Effects of Concentration of Soybean Protein Isolate and Maltose and Oil Phase Volume Fraction on Freeze–Thaw Stability of Pickering Emulsion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Dispersions Containing Soy Protein Isolate and Maltose

2.3. Characterization of SPI–maltose Particles

2.4. Determination of SPI–maltose H0

2.5. Interfacial Behavior of Nanoparticles

2.6. Preparation of Pickering Emulsions

2.7. Stability Analysis of Pickering Emulsion

2.8. Confocal Laser Scanning Microscope (CLSM)

2.9. Rheological Measurement

2.10. Differential Scanning Calorimetry (DSC)

2.11. Statistical Analysis

3. Results

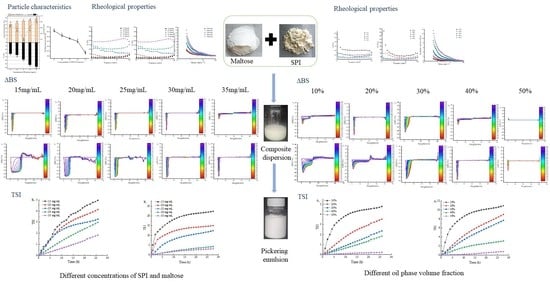

3.1. Particle Size and Potential Change of SPI–maltose

3.2. The H0 of SPI–maltose

3.3. The Interfacial Tension of SPI–maltose

3.4. Pickering Emulsion’s Freeze–thaw Stability

3.5. The CLSM of Pickering Emulsion

3.6. Rheological Properties of the Pickering Emulsion

3.7. Pickering Emulsion’s Thermal Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Zhu, F. Frozen steamed breads and boiled noodles: Quality affected by ingredients and processing. Food Chem. 2021, 349, 129178. [Google Scholar] [CrossRef] [PubMed]

- Degner, B.M.; Chung, C.; Schlegel, V.; Hutkins, R.; McClements, D. Factors Influencing the Freeze-Thaw Stability of Emulsion-Based Foods. Compr. Rev. Food Sci. Food Saf. 2014, 13, 98–113. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.; Cui, Q.; Zhou, M.; Wang, X.; Zhao, X.-H. Improving freeze–thaw stability of soy protein isolate-glucosamine emulsion by transglutaminase glycosylation. Food Bioprod. Process. 2021, 128, 77–83. [Google Scholar] [CrossRef]

- Yan, X.; Ma, C.; Cui, F.; McClements, D.J.; Liu, X.; Liu, F. Protein-stabilized Pickering emulsions: Formation, stability, properties, and applications in foods. Trends Food Sci. Technol. 2020, 103, 293–303. [Google Scholar] [CrossRef]

- Doost, A.S.; Nasrabadi, M.N.; Kassozi, V.; Dewettinck, K.; Stevens, C.V.; Van der Meeren, P. Pickering stabilization of thymol through green emulsification using soluble fraction of almond gum—Whey protein isolate nano-complexes. Food Hydrocoll. 2018, 88, 218–227. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Yang, J.; Shao, G.; Qu, D.; Zhao, H.; Yang, L.; Zhu, L.; He, Y.; Liu, H.; Zhu, D. Soy protein isolated-soy hull polysaccharides stabilized O/W emulsion: Effect of polysaccharides concentration on the storage stability and interfacial rheological properties. Food Hydrocoll. 2019, 101, 105490. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, B.; Adhikari, B. Maillard reaction between pea protein isolate and maltodextrin via wet-heating route for emulsion stabilisation. Futur. Foods 2022, 6, 100193. [Google Scholar] [CrossRef]

- Zhu, X.-F.; Zhang, N.; Lin, W.-F.; Tang, C.-H. Freeze-thaw stability of Pickering emulsions stabilized by soy and whey protein particles. Food Hydrocoll. 2017, 69, 173–184. [Google Scholar] [CrossRef]

- Zhu, X.-F.; Zheng, J.; Liu, F.; Qiu, C.-Y.; Lin, W.-F.; Tang, C.-H. Freeze-thaw stability of Pickering emulsions stabilized by soy protein nanoparticles. Influence of ionic strength before or after emulsification. Food Hydrocoll. 2018, 74, 37–45. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, J.; Chen, J.; Wang, Z.; Wang, X.; Zhong, J. Protein nanoparticles for Pickering emulsions: A comprehensive review on their shapes, preparation methods, and modification methods. Trends Food Sci. Technol. 2021, 113, 26–41. [Google Scholar] [CrossRef]

- Lang, A.; Lan, W.; Gu, Y.; Wang, Z.; Xie, J. Effects of ε -polylysine and chitooligosaccharide Maillard reaction products on quality of refrigerated sea bass fillets. J. Sci. Food Agric. 2022, 103, 152–163. [Google Scholar] [CrossRef] [PubMed]

- Binks, B.P.; Horozov, T.S. (Eds.) Colloidal Particles at Liquid Interfaces; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Wang, Y.; Zhang, A.; Wang, X.; Xu, N.; Jiang, L. The radiation assisted-Maillard reaction comprehensively improves the freeze-thaw stability of soy protein-stabilized oil-in-water emulsions. Food Hydrocoll. 2020, 103, 105684. [Google Scholar] [CrossRef]

- Wu, Y.; Mou, T.; Ma, K.; Fan, F. Color-based clustering algorithm as a novel image analytical method for characterizing maltose crystallinity in amorphous food models. Food Res. Int. 2021, 144, 110367. [Google Scholar] [CrossRef] [PubMed]

- Ding, M.; Liu, L.; Zhang, T.; Tao, N.; Wang, X.; Zhong, J. Effect of interfacial layer number on the storage stability and in vitro digestion of fish oil-loaded multilayer emulsions consisting of gelatin particle and polysaccharides. Food Chem. 2020, 336, 127686. [Google Scholar] [CrossRef] [PubMed]

- Cabezas, D.M.; Pascual, G.N.; Wagner, J.R.; Palazolo, G.G. Nanoparticles assembled from mixtures of whey protein isolate and soluble soybean polysaccharides. Structure, interfacial behavior and application on emulsions subjected to freeze-thawing. Food Hydrocoll. 2019, 95, 445–453. [Google Scholar] [CrossRef]

- Chen, F.P.; Li, B.S.; Tang, C.H. Nano-complexation between curcumin and soy protein isolate: Influence on curcumin stability/bio-accessibility and in vitro protein digestibility. J. Agric. Food Chem. 2015, 63, 3559–3569. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Guo, S.; Li, X.; Jiang, S.; Zhong, X.; Zheng, Z. Gel properties of transglutaminase-induced soy protein isolate–polyphenol complex: Influence of epigallocatechin-3-gallate. J. Sci. Food Agric. 2021, 101, 3870–3879. [Google Scholar] [CrossRef]

- Feng, J.; Yan, Z.; Song, J.; He, J.; Zhao, G.; Fan, H. Study on the structure-activity relationship between the molecular structure of sulfate gemini surfactant and surface activity, thermodynamic properties and foam properties. Chem. Eng. Sci. 2021, 245, 116857. [Google Scholar] [CrossRef]

- Zhu, X.-F.; Zheng, J.; Liu, F.; Qiu, C.-Y.; Lin, W.-F.; Tang, C.-H. The influence of ionic strength on the characteristics of heat-induced soy protein aggregate nanoparticles and the freeze–thaw stability of the resultant Pickering emulsions. Food Funct. 2017, 8, 2974–2981. [Google Scholar] [CrossRef]

- Gmach, O.; Golda, J.; Kulozik, U. Freeze-thaw stability of emulsions made with native and enzymatically modified egg yolk fractions. Food Hydrocoll. 2021, 123, 107109. [Google Scholar] [CrossRef]

- Zhu, Y.; McClements, D.J.; Zhou, W.; Peng, S.; Zhou, L.; Zou, L.; Liu, W. Influence of ionic strength and thermal pretreatment on the freeze-thaw stability of Pickering emulsion gels. Food Chem. 2019, 303, 125401. [Google Scholar] [CrossRef]

- Puppo, M.; Beaumal, V.; Chapleau, N.; Speroni, F.; de Lamballerie, M.; Añón, M.; Anton, M. Physicochemical and rheological properties of soybean protein emulsions processed with a combined temperature/high-pressure treatment. Food Hydrocoll. 2008, 22, 1079–1089. [Google Scholar] [CrossRef]

- Chen, Y.-B.; Zhu, X.-F.; Liu, T.-X.; Lin, W.-F.; Tang, C.-H.; Liu, R. Improving freeze-thaw stability of soy nanoparticle-stabilized emulsions through increasing particle size and surface hydrophobicity. Food Hydrocoll. 2018, 87, 404–412. [Google Scholar] [CrossRef]

- Kan, X.; Chen, G.; Zhou, W.; Zeng, X. Application of protein-polysaccharide Maillard conjugates as emulsifiers: Source, preparation and functional properties. Food Res. Int. 2021, 150, 110740. [Google Scholar] [CrossRef] [PubMed]

- Hao, Z.-Z.; Peng, X.-Q.; Tang, C.-H. Edible Pickering high internal phase emulsions stabilized by soy glycinin: Improvement of emulsification performance and Pickering stabilization by glycation with soy polysaccharide. Food Hydrocoll. 2020, 103, 105672. [Google Scholar] [CrossRef]

- Dickinson, E. Interfacial structure and stability of food emulsions as affected by protein–polysaccharide interactions. Soft Matter 2008, 4, 932–942. [Google Scholar] [CrossRef]

- Jafari, S.M.; Doost, A.S.; Nasrabadi, M.N.; Boostani, S.; Van der Meeren, P. Phytoparticles for the stabilization of Pickering emulsions in the formulation of novel food colloidal dispersions. Trends Food Sci. Technol. 2020, 98, 117–128. [Google Scholar] [CrossRef]

- Marefati, A.; Rayner, M.; Timgren, A.; Dejmek, P.; Sjöö, M. Freezing and freeze-drying of Pickering emulsions stabilized by starch granules. Colloids Surf. A Physicochem. Eng. Asp. 2013, 436, 512–520. [Google Scholar] [CrossRef]

- Cornacchia, L.; Roos, Y.H. Lipid and water crystallization in protein-stabilised oil-in-water emulsions. Food Hydrocoll. 2011, 25, 1726–1736. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, J.; Cao, Y.; Wang, J.; Xiao, J. Influence of microcrystalline cellulose on the microrheological property and freeze-thaw stability of soybean protein hydrolysate stabilized curcumin emulsion. LWT-Food Sci. Technol. 2016, 66, 590–597. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Jia, H.; Gao, G.; Wang, X.; Zhang, X.; Wang, Y. Using Cellulose Nanofibers and Its Palm Oil Pickering Emulsion as Fat Substitutes in Emulsified Sausage. J. Food Sci. 2018, 83, 1740–1747. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Jiao, Q.; Wang, L.; Zhang, Y.; Jiang, B.; Li, D.; Feng, Z.; Liu, C. Preparation and evaluation of a novel high internal phase Pickering emulsion based on whey protein isolate nanofibrils derived by hydrothermal method. Food Hydrocoll. 2021, 123, 107180. [Google Scholar] [CrossRef]

- Borderías, A.J.; Tovar, C.A.; Domínguez-Timón, F.; Díaz, M.T.; Pedrosa, M.M.; Moreno, H.M. Characterization of healthier mixed surimi gels obtained through partial substitution of myofibrillar proteins by pea protein isolates. Food Hydrocoll. 2020, 107, 105976. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Liu, C.; Liu, C. Application of LF-NMR to the characterization of camellia oil-loaded pickering emulsion fabricated by soy protein isolate. Food Hydrocoll. 2020, 112, 106329. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, X.; Gong, Y.; Li, Z.; Guo, Y.; Yu, D.; Pan, M. Emulsion gels stabilized by soybean protein isolate and pectin: Effects of high intensity ultrasound on the gel properties, stability and β-carotene digestive characteristics. Ultrason. Sonochemistry 2021, 79, 105756. [Google Scholar] [CrossRef]

- Rajasekaran, B.; Singh, A.; Nagarajan, M.; Benjakul, S. Effect of chitooligosaccharide and α-tocopherol on physical properties and oxidative stability of shrimp oil-in-water emulsion stabilized by bovine serum albumin-chitosan complex. Food Control. 2022, 137, 108899. [Google Scholar] [CrossRef]

- Huang, X.; Tu, R.; Song, H.; Dong, K.; Geng, F.; Chen, L.; Huang, Q.; Wu, Y. Fabrication of gelatin-EGCG-pectin ternary complex stabilized W/O/W double emulsions by ultrasonic emulsification: Physicochemical stability, rheological properties and structure. J. Food Eng. 2023, 338, 111259. [Google Scholar] [CrossRef]

| Concentrations (mg/mL) | Shear Rate (S−1) | ||

|---|---|---|---|

| 0.5–100 | |||

| N | K/(Pa·Sn) | R2 | |

| 15 | 0.229 ± 0.012 a | 2.123 ± 0.137 e | 0.982 |

| 20 | 0.225 ± 0.010 b | 2.528 ± 0.186 d | 0.987 |

| 25 | 0.230 ± 0.011 a | 4.537 ± 0.157 c | 0.989 |

| 30 | 0.220 ± 0.009 c | 6.886 ± 0.264 b | 0.984 |

| 35 | 0.191 ± 0.007 d | 8.663 ± 0.356 a | 0.978 |

| Oil Phase Volume Fraction/(%) | Shear Rate (S−1) | ||

|---|---|---|---|

| 0.5–100 | |||

| N | K/(Pa·Sn) | R2 | |

| 10 | 0.148 ± 0.003 b | 0.567 ± 0.023 e | 0.989 |

| 20 | 0.148 ± 0.002 b | 1.13426 ± 0.054 d | 0.989 |

| 30 | 0.148 ± 0.001 b | 2.26852 ± 0.126 c | 0.989 |

| 40 | 0.148 ± 0.004 b | 4.53703 ± 0.275 b | 0.989 |

| 50 | 0.230 ± 0.014 a | 6.88594 ± 0.327 a | 0.984 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.; Yang, Y.; Chen, F.; Fan, J.; Wang, B.; Bian, X.; Xu, Y.; Liu, B.; Fu, Y.; Shi, Y.; et al. Effects of Concentration of Soybean Protein Isolate and Maltose and Oil Phase Volume Fraction on Freeze–Thaw Stability of Pickering Emulsion. Foods 2022, 11, 4018. https://doi.org/10.3390/foods11244018

Song Z, Yang Y, Chen F, Fan J, Wang B, Bian X, Xu Y, Liu B, Fu Y, Shi Y, et al. Effects of Concentration of Soybean Protein Isolate and Maltose and Oil Phase Volume Fraction on Freeze–Thaw Stability of Pickering Emulsion. Foods. 2022; 11(24):4018. https://doi.org/10.3390/foods11244018

Chicago/Turabian StyleSong, Ziyue, Yang Yang, Fenglian Chen, Jing Fan, Bing Wang, Xin Bian, Yue Xu, Baoxiang Liu, Yao Fu, Yanguo Shi, and et al. 2022. "Effects of Concentration of Soybean Protein Isolate and Maltose and Oil Phase Volume Fraction on Freeze–Thaw Stability of Pickering Emulsion" Foods 11, no. 24: 4018. https://doi.org/10.3390/foods11244018