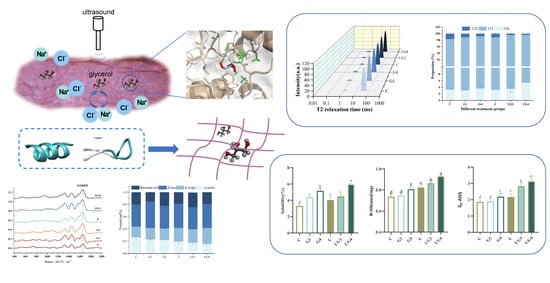

Effect of Ultrasound Combined with Glycerol-Mediated Low-Sodium Curing on the Quality and Protein Structure of Pork Tenderloin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Treatment of Pork Loin and Preparation of MP Extracts

2.3. Measurement of Quality Traits

2.4. Low-Field Nuclear Magnetic Resonance (LF-NMR)

2.5. Solubility

2.6. Reactive Sulfhydryl Groups (R-SH)

2.7. Surface Hydrophobicity (S0-ANS)

2.8. Raman Spectra Measurements

2.9. UV Second Derivative Absorption Spectra

2.10. Scanning Electron Microscope (SEM)

2.11. Statistical Analysis

3. Results and Discussion

3.1. Quality Indicators

3.1.1. aw

3.1.2. Salt Content

3.1.3. Cooking Loss

3.1.4. Analysis of Texture Parameters

3.2. LF-NMR

3.3. Solubility

3.4. R-SH Content

3.5. S0-ANS

3.6. Secondary Structure

3.7. UV Second Derivative Absorption Spectra

3.8. SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Inguglia, E.S.; Zhang, Z.; Tiwari, B.K.; Kerry, J.P.; Burgess, C.M. Salt reduction strategies in processed meat products—A review. Trends Food Sci. Tech. 2017, 59, 70–78. [Google Scholar] [CrossRef]

- Hoppu, U.; Hopia, A.; Pohjanheimo, T.; Rotola-Pukkila, M.; Makinen, S.; Pihlanto, A.; Sandell, M. Effect of Salt Reduction on Consumer Acceptance and Sensory Quality of Food. Foods 2017, 6, 103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kloss, L.; Meyer, J.D.; Graeve, L.; Vetter, W. Sodium intake and its reduction by food reformulation in the European Union—A review. NFS J. 2015, 1, 9–19. [Google Scholar] [CrossRef] [Green Version]

- Jankovic, S.; Nikolic, D.; Djinovic-Stojanovic, J.; Radicevic, T.; Stefanovic, S.; Spiric, D.; Jovanovic, J. Sodium intake associated with meat product consumption in Serbia. IOP Conf. Ser. Earth Environ. Sci. 2019, 333, 012065. [Google Scholar] [CrossRef] [Green Version]

- Bhana, N.; Utter, J.; Eyles, H. Knowledge, Attitudes and Behaviours Related to Dietary Salt Intake in High-Income Countries: A Systematic Review. Curr. Nutr. Rep. 2018, 7, 183–197. [Google Scholar] [CrossRef]

- Desmond, E. Reducing salt: A challenge for the meat industry. Meat Sci. 2006, 74, 188–196. [Google Scholar] [CrossRef]

- Agarwal, S.; Fulgoni, V.L., 3rd; Spence, L.; Samuel, P. Sodium intake status in United States and potential reduction modeling: An NHANES 2007–2010 analysis. Food Sci. Nutr. 2015, 3, 577–585. [Google Scholar] [CrossRef]

- Barcenilla, C.; Alvarez-Ordonez, A.; Lopez, M.; Alvseike, O.; Prieto, M. Microbiological Safety and Shelf-Life of Low-Salt Meat Products—A Review. Foods 2022, 11, 2331. [Google Scholar] [CrossRef]

- Petit, G.; Jury, V.; de Lamballerie, M.; Duranton, F.; Pottier, L.; Martin, J.L. Salt Intake from Processed Meat Products: Benefits, Risks and Evolving Practices. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1453–1473. [Google Scholar] [CrossRef] [Green Version]

- Gong, X.; Wan, J.; Zhou, Y.; Zhou, Y.; Zhu, Q.; Liu, L.; Chen, D.; Huang, Y.; Gu, S.; Li, M. Mediated curing strategy: An overview of salt reduction for dry-cured meat products. Food Rev. Int. 2022, 1–16. [Google Scholar] [CrossRef]

- Cui, H.; Xue, C.; Xue, Y.; Su, W.; Li, Z.; Cong, H. Development of shelf-stable, ready-to-eat (RTE) shrimps (Litopenaeus vannamei) using water activity lowering agent by response surface methodology. J. Food Sci. Tech. Mysore 2013, 50, 1137–1143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, M.; Zhu, K.; Guo, X.; Peng, W.; Zhou, H. Effect of water activity (aw) and irradiation on the shelf-life of fresh noodles. Innov. Food Sci. Emerg. 2011, 12, 526–530. [Google Scholar] [CrossRef]

- Semenoglou, I.; Dimopoulos, G.; Tsironi, T.; Taoukis, P. Mathematical modelling of the effect of solution concentration and the combined application of pulsed electric fields on mass transfer during osmotic dehydration of sea bass fillets. Food Bioprod. Process. 2020, 121, 186–192. [Google Scholar] [CrossRef]

- Liu, C.; Wan, J.; Zhou, Y.; Hu, K.; Zhu, Q.; Tang, P.; Xu, S.; Song, L. Proteome profile of glycrol-mediated salt-reduction cured meat reveals the formation mechanism of eating quality. Food Chem. 2022, 382, 132395. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.; Ma, Y.; Lei, Y.; Zhu, X.; Zhang, L.; Hu, L.; Lu, S.; Guo, X.; Zhang, J. Ultrasonic structural modification of myofibrillar proteins from Coregonus peled improves emulsification properties. Ultrason. Sonochem. 2021, 76, 105659. [Google Scholar] [CrossRef] [PubMed]

- Barbhuiya, R.I.; Singha, P.; Singh, S.K. A comprehensive review on impact of non-thermal processing on the structural changes of food components. Food Res. Int. 2021, 149, 110647. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, Y.; Zhou, Y.; Leng, Y. Effect of ultrasonic-assisted brining on mass transfer of beef. J. Food Process Eng. 2019, 42, e13257. [Google Scholar] [CrossRef]

- Shahabi Mohammadabadi, S.; Goli, M.; Naji Tabasi, S. Optimization of Bioactive Compound Extraction from Eggplant Peel by Response Surface Methodology: Ultrasound-Assisted Solvent Qualitative and Quantitative Effect. Foods. 2022, 11, 3263. [Google Scholar] [CrossRef]

- Carcel, J.A.; Benedito, J.; Bon, J.; Mulet, A. High intensity ultrasound effects on meat brining. Meat Sci. 2007, 76, 611–619. [Google Scholar] [CrossRef]

- Kang, D.C.; Gao, X.Q.; Ge, Q.F.; Zhou, G.H.; Zhang, W.G. Effects of ultrasound on the beef structure and water distribution during curing through protein degradation and modification. Ultrason. Sonochem. 2017, 38, 317–325. [Google Scholar] [CrossRef]

- Kang, D.C.; Zou, Y.H.; Cheng, Y.P.; Xing, L.J.; Zhou, G.H.; Zhang, W.G. Effects of power ultrasound on oxidation and structure of beef proteins during curing processing. Ultrason. Sonochem. 2016, 33, 47–53. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, M.; Liu, H.; Li, Q.; Xue, D.; Nian, Y.; Zhao, D.; Shan, K.; Dai, C.; Li, C. Ultrasound treatment can increase digestibility of myofibrillar protein of pork with modified atmosphere packaging. Food Chem. 2022, 377, 131811. [Google Scholar] [CrossRef] [PubMed]

- Van Nguyen, M.; Thorarinsdottir, K.A.; Gudmundsdottir, A.; Thorkelsson, G.; Arason, S. The effects of salt concentration on conformational changes in cod (Gadus morhua) proteins during brine salting. Food Chem. 2011, 125, 1013–1019. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, Y.; Wan, J.; Zhu, Q.; Bi, S.; Zhou, Y.; Gu, S.; Chen, D.; Huang, Y.; Hu, B. Mechanism of polyhydroxy alcohol-mediated curing on moisture migration of minced pork tenderloin: On the basis of molecular docking. Food Chem. X 2022, 15, 100401. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Li, D.; Zhou, Y. Effect of xanthan gum on the quality of low sodium salted beef and property of myofibril proteins. Food Sci. Hum. Wellness 2021, 10, 112–118. [Google Scholar] [CrossRef]

- Guo, X.; Tao, S.; Pan, J.; Lin, X.; Ji, C.; Liang, H.; Dong, X.; Li, S. Effects of l-Lysine on the physiochemical properties and sensory characteristics of salt-reduced reconstructed ham. Meat Sci. 2020, 166, 108133. [Google Scholar] [CrossRef]

- Walayat, N.; Wang, X.; Liu, J.; Nawaz, A.; Zhang, Z.; Khalifa, I.; Rincón Cervera, M.Á.; Pateiro, M.; Lorenzo, J.M.; Nikoo, M.; et al. Kappa-carrageenan as an effective cryoprotectant on water mobility and functional properties of grass carp myofibrillar protein gel during frozen storage. LWT 2022, 154, 112675. [Google Scholar] [CrossRef]

- Zhao, X.; Qi, J.; Fan, C.; Wang, B.; Yang, C.; Liu, D. Ultrasound treatment enhanced the ability of the porcine myofibrillar protein to bind furan compounds: Investigation of underlying mechanisms. Food Chem. 2022, 384, 132472. [Google Scholar] [CrossRef]

- Kang, Z.L.; Zhang, X.H.; Li, X.; Song, Z.J.; Ma, H.J.; Lu, F.; Zhu, M.M.; Zhao, S.M.; Wang, Z.R. The effects of sodium chloride on proteins aggregation, conformation and gel properties of pork myofibrillar protein Running Head: Relationship aggregation, conformation and gel properties. J. Food Sci. Technol. 2021, 58, 2258–2264. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Yang, Y.; Tang, X.; Chen, Y.; You, Y. Chemical forces and water holding capacity study of heat-induced myofibrillar protein gel as affected by high pressure. Food Chem. 2015, 188, 111–118. [Google Scholar] [CrossRef]

- Zhuang, X.; Han, M.; Bai, Y.; Liu, Y.; Xing, L.; Xu, X.-l.; Zhou, G.-h. Insight into the mechanism of myofibrillar protein gel improved by insoluble dietary fiber. Food Hydrocolloid. 2018, 74, 219–226. [Google Scholar] [CrossRef]

- Zhang, M.; Li, F.; Diao, X.; Kong, B.; Xia, X. Moisture migration, microstructure damage and protein structure changes in porcine longissimus muscle as influenced by multiple freeze-thaw cycles. Meat Sci. 2017, 133, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Ma, W.; Xian, Z.; Liu, Q.; Hui, A.; Zhang, W. The impact of quick-freezing methods on the quality, moisture distribution and microstructure of prepared ground pork during storage duration. Ultrason. Sonochem. 2021, 78, 105707. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, J.; Zhou, L.; Wang, L.; Zhang, W. Influence of ultrasound-assisted tumbling on NaCl transport and the quality of pork. Ultrason. Sonochem. 2021, 79, 105759. [Google Scholar] [CrossRef] [PubMed]

- Inguglia, E.S.; Zhang, Z.; Burgess, C.; Kerry, J.P.; Tiwari, B.K. Influence of extrinsic operational parameters on salt diffusion during ultrasound assisted meat curing. Ultrasonics 2018, 83, 164–170. [Google Scholar] [CrossRef] [PubMed]

- Checmarev, G.; Casales, M.R.; Yeannes, M.I.; Bevilacqua, A.E. Mass Transfer Modeling during Osmotic Dehydration of Chub Mackerel (Scomber japonicus) Slices in Salt and Glycerol Solution at Different Temperatures. J. Food Process. Pres. 2014, 38, 1599–1607. [Google Scholar] [CrossRef]

- Kang, D.; Zhang, W.; Lorenzo, J.M.; Chen, X. Structural and functional modification of food proteins by high power ultrasound and its application in meat processing. Crit. Rev. Food Sci. Nutr. 2021, 61, 1914–1933. [Google Scholar] [CrossRef]

- Sorapukdee, S.; Uesakulrungrueng, C.; Pilasombut, K. Effects of Humectant and Roasting on Physicochemical and Sensory Properties of Jerky Made from Spent Hen Meat. Korean J. Food Sci. Anim. Resour. 2016, 36, 326–334. [Google Scholar] [CrossRef] [Green Version]

- Yeung, C.K.; Huang, S.C. Effects of Ultrasound Pretreatment and Ageing Processing on Quality and Tenderness of Pork Loin. J. Food Nutr. Res. 2017, 5, 809–816. [Google Scholar] [CrossRef]

- Suslick, K.S.; Flannigan, D.J. Inside a collapsing bubble: Sonoluminescence and the conditions during cavitation. Annu. Rev. Phys. Chem. 2008, 59, 659–683. [Google Scholar] [CrossRef]

- Pan, Q.; Yang, G.H.; Wang, Y.; Wang, X.X.; Zhou, Y.; Li, P.J.; Chen, C.G. Application of ultrasound-assisted and tumbling dry-curing techniques for reduced-sodium bacon. J. Food Process. Pres. 2020, 44, e14607. [Google Scholar] [CrossRef]

- Ojha, K.S.; Keenan, D.F.; Bright, A.; Kerry, J.P.; Tiwari, B.K. Ultrasound assisted diffusion of sodium salt replacer and effect on physicochemical properties of pork meat. Int. J. Food Sci. Tech. 2016, 51, 37–45. [Google Scholar] [CrossRef]

- Baier, S.K.; McClements, D.J. Impact of sorbitol on the thermostability and heat-induced gelation of bovine serum albumin. Food Res. Int. 2003, 36, 1081–1087. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, X.; Xue, S.; Xu, X. Effects of ultrasound frequency mode on myofibrillar protein structure and emulsifying properties. Int. J. Biol. Macromol. 2020, 163, 1768–1779. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.P.; Zhang, X.H.; Lu, F.; Kang, Z.L. Effect of sodium bicarbonate and sodium chloride on aggregation and conformation of pork myofibrillar protein. Food Chem. 2021, 350, 129233. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Xing, L.; Kang, D.; Zhou, L.; Wang, L.; Zhang, W. Effects of ultrasound-assisted vacuum tumbling on the oxidation and physicochemical properties of pork myofibrillar proteins. Ultrason. Sonochem. 2021, 74, 105582. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Lian, H.; Jia, H.; Li, S.; Hao, R.; Wang, Y.; Zhang, X.; Dong, X. Ultrasound treatment modified the functional mode of gallic acid on properties of fish myofibrillar protein. Food Chem. 2020, 320, 126637. [Google Scholar] [CrossRef] [PubMed]

- Herrero, A.M. Raman Spectroscopy for Monitoring Protein Structure in Muscle Food Systems. Crit. Rev. Food Sci. Nutr. 2008, 48, 512–523. [Google Scholar] [CrossRef] [PubMed]

- Hirai, M.; Ajito, S.; Sugiyama, M.; Iwase, H.; Takata, S.I.; Shimizu, N.; Igarashi, N.; Martel, A.; Porcar, L. Direct Evidence for the Effect of Glycerol on Protein Hydration and Thermal Structural Transition. Biophys. J. 2018, 115, 313–327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, Q.; Yu, Z.; Zeng, W. Structural and functional modifications of myofibrillar protein by natural phenolic compounds and their application in pork meatball. Food Res. Int. 2021, 148, 110593. [Google Scholar] [CrossRef] [PubMed]

- Nian, L.; Cao, A.; Cai, L.; Ji, H.; Liu, S. Effect of vacuum impregnation of red sea bream (Pagrosomus major) with herring AFP combined with CS@Fe3O4 nanoparticles during freeze-thaw cycles. Food Chem. 2019, 291, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Sun, X.; Wei, Y.; Ma, Y.; Sun, P.; Li, X. Effects of ultrasonic treatment on physico-chemical properties and structure of tuna (Thunnus tonggol) myofibrillar proteins. J. Food Compos. Anal. 2022, 108, 104438. [Google Scholar] [CrossRef]

- Wang, X.; Feng, T.; Wang, X.; Zhang, X.; Xia, S. Gelation and microstructural properties of fish myofibrillar protein gels with the incorporation of l-lysine and l-arginine at low ionic strength. J. Sci. Food Agric. 2021, 101, 5469–5477. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Y.; Tayyab Rashid, M.; Yan, J.K.; Ma, H. Effect of multi-frequency ultrasound thawing on the structure and rheological properties of myofibrillar proteins from small yellow croaker. Ultrason. Sonochem. 2021, 70, 105352. [Google Scholar] [CrossRef] [PubMed]

| Samples | aw | Salt Content | Cooking Loss (%) | TPA | ||

|---|---|---|---|---|---|---|

| Hardness (gf) | Chewiness (gf) | Springiness | ||||

| C | 0.967 ± 0.007 a | 0.277 ± 0.006 b | 19.233 ± 1.150 a | 8406.980 ± 397.972 a | 3421.360 ± 145.948 a | 0.902 ± 0.478 a |

| G1 | 0.962 ± 0.002 ab | 0.267 ± 0.006 bc | 18.410 ± 0.577 a | 7129.688 ± 235.097 bc | 2784.278 ± 278.093 ab | 0.893 ± 0.465 a |

| G4 | 0.954 ± 0.003 bc | 0.263 ± 0.006 c | 16.307 ± 0.670 b | 6751.389 ± 125.456 cd | 2318.975 ± 309.291 bc | 0.584 ± 0.496 b |

| U | 0.952 ± 0.004 cd | 0.327 ± 0.006 a | 16.973 ± 0.468 b | 7555.964 ± 458.378 a | 2885.084 ± 321.206 ab | 0.682 ± 0.163 ab |

| UG1 | 0.946 ± 0.002 d | 0.263 ± 0.006 c | 16.746 ± 0.783 b | 6176.572 ± 370.174 de | 2284.247 ± 512.911 bc | 0.760 ± 0.196 ab |

| UG4 | 0.944 ± 0.002 d | 0.243 ± 0.006 d | 14.637 ± 0.389 c | 5575.223 ± 415.194 e | 1736.976 ± 445.675 c | 0.547 ± 0.056 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, S.; Zhu, Q.; Zhou, Y.; Wan, J.; Liu, L.; Zhou, Y.; Chen, D.; Huang, Y.; Chen, L.; Zhong, X. Effect of Ultrasound Combined with Glycerol-Mediated Low-Sodium Curing on the Quality and Protein Structure of Pork Tenderloin. Foods 2022, 11, 3798. https://doi.org/10.3390/foods11233798

Gu S, Zhu Q, Zhou Y, Wan J, Liu L, Zhou Y, Chen D, Huang Y, Chen L, Zhong X. Effect of Ultrasound Combined with Glycerol-Mediated Low-Sodium Curing on the Quality and Protein Structure of Pork Tenderloin. Foods. 2022; 11(23):3798. https://doi.org/10.3390/foods11233798

Chicago/Turabian StyleGu, Sha, Qiujin Zhu, Ying Zhou, Jing Wan, Linggao Liu, Yeling Zhou, Dan Chen, Yanpei Huang, Li Chen, and Xiaolin Zhong. 2022. "Effect of Ultrasound Combined with Glycerol-Mediated Low-Sodium Curing on the Quality and Protein Structure of Pork Tenderloin" Foods 11, no. 23: 3798. https://doi.org/10.3390/foods11233798