.875 | 0.39 ± 0.04 a | 0.38 ± 0.02 a | ND b |

| 9 | (Z)-4-hexadecen-6-yne | 23.939 | ND b | ND b | 17.93 ± 0.20 a |

| 10 | 3-caren-10-al | 42.614 | 1.35 ± 0.05 a | ND b | ND b |

| 11 | 4-hydroxy-2,2,4-trimethyl-cyclohexanemethanol | 44.141 | ND b | 6.18 ± 0.27 a | 5.72 ± 1.06 a |

| 12 | 15-Crown-5 | 54.092 | 0.06 ± 0.01 a | ND b | ND b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, Q.; Zhao, J.; Sun, Y.; Zhao, Y.; Zhang, B. Utilization of Lemon Peel for the Production of Vinegar by a Combination of Alcoholic and Acetic Fermentations. Foods 2023, 12, 2488. https://doi.org/10.3390/foods12132488

Ou Q, Zhao J, Sun Y, Zhao Y, Zhang B. Utilization of Lemon Peel for the Production of Vinegar by a Combination of Alcoholic and Acetic Fermentations. Foods. 2023; 12(13):2488. https://doi.org/10.3390/foods12132488

Chicago/Turabian StyleOu, Qingyuan, Jian Zhao, Yuheng Sun, Yu Zhao, and Baoshan Zhang. 2023. "Utilization of Lemon Peel for the Production of Vinegar by a Combination of Alcoholic and Acetic Fermentations" Foods 12, no. 13: 2488. https://doi.org/10.3390/foods12132488