3.1. Characteristics of Flours and Criteria for Pizza Formulation

Pizza formulation is reported in

Table 1, while the nutritional characteristics of the flours used in the experimental trials are reported in

Table 2.

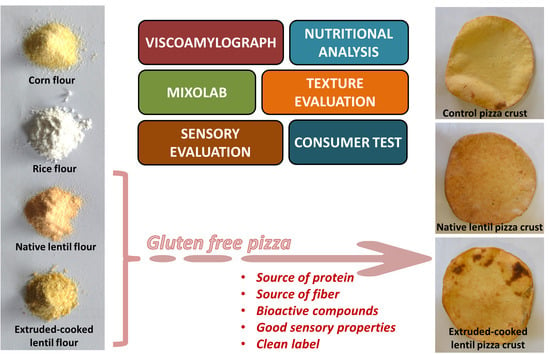

In setting up the formulation of the control pizza, corn and rice flours were used in a 1:4 ratio. The quantity of corn flour, typically bright yellow, was smaller than rice to obtain, in the mixture, a yellowish color similar to that of a conventional wheat-based dough. Moreover, the selected flour ratio assured that the intense smell of the corn flour did not prevail, as assessed in preliminary trials.

As for the nutritional characteristics, rice and corn flours were richer in carbohydrates and presented lower contents of proteins and fibers compared to lentil flours (both NL and ECL). In particular, rice flour showed the lowest protein and fiber content. Lentil flour, instead, showed a relevant protein content, in agreement with the range of values reported in other studies [

45,

46]. The lentil, indeed, is known to be a protein crop, as are other pulses. In addition, the lentil is rich in lysine but poor in sulfur amino acids and is complemented by cereals such as rice and corn, which are rich in sulfur amino acids but are limited in lysine. As such, it is a practical and convenient strategy to improve the protein quality of plant-based food [

47]. Therefore, NL and ECL flours were used to partly substitute rice flour at a level of 10 g/100 g of dough. Significant differences in the nutritional compositions were observed between NL and ECL, with the latter showing lower values of proteins and fibers. The difference between NL and ECL was due to thermo-mechanical degradations related to the extrusion-cooking treatment [

21,

26].

The gelation properties (viscoamylograph data) of the flours used for preparing the experimental GF pizza samples are reported in

Table 3.

The ECL flour showed a significantly higher initial viscosity than the other flours. This result was expected, because the extrusion-cooking treatment was specifically aimed at gelatinizing the starch granules, while in the raw flours (rice, corn, and NL) the starch remained in its native form. The ECL flour showed the lowest peak viscosity, again indicating that the starch had already been completely pregelatinized during the extrusion-cooking process. The ECL flour also showed a very limited retrogradation, with significantly lower values of the cooling maximum viscosity and the setback compared to the other flours. A lower tendency towards retrogradation is appreciated in the production of bakery products, which should stay soft as long as possible. A limited setback, but greater than in ECL, was also observed in NL, confirming the results of [

48]. Overall, with the exception of the initial viscosity value of ECL, all the viscoamylograph indices were lower in lentil flour than in the cereal flours, mainly due to the significantly higher protein content of the former. Proteins, indeed, tend to act as a physical barrier for starch swelling. A negative correlation between protein content with the peak viscosity was found by other authors [

49,

50]. The very limited breakdown of NL and ECL indicated that the paste viscosity of the lentil gels, despite the fact that they were not very elevated, were stable through the analysis and had a good shearing resistance, as already reported by other authors [

51,

52]. Overall, these results showed that lentil flours, and particularly ECL, were suitable for the preparation of GF pizza.

The gels from rice and corn flours showed remarkably high peak viscosity values, indicating a rapid and pronounced swelling of the native starch granules. The viscosity of gel from corn flour also remained high at its cooking temperature and under prolonged stirring (95 °C for 30 min), recording a very high value of minimum viscosity and a limited breakdown. During its subsequent cooling, the viscosity of both corn and rice gels noticeably increased, thus indicating a strong tendency towards starch retrogradation, which could be useful in noodle preparation [

53] but is undesired in baked goods. These findings further justified the choice of partly replacing rice and corn flour in the preparation of GF pizza.

Regarding the better evaluation of its suitability to the preparation of GF pizza, ECL flour was also analyzed by Mixolab, in comparison with NL flour (

Figure 2). Mixolab, indeed, is particularly suitable for analyzing the properties of starch associated with thermal processes, and the variations of dough consistency during mixing, simultaneously. The latter are important for the preparation of baked goods. Mixolab, therefore, substantially substitutes the separate use of the viscoamylograph and the farinograph [

54]. The first part of the Mixolab curve records the dough behavior during mixing. In the second part of the analysis, the dough behavior, during its simultaneous mechanical shear stress and the temperature increase, is recorded. When a conventional gluten-containing dough is analyzed, the torque increases during the first stage until it reaches a maximum (C1). In the second part of the analysis, a decrease in the torque is usually observed, until it reaches a minimum value (C2).

The Mixolab profiles of the examined flours agreed with the viscoamylograph findings. ECL, in fact, showed a very high maximum torque in the first part of the analysis (C1). This result was due to the presence of pregelatinized starch, which increased the water absorption, producing a more consistent system that was already at 50 °C. On the contrary, NL showed an extremely low initial value of torque, because the contained starch, still native, could not gelatinize at 50 °C. Even at its minimum (C2), ECL showed a higher torque value than NL, indicating its ability to form a sufficiently structured gel to simulate a conventional (gluten-containing) dough. This ability, instead, was absent in NL which, before raising the temperature to 90 °C, never reached 0.4 Nm, which is the torque value below which the dough is considered not workable [

55]. The torque of NL dough increased only with its subsequent heating at 90 °C, when the native starch of this flour gelatinized.

Viscoamylograph and Mixolab data clearly showed that rice, corn, and NL flours were not able to produce a viscous system after simple hydration, i.e., without heating at a sufficiently high temperature to achieve starch gelatinization (approximatively 95 °C). Therefore, hydrocolloids, namely HPMC (E464) and psyllium seed husk powder, were included in the formulation of pizza, to mime gluten and improve the dough structure. HPMC is known for its strong gelation capacity, which is able to increase dough viscosity [

56]. This additive was not used in pizza with NL to verify the effectiveness of ECL as hydrocolloid. Psyllium husks are generally used in combination with other hydrocolloids, such as HPMC, to improve the rheological properties of GF doughs [

56,

57,

58,

59,

60].

Psyllium has water-absorbing and gel-forming properties at room temperature. It is composed of arabinoxylans, whose numerous hydroxyl groups increase the capacity to bind to water and generate viscous solutions [

61]. While, usually, GF products rely on the preparation of a batter, arabinoxylans act as a structuring agent that helps to retain the shape of a consistent dough without the need of a pan [

62]. The structuring properties of psyllium were important in this research because, regarding the aim of keeping high the sensory properties of GF pizza, it was needed to obtain a sheetable dough instead of a batter.

Psyllium is also an effective anti-staling agent, appreciated in GF formulations [

63]. Moreover, being a soluble fiber, it shows some health benefits, such as gut regulation, as well as blood glucose and cholesterol control [

64]. Therefore, psyllium was also included in the formulation of GF pizza to elevate the fiber content of the final products.

3.2. Characteristics of GF Pizza Crust

Table 4 reports the nutritional characteristics of the experimental GF pizza samples. The addition of lentil flour had a positive impact on the nutritional profile of pizza, determining a significant increase in protein and fiber content.

In particular, the NL and ECL pizza samples were able to provide >12% of the energy value by adding proteins and could, therefore, be labeled with the nutritional claim “a source of proteins” according to the Regulation (EC) No. 1924/06 [

65]. Moreover, all pizza types were able to provide more than 3 g/100 g of fibers, which could also add the “source of fibers” claim [

65]. The control pizza reached the level of fiber, due to the presence of psyllium.

The raffinose family, oligosaccharides (RFOs), or α-galactosides, were also determined (

Table 5), because these undigestible oligosaccharides are usually found in legumes, including lentils [

66]. RFOs include raffinose, verbascose, and stachyose, and are mostly considered as antinutrients, causing flatulence and intestinal discomfort [

67]. At the same time, since RFOs act as substrate for intestinal bacteria, they are also considered as prebiotics [

68]. These compounds were not detected in the control pizza. This result was expected because the content of RFOs in rice and corn is generally quite low [

69]. Moreover, the detrimental effect of baking, and the dilution with other ingredients, further lowered their amount. Instead, RFOs were detected both in NL and ECL pizzas. With the exception of stachyose, which was the most abundant oligosaccharide—as observed in previous works [

66]—no significant differences were observed between the NL and ECL pizzas. The amount of stachyose, instead, was minor in the ECL compared to the NL, pizza, due to the thermal effect known to reduce these compounds. Other authors, in fact, observed a decrease in lentil oligosaccharides with cooking (boiling or roasting) [

70].

As for bioactive compounds (

Table 6), high levels of anthocyanins were assessed in the NL pizza. Anthocyanins, indeed, are known to be abundant in the red lentil [

71]. Lower amounts of anthocyanins were observed in the ECL, compared to the NL, pizza, due to the thermal degradation [

72] that occurred during extrusion-cooking. A relevant reduction in the level of total anthocyanins has also been observed during the extrusion-cooking of blue and red corn [

73]. On the contrary, carotenoids were not affected by the extrusion-cooking process, as shown by the lack of significant differences in the carotenoid content between the NL and ECL pizzas. Similarly, other authors reported that the total carotenoid content did not decrease during the extrusion-cooking of corn [

74]. Carotenoids, indeed, are known to be more heat-stable than other total anthocyanins. An average decrease in the total carotenoids of about 15% was observed after heating pigment-rich fruits, such as papaya and pineapple, at 100 °C for 8 min, whereas with the same combination of time and temperature, the content of total anthocyanins decreased by about 30% [

75]. Therefore, carotenoids were abundant in all samples, even in the control, where it was contributed by corn flour. Polyphenols, instead, were quantified in lower amounts. Overall, these compounds can prevent or reduce lipid oxidation and can scavenge oxygen free radicals [

76], as well as having a strong Pearson’s correlation with antioxidant activity, carotenoids, and total flavonoids [

77]. Therefore, the in vitro antioxidant activity was measured in the experimental GF pizza samples. Due to the higher content of bioactive compounds, the ECL and NL pizzas showed a significantly higher antioxidant activity than the control. A lower antioxidant activity was observed in the ECL pizza, compared to the NL pizza, but this difference was not statistically significant.

As for the physical characteristics of GF pizza, related to its quality, no significant difference in pliability was observed between the control and ECL pizzas. A good-quality pizza should be easily pliable and should have, at least in the central part, a soft consistency [

78]. Instead, the NL pizza was significantly (

p < 0.05) less pliable; therefore, it required a higher force to be bent (

Table 7). This result is very interesting, as it shows that the use of ECL flour made it possible to obtain a baked product with good pliability even without the addition of HPMC, while the NL pizza was unable to achieve the mechanical characteristics of the control in the absence of HPMC.

The color of baked goods, including pizza, is due to the combined effect of the Maillard reaction, induced by baking, and the contribution of bioactive pigments, such as anthocyanins and carotenoids, that are present in the flours. In fact, the color of the experimental GF pizza samples was influenced by the addition of both lentil flours, with a significant (

p < 0.05) decrease in L* and an increase in a* and b*, compared with the control pizza. This result was due to the color of the lentil flour used: the NL flour was reddish and the ECL flour was amber yellow (

Figure 3). As a consequence, the NL pizza showed also a significantly higher a* value than the ECL pizza. Color is a fundamental component of food appearance, known to influence the willingness to buy, as expressed by consumers [

79]. Color alterations have already been observed as a consequence of the addition of pulse flour to pizza crusts [

17], depending on the color of the pulse flour added. In view of its reduction, it is advisable to carry out a preliminary selection of the fortifying flours by preferring those flours which, with the addition of water, give the dough a similar appearance to the traditional wheat dough.

As for the total color difference, compared to the control (∆E), the ECL pizza showed a perceptible difference in color, but this difference was even greater between the control pizza and the NL pizza, as can be observed in

Figure 4.

Baking involves physical changes in the bakery products, related to the increase in volume which, in turn, is due to the heat-induced expansion of the gases incorporated into the dough during the kneading and fermentation phases. This increase in volume resulted in an associated increase in the thickness of pizza samples (up to 111.1%), and a moderate decrease in diameter (10–13%). Similar values were observed in pizza prepared from blends of wheat and chickpea flour [

17]. The increase in thickness demonstrated a good leavening degree and, above all, showed that a sufficiently developed and extensible dough was obtained, which was able to retain the gases. The highest increase in thickness was observed in the control pizza, while the lowest was observed in the NL pizza; however, the differences among the samples were not statistically significant.

As for the sensorial profile (

Table 8), the addition of ECL and NL intensified (but not significantly) the global odor of pizza compared to the control, mostly by contributing a moderate lentil odor. The latter was perceived without any significant differences between the ECL and NL pizzas. Moreover, the color was perceived as significantly different among the three pizza types, with the NL pizza being the most intensely colored, showing orange undertones. The sensory evaluation of color agreed with the colorimeter measures.

The control pizza and the ECL pizza did not show significant differences in consistency, being both moderately soft, whereas the NL pizza was significantly harder and less compressible. NL pizza was also less pliable and more rigid than the control and ECL pizzas, which appeared more elastic and pliable. The control and ECL pizzas did not show significant differences between them, again in agreement with the instrumental determinations, highlighting the positive effect of ECL flour on the mechanical properties of pizza.

Flavor notes, namely, saltiness and sweetness, instead, were not influenced by the addition of lentil flours. The lentil flavor was moderately perceived in both the NL and ECL pizzas, without significant differences between them. Therefore, in an overall sensory comparison with the control, the ECL pizza differed substantially only in the intensity of the lentil odor and flavor, and in the color.

The consumer test indicated that no one expressed a dislike towards the three GF pizza types, highlighting that even the qualitative level of the NL pizza, despite being lower than the control and ECL pizzas, was not too low. The three types of pizza, therefore, were liked by all consumers, but to a different extent. The liked level of the NL pizza was lower than the control pizza, while between the ECL and control pizzas, there were no significant differences. The lower liked level of the NL pizza was probably imputable to its unusual orange color, harder consistency, and reduced pliability.