Optimized Roasting Conditions of Germinated Wheat for a Novel Cereal Beverage and Its Sensory Properties

Abstract

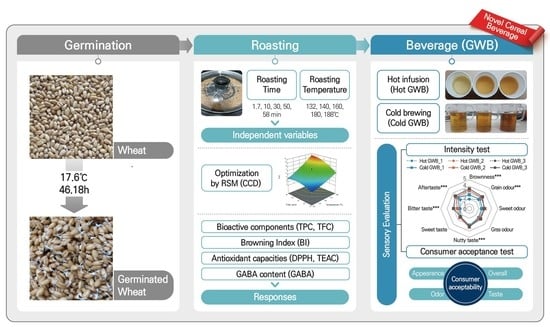

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Chemicals

2.2. Preparation of Roasted Germinated Wheat

2.3. Analysis of Responses

2.3.1. Browning Index

2.3.2. Total Flavonoid Content

2.3.3. Total Phenolic Content

2.3.4. DPPH Radical Scavenging Activity

2.3.5. Trolox Equivalent Antioxidant Capacity

2.3.6. γ-Aminobutyric Acid Content

2.4. Sensory Evaluation

2.5. Statistical Analysis

3. Results and Discussion

3.1. Roasting Time-Temperature Impact on BI

3.2. Roasting Time-Temperature Impact on Bioactive Compounds

3.3. Roasting Time-Temperature Impact on Antioxidant Capacity

3.4. Roasting Time-Temperature Impact on GABA Content

3.5. Optimization of Roasting Time-Temperature by RSM

3.6. Validation of Optimal Roasting Conditions

3.7. Consumer Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gawlik-Dziki, U.; Dziki, D.; Nowak, R.; Świeca, M.; Olech, M.; Pietrzak, W. Influence of sprouting and elicitation on phenolic acids profile and antioxidant activity of wheat seedlings. J. Cereal Sci. 2016, 70, 221–228. [Google Scholar] [CrossRef]

- Yang, B.; Yin, Y.; Liu, C.; Zhao, Z.; Guo, M. Effect of germination time on the compositional, functional and antioxidant properties of whole wheat malt and its end-use evaluation in cookie-making. Food Chem. 2021, 349, 129125. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, P.; Weng, Y.; Ma, Y.; Gu, Z.; Yang, R. Comparison of phenolic profiles, antioxidant capacity and relevant enzyme activity of different Chinese wheat varieties during germination. Food Biosci. 2017, 20, 159–167. [Google Scholar] [CrossRef]

- Ng, L.-T.; Huang, S.-H.; Chen, Y.-T.; Su, C.-H. Changes of tocopherols, tocotrienols, γ-oryzanol, and γ-aminobutyric acid levels in the germinated brown rice of pigmented and nonpigmented cultivars. J. Agric. Food Chem. 2013, 61, 12604–12611. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Guo, X.; Liu, Y.; Zhang, M.; Zhang, R.; Abbasi, A.M.; You, L.; Li, T.; Liu, R.H. Comparative assessment of phytochemical profile, antioxidant capacity and anti-proliferative activity in different varieties of brown rice (Oryza sativa L.). LWT 2018, 96, 19–25. [Google Scholar] [CrossRef]

- Marti, A.; Cardone, G.; Pagani, M.A.; Casiraghi, M.C. Flour from sprouted wheat as a new ingredient in bread-making. LWT 2018, 89, 237–243. [Google Scholar] [CrossRef] [Green Version]

- Olaerts, H.; Vandekerckhove, L.; Courtin, C.M. A closer look at the bread making process and the quality of bread as a function of the degree of preharvest sprouting of wheat (Triticum aestivum). J. Cereal Sci. 2018, 80, 188–197. [Google Scholar] [CrossRef]

- Kim, H.-J.; Han, J.-A.; Lim, S.-T.; Cho, D.-H. Effects of germination and roasting on physicochemical and sensory characteristics of brown rice for tea infusion. Food Chem. 2021, 350, 129240. [Google Scholar] [CrossRef]

- Guo, H.; Yang, X.; Zhou, H.; Luo, X.; Qin, P.; Li, J.; Ren, G. Comparison of nutritional composition, aroma compounds, and biological activities of two kinds of tartary buckwheat tea. J. Food Sci. 2017, 82, 1735–1741. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhang, P.; Warner, R.D.; Shen, S.; Fang, Z. Cereal grain-based functional beverages: From cereal grain bioactive phytochemicals to beverage processing technologies, health benefits and product features. Crit. Rev. Food Sci. Nutr. 2020, 1–25. [Google Scholar] [CrossRef]

- Zhu, Y.-M.; Dong, J.-J.; Jin, J.; Liu, J.-H.; Zheng, X.-Q.; Lu, J.-L.; Liang, Y.-R.; Ye, J.-H. Roasting process shaping the chemical profile of roasted green tea and the association with aroma features. Food Chem. 2021, 353, 129428. [Google Scholar] [CrossRef] [PubMed]

- Cho, D.-H.; Lim, S.-T. Germinated brown rice and its bio-functional compounds. Food Chem. 2016, 196, 259–271. [Google Scholar] [CrossRef]

- Jogihalli, P.; Singh, L.; Kumar, K.; Sharanagat, V.S. Novel continuous roasting of chickpea (Cicer arietinum): Study on physico-functional, antioxidant and roasting characteristics. LWT 2017, 86, 456–464. [Google Scholar] [CrossRef]

- Aung, T.; Kim, S.-J.; Eun, J.-B. A hybrid RSM-ANN-GA approach on optimisation of extraction conditions for bioactive component-rich laver (Porphyra dentata) extract. Food Chem. 2022, 366, 130689. [Google Scholar] [CrossRef] [PubMed]

- Kumari, M.; Gupta, S.K. Response surface methodological (RSM) approach for optimizing the removal of trihalomethanes (THMs) and its precursor’s by surfactant modified magnetic nanoadsorbents (sMNP)-An endeavor to diminish probable cancer risk. Sci. Rep. 2019, 9, 18339. [Google Scholar] [CrossRef] [PubMed]

- Uysal, N.; Sumnu, G.; Sahin, S. Optimization of microwave–infrared roasting of hazelnut. J. Food Eng. 2009, 90, 255–261. [Google Scholar] [CrossRef]

- Kim, B.R.; Park, S.S.; Youn, G.-J.; Kwak, Y.J.; Kim, M.J. Characteristics of Sunsik, a Cereal-Based Ready-to-Drink Korean Beverage, with Added Germinated Wheat and Herbal Plant Extract. Foods 2020, 9, 1654. [Google Scholar] [CrossRef]

- Wu, L.; Huang, Z.; Qin, P.; Ren, G. Effects of processing on phytochemical profiles and biological activities for production of sorghum tea. Food Res. Int. 2013, 53, 678–685. [Google Scholar] [CrossRef]

- Zambrano-Zaragoza, M.; Mercado-Silva, E.; Gutiérrez-Cortez, E.; Cornejo-Villegas, M.; Quintanar-Guerrero, D. The effect of nano-coatings with α-tocopherol and xanthan gum on shelf-life and browning index of fresh-cut “Red Delicious” apples. Innov. Food Sci. Emerg. Technol. 2014, 22, 188–196. [Google Scholar] [CrossRef]

- Gujral, H.S.; Sharma, P.; Gill, B.S.; Kaur, S. Effect of incorporating hydrothermal, kilned and defatted oats on antioxidant and chapatti making properties of wheat flour. Food Chem. 2013, 138, 1400–1406. [Google Scholar] [CrossRef]

- Wong, S.P.; Leong, L.P.; Koh, J.H.W. Antioxidant activities of aqueous extracts of selected plants. Food Chem. 2006, 99, 775–783. [Google Scholar] [CrossRef]

- Simsek, S.; El, S.N. In vitro starch digestibility, estimated glycemic index and antioxidant potential of taro (Colocasia esculenta L. Schott) corm. Food Chem. 2015, 168, 257–261. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Saxena, D.C.; Riar, C.S. Changes in the GABA and polyphenols contents of foxtail millet on germination and their relationship with in vitro antioxidant activity. Food Chem. 2018, 245, 863–870. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.K.; Shin, E.-C.; Lim, H.-J.; Choi, S.J.; Kim, C.R.; Suh, S.H.; Kim, C.-J.; Park, G.G.; Park, C.-S.; Kim, H.K. Characterization of nutritional composition, antioxidative capacity, and sensory attributes of Seomae mugwort, a native Korean variety of Artemisia argyi H. Lev. & Vaniot. J. Anal. Methods Chem. 2015, 2015, 916346. [Google Scholar]

- Sharma, P.; Gujral, H.S. Effect of sand roasting and microwave cooking on antioxidant activity of barley. Food Res. Int. 2011, 44, 235–240. [Google Scholar] [CrossRef]

- Sacchetti, G.; Ioannone, F.; De Gregorio, M.; Di Mattia, C.; Serafini, M.; Mastrocola, D. Non enzymatic browning during cocoa roasting as affected by processing time and temperature. J. Food Eng. 2016, 169, 44–52. [Google Scholar] [CrossRef]

- Hedegaard, R.; Skibsted, L. Shelf-life of food powders. In Handbook of Food Powders; Elsevier: Amsterdam, The Netherlands, 2013; pp. 409–434. [Google Scholar]

- Thakur, A.; Pandey, P.; Dalbhagat, C.G.; Mishra, H.N. Development of grain-based carbonated beverage premix using maize (Zea Mays), Bengal gram (Cicer Arietinum), and finger millet (Eleusine Coracana). J. Food Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Park, M.; Lee, K.-G. Effect of roasting temperature and time on volatile compounds, total polyphenols, total flavonoids, and lignan of omija (Schisandra chinensis Baillon) fruit extract. Food Chem. 2021, 338, 127836. [Google Scholar] [CrossRef]

- Peng, M.; Lu, D.; Liu, J.; Jiang, B.; Chen, J. Effect of roasting on the antioxidant activity, phenolic composition, and nutritional quality of pumpkin (Cucurbita pepo L.) seeds. Front. Nutr. 2021, 8, 647354. [Google Scholar] [CrossRef]

- Mir, S.A.; Bosco, S.J.D.; Shah, M.A.; Mir, M.M. Effect of puffing on physical and antioxidant properties of brown rice. Food Chem. 2016, 191, 139–146. [Google Scholar] [CrossRef]

- Žilić, S. Phenolic compounds of wheat. Their content, antioxidant capacity and bioaccessibility. MOJ Food Process. Technol. 2016, 2, 00037. [Google Scholar] [CrossRef]

- Gallegos-Infante, J.A.; Rocha-Guzman, N.E.; Gonzalez-Laredo, R.F.; Pulido-Alonso, J. Effect of processing on the antioxidant properties of extracts from Mexican barley (Hordeum vulgare) cultivar. Food Chem. 2010, 119, 903–906. [Google Scholar] [CrossRef]

- Kocadağlı, T.; Gökmen, V. Effect of roasting and brewing on the antioxidant capacity of espresso brews determined by the QUENCHER procedure. Food Res. Int. 2016, 89, 976–981. [Google Scholar] [CrossRef]

- Lin, J.-T.; Liu, S.-C.; Hu, C.-C.; Shyu, Y.-S.; Hsu, C.-Y.; Yang, D.-J. Effects of roasting temperature and duration on fatty acid composition, phenolic composition, Maillard reaction degree and antioxidant attribute of almond (Prunus dulcis) kernel. Food Chem. 2016, 190, 520–528. [Google Scholar] [CrossRef] [PubMed]

- Otles, S.; Selek, I. Effect of processing on the phenolic content and antioxidant activity of chestnuts. Qual. Assur. Saf. Crop. Foods 2012, 4, e3–e11. [Google Scholar] [CrossRef]

- Kim, M.J.; Kwak, H.S.; Kim, S.S. Effects of germination on protein, γ-aminobutyric acid, phenolic acids, and antioxidant capacity in wheat. Molecules 2018, 23, 2244. [Google Scholar] [CrossRef] [Green Version]

- Chiang, S.-H.; Tsou, M.-F.; Chang, C.-Y.; Chen, C.-W. Physicochemical characteristics, sensory quality, and antioxidant properties of Paochung tea infusion brewed in cold water. Int. J. Food Prop. 2020, 23, 1611–1623. [Google Scholar] [CrossRef]

- Lin, S.D.; Yang, J.H.; Hsieh, Y.J.; Liu, E.H.; Mau, J.L. Effect of different brewing methods on quality of green tea. J. Food Process. Preserv. 2014, 38, 1234–1243. [Google Scholar] [CrossRef]

| Independent Variables | Notation | Coded Level | ||||

|---|---|---|---|---|---|---|

| −α | −1 | 0 | +1 | +α | ||

| Temperature (°C) | X1 | 132 | 140 | 160 | 180 | 188 |

| Time (min) | X2 | 1.7 | 10 | 30 | 50 | 58 |

| Experiment No. | Actual Level | |

|---|---|---|

| X1 Temperature (°C) | X2 Time (min) | |

| 1 | 140 | 10 |

| 2 | 180 | 10 |

| 3 | 140 | 50 |

| 4 | 180 | 50 |

| 5 | 132 | 30 |

| 6 | 188 | 30 |

| 7 | 160 | 1.7 |

| 8 | 160 | 58 |

| 9 | 160 | 30 |

| 10 | 160 | 30 |

| 11 | 160 | 30 |

| 12 | 160 | 30 |

| 13 | 160 | 30 |

| Experiment No. | Independent Variables | Response Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| X1 Temperature (°C) | X2 Time (min) | Y1 BI *** | Y2 TFC *** (mg CE/g) | Y3 TPC *** (mg GE/g) | Y4 DPPH *** (µM TE/g) | Y5 TEAC *** (mM TE/g) | Y6 GABA *** (mg/g) | |

| 1 | 140 (−1) | 10 (−1) | 35.20 ± 1.24 h | 0.61 ± 0.01 cde | 0.94 ± 0.06 d | 1.30 ± 0.45 g | 3.94 ± 0.46 de | 1.37 ± 0.08 de |

| 2 | 180 (+1) | 10 (−1) | 57.24 ± 2.03 d | 0.62 ± 0.07 cde | 1.13 ± 0.07 cd | 2.98 ± 0.11 cd | 6.48 ± 0.36 de | 1.47 ± 0.03 de |

| 3 | 140 (−1) | 50 (+1) | 44.40 ± 2.11 f | 0.62 ± 0.03 cde | 0.94 ± 0.09 d | 1.95 ± 0.20 ef | 4.72 ± 0.07 de | 1.40 ± 0.10 de |

| 4 | 180 (+1) | 50 (+1) | 84.45 ± 0.77 a | 0.80 ± 0.04 a | 2.05 ± 0.10 a | 5.41 ± 0.50 a | 9.38 ± 0.11 a | 2.59 ± 0.09 a |

| 5 | 132 (−α) | 30 (0) | 42.15 ± 1.12 fg | 0.64 ± 0.07 cd | 0.94 ± 0.04 d | 2.02 ± 0.17 e | 4.77 ± 0.17 d | 1.56 ± 0.08 d |

| 6 | 188 (+α) | 30 (0) | 84.48 ± 1.80 a | 0.76 ± 0.06 ab | 2.04 ± 0.11 a | 4.96 ± 0.10 a | 9.76 ± 0.82 b | 2.08 ± 0.03 b |

| 7 | 160 (0) | 1.7 (−α) | 40.26 ± 1.54 g | 0.68 ± 0.08 bc | 0.93 ± 0.07 d | 1.48 ± 0.33 fg | 3.95 ± 0.01 de | 1.46 ± 0.15 de |

| 8 | 160 (0) | 58 (+α) | 63.53 ± 1.60 c | 0.60 ± 0.01 cde | 1.19 ± 0.08 c | 3.26 ± 0.13 bc | 6.83 ± 0.01 d | 1.55 ± 0.11 d |

| 9 | 160 (0) | 30 (0) | 67.44 ± 0.60 b | 0.56 ± 0.02 de | 1.44 ± 0.04 b | 3.52 ± 0.17 b | 7.53 ± 0.30 c | 1.87 ± 0.12 c |

| 10 | 160 (0) | 30 (0) | 58.31 ± 1.87 d | 0.59 ± 0.03 cde | 1.07 ± 0.09 cd | 2.98 ± 0.13 cd | 6.56 ± 0.47 f | 1.12 ± 0.12 f |

| 11 | 160 (0) | 30 (0) | 51.69 ± 1.40 e | 0.56 ± 0.05 de | 1.08 ± 0.10 cd | 2.63 ± 0.09 d | 6.27 ± 0.22 e | 1.33 ± 0.05 e |

| 12 | 160 (0) | 30 (0) | 51.99 ± 0.29 e | 0.65 ± 0.03 cd | 1.07 ± 0.09 cd | 2.75 ± 0.09 cd | 6.65 ± 0.52 ef | 1.27 ± 0.07 ef |

| 13 | 160 (0) | 30 (0) | 56.17 ± 1.03 d | 0.53 ± 0.02 e | 1.12 ± 0.12 cd | 2.92 ± 0.14 cd | 6.30 ± 0.16 ei | 1.34 ± 0.07 e |

| BI | TFC | TPC | DPPH | TEAC | GABA | ||

|---|---|---|---|---|---|---|---|

| Constant | β0 | 56.72 | 0.5758 | 1.15 | 2.96 | 6.66 | 1.40 |

| Linear | β1 | 15.24 *** | 0.0459 * | 0.3551 *** | 1.16 *** | 1.78 *** | 0.2542 * |

| β2 | 8.67 ** | 0.0096 | 0.1606 * | 0.7014 *** | 0.9684 *** | 0.1611 | |

| Quadratic | β11 | - | 0.0592 * | 0.1661 * | 0.2594 | 0.2515 | 0.2188 |

| β22 | 0.0315 | −0.0507 | −0.3005 * | −0.6842 ** | 0.0615 | ||

| Interaction | β12 | - | 0.0415 | 0.2313 * | 0.4453 * | 0.5277 * | 0.2729 |

| R2 | 0.8631 | 0.7306 | 0.9190 | 0.9637 | 0.9709 | 0.7499 | |

| Adjusted R2 | 0.8357 | 0.5381 | 0.8611 | 0.9377 | 0.9502 | 0.5712 | |

| Lack of Fit (p value) | 0.5627 | 0.2638 | 0.6478 | 0.7288 | 0.9375 | 0.5529 | |

| p value | <0.0001 | 0.0554 | 0.0011 | <0.0001 | <0.0001 | 0.044 | |

| Responses | Goal | Predicted Value | Experimental Value | Absolute Residual Error (%) |

|---|---|---|---|---|

| BI | In range | 78.73 | 73.54 ± 1.80 | 7.06 |

| TFC (mg CE/g) | Maximize | 0.74 | 0.72 ± 0.03 | 3.12 |

| TPC (mg GE/g) | Maximize | 1.95 | 1.96 ± 0.06 | 0.61 |

| DPPH (μM TE/g) | Maximize | 5.10 | 4.66 ± 0.18 | 9.41 |

| TEAC (mM TE/g) | Maximize | 9.45 | 10.20 ± 1.23 | 7.35 |

| GABA (mg/g) | Maximize | 2.25 | 2.46 ± 0.14 | 8.71 |

| Samples | Appearance *** | Odor *** | Taste *** | Overall *** |

|---|---|---|---|---|

| Hot GWB_1 | 5.37 ± 1.37 b | 5.24 ± 1.78 c | 5.32 ± 1.71 c | 5.33 ± 1.77 b |

| Hot GWB_2 | 5.60 ± 1.34 b | 4.97 ± 1.86 c | 5.45 ± 1.79 c | 5.49 ± 1.72 b |

| Hot GWB_3 | 5.58 ± 1.40 b | 5.00 ± 1.78 c | 5.41 ± 1.63 c | 5.42 ± 1.60 b |

| Cold GWB_1 | 6.30 ± 1.26 a | 6.06 ± 1.34 b | 6.32 ± 1.41 ab | 6.38 ± 1.33 a |

| Cold GWB_2 | 6.52 ± 1.18 a | 6.54 ± 1.30 a | 6.62 ± 1.47 a | 6.54 ± 1.41 a |

| Cold GWB_3 | 6.45 ± 1.35 a | 6.20 ± 1.38 ab | 5.99 ± 1.88 b | 6.13 ± 1.75 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aung, T.; Kim, B.R.; Kim, M.J. Optimized Roasting Conditions of Germinated Wheat for a Novel Cereal Beverage and Its Sensory Properties. Foods 2022, 11, 481. https://doi.org/10.3390/foods11030481

Aung T, Kim BR, Kim MJ. Optimized Roasting Conditions of Germinated Wheat for a Novel Cereal Beverage and Its Sensory Properties. Foods. 2022; 11(3):481. https://doi.org/10.3390/foods11030481

Chicago/Turabian StyleAung, Thinzar, Bo Ram Kim, and Mi Jeong Kim. 2022. "Optimized Roasting Conditions of Germinated Wheat for a Novel Cereal Beverage and Its Sensory Properties" Foods 11, no. 3: 481. https://doi.org/10.3390/foods11030481