Influence of Emulsifying Salts on the Growth of Bacillus thuringiensis CFBP 3476 and Clostridium perfringens ATCC 13124 in Processed Cheese

Abstract

:1. Introduction

2. Materials and Methods

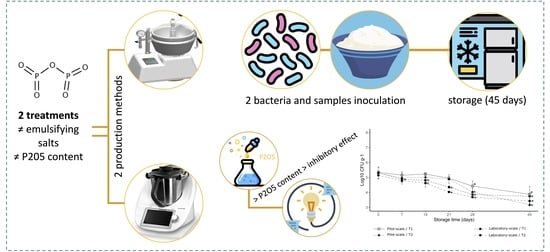

2.1. Materials and Treatments

2.2. In Vitro Inhibitory Activity

2.3. In Situ Inhibitory Activity

2.3.1. Production of Processed Cheese

2.3.2. Microbiological Analyses

2.3.3. Water Activity and pH

2.4. Statistical Analysis

3. Results

3.1. In Vitro Inhibitory Activity

3.2. In Situ Inhibitory Activity

3.3. Water Activity and pH

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Processed Cheese and Substitute/Imitation Cheese Products. In Fundamentals of Cheese Science; Springer: Berlin, Germany, 2017; pp. 589–627. [Google Scholar]

- Ramel, P.R.; Marangoni, A.G. Processed Cheese as a Polymer Matrix Composite: A Particle Toolkit for the Replacement of Milk Fat with Canola Oil in Processed Cheese. Food Res. Int. 2018, 107, 110–118. [Google Scholar] [CrossRef] [PubMed]

- Farahat, E.S.A.; Mohamed, A.G.; El-Loly, M.M.; Gafour, W.A.M.S. Innovative Vegetables-Processed Cheese: I. Physicochemical, Rheological and Sensory Characteristics. Food Biosci. 2021, 42, 101128. [Google Scholar] [CrossRef]

- Vollmer, A.H.; Kieferle, I.; Youssef, N.N.; Kulozik, U. Mechanisms of Structure Formation Underlying the Creaming Reaction in a Processed Cheese Model System as Revealed by Light and Transmission Electron Microscopy. J. Dairy Sci. 2021, 104, 9505–9520. [Google Scholar] [CrossRef] [PubMed]

- Buňka, F.; Černíková, M.; Salek, R.N. Chapter 6—Functionality of Salts Used in Processed Cheese Manufacture. In Processed Cheese Science and Technology; El-Bakry, M., Mehta, B.M., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 147–176. ISBN 9780128214459. [Google Scholar]

- Noronha, N.; O’Riordan, E.D.; O’Sullivan, M. Influence of Processing Parameters on the Texture and Microstructure of Imitation Cheese. Eur. Food Res. Technol. 2008, 226, 385–393. [Google Scholar] [CrossRef]

- McIntyre, I.; O’Sullivan, M.; O’Riordan, D. Monitoring the Progression of Calcium and Protein Solubilisation as Affected by Calcium Chelators during Small-Scale Manufacture of Casein-Based Food Matrices. Food Chem. 2017, 237, 597–604. [Google Scholar] [CrossRef] [PubMed]

- Guinee, T.P.; Carić, M.; Kaláb, M. Pasteurized Processed Cheese and Substitute/Imitation Cheese Products. In Cheese: Chemistry, Physics and Microbiology; Fox, P.F., McSweeney, P.L.H., Cogan, T.M., Guinee, T.P., Eds.; Academic Press: New York, NY, USA, 2004; Volume 2, pp. 349–394. [Google Scholar]

- Talbot-Walsh, G.; Kannar, D.; Selomulya, C. A Review on Technological Parameters and Recent Advances in the Fortification of Processed Cheese. Trends Food Sci. Technol. 2018, 81, 193–202. [Google Scholar] [CrossRef]

- Nogueira, E.B.; Costa-Lima, B.R.C.; Torres, F.; Regazone, A.V.; Melo, L.; Franco, R.M.; Cortez, M.A.S. Effect of Potassium-Based Emulsifying Salts on the Sensory and Physicochemical Parameters of Low-Sodium Spreadable Processed Cheese. Int. J. Dairy Technol. 2018, 71, 717–722. [Google Scholar] [CrossRef]

- Mozuraityte, R.; Berget, I.; Mahdalova, M.; Grønsberg, A.; Øye, E.R.; Greiff, K. Sodium Reduction in Processed Cheese Spreads and the Effect on Physicochemical Properties. Int. Dairy J. 2019, 90, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Buňková, L.; Buňka, F. Microflora of Processed Cheese and the Factors Affecting It. Crit. Rev. Food Sci. Nutr. 2017, 57, 2392–2403. [Google Scholar] [CrossRef]

- Martinez-Rios, V.; Jørgensen, M.Ø.; Koukou, I.; Gkogka, E.; Dalgaard, P. Growth and Growth Boundary Model with Terms for Melting Salts to Predict Growth Responses of Listeria monocytogenes in Spreadable Processed Cheese. Food Microbiol. 2019, 84, 103255. [Google Scholar] [CrossRef]

- Fu, W.; Watanabe, Y.; Inoue, K.; Moriguchi, N.; Fusa, K.; Yanagisawa, Y.; Mutoh, T.; Nakamura, T. Effects of Pre-Cooked Cheeses of Different Emulsifying Conditions on Mechanical Properties and Microstructure of Processed Cheese. Food Chem. 2018, 245, 47–52. [Google Scholar] [CrossRef] [PubMed]

- Salek, R.N.; Vašina, M.; Lapčík, L.; Černíková, M.; Lorencová, E.; Li, P.; Buňka, F. Evaluation of Various Emulsifying Salts Addition on Selected Properties of Processed Cheese Sauce with the Use of Mechanical Vibration Damping and Rheological Methods. LWT 2019, 107, 178–184. [Google Scholar] [CrossRef]

- Talbot-Walsh, G.; Selomulya, C. The Effect of Rennet Casein Hydration on Gel Strength and Matrix Stability of Block-Type Processed Cheese. Food Struct. 2021, 28, 100174. [Google Scholar] [CrossRef]

- Vollmer, A.H.; Kieferle, I.; Pusl, A.; Kulozik, U. Effect of Pentasodium Triphosphate Concentration on Physicochemical Properties, Microstructure, and Formation of Casein Fibrils in Model Processed Cheese. J. Dairy Sci. 2021, 104, 11442–11456. [Google Scholar] [CrossRef] [PubMed]

- Eckner, K.F.; Dustman, W.A.; Rys-Rodriguez, A.A. Contribution of Composition, Physicochemical Characteristics and Polyphosphates to the Microbial Safety of Pasteurized Cheese Spreads. J. Food Prot. 1994, 57, 295–300. [Google Scholar] [CrossRef]

- Loessner, M.J.; Maier, S.K.; Schiwek, P.; Scherer, S. Long-Chain Polyphosphates Inhibit Growth of Clostridium tyrobutyricum in Processed Cheese Spreads. J. Food Prot. 1997, 60, 493–498. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S.; Kim, S.; Lee, J.; Ha, J.; Yoon, Y. Quantitative Microbial Risk Assessment for Clostridium perfringens in Natural and Processed Cheeses. Asian-Australas. J. Anim. Sci. 2016, 29, 1188–1196. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, R.B.A.; Baptista, R.C.; Chincha, A.A.I.A.; Conceição, D.A.; Nascimento, J.S.; Costa, L.E.O.; Cruz, A.G.; Sant’Ana, A.S. Thermal Inactivation Kinetics of Paenibacillus sanguinis 2301083PRC and Clostridium sporogenes JCM1416MGA in Full and Low Fat “Requeijão Cremoso”. Food Control 2018, 84, 395–402. [Google Scholar] [CrossRef]

- Oliveira, R.B.A.; Lopes, L.S.; Baptista, R.C.; Chincha, A.A.I.A.; Portela, J.B.; Nascimento, J.S.; Costa, L.E.O.; Cruz, A.G.; Sant’Ana, A.S. Occurrence, Populations, Diversity, and Growth Potential of Spore-Forming Bacteria in “Requeijão Cremoso”. LWT Food Sci. Technol. 2018, 89, 24–31. [Google Scholar] [CrossRef]

- Fusieger, A.; da Silva, R.R.; de Jesus Silva, S.R.; Honorato, J.A.; Teixeira, C.G.; Souza, L.V.; Magalhães, I.N.S.; da Silva Costa, N.A.; Walter, A.; Nero, L.A.; et al. Inhibitory Activity of an Emulsifying Salt Polyphosphate (JOHA HBS®) Used in Processed Cheese: An in Vitro Analysis of Its Antibacterial Potential. LWT Food Sci. Technol. 2022, 167, 113777. [Google Scholar] [CrossRef]

- ISO 7932; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Presumptive Bacillus cereus Colony Count Technique at 30 Degrees. International Organization for Standardization: Geneva, Switzerland, 2004.

- Zhao, X.; da Silva, M.B.R.; Van der Linden, I.; Franco, B.D.G.M.; Uyttendaele, M. Behavior of the Biological Control Agent Bacillus thuringiensis subsp. aizawai ABTS-1857 and Salmonella enterica on Spinach Plants and Cut Leaves. Front. Microbiol. 2021, 12, 626029. [Google Scholar] [CrossRef] [PubMed]

- ISO 7937:2004; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Clostridium perfringens—Colony-Count Technique. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 4833-1; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization: Geneva, Switzerland, 2003.

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis, 2nd ed.; Springer: New York, NY, USA, 2016; ISBN 9783319242774. [Google Scholar]

- Buňková, L.; Pleva, P.; Buňka, F.; Valášek, P.; Kráčmar, S. Antibacterial Effects of Commercially Available Phosphates on Selected Microorganisms. Acta Univ. Agric. Silvic. Mendel. Brun. 2008, 56, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Lorencová, E.; Vltavská, P.; Budinský, P.; Koutný, M. Antibacterial Effect of Phosphates and Polyphosphates with Different Chain Length. J. Environ. Sci. Health Part A 2012, 47, 2241–2245. [Google Scholar] [CrossRef] [PubMed]

- Catania, A.M.; Civera, T.; di Ciccio, P.A.; Grassi, M.A.; Morra, P.; Dalmasso, A. Characterization of Vegetative Bacillus cereus and Bacillus subtilis Strains Isolated from Processed Cheese Products in an Italian Dairy Plant. Foods 2021, 10, 2876. [Google Scholar] [CrossRef] [PubMed]

- Ehling-Schulz, M.; Lereclus, D.; Koehler, T.M. The Bacillus cereus Group: Bacillus Species with Pathogenic Potential. Microbiol. Spectr. 2019, 7. [Google Scholar] [CrossRef] [PubMed]

- Bağcıoğlu, M.; Fricker, M.; Johler, S.; Ehling-Schulz, M. Detection and Identification of Bacillus cereus, Bacillus cytotoxicus, Bacillus thuringiensis, Bacillus mycoides and Bacillus weihenstephanensis via Machine Learning Based FTIR Spectroscopy. Front. Microbiol. 2019, 10, 902. [Google Scholar] [CrossRef]

- Maier, S.K.; Scherer, S.; Loessner, M.J. Long-Chain Polyphosphate Causes Cell Lysis and Inhibits Bacillus cereus Septum Formation, Which Is Dependent on Divalent Cations. Appl. Environ. Microbiol. 1999, 65, 3942–3949. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, S.; Paredes-Sabja, D.; Sarker, M.R. Inhibitory Effects of Polyphosphates on Clostridium perfringens Growth, Sporulation and Spore Outgrowth. Food Microbiol. 2008, 25, 802–808. [Google Scholar] [CrossRef]

- Christ, J.J.; Blank, L.M. Enzymatic Quantification and Length Determination of Polyphosphate down to a Chain Length of Two. Anal. Biochem. 2018, 548, 82–90. [Google Scholar] [CrossRef]

- Lee, R.M.; Hartman, P.A.; Stahr2, H.M.; Olson3, D.G.; Williams, F.D. Antibacterial Mechanism of Long-Chain Polyphosphates in Staphylococcus aureus. J. Food Prot. 1994, 57, 289–294. [Google Scholar] [CrossRef]

- Buňka, F.; Doudová, L.; Weiserová, E.; Černíková, M.; Kuchař, D.; Slavíková, Š.; Nagyová, G.; Ponížil, P.; Grůber, T.; Michálek, J. The Effect of Concentration and Composition of Ternary Emulsifying Salts on the Textural Properties of Processed Cheese Spreads. LWT Food Sci. Technol. 2014, 58, 247–255. [Google Scholar] [CrossRef]

- Nagyová, G.; Buňka, F.; Salek, R.N.; Černíková, M.; Mančík, P.; Grůber, T.; Kuchař, D. Use of Sodium Polyphosphates with Different Linear Lengths in the Production of Spreadable Processed Cheese. J. Dairy Sci. 2014, 97, 111–122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Awad, R.A.; Abdel-Hamid, L.B.; El-Shabrawy, S.A.; Singh, R.K. Physical and Sensory Properties of Block Processed Cheese with Formulated Emulsifying Salt Mixtures. Int. J. Food Prop. 2004, 7, 429–448. [Google Scholar] [CrossRef]

- Kim, N.H.; Lee, N.Y.; Kim, M.G.; Kim, H.W.; Cho, T.J.; Joo, I.S.; Heo, E.J.; Rhee, M.S. Microbiological Criteria and Ecology of Commercially Available Processed Cheeses According to the Product Specification and Physicochemical Characteristics. Food Res. Int. 2018, 106, 468–474. [Google Scholar] [CrossRef]

| Storage Time (Days) | Pilot-Scale | Laboratory-Scale | ||

|---|---|---|---|---|

| T1 | T2 | T1 | T2 | |

| 0 | 5.88 ± 0.04 ab | 5.77 ± 0.01 a | 5.74 ± 0.01 a | 5.52 ± 0.04 a |

| 7 | 5.72 ± 0.04 d | 5.49 ± 0.06 e | 5.76 ± 0.12 a | 5.52 ± 0.06 a |

| 14 | 5.83 ± 0.07 bc | 5.53 ± 0.01 de | 5.87 ± 0.11 a | 5.60 ± 0.04 a |

| 21 | 5.92 ± 0.03 a | 5.67 ± 0.04 b | 5.75 ± 0.03 a | 5.52 ± 0.04 a |

| 28 | 5.78 ± 0.01 cd | 5.59 ± 0.04 cd | 5.80 ± 0.05 a | 5.54 ± 0.07 a |

| 45 | 5.85 ± 0.01 bc | 5.63 ± 0.01 bc | 5.78 ± 0.06 a | 5.52 ± 0.03 a |

| Storage Time (Days) | Pilot-Scale | Laboratory-Scale | ||

|---|---|---|---|---|

| T1 | T2 | T1 | T2 | |

| 0 | 0.983 ± 0.001 | 0.982 ± 0.001 | 0.985 ± 0.002 | 0.975 ± 0.010 |

| 7 | 0.985 ± 0.002 | 0.986 ± 0.001 | 0.983 ± 0.001 | 0.984 ± 0.001 |

| 14 | 0.991 ± 0.005 | 0.987 ± 0.005 | 0.990 ± 0.002 | 0.991 ± 0.007 |

| 21 | 0.983 ± 0.001 | 0.985 ± 0.002 | 0.979 ± 0.009 | 0.980 ± 0.012 |

| 28 | 0.984 ± 0.000 | 0.984 ± 0.002 | 0.986 ± 0.012 | 0.987 ± 0.010 |

| 45 | 0.984 ± 0.001 | 0.984 ± 0.001 | 0.983 ± 0.004 | 0.980 ± 0.004 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fusieger, A.; da Silva, R.R.; Cavicchioli, V.Q.; Rodrigues, R.d.S.; Honorato, J.A.; de Jesus Silva, S.R.; Pena, M.L.; Caggia, C.; Nero, L.A.; de Carvalho, A.F. Influence of Emulsifying Salts on the Growth of Bacillus thuringiensis CFBP 3476 and Clostridium perfringens ATCC 13124 in Processed Cheese. Foods 2022, 11, 3217. https://doi.org/10.3390/foods11203217

Fusieger A, da Silva RR, Cavicchioli VQ, Rodrigues RdS, Honorato JA, de Jesus Silva SR, Pena ML, Caggia C, Nero LA, de Carvalho AF. Influence of Emulsifying Salts on the Growth of Bacillus thuringiensis CFBP 3476 and Clostridium perfringens ATCC 13124 in Processed Cheese. Foods. 2022; 11(20):3217. https://doi.org/10.3390/foods11203217

Chicago/Turabian StyleFusieger, Andressa, Raiane Rodrigues da Silva, Valéria Quintana Cavicchioli, Rafaela da Silva Rodrigues, Jaqueline Aparecida Honorato, Sidney Rodrigues de Jesus Silva, Mariana Lage Pena, Cinzia Caggia, Luís Augusto Nero, and Antonio Fernandes de Carvalho. 2022. "Influence of Emulsifying Salts on the Growth of Bacillus thuringiensis CFBP 3476 and Clostridium perfringens ATCC 13124 in Processed Cheese" Foods 11, no. 20: 3217. https://doi.org/10.3390/foods11203217