Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

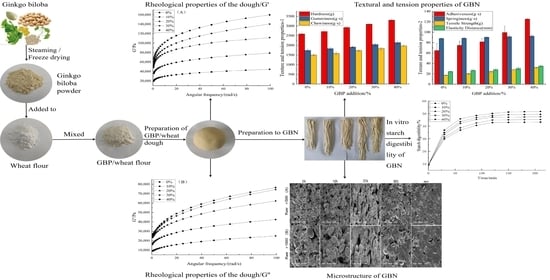

2.2. Preparation of GBP

2.3. Sample Preparation

2.4. Physicochemical Characterization of Samples

2.4.1. Determination of Ginkgolic Acid Content

2.4.2. Farinogram Properties

2.4.3. Pasting Properties

2.4.4. Dynamic Rheological Properties

2.5. Preparation of Ginkgo Biloba Fresh Wet Noodles (GBN)

2.6. Cooking Properties

2.7. Texture Properties

2.8. Sensory Evaluation

2.9. Scanning Electron Microscope (SEM) of GBN

2.10. In Vitro Starch Digestibility and Estimated Glycemic Index (eGI) Value

2.11. Statistical Analysis

3. Results and Discussion

3.1. Chemical Characterization of Wheat Flour Supplemented with GBP

3.2. Farinograph Properties

3.3. Pasting Properties

3.4. Dynamic Rheological Properties

3.5. Cooking Properties

3.6. Texture and Tension Properties

3.7. Sensory Properties

3.8. Microstructure

3.9. In Vitro Starch Digestibility

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nguyen, T.T.L.; Flanagan, B.M.; Tao, K.; Ni, D.; Gidley, M.J.; Fox, G.P.; Gilbert, R.G. Effect of processing on the solubility and molecular size of oat β-glucan and consequences for starch digestibility of oat-fortified noodles. Food Chem. 2022, 372, 131291. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.J.; Guo, X.D.; Liu, H.; Xu, B.N.; Wang, M. Cooking, textural, sensorial, and antioxidant properties of common and tartary buckwheat noodles. Food Sci. Biotechnol. 2013, 22, 153–159. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, C.; He, F.; Tian, J. Textural Characteristics and Sensory Evaluation of Cooked Dry Chinese Noodles Based on Wheat-Sweet Potato Composite Flour. Int. J. Food Prop. 2010, 13, 294–307. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Tian, Y.; Chen, Z.; Chen, J. Effects of Hericium erinaceus powder on the digestion, gelatinization of starch, and quality characteristics of Chinese noodles. Cereal Chem. 2021, 98, 482–491. [Google Scholar] [CrossRef]

- Shiau, S.Y.; Li, G.H.; Pan, W.C.; Xiong, C. Effect of pitaya peel powder addition on the phytochemical and textural properties and sensory acceptability of dried and cooked noodles. J. Food Process Preserv. 2020, 44, e14491. [Google Scholar] [CrossRef]

- Tao, C.; Wang, K.; Liu, X.; Gou, E. Effects of potato starch on the properties of wheat dough and the quality of fresh noodles. CYTA J. Food 2020, 18, 427–434. [Google Scholar] [CrossRef]

- Zhang, N.; Gao, Y.; Tong, L.; Li, Z. Superheated steam processing improved the qualities of oats flour and noodles. J. Cereal Sci. 2018, 83, 96–100. [Google Scholar] [CrossRef]

- López-Gutiérrez, N.; Romero-González, R.; Vidal, J.L.M.; Frenich, A.G. Quality control evaluation of nutraceutical products from Ginkgo biloba using liquid chromatography coupled to high resolution mass spectrometry. J. Pharm. Biomed. 2016, 121, 151–160. [Google Scholar] [CrossRef]

- Shen, D.; Shi, H.; Wu, C.; Fan, G.; Li, T. Evaluation of proximate composition, flavonoids, and antioxidant capacity of ginkgo seeds fermented with different rice wine starters. J. Wood Sci. 2020, 85, 4351–4358. [Google Scholar] [CrossRef]

- Ngan, N.T.T.; Quang, T.H.; Tai, B.H.; Song, S.B.; Lee, D.; Kim, Y.H. Anti-inflammatory and PPAR Transactivational Effects of Components from the Stem Bark ofGinkgo biloba. J. Agric. Food Chem. 2012, 60, 2815–2824. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, S.Y. Antioxidant Activity and Phenolic Compounds in Selected Herbs. J. Agric. Food Chem. 2001, 49, 5165–5170. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Liu, T.; Chai, Z.; Jie, S.; Li, Z.; Liu, M.; Dong, W.; Wang, X.; Zhou, B. lincRNA-p21 Mediates the Anti-Cancer Effect of Ginkgo Biloba Extract EGb 761 by Stabilizing E-Cadherin Protein in Colon Cancer. Med. Sci. Monitor. 2018, 24, 9488–9496. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; Zhang, Z.; Fan, L.; Li, J. Evaluation of physical stability of high pressure homogenization treatment cloudy ginkgo beverages. LWT 2019, 111, 31–38. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y. The main active constituents and detoxification process of Ginkgo biloba seeds and their potential use in functional health foods. J. Food Compos. Anal. 2019, 83, 103247. [Google Scholar] [CrossRef]

- Da Silva Santos, B.R.; Silva, E.F.R.; Minho, L.A.C.; Brandao, G.C.; dos Santos, A.M.P.; dos Santos, W.P.C.; Silva, M.V.L.; dos Santos, W.N.L. Evaluation of the nutritional composition in effect of processing cassava leaves (Manihot esculenta) using multivariate analysis techniques. Microchem. J. 2020, 152, 104271. [Google Scholar] [CrossRef]

- Koch, E.; Jaggy, H.; Chatterjee, S.S. Evidence for immunotoxic e ects of crude Ginkgo biloba L. leaf extracts using the popliteal lymph node assay in the mouse. Int. Immunopharmacol. 2000, 22, 229–236. [Google Scholar] [CrossRef]

- Shin, C.S.; Yoon, N.; Oh, B.S.; Jeong, H.S.; Yeoun, P.S.; Kim, D.J. Variation of Toxin Content in Ginkgo Fruits According to Thermal Treatment. Natl. Acad. Sci. Lett. 2020, 43, 673–676. [Google Scholar] [CrossRef]

- Fan, G.J.; Wang, X.; Wu, C.E.; Pan, H.M.; Yang, J.T.; Li, T.T.; Tang, Z.X.; Cao, F.L. Effect of heating on the content and composition of ginkgolic acids in ginkgo seeds. Qual. Assur. Saf. Crops Foods 2017, 9, 195–199. [Google Scholar] [CrossRef]

- Amoussa, A.M.O.; Zhang, L.; Lagnika, C.; Riaz, A.; Zhang, L.; Liu, X.; Beta, T. Effects of preheating and drying methods on pyridoxine, phenolic compounds, ginkgolic acids, and antioxidant capacity ofGinkgo biloba nuts. J. Wood Sci. 2021, 86, 4197–4208. [Google Scholar]

- AOAC. Association of Official Analytical Chemists, 17th ed.; AOAC: Washington, DC, USA, 2000. [Google Scholar]

- Guan, E.; Yang, Y.; Pang, J.; Zhang, T.; Li, M.; Bian, K. Ultrafine grinding of wheat flour: Effect of flour/starch granule profiles and particle size distribution on falling number and pasting properties. Food Sci. Nutr. 2020, 8, 2581–2587. [Google Scholar] [CrossRef]

- Iuga, M.; Boestean, O.; Ghendov-Mosanu, A.; Mironeasa, S. Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties. Foods 2020, 9, 828. [Google Scholar] [CrossRef] [PubMed]

- Mironeasa, S.; Codină, G.G. Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours. Foods 2019, 8, 626. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, K.; Zhou, H.; Zhu, K.; Guo, X.; Peng, W. Water Cooking Stability of Dried Noodles Enriched with Different Particle Size and Concentration Green Tea Powders. Foods 2020, 9, 298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, S.; Wang, L.; Wang, A.; Zhang, Q.; Li, Z.; Qiu, J. Effect of Moisture Distribution Changes Induced by Different Cooking Temperature on Cooking Quality and Texture Properties of Noodles Made from Whole Tartary Buckwheat. Foods 2021, 10, 2543. [Google Scholar] [CrossRef]

- Kang, M.J.; Chung, S.; Kim, S.S. The Effects of Transglutaminase and Refrigerated Storage on the Physicochemical Properties of Whole Wheat Dough and Noodles. Foods 2021, 10, 1675. [Google Scholar] [CrossRef]

- Wang, R.; Li, M.; Wei, Y.; Guo, B.; Brennan, M.; Brennan, C. Quality Differences between Fresh and Dried Buckwheat Noodles Associated with Water Status and Inner Structure. Foods 2021, 10, 187. [Google Scholar] [CrossRef]

- Liu, F.; Guo, X.; Xing, J.; Zhu, K. Effect of thermal treatments onin vitrostarch digestibility of sorghum dried noodles. Food Funct. 2020, 11, 3420–3431. [Google Scholar] [CrossRef]

- Goñi, I.; Garcia-Alonso, A.; Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Granfeldt, Y.; Bjorck, I.; Drews, A.; Tovar, J. An in vitro procedure based on chewing to predict metabolic response to starch in cereal and legume products. Eur. J. Clin. Nutr. 1992, 46, 649–660. [Google Scholar] [CrossRef] [Green Version]

- The United States Pharmacopeial Convention. US Pharmacopeia/National Formulary (USP36-NF31) [M]; US Pharmacopeia Origination Press: Washington, DC, USA, 2013; pp. 1479–1481. [Google Scholar]

- Chinese Pharmacopoeia Commission. Chinese Pharmacopoeia; Peoples Medical Publishing House: Beijing, China, 2010; Volume 1, p. 392. [Google Scholar]

- British Pharmacopoeia Commission. British Pharmacopoeia (BP8.0) [M]; The Staionery Office: London, UK, 2014; pp. 1183–1185. [Google Scholar]

- Sudha, M.L.; Vetrimani, R.; Leelavathi, K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Biosci. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Lin, S.; Jin, X.; Gao, J.; Qiu, Z.; Ying, J.; Wang, Y.; Dong, Z.; Zhou, W. Impact of wheat bran micronization on dough properties and bread quality: Part I—Bran functionality and dough properties. Food Chem. 2021, 353, 129407. [Google Scholar] [CrossRef] [PubMed]

- Ashoush, I.S.; Gadallah, M.G.E. Utilization of Mango Peels and Seed Kernels Powders as Sources of Phytochemicals in Biscuit. J. Dairy Sci. 2011, 1, 35–42. [Google Scholar]

- Zheng, B.; Zhao, H.; Zhou, Q.; Cai, J.; Wang, X.; Cao, W.; Dai, T.; Jiang, D. Relationships of protein composition, gluten structure, and dough rheological properties with short biscuits quality of soft wheat varieties. AGRON J. 2020, 112, 1921–1930. [Google Scholar] [CrossRef]

- Gao, X.; Tong, J.; Guo, L.; Yu, L.; Li, S.; Yang, B.; Wang, L.; Liu, Y.; Li, F.; Guo, J.; et al. Influence of gluten and starch granules interactions on dough mixing properties in wheat (Triticum aestivum L.). Food Hydrocoll. 2020, 106, 105885. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, M.; Dong, S.; Guo, P.; Li, H. Impact of potato pulp on the processing characteristics and gluten structures of wheat flour dough. J. Food Process. Preserv. 2020, 44, e14473. [Google Scholar] [CrossRef]

- Chisenga, S.M.; Workneh, T.S.; Bultosa, G.; Alimi, B.A.; Siwela, M. Dough rheology and loaf quality of wheat-cassava bread using different cassava varieties and wheat substitution levels. Food Biosci. 2020, 34, 100529. [Google Scholar] [CrossRef]

- Blazek, J.; Copeland, L. Pasting and swelling properties of wheat flour and starch in relation to amylose content. Carbohydr. Polym. 2008, 71, 380–387. [Google Scholar] [CrossRef]

- Varavinit, S.; Shobsngob, S.; Varanyanond, W.; Chinachoti, P.; Naivikul, O. Effect of Amylose Content on Gelatinization, Retrogradation and Pasting Properties of Flours from Different Cultivars of Thai Rice. Starch-Stärke 2003, 55, 410–415. [Google Scholar] [CrossRef]

- Li, Q.-M.; Li, Y.; Zou, J.-H.; Guo, S.-Y.; Wang, F.; Yu, P.; Su, X.-J. Influence of Adding Chinese Yam (Dioscorea opposita Thunb.) Flour on Dough Rheology, Gluten Structure, Baking Performance, and Antioxidant Properties of Bread. Foods 2020, 9, 256. [Google Scholar] [CrossRef] [Green Version]

- Xiao, F.; Zhang, X.; Niu, M.; Xiang, X.; Chang, Y.; Zhao, Z.; Xiong, L.; Zhao, S.; Rong, J.; Tang, C.; et al. Gluten development and water distribution in bread dough influenced by bran components and glucose oxidase. LWT 2021, 137, 110427. [Google Scholar] [CrossRef]

- Wang, C.; Yang, Z.; Xing, J.; Guo, X.; Zhu, K. Effects of insoluble dietary fiber and ferulic acid on the rheological properties of dough. Food Hydrocoll. 2021, 121, 107008. [Google Scholar] [CrossRef]

- Korus, J.; Juszczak, L.; Witczak, M.; Ziobro, R. Effect of Citrus Fiber on the Rheological Properties of Dough and Quality of the Gluten-Free Bread. Appl. Sci. 2020, 10, 6633. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, Y.; Zhu, H.; Li, Y.; Xiao, Q.; Yi, C. Effect of Soy Protein Isolate on Textural Properties, Cooking Properties and Flavor of Whole-Grain Flat Rice Noodles. Foods 2021, 10, 1085. [Google Scholar] [CrossRef]

- Song, X.; Zhu, W.; Pei, Y.; Ai, Z.; Chen, J. Effects of wheat bran with different colors on the qualities of dry noodles. J. Cereal Sci. 2013, 58, 400–407. [Google Scholar] [CrossRef]

- Balestra, F.; Cocci, E.; Pinnavaia, G.G.; Romani, S. Evaluation of antioxidant, rheological and sensorial properties of wheat flour dough and bread containing ginger powder. LWT 2011, 44, 700–705. [Google Scholar] [CrossRef]

- Sun, K.N.; Liao, A.M.; Zhang, F.; Thakur, K.; Zhang, J.G.; Huang, J.H.; Wei, Z.J. Microstructural, Textural, Sensory Properties and Quality of Wheat–Yam Composite Flour Noodles. Foods 2019, 8, 519. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Wang, K.; Xue, W.; Wang, L.; Zhang, C.; Zhang, X.; Chen, Z. In vitro starch digestibility, edible quality and microstructure of instant rice noodles enriched with rice bran insoluble dietary fiber. LWT 2021, 142, 111008. [Google Scholar] [CrossRef]

- Jia, B.; Yao, Y.; Liu, J.; Guan, W.; Brennan, C.S.; Brennan, M.A. Physical Properties and In Vitro Starch Digestibility of Noodles Substituted with Tartary Buckwheat Flour. Starch-Stärke 2019, 71, 1800314. [Google Scholar] [CrossRef]

- Fu, M.; Sun, X.; Wu, D.; Meng, L.; Feng, X.; Cheng, W.; Gao, C.; Yang, Y.; Shen, X.; Tang, X. Effect of partial substitution of buckwheat on cooking characteristics, nutritional composition, and in vitro starch digestibility of extruded gluten-free rice noodles. LWT 2020, 126, 109332. [Google Scholar] [CrossRef]

| Item | Full Score/Score | Marking Criterion |

|---|---|---|

| Color | 10 | Deep colour and bright 8–10; Light yellow and less bright 5–7; Light yellow 1–4 |

| Appearance | 10 | Smooth and irregular shape 8–10; Less smooth and in shape 5–7; Rough and unshaped 1–4 |

| Palatability | 20 | Suitable hardness 17–20; Harder or softer 12–16; Over-hard or soft 1–12 |

| Toughness | 25 | Elastic 21–25; Poor elasticity 16–20; Worse elasticity 11–15; Worst elasticity 1–10 |

| Viscosity | 25 | Non-sticky 21–25; Less sticky 16–20; Sticky hair 10–15; Very sticky 1–10 |

| Smoothness | 5 | Smooth 5; Less smooth 3–4; Coarse 1–2 |

| Flavor | 5 | Ginkgo flavor 5; Non-smell 3–4; Smell 1–2 |

| Total score | 100 | Refined grade wheat flour products score ≥ 85; ordinary wheat flour products score ≥ 75 |

| Item | 0% | 10% | 20% | 30% | 40% | 100% |

|---|---|---|---|---|---|---|

| Moisture (%) | 13.65 ± 0.44 a | 12.94 ± 0.09 b | 12.31 ± 0.04 c | 11.91 ± 0.06 d | 11.57 ± 0.12 d | 10.20 ± 0.11 e |

| Protein (g/100 g) | 17.41 ± 0.41 a | 16.55 ± 0.08 b | 16.39 ± 0.08 b | 15.67 ± 0.10 c | 15.34 ± 0.12 c | 13.75 ± 0.10 d |

| Total sugar (mg/g) | 656.61 ± 1.37 a | 654.32 ± 0.56 b | 651.95 ± 0.85 c | 649.24 ± 0.65 d | 646.62 ± 0.92 e | 639.23 ± 0.71 fc |

| Starch (g/100 g) | 63.59 ± 0.24 a | 60.73 ± 0.57 b | 57.30 ± 0.74 c | 54.68 ± 0.41 d | 52.20 ± 0.35 e | 34.83 ± 0.52 f |

| Amylose (mg/g) | 118.45 ± 2.00 f | 150.21 ± 7.22 e | 177.56 ± 1.77 d | 207.71 ± 2.31 c | 229.77 ± 0.55 b | 321.46 ± 3.33 a |

| Gluten (g/100 g) | 32.39 ± 0.49 a | 29.31 ± 0.36 b | 23.80 ± 0.27 c | 19.94 ± 0.43 d | 15.82 ± 0.34 e | - |

| Fibre(mg/g) | 0.87 ± 0.01 f | 0.93 ± 0.01 e | 1.03 ± 0.03 d | 1.11 ± 0.02 c | 1.17 ± 0.01 b | 1.56 ± 0.04 a |

| Total flavonoids (mg/g) | - | 0.29 ± 0.02 e | 0.51 ± 0.03 d | 0.78 ± 0.03 c | 0.97 ± 0.02 b | 2.00 ± 0.05 a |

| Ginkgolic acid (mg/kg) | - | 0.28 ± 0.03 e | 0.40 ± 0.02 d | 0.69 ± 0.04 c | 0.82 ± 0.04 b | 2.06 ± 0.09 a |

| Sample | Water Absorption (%) | Dough Development Time (min) | Dough Stability Time (min) | Mixing Tolerance Index(FU) |

|---|---|---|---|---|

| 0% | 53.94 ± 0.39 e | 0.92 ± 0.06 b | 3.55 ± 0.05 a | 231.31 ± 15.06 d |

| 10% | 54.9 ± 0.76 d | 1.03 ± 0.05 ab | 1.20 ± 0.14 b | 399.83 ± 14.69 c |

| 20% | 55.57 ± 0.40 c | 1.10 ± 0.14 a | 1.07 ± 0.12 bc | 426.50 ± 22.48 c |

| 30% | 57.08 ± 0.20 b | 1.17 ± 0.12 a | 0.93 ± 0.17 bc | 519.80 ± 12.25 b |

| 40% | 58.00 ± 0.17 a | 1.20 ± 0.28 a | 0.80 ± 0.08 c | 579.80 ± 14.72 a |

| Sample | Peak Viscosity (cP) | Trough Viscosity (cP) | Breakdown (cP) | Final Viscosity (cP) | Setback (cP) |

|---|---|---|---|---|---|

| 0% | 2621.00 ± 60.83 a | 1943.33 ± 69.81 a | 677.67 ± 11.90 a | 3091.67 ± 66.38 a | 1148.33 ± 46.02 a |

| 10% | 1997.00 ± 40.42 b | 1404.33 ± 20.43 b | 592.67 ± 30.92 b | 2470.00 ± 46.61 b | 1065.67 ± 34.34 b |

| 20% | 1762.05 ± 69.90 c | 1265.00 ± 44.86 c | 497.00 ± 25.39 c | 2226.67 ± 70.48 c | 961.67 ± 28.69 c |

| 30% | 1414.67 ± 40.89 d | 1001.33 ± 31.37 d | 413.33 ± 10.21 d | 1835.00 ± 67.94 d | 833.67 ± 36.57 d |

| 40% | 1268.67 ± 42.60 e | 894.67 ± 29.91 e | 374.00 ± 12.96 d | 1693.33 ± 49.09 e | 798.67 ± 19.60 d |

| Sample | G′ = K′ × Wn′ | G″ = K″ × Wn″ | ||||

|---|---|---|---|---|---|---|

| K′ (Pa sn′) | n′ | R21 | K″ (Pa sn″) | n″ | R22 | |

| 0% | 20,951.70 ± 137.45 e | 0.159 ± 0.002 c | 0.996 | 8376.21 ± 213.92 d | 0.227 ± 0.008 c | 0.977 |

| 10% | 37,035.29 ± 186.07 d | 0.161 ± 0.002 b | 0.998 | 16,231.66 ± 278.27 c | 0.200 ± 0.005 c | 0.986 |

| 20% | 55,210.75 ± 228.67 c | 0.153 ± 0.001 b | 0.998 | 22,527.66 ± 524.78 b | 0.210 ± 0.007 b | 0.977 |

| 30% | 58,392.86 ± 445.39 b | 0.186 ± 0.002 a | 0.997 | 24,043.43 ± 634.59 a | 0.234 ± 0.008 b | 0.977 |

| 40% | 66,692.16 ± 316.67 a | 0.187 ± 0.001 a | 0.999 | 23,472.34 ± 353.38 a | 0.251 ± 0.004 a | 0.994 |

| Sample | Optimal Cooked Time (s) | Water Absorption (%) | Cooking Loss (%) |

|---|---|---|---|

| 0% | 336.66 ± 3.43 e | 4.10 ± 0.05 e | 6.11 ± 0.10 e |

| 10% | 346.66 ± 4.22 d | 5.99 ± 0.13 d | 6.83 ± 0.10 d |

| 20% | 383.33 ± 4.51 c | 9.09 ± 0.07 c | 7.51 ± 0.09 c |

| 30% | 406.66 ± 2.45 b | 10.49 ± 0.48 b | 8.30 ± 0.06 b |

| 40% | 433.33 ± 5.27 a | 11.20 ± 0.34 a | 11.43 ± 0.09 a |

| Sample | Hardness (g) | Adhesiveness (g·s) | Springiness (g·s) | Chewiness (g·s) | Tensile Strength (g) | Elasticity Distance (mm) |

|---|---|---|---|---|---|---|

| 0% | 2588.13 ± 51.58 e | 64.73 ± 13.88 a | 88.01 ± 0.75 b | 1499.79 ± 25.24 d | 17.37 ± 0.32 e | 24.38 ± 0.33 a |

| 10% | 2715.46 ± 6.04 d | 74.73 ± 7.88 a | 88.45 ± 1.25 b | 1586.82 ± 76.00 d | 20.30 ± 0.89 d | 26.75 ± 1.16 b |

| 20% | 2923.57 ± 54.38 c | 81.54 ± 6.06 a | 90.44 ± 1.60 ab | 1728.82 ± 39.70 c | 24.42 ± 0.88 c | 28.08 ± 1.35 c |

| 30% | 3095.09 ± 9.32 b | 99.42 ± 12.14 b | 91.54 ± 2.21 a | 1838.01 ± 51.93 b | 28.09 ± 0.16 b | 30.32 ± 2.12 d |

| 40% | 3301.09 ± 45.36 a | 125.29 ± 1.45 c | 92.44 ± 1.78 a | 1981.41 ± 41.70 a | 32.26 ± 0.85 a | 35.08 ± 1.10 e |

| Sample | Color | Appearance | Palatability | Toughness | Viscosity | Smoothness | Flavor | Total |

|---|---|---|---|---|---|---|---|---|

| 0% | 8.22 ± 0.19 b | 7.28 ± 0.13 bc | 18.02 ± 0.10 b | 20.14 ± 0.96 ab | 20.88 ± 0.53 ab | 4.38 ± 0.03 bc | 4.25 ± 0.09 c | 83.27 ± 2.09 bc |

| 10% | 8.27 ± 0.24 b | 7.40 ± 0.13 ab | 18.42 ± 0.21 a | 20.54 ± 0.45 a | 20.95 ± 1.20 ab | 4.60 ± 0.15 a | 4.35 ± 0.15 bc | 84.37 ± 2.40 ab |

| 20% | 8.57 ± 0.10 a | 7.50 ± 0.05 a | 18.08 ± 0.07 b | 20.93 ± 0.26 a | 21.76 ± 0.54 b | 4.55 ± 0.05 ab | 4.52 ± 0.15 ab | 86.33 ± 1.26 a |

| 30% | 8.17 ± 0.08 b | 7.20 ± 0.05 bc | 17.87 ± 0.21 b | 20.22 ± 0.50 a | 19.80 ± 0.40 bc | 4.43 ± 0.13 ab | 4.60 ± 0.04 a | 81.94 ± 1.45 c |

| 40% | 8.00 ± 0.05 b | 7.08 ± 0.15 c | 17.45 ± 0.18 c | 19.32 ± 0.22 b | 19.24 ± 0.38 c | 4.22 ± 0.08 c | 4.15 ± 0.05 c | 79.46 ± 1.11 d |

| Samples | Kinetics Parameters | ||||

|---|---|---|---|---|---|

| C∞(%) | K × 10−2 (min−1) | R2 | AUC | eGI | |

| White Bread | 59.22 ± 0.09 a | 4.24 ± 0.02 a | 0.9989 | 9068.42 ± 16.82 a | 94.40 ± 0.05 a |

| 0% | 50.89 ± 0.12 b | 4.13 ± 0.01 b | 0.9982 | 7766.10 ± 22.74 b | 82.02 ± 0.47 b |

| 10% | 48.82 ± 0.07 c | 4.01 ± 0.01 c | 0.9984 | 7421.16 ± 19.48 c | 78.74 ± 0.35 c |

| 20% | 47.17 ± 0.62 d | 3.98 ± 0.03 c | 0.9993 | 7166.85 ± 17.31 d | 76.32 ± 0.31 d |

| 30% | 44.85 ± 0.21 e | 3.75 ± 0.02 d | 0.9964 | 6752.25 ± 20.36 e | 72.38 ± 0.19 e |

| 40% | 42.83 ± 0.14 f | 3.73 ± 0.04 d | 0.9972 | 6444.32 ± 19.35 f | 69.45 ± 0.62 f |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Zhou, W.; Wu, A.; Qian, X.; Xie, L.; Zhou, X.; Zhang, L. Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles. Foods 2022, 11, 698. https://doi.org/10.3390/foods11050698

Li L, Zhou W, Wu A, Qian X, Xie L, Zhou X, Zhang L. Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles. Foods. 2022; 11(5):698. https://doi.org/10.3390/foods11050698

Chicago/Turabian StyleLi, Liangyi, Wenhua Zhou, Anqi Wu, Xin Qian, Le Xie, Xiaojie Zhou, and Lin Zhang. 2022. "Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles" Foods 11, no. 5: 698. https://doi.org/10.3390/foods11050698