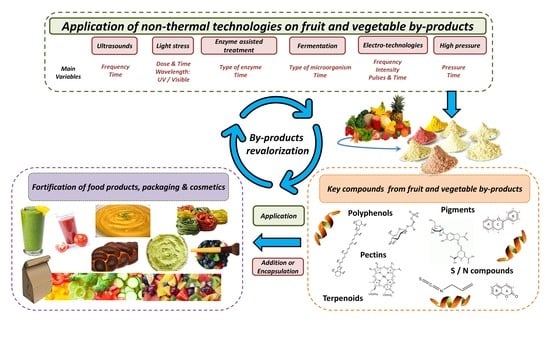

By-Products Revalorization with Non-Thermal Treatments to Enhance Phytochemical Compounds of Fruit and Vegetables Derived Products: A Review

Abstract

:1. Introduction

2. Fruit and Vegetables By-Products as a Source of Valuable Compounds

2.1. Phytochemical Compounds

2.1.1. Polyphenols

2.1.2. Bioactive Pigments

Water-Soluble Compounds: Anthocyanins and Betalains

Fat-Soluble Compounds: Carotenoids and Chlorophylls

2.1.3. Sulfur Compounds

2.2. Pectins

3. Potential and Innovative Non-Thermal Techniques for Revalorization of Fruit & Vegetables By-Products

3.1. Electro-Technologies: Pulses Electric Fields

3.2. Enzyme-Assisted Extraction

3.3. Fermentation

3.4. High Hydrostatic Pressure

3.5. Light Stress

3.6. Supercritical Fluid Extraction

3.7. Ultrasound-Assisted Extraction (UAE)

4. Scientific Literature Review about Non-Thermal Technologies Used for Revalorization of Fruits & Vegetable By-Products

5. Effect of Non-Thermal Technologies on Fruit and Vegetable By-Products Polyphenols

| Non-Thermal Technology | By-Product | Findings | Reference | |

|---|---|---|---|---|

| Flavonols | Solid-state Fermentation (A. niger and R. oligosporus) | Plum pomace | Increase of quercentin-3-glucoside (23 to 34 mg/100 g dry matter by A. niger; 22 to 24 mg/100 g dry matter by R. oligosporus), and quercentin-3-rutinoside (21 to 25 mg/100 g dry matter by A. niger) when 2 × 107 spores/g of solid was inoculated and fermentation took place during 14 days at 30 °C | [83] |

| Solid-state Fermentation (A. niger and R. oligosporus) | Plum brandy distilleries waste | Increase of quercentin-3-glucoside (92 to 120 mg/100 g dry matter by A. niger; 92 to 110 mg/100 g dry matter by R. oligosporus), quercentin-3-rutinoside (42 to 64 mg/100 g dry matter by A. niger; 42 to 74 mg/100 g dry matter by R. oligosporus) and quercentin-3-galactoside (26 to 36 mg/100 g dry matter by R. oligosporus) when 2 × 107 spores/g of solid was inoculated and fermentation took place during 14 days at 30 °C | [83] | |

| Ultrasound assisted solid liquid extraction | Skins of red and yellow onions | Recovery of quercetin aglycona (118%) after extracted eight times with 20 mL Ethanol (85% v/v) for 15 min at 25 °C | [34,81] | |

| Polyphenols | High hydrostatic pressure | Orange and lemon peels | More intense HPP conditions (500 MPa, 10 min), polyphenols decrease (lemon: 291.08 to 211.95 mg GAE/100 g fresh peel extracts; orange: 400 to 215.31 mg GAE/100 g fresh peel extracts). | [84,85] |

| High hydrostatic pressure | Pineapple by-products | Accumulation of bromelain (increase of 350%) and TPC (increase of 36%) at 225 MPa, 8.5 min | [86,87] | |

| Electro-technologies | Mango peel | Recovery of polyphenols (+400%) at E = 13.3 kV/cm (160 kJ/kg); V = 40 kV (160 kJ/kg) | [54,88] | |

| Electro-technologies | Olive kernel | Recovery of polyphenols E = 13.3 kV/cm (0–141 kJ/kg), V = 40 kV (0–141 kJ/kg) | [54,89] | |

| Electro-technologies | Orange peel | Up to 159% in polyphenol extraction recovery after PEF pre-treatment at an electric field densities 1 kV/cm and 7 kV/cm (60 μs, 20 pulses, f = 1 Hz). Recovery of naringin and hesperidin increased ≈2- and 3-fold, respectively. | [84] | |

| Electro-technologies | Orange peel | Recovery of polyphenols (from 20%, to 159%) for orange peel PEF treated at E = 1–7 kV/cm (0.06–3.77 kJ/kg) + Pressing 5 bars | [54,90] | |

| Electro-technologies | Papaya peel and seeds | Recovery of polyphenols (>50%) at E = 13.3 kV/cm (160 kJ/kg); V = 40 kV (160 kJ/kg) | [54,91] | |

| Electro-technologies | Raspseeds stems and leaves | Recovery polyphenols (36–42%) at E = 0.2–5 kV/cm (0–700 kJ/kg) | [54,92] | |

| Electro-technologies | Raspseeds seeds | Recovery polyphenols (around 50%) at V = 40 kV (0–400 kJ/kg) | [54,93] | |

| Electro-technologies | Winery wastes and by-products (peel) | Recovery of polyphenols (42%) E = 5–10 kV/cm (1.8–6.7 kJ/kg) | [54,94] | |

| Electro-technologies | Winery wastes and by-products (pomace) | Recovery of polyphenols (>40%) at E = 13.3 kV/cm (0–564 kJ/kg) V = 40 kV (0–218 kJ/kg) | [54,95] | |

| Electro-technologies | Winery wastes and by-products (seed) | Recovery of polyphenols (>40%) at E = 8–20 kV/cm (0–53 kJ/kg) V = 40 kV (0–53 kJ/kg) | [54,96] | |

| Electro-technologies | Fermented grapes pomace | Increase of recovery by 1.2 kV/cm 18 kJ/kg 20 °C (the ratio of total anthocyanins to total flavan-3-ols was increased from 7.1 in non-treated to 9.0 in PEF-treated samples) | [97,98] | |

| Electro-technologies | Winery wastes and by-products (grapes) | Increase 13% at 0.5 kV/cm, 50 pulses, 0.1 kJ/kg Increase 28% at 2.4 kV/cm, 50 pulses 2.3 kJ/kg | [99,100] | |

| Electro-technologies | Winery wastes and by-products (grapes) | Increase 34% at 0.7 kV/cm, 200 ms, 31 Wh/kg | [99,100] | |

| Electro-technologies | Winery wastes and by-products (vine shoots) | Up to 2-fold increase in TPC (Kaempferol, epicatechin, resveratrol) at 13.3 kV/cm, 0–1500 pulses, 50–762 kJ/kg/3 h compared to untreated | [99,101] | |

| Electro-tecnologies | Citrus peel (orange and pomelo) | Increase of polyphenols recovery, 16 mg/g dry matter for skins (for albedo + flavedo) (E = 10 kV/cm and 50% ethanol solution) | [102] | |

| Enzymed-assisted extraction | Grape residues | Novoferm® (1:10, 12 h and 40 °C) had the strongest effect on phenolic release (90%) from grape waste (100 mg of dry material was suspended in 1.4 mL of 0.2 M acetates buffer (pH 3.5)). | [60] | |

| Light stress (UV-B and UV-C; single and combined) | Bimi broccoli leaves and stalks | UV increased initial TPC of leaves/stalks up to 31–97/30–75%, 10 kJ/m2 UV-B (UV-B10) + C induced the highest TPC increase (110%) in leaves while UV-B10 and UV-B10 + C led to the highest TPC of stalks after 48 h | [80] | |

| Optimized supercritical Fluid Extraction | Broccoli by-products | Decrease of polyphenols (<20%) at 400 bars, 40 °C, 5% of ethanol compared with conventional treatment | [79] | |

| Solid-state Fermentation (A. niger and R. oligosporus) | Plum brandy distilleries waste | Increase of 3-Caffeoylquinic acid (33 to 53 mg/100 g dry matter by A. niger; 33 to 46 mg/100 g dry matter by R. oligosporus) when 2 × 107 spores/g of solid was inoculated and fermentation took place during 14 days at 30 °C | [83] | |

| Solid-state Fermentation (A. niger and R. oligosporus) | Plum pomace | Increase of 5-Caffeoylquinic acid (22 to 24 mg/100 g dry matter by A. niger; 22 to 24 mg/100 g dry matter by R. oligosporus) when 2 × 107 spores/g of solid was inoculated and fermentation took place during 14 days at 30 °C | [83] | |

| Subcritical/critical Fluid Extraction | White grape seeds | Improved recovery of gallic acid, catechin, and epicatechin (>70%) at 1 mL/min CO2 flow rate, 20 min extraction, 35 °C, organic modifier density (0.85–0.95 g/mL), modifier (ethanol-methanol: 10–40). | [99,103] | |

| Ultrasounds | Grape marc | Increase of 11–35% at 24 kHz, 20–75 W/mL | [99,104] | |

| Ultrasounds | Orange peel (50:50 EtOH:Water) | Recovery of caffeic (207%), p-coumaric (180%), ferulic (192%), sinapic acid (66%), and p-hydroxybenzoic (94%) at 25 KHz, 150 W, 15 min | [84] | |

| Ultrasounds | Orange peel (20:80; 80:20, EtOH:Water) | Recovery of naringin (38%), hesperidin (42%), TPC (31%) at 25 kHz, 50–150 W, 60 min | [84] | |

| Ultrasounds | Winery wastes and by-products (grapes) | Increase of 7% (sum of anthocyanins and tannins) at 24 kHz, 5–15 min, 121–363 kJ/kg | [99,104] | |

| Flavonoids | Pulsed electric fields | Orange peel | Increase at 5 kV/cm and 20 pulses | [97] |

6. Effect of Non-Thermal Technologies on Fruit & Vegetable By-Products Pigments

| Non-Thermal Technology | By-Product | Findings | Reference | |

|---|---|---|---|---|

| Anthocyanins | Electro-technologies | Winery wastes and by-products (pomace) | Recovery of polyphenols (>20%) at E = 13.3 kV/cm (0–564 kJ/kg) V = 40 kV (0–218 kJ/kg) | [95,99] |

| High pressure | Wine by-products | Recovery of 41% at 600 MPa, 60 min/solvent (50–50% ethanol in water) | [99,109] | |

| High pressure | Wine by-products | Recovery of 22–83% at 200–600 MPa, 30–90 min, solvent (20–80%; 100–0% ethanol in water) | [99,110] | |

| Pulsed electric fields | Blueberry pomace (press cake) | Increase of Delphinidin, Cyanidin, Petunidin, Peonidin, and Malvidin. 51%, 71% and 95% at 1 kV/cm, 3 kV/cm, and 5 kV/cm, respectively | [107] | |

| Pulsed electric fields | Blueberry by-product | Anthocyanin extraction increased (>30%) with PEF process intensification (1–35 kV/cm; 1–10–41 kJ/kg; 10 Hz, 2–100 pulses, 2 μs | [105,106,111,112] | |

| Pulsed electric fields | Grape by-product (pomace and peel) | Improved anthocyanin extraction (up to 18.9%) at 1.2, 1.8, and 3.0 kV/cm, 18 kJ/kg, 200–2000 pulses, 100 μs | [106,108] | |

| Pulsed electric fields | Plum by-product | No increase anthocyanins at 37.8–289.8 W, 0.7–25.2 pulses, 10 Hz, 6 μs | [106,108] | |

| Pulsed electric fields | Peach by-product | Improved anthocyanin extraction (up to 11.8-fold) at 0.8 kV/cm, 0.2 kJ/kg; 0.1 Hz 4 μs | [106,113] | |

| Pulsed electric fields | Raspberry by-product | Increase 27.5% at 1 kV/cm, 6 kJ/kg, 20 Hz and 20 μs | [106,114] | |

| Pulsed electric fields | Sour cherry by-product | Improved anthocyanin extraction (up to 54%); 1 kV/cm, 10 kJ/kg, 10 Hz, 20 μs | [106,115] | |

| Pulsed electric fields | Sweet cherry by-product | Improved anthocyanin extraction (up to 38.4%) at 0.5 kV/cm, 10 kJ/kg, 5 Hz, 20 μs | [106,116] | |

| Pulsed electric fields | Winery wastes and by-products (grapes) | Increase of anthocyanins: 3-fold at 3 kV/cm 50 pulses; 1.6 and 2-fold ↑ 5 kV/cm 1 ms | [99,117] | |

| Pulsed electric fields | Winery wastes and by-products (grapes) | Increase of 51–62% at 0.8–5 kV/cm, 1–100 ms, 42–53 kJ/kg | [99,117] | |

| Pulsed electric fields | Winery wastes and by-products (grapes) | Increased anthocyanin content (1.6–1.9 fold more) at 5 kV/cm, 1 ms, 48 kJ/kg | [99,118] | |

| Pulsed electric fields | Winery wastes and by-products (pomace) | Increase of Anthocyanins (2-fold more) at 13.3 kV/cm, 0–564 kJ/kg | [99,101] | |

| Pulsed electric fields + ultrasounds | Blueberry by-products | Increase of anthoycanin extraction (3 fold more) (PEF: 60% ethanol 1:6 and 20 kV/cm; Ultrasounds: 1:6, 40 °C, 60 min at 125 W) | [119] | |

| Subcritical/critical Fluid Extraction | Grape skin | Recovery of 85% at 100–130 bar, pH of 2–4, 25–30% ethanol, 25–50 mL/min CO2 flow, and 3–10% extract flow ratio | [99,120] | |

| Ultrasounds | Eggplant by-product | US-assisted extraction (15–45 min) was preferable to conventional solid-liquid extraction due to the lower temperature (25 °C) used and higher delphinidin 3-O-rutinoside content (1.5 fold more). | [82] | |

| Ultrasounds | Jabuticaba by-products | The highest concentration at 1.1 W/cm2, 3 min, 10 KHz | [106,121,122] | |

| Ultrasounds | Pomegranate peel | 116 W sonication power with 80% duty cycle for 6 min for extraction of 22.51 mg cyanidin-3-glucosides/100 g pomegranate peel. | [106,123] | |

| Betalains | Pulsed electric fields | Opuntia stricta peels | Total colorants to ≈80 mg/100 g FW (20 kV, frequency of 0.5 Hz, number of pulses of 50) | [124] |

| Pulsed electric fields | Red pricky pear peels | Increase of 2.4 fold colorants (betanin and isobetanin) at 8–23 kV/cm 50–300 pulses + aqueous extraction | [125] | |

| Ultrasound | Opuntia stricta peels | Total colorants to ≈80 mg/100 g FW (400 W power at 24 kHz frequency for 5–15 min) | [124] | |

| Carotenoids | Electro-technologies | Olive kernel | Recovery of polyphenols (2-fold more) E = 13.3 kV/cm (0–141 kJ/kg), V = 40 kV (0–141 kJ/kg) | [54,89] |

| Microemulsion (Ultrasounds + enzyme) | Tomato pomace | Recovery of lycopene (>20%). The optimal conditions (tomato pomace: double distilled water 1:6): combined ultrasound (20–37 W, amplitude 90% and sonication temperature of 10 °C for 15 min) and enzyme pretreatments (0.2 mL/kg, 30 min, pH 4, 35 °C), saponin as a natural surfactant, and glycerol as a co-surfactant. | [55,126] | |

| Pulsed Electric Fields | Tomato waste | Recovery of 12–18% of lycopene in acetone and ethyl lactate extracts at 5 kJ/Kg and 5 kV/cm (20 °C). | [55,105,127] | |

| Supercritical Fluid Extraction | Broccoli by-products | Decrease of beta-carotene (>10%) compared with conventional treatment at 400 bars, 5% of ethanol | [79] | |

| Supercritical fluid extraction | F&V waste: -sweet potato, tomato, apricot, pumpkin and peach peels -green, yellow and red peppers | Total carotenoid recovery values were greater than 90% w/w, with β-carotene being the most successfully extracted compound (TCRs 88–100% w/w), at 350 bar, 15 g/min CO2, 15.5% (v/v) ethanol as co-solvent, 30 min of extraction time) | [128,129] | |

| Ultrasound | Orange processing waste | Optimization of β-carotene extraction with enzyme assisted technology at 20 kHz, 500 W and 25 °C | [129,130] | |

| Ultrasound | Red pricky pear peels | Increase of 2.6 fold colorants (betanin and isobetanin) at 400 W 5–15 min + aqueous extraction | [125] | |

| Ultrasound | Tomato pomace | Lycopene increase (>10%) at 25–40 °C, 0–10 min, 0–100 kPa; 58–94 μm; Hexane %: 25–75 | [55,131,132] | |

| Ultrasounds | Tomato peel | 5-fold lower all-trans lycopene content by ultrasounds (30 min 0 °C) compared to thermal extraction (75 °C, 1–2 h). | [14] | |

| Chlorophylls | Electro-technologies | Olive kernel | Recovery of polyphenols (>30%) E = 13.3 kV/cm (0–141 kJ/kg), V = 40 kV (0–141 kJ/kg) | [54] |

| Supercritical Fluid Extraction | Broccoli by-products | Increase of chlorophylls (>10%) at 400 bars, and 5% of ethanol | [79] |

7. Effect of Non-Thermal Technologies on Fruit and Vegetable By-Products Pectins and Sulfur Compounds

| Non-Thermal Technology | By-Product | Findings | Reference | |

|---|---|---|---|---|

| Pectin | Enzymes | Apple Pomace | Recovery of 14% by Celluclast 18 h | [133,134] |

| Enzymes | Kiwi pomace | Recovery of 4% by celluclast 25 °C 0.5 h | [133,135] | |

| Enzymes | Passion fruit pomace | Recovery of 2.6–9.2% by Cellyclast 0.5–2 h | [133,136] | |

| Enzymes | Lime peel | Recovery of 26% by Validase TRL 4 h | [133,137] | |

| High pressure | Cactus pear peel | Increase of 22% soluble pectin at 600 MPa 10 min | [138,139] | |

| High pressure | Cactus pear peel | Increase of 9% insoluble pectin at 600 MPa 10 min | [138,139] | |

| High pressure | Mango peel | Increase of 15% soluble pectin at 600 MPa 10 min | [138,139] | |

| High pressure | Orange peel | Increase of 59% soluble pectin at 600 MPa 10 min | [138,139] | |

| High pressure | Passion fruit peel | Recovery of pectin was increased from 7.4 to 14.3% due to HPP pre-treatment. D-GalA of pectin was 65% higher than conventional treatment | [65,140] | |

| High pressure | Tomato peel | 300 MPa pressure performed at 10, 20, 30, and 45 min. 14–15% of pectin recovery at 30 and 45 min | [65,141] | |

| Moderate electric field | Passion fruit peel | Increase of galacturonic acid (GA) (recovery and content) at 40 min; 100 V; pH 1 (GA); pH 3 (Recovery) | [65,140] | |

| Ultrasounds | Grapefruit peel | Recovery of 18.2% by 30 °C 10–60 min, 0.2–0.53 W/mL | [131,142] | |

| Ultrasounds-enzyme assisted extraction without or with hemicellulase or cellulase | Discarded carrots | The pectin was rich in α- and β-carotenes, lutein and α-tocopherol. US-hemicellulase led to the highest pectin recovery (27.1%) at 12.27 W/cm2: 20 kHz, 80% amplitude, 20 min | [143] | |

| Sulfur compounds | Electro-technologies | Raspseeds seeds | Recovery of isothyocyanates (>15%) at V = 40 kV (0–400 kJ/kg) | [54,93] |

| Light stress (UV-B and UV-C; single and combined) | Bimi broccoli leaves and stalks | UV-B (10 kJ/m2) + C increased 34% of glucobrassicin levels of leaves | [80] |

8. Trends and Challenges for Fruit & Vegetable By-Products Application in Food Systems

8.1. Minimally Processed Fresh Fruit and Vegetables

8.2. Fruit- & Vegetable-Based Beverages and Purees

8.3. Pasta, Bakery and Confectionary Products

8.4. Food Packaging and Edible Coatings

8.5. Pharmacologic and Cosmetic Uses

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Organización de las Naciones Unidas para la Alimentación y la Agricultura. Plataforma Técnica Sobre la Medición y la Reducción de Las Pérdidas y el Desperdicio de Alimentos. Available online: https://www.fao.org/platform-food-loss-waste/es/ (accessed on 26 November 2021).

- Bhat, R. Sustainability challenges in the valorization of agri-food wastes and by-products. In Valorization of Agri-Food Wastes and By-Products; Bhat, R., Ed.; Academic Press: Cambridge, MA, USA, 2021; Chapter 1; pp. 1–27. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and Vegetable Waste: Bioactive Compounds, Their Extraction, and Possible Utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef] [Green Version]

- FAO. Organización de las Naciones Unidas para la Alimentación y la Agricultura. El Estado Mundial de la Agricultura y la Alimentación. Progresos en la Lucha Contra la Pérdida y el Desperdicio de Alimentos. Available online: https://www.fao.org/3/ca6030es/ca6030es.pdf (accessed on 26 November 2021).

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- FAO. Organización de las Naciones Unidas para la Alimentación y la Agricultura. El futuro de la Alimentación y la Agricultura: Tendencias y Desafíos. Available online: https://www.fao.org/3/i6881s/i6881s.pdf (accessed on 26 November 2021).

- Simões, S.; Costa, A.; Faria-Silva, A.C.; Ascenso, A.; Marto, J.; Carvalheiro, M.; Gonçalves, L.M.; Marques, M.; Paiva, A.; Bento, M.; et al. Sustainable valorization of food-processing industry by-products: Challenges and opportunities to obtain bioactive compounds. In Valorization of Agri-Food Wastes and By-Products; Bhat, R., Ed.; Academic Press: Cambridge, MA, USA, 2021; Chapter 32; pp. 619–644. [Google Scholar] [CrossRef]

- Coman, V.; Teleky, B.-E.; Mitrea, L.; Martău, G.A.; Szabo, K.; Călinoiu, L.-F.; Vodnar, D.C. Bioactive potential of fruit and vegetable wastes. In Advances in Food and Nutrition Research; Toldrá, F., Ed.; Academic Press: Cambridge, MA, USA, 2020; Volume 91, Chapter 5; pp. 157–225. [Google Scholar]

- Artés-Hernández, F.; Castillejo, N.; Martínez-Zamora, L.; Martínez-Hernández, G.B. Phytochemical Fortification in Fruit and Vegetable Beverages with Green Technologies. Foods 2021, 10, 2534. [Google Scholar] [CrossRef] [PubMed]

- Majumder, P.; Annegowda, H.V. Fruit and vegetable by-products: Novel ingredients for a sustainable society. In Valorization of Agri-Food Wastes and By-Products; Bhat, R., Ed.; Academic Press: Cambridge, MA, USA, 2021; Chapter 7; pp. 133–156. [Google Scholar] [CrossRef]

- Rose, N.; Reynolds, T.; Kolodinsky, J. P90 Consumer Use of Food Labels Increases as “Clean Label” Trend Continues. J. Nutr. Educ. Behav. 2020, 52, S58–S59. [Google Scholar] [CrossRef]

- Roobab, U.; Shabbir, M.A.; Khan, A.W.; Arshad, R.N.; Bekhit, A.E.-D.; Zeng, X.-A.; Inam-Ur-Raheem, M.; Aadil, R.M. High-pressure treatments for better quality clean-label juices and beverages: Overview and advances. LWT 2021, 149, 111828. [Google Scholar] [CrossRef]

- Castillejo, N.; Martínez-Hernández, G.B.; Artés-Hernández, F. Revalorized broccoli by-products and mustard improved quality during shelf life of a kale pesto sauce. Food Sci. Technol. Int. 2021, 27, 734–745. [Google Scholar] [CrossRef]

- Martínez-Hernández, G.B.; Castillejo, N.; Artés-Hernández, F. Effect of fresh–cut apples fortification with lycopene microspheres, revalorized from tomato by-products, during shelf life. Postharvest Biol. Technol. 2019, 156, 110925. [Google Scholar] [CrossRef]

- Tarazona-Díaz, M.P.; Viegas, J.; Moldao-Martins, M.; Aguayo, E. Bioactive compounds from flesh and by-product of fresh-cut watermelon cultivars. J. Sci. Food Agric. 2011, 91, 805–812. [Google Scholar] [CrossRef]

- Martínez-Sánchez, A.; López-Cañavate, M.E.; Guirao-Martínez, J.; Roca, M.J.; Aguayo, E. Aloe vera Flowers, a Byproduct with Great Potential and Wide Application, Depending on Maturity Stage. Foods 2020, 9, 1542. [Google Scholar] [CrossRef] [PubMed]

- Bustamante, M.A.; Moral, R.; Paredes, C.; Pérez-Espinosa, A.; Moreno-Caselles, J.; Pérez-Murcia, M.D. Agrochemical characterisation of the solid by-products and residues from the winery and distillery industry. Waste Manag. 2008, 28, 372–380. [Google Scholar] [CrossRef]

- Anticona, M.; Blesa, J.; Frigola, A.; Esteve, M.J. High Biological Value Compounds Extraction from Citrus Waste with Non-Conventional Methods. Foods 2020, 9, 811. [Google Scholar] [CrossRef] [PubMed]

- Fierascu, R.C.; Sieniawska, E.; Ortan, A.; Fierascu, I.; Xiao, J. Fruits By-Products—A Source of Valuable Active Principles. A Short Review. Front. Bioeng. Biotechnol. 2020, 8, 319. [Google Scholar] [CrossRef] [Green Version]

- Bhat, R. Valorization of Agri-Food Wastes and By-Products. Recent Trends, Innovations and Sustainability Challenges; Elsevier: Amsterdam, The Netherlands, 2021; Chapter 2; pp. 23–44. [Google Scholar] [CrossRef]

- Mourtzinos, I.; Goula, A. Polyphenols in Agricultural Byproducts and Food Waste. In Polyphenols in Plants, 2nd ed.; Watson, R.R., Ed.; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar] [CrossRef]

- Dilucia, F.; Lacivita, V.; Conte, A.; Del Nobile, M.A. Sustainable Use of Fruit and Vegetable By-Products to Enhance Food Packaging Performance. Foods 2020, 9, 857. [Google Scholar] [CrossRef]

- Swallah, M.S.; Sun, H.; Affoh, R.; Fu, H.; Yu, H. Antioxidant Potential Overviews of Secondary Metabolites (Polyphenols) in Fruits. Int. J. Food Sci. 2020, 2020, 9081686. [Google Scholar] [CrossRef]

- Kelly, N.P.; Kelly, A.L.; O’Mahony, J.A. Strategies for enrichment and purification of polyphenols from fruit-based materials. Trends Food Sci. Technol. 2019, 83, 248–258. [Google Scholar] [CrossRef]

- Li, W.; Yang, R.; Ying, D.; Yu, J.; Sanguansri, L.; Augustin, M.A. Analysis of polyphenols in apple pomace: A comparative study of different extraction and hydrolysis procedures. Ind. Crops Prod. 2020, 147, 112250. [Google Scholar] [CrossRef]

- Jiménez-Moreno, N.; Cimminelli, M.J.; Volpe, F.; Ansó, R.; Esparza, I.; Mármol, I.; Rodríguez-Yoldi, M.J.; Ancín-Azpilicueta, C. Phenolic Composition of Artichoke Waste and its Antioxidant Capacity on Differentiated Caco-2 Cells. Nutrients 2019, 11, 1723. [Google Scholar] [CrossRef] [Green Version]

- Melo, P.E.F.; Silva, A.P.M.; Marques, F.P.; Ribeiro, P.R.V.; Souza Filho, M.d.s.M.; Brito, E.S.; Lima, J.R.; Azeredo, H.M.C. Antioxidant films from mango kernel components. Food Hydrocoll. 2019, 95, 487–495. [Google Scholar] [CrossRef]

- Hanani, Z.A.N.; Yee, F.C.; Nor-Khaizura, M.A.R. Effect of pomegranate (Punica granatum L.) peel powder on the antioxidant and antimicrobial properties of fish gelatin films as active packaging. Food Hydrocoll. 2019, 89, 253–259. [Google Scholar] [CrossRef]

- Zhao, Y.; Saldaña, M.D.A. Use of potato by-products and gallic acid for development of bioactive film packaging by subcritical water technology. J. Supercrit. Fluids 2019, 143, 97–106. [Google Scholar] [CrossRef]

- Szabo, K.; Dulf, F.V.; Diaconeasa, Z.; Vodnar, D.C. Antimicrobial and antioxidant properties of tomato processing byproducts and their correlation with the biochemical composition. LWT 2019, 116, 108558. [Google Scholar] [CrossRef]

- Chaouch, M.A.; Benvenuti, S. The Role of Fruit by-Products as Bioactive Compounds for Intestinal Health. Foods 2020, 9, 1716. [Google Scholar] [CrossRef] [PubMed]

- Teruel-Andreu, C.; Andreu-Coll, L.; López-Lluch, D.; Sendra, E.; Hernández, F.; Cano-Lamadrid, M. Ficus carica Fruits, by-Products and Based Products as Potential Sources of Bioactive Compounds: A Review. Agronomy 2021, 11, 1834. [Google Scholar] [CrossRef]

- Avram, A.M.; Morin, P.; Brownmiller, C.; Howard, L.R.; Sengupta, A.; Wickramasinghe, S.R. Concentrations of polyphenols from blueberry pomace extract using nanofiltration. Food Bioprod. Processing 2017, 106, 91–101. [Google Scholar] [CrossRef]

- Campone, L.; Celano, R.; Lisa Piccinelli, A.; Pagano, I.; Carabetta, S.; Sanzo, R.D.; Russo, M.; Ibañez, E.; Cifuentes, A.; Rastrelli, L. Response surface methodology to optimize supercritical carbon dioxide/co-solvent extraction of brown onion skin by-product as source of nutraceutical compounds. Food Chem. 2018, 269, 495–502. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef] [PubMed]

- Sudhakar, P.; Latha, P.; Reddy, P.V. Plant pigments. In Phenotyping Crop Plants for Physiological and Biochemical Traits; Sudhakar, P., Latha, P., Reddy, P.V., Eds.; Academic Press: Cambridge, MA, USA, 2016; Chapter 15; pp. 121–127. [Google Scholar] [CrossRef]

- Dikshit, R.; Tallapragada, P. Comparative Study of Natural and Artificial Flavoring Agents and Dyes. In Natural and Artificial Flavoring Agents and Food Dyes; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: Cambridge, MA, USA, 2018; Chapter 3; pp. 83–111. [Google Scholar] [CrossRef]

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563. [Google Scholar] [CrossRef]

- Choo, W.S.; Saik, A.Y.H. Valorization of fruit and vegetable waste for bioactive pigments: Extraction and utilization. In Valorization of Agri-Food Wastes and By-Products; Bhat, R., Ed.; Academic Press: Cambridge, MA, USA, 2021; Chapter 4; pp. 61–81. [Google Scholar] [CrossRef]

- Additives, E.P.O.F.; Food, N.S.A.T. Scientific Opinion on the re-evaluation of anthocyanins (E 163) as a food additive. EFSA J. 2013, 11, 3145. [Google Scholar] [CrossRef]

- Additives, E.P.O.F.; Food, N.S.A.T. Scientific Opinion on the re-evaluation of beetroot red (E 162) as a food additive. EFSA J. 2015, 13, 4318. [Google Scholar] [CrossRef]

- Otalora, C.M.; Bonifazi, E.; Fissore, E.N.; Basanta, F.; Gerschenson, L.N. Thermal Stability of Betalains in By-Products of the Blanching and Cutting of Beta vulgaris L. var conditiva. Pol. J. Food Nutr. Sci. 2020, 70, 15–24. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sasaki, N.; Ohmiya, A. Biosynthesis of plant pigments: Anthocyanins, betalains and carotenoids. Plant J. 2008, 54, 733–749. [Google Scholar] [CrossRef]

- Doleman, J.F.; Grisar, K.; Van Liedekerke, L.; Saha, S.; Roe, M.; Tapp, H.S.; Mithen, R.F. The contribution of alliaceous and cruciferous vegetables to dietary sulphur intake. Food Chem. 2017, 234, 38–45. [Google Scholar] [CrossRef]

- Miękus, N.; Marszałek, K.; Podlacha, M.; Iqbal, A.; Puchalski, C.; Świergiel, A.H. Health Benefits of Plant-Derived Sulfur Compounds, Glucosinolates, and Organosulfur Compounds. Molecules 2020, 25, 3804. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Jubete, L.; Valverde, J.; Kehoe, K.; Reilly, K.; Rai, D.K.; Barry-Ryan, C. Development of a Novel Functional Soup Rich in Bioactive Sulforaphane Using Broccoli (Brassica oleracea L. ssp. italica) Florets and Byproducts. Food Bioprocess Technol. 2014, 7, 1310–1321. [Google Scholar] [CrossRef] [Green Version]

- Drabińska, N.; Ciska, E.; Szmatowicz, B.; Krupa-Kozak, U. Broccoli by-products improve the nutraceutical potential of gluten-free mini sponge cakes. Food Chem. 2018, 267, 170–177. [Google Scholar] [CrossRef]

- Wicker, L.; Kim, Y. Pectin and Health. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 289–293. [Google Scholar] [CrossRef]

- Perussello, C.A.; Zhang, Z.; Marzocchella, A.; Tiwari, B.K. Valorization of Apple Pomace by Extraction of Valuable Compounds. Compr. Rev. Food Sci. Food Saf. 2017, 16, 776–796. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Müller-Maatsch, J.; Bencivenni, M.; Caligiani, A.; Tedeschi, T.; Bruggeman, G.; Bosch, M.; Petrusan, J.; Van Droogenbroeck, B.; Elst, K.; Sforza, S. Pectin content and composition from different food waste streams. Food Chem. 2016, 201, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Vaquero, M.; Ravindran, R.; Walsh, O.; O’Doherty, J.; Jaiswal, A.K.; Tiwari, B.K.; Rajauria, G. Evaluation of Ultrasound, Microwave, Ultrasound–Microwave, Hydrothermal and High Pressure Assisted Extraction Technologies for the Recovery of Phytochemicals and Antioxidants from Brown Macroalgae. Mar. Drugs 2021, 19, 309. [Google Scholar] [CrossRef]

- Garcia-Vaquero, M.; Ummat, V.; Tiwari, B.; Rajauria, G. Exploring Ultrasound, Microwave and Ultrasound-Microwave Assisted Extraction Technologies to Increase the Extraction of Bioactive Compounds and Antioxidants from Brown Macroalgae. Mar. Drugs 2020, 18, 172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dimou, C.; Karantonis, C.H.; Skalkos, D.; Koutelidakis, E.A. Valorization of Fruits by-products to Unconventional Sources of Additives, Oil, Biomolecules and Innovative Functional Foods. Curr. Pharm. Biotechnol. 2019, 20, 776–786. [Google Scholar] [CrossRef]

- Puértolas, E.; Barba, F.J. Electrotechnologies applied to valorization of by-products from food industry: Main findings, energy and economic cost of their industrialization. Food Bioprod. Processing 2016, 100, 172–184. [Google Scholar] [CrossRef]

- Madia, V.N.; De Vita, D.; Ialongo, D.; Tudino, V.; De Leo, A.; Scipione, L.; Di Santo, R.; Costi, R.; Messore, A. Recent Advances in Recovery of Lycopene from Tomato Waste: A Potent Antioxidant with Endless Benefits. Molecules 2021, 26, 4495. [Google Scholar] [CrossRef] [PubMed]

- Arshad, R.N.; Abdul-Malek, Z.; Roobab, U.; Munir, M.A.; Naderipour, A.; Qureshi, M.I.; El-Din Bekhit, A.; Liu, Z.-W.; Aadil, R.M. Pulsed electric field: A potential alternative towards a sustainable food processing. Trends Food Sci. Technol. 2021, 111, 43–54. [Google Scholar] [CrossRef]

- Ben Ammar, J.; Lanoisellé, J.-L.; Lebovka, N.I.; Van Hecke, E.; Vorobiev, E. Impact of a Pulsed Electric Field on Damage of Plant Tissues: Effects of Cell Size and Tissue Electrical Conductivity. J. Food Sci. 2011, 76, E90–E97. [Google Scholar] [CrossRef]

- Rai Naveed, A. Effective valorization of food wastes and by-products through pulsed electric field: A systematic review. J. Food Process Eng. 2021, 44, e13629. [Google Scholar] [CrossRef]

- Costa, J.R.; Tonon, R.V.; Cabral, L.; Gottschalk, L.; Pastrana, L.; Pintado, M.E. Valorization of Agricultural Lignocellulosic Plant Byproducts through Enzymatic and Enzyme-Assisted Extraction of High-Value-Added Compounds: A Review. ACS Sustain. Chem. Eng. 2020, 8, 13112–13125. [Google Scholar] [CrossRef]

- Gómez-García, R.; Martínez-Ávila, G.C.G.; Aguilar, C.N. Enzyme-assisted extraction of antioxidative phenolics from grape (Vitis vinifera L.) residues. 3 Biotech 2012, 2, 297–300. [Google Scholar] [CrossRef] [Green Version]

- Voidarou, C.; Antoniadou, Μ.; Rozos, G.; Tzora, A.; Skoufos, I.; Varzakas, T.; Lagiou, A.; Bezirtzoglou, E. Fermentative Foods: Microbiology, Biochemistry, Potential Human Health Benefits and Public Health Issues. Foods 2021, 10, 69. [Google Scholar] [CrossRef]

- Azam, M.T.; Ahmad, A. Date Palm Waste: An Efficient Source for Production of Glucose and Lactic Acid. In Sustainable Agriculture Reviews 34: Date Palm for Food, Medicine and the Environment; Naushad, M., Lichtfouse, E., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 155–178. [Google Scholar] [CrossRef]

- Sabater, C.; Ruiz, L.; Delgado, S.; Ruas-Madiedo, P.; Margolles, A. Valorization of Vegetable Food Waste and By-Products Through Fermentation Processes. Front. Microbiol. 2020, 11, 2604. [Google Scholar] [CrossRef]

- Vásquez, Z.S.; de Carvalho Neto, D.P.; Pereira, G.V.M.; Vandenberghe, L.P.S.; de Oliveira, P.Z.; Tiburcio, P.B.; Rogez, H.L.G.; Góes Neto, A.; Soccol, C.R. Biotechnological approaches for cocoa waste management: A review. Waste Manag. 2019, 90, 72–83. [Google Scholar] [CrossRef]

- Gavahian, M.; Mathad, G.N.; Pandiselvam, R.; Lin, J.; Sun, D.-W. Emerging technologies to obtain pectin from food processing by-products: A strategy for enhancing resource efficiency. Trends Food Sci. Technol. 2021, 115, 42–54. [Google Scholar] [CrossRef]

- Tewari, S.; Sehrawat, R.; Nema, P.K.; Kaur, B.P. Preservation effect of high pressure processing on ascorbic acid of fruits and vegetables: A review. J. Food Biochem. 2017, 41, e12319. [Google Scholar] [CrossRef]

- Martínez-Zamora, L.; Castillejo, N.; Artés-Hernández, F. Postharvest UV-B and UV-C radiation enhanced the biosynthesis of glucosinolates and isothiocyanates in Brassicaceae sprouts. Postharvest Biol. Technol. 2021, 181, 111650. [Google Scholar] [CrossRef]

- Castillejo, N.; Martínez-Zamora, L.; Artés-Hernández, F. Periodical UV-B radiation hormesis in biosynthesis of kale sprouts nutraceuticals. Plant Physiol. Biochem. 2021, 165, 274–285. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, W. UV treatment improved the quality of postharvest fruits and vegetables by inducing resistance. Trends Food Sci. Technol. 2019, 92, 71–80. [Google Scholar] [CrossRef]

- Giménez, A.; Martínez-Ballesta, M.D.C.; Egea-Gilabert, C.; Gómez, P.A.; Artés-Hernández, F.; Pennisi, G.; Orsini, F.; Crepaldi, A.; Fernández, J.A. Combined Effect of Salinity and LED Lights on the Yield and Quality of Purslane (Portulaca oleracea L.) Microgreens. Horticulturae 2021, 7, 180. [Google Scholar] [CrossRef]

- Martínez-Zamora, L.; Castillejo, N.; Artés-Hernández, F. Postharvest UV-B and Photoperiod with Blue + Red LEDs as Strategies to Stimulate Carotenogenesis in Bell Peppers. Appl. Sci. 2021, 11, 3736. [Google Scholar] [CrossRef]

- Martínez-Zamora, L.; Castillejo, N.; Gómez, P.A.; Artés-Hernández, F. Amelioration Effect of LED Lighting in the Bioactive Compounds Synthesis during Carrot Sprouting. Agronomy 2021, 11, 304. [Google Scholar] [CrossRef]

- Castillejo, N.; Martínez-Zamora, L.; Gómez, P.A.; Pennisi, G.; Crepaldi, A.; Fernández, J.A.; Orsini, F.; Artés-Hernández, F. Postharvest yellow LED lighting affects phenolics and glucosinolates biosynthesis in broccoli sprouts. J. Food Compos. Anal. 2021, 103, 104101. [Google Scholar] [CrossRef]

- Wrona, O.; Rafińska, K.; Możeński, C.; Buszewski, B. Supercritical Fluid Extraction of Bioactive Compounds from Plant Materials. J. AOAC Int. 2017, 100, 1624–1635. [Google Scholar] [CrossRef]

- Jadhav, H.B.; Annapure, U.S.; Deshmukh, R.R. Non-thermal Technologies for Food Processing. Front. Nutr. 2021, 8, 657090. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.-H.; Wang, L.-H.; Zeng, X.-A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 explanation and elaboration: Updated guidance and exemplars for reporting systematic reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef] [PubMed]

- Borja-Martínez, M.; Lozano-Sánchez, J.; Borrás-Linares, I.; Pedreño, M.A.; Sabater-Jara, A.B. Revalorization of Broccoli By-Products for Cosmetic Uses Using Supercritical Fluid Extraction. Antioxidants 2020, 9, 1195. [Google Scholar] [CrossRef] [PubMed]

- Formica-Oliveira, A.C.; Martínez-Hernández, G.B.; Díaz-López, V.; Artés, F.; Artés-Hernández, F. Use of postharvest UV-B and UV-C radiation treatments to revalorize broccoli byproducts and edible florets. Innov. Food Sci. Emerg. Technol. 2017, 43, 77–83. [Google Scholar] [CrossRef]

- Ren, F.; Nian, Y.; Perussello, C.A. Effect of storage, food processing and novel extraction technologies on onions flavonoid content: A review. Food Res. Int. 2020, 132, 108953. [Google Scholar] [CrossRef]

- Dranca, F.; Oroian, M. Optimization of ultrasound-assisted extraction of total monomeric anthocyanin (TMA) and total phenolic content (TPC) from eggplant (Solanum melongena L.) peel. Ultrason. Sonochem. 2016, 31, 637–646. [Google Scholar] [CrossRef]

- Dulf, F.V.; Vodnar, D.C.; Socaciu, C. Effects of solid-state fermentation with two filamentous fungi on the total phenolic contents, flavonoids, antioxidant activities and lipid fractions of plum fruit (Prunus domestica L.) by-products. Food Chem. 2016, 209, 27–36. [Google Scholar] [CrossRef]

- Putnik, P.; Bursać Kovačević, D.; Režek Jambrak, A.; Barba, F.J.; Cravotto, G.; Binello, A.; Lorenzo, J.M.; Shpigelman, A. Innovative “Green” and Novel Strategies for the Extraction of Bioactive Added Value Compounds from Citrus Wastes—A Review. Molecules 2017, 22, 680. [Google Scholar] [CrossRef] [Green Version]

- Casquete, R.; Castro, S.M.; Villalobos, M.C.; Serradilla, M.J.; Queirós, R.P.; Saraiva, J.A.; Córdoba, M.G.; Teixeira, P. High pressure extraction of phenolic compounds from citrus peels†. High Press. Res. 2014, 34, 447–451. [Google Scholar] [CrossRef]

- Santos, D.I.; Martins, C.F.; Amaral, R.A.; Brito, L.; Saraiva, J.A.; Vicente, A.A.; Moldão-Martins, M. Pineapple (Ananas comosus L.) By-Products Valorization: Novel Bio Ingredients for Functional Foods. Molecules 2021, 26, 3216. [Google Scholar] [CrossRef] [PubMed]

- Santos, D.I.; Pinto, C.A.; Corrêa-Filho, L.C.; Saraiva, J.A.; Vicente, A.A.; Moldão-Martins, M. Effect of moderate hydrostatic pressures on the enzymatic activity and bioactive composition of pineapple by-products. J. Food Process Eng. 2020, e13537. [Google Scholar] [CrossRef]

- Parniakov, O.; Barba, F.J.; Grimi, N.; Lebovka, N.; Vorobiev, E. Extraction assisted by pulsed electric energy as a potential tool for green and sustainable recovery of nutritionally valuable compounds from mango peels. Food Chem. 2016, 192, 842–848. [Google Scholar] [CrossRef]

- Roselló-Soto, E.; Barba, F.J.; Parniakov, O.; Galanakis, C.M.; Lebovka, N.; Grimi, N.; Vorobiev, E. High Voltage Electrical Discharges, Pulsed Electric Field, and Ultrasound Assisted Extraction of Protein and Phenolic Compounds from Olive Kernel. Food Bioprocess Technol. 2015, 8, 885–894. [Google Scholar] [CrossRef]

- Luengo, E.; Álvarez, I.; Raso, J. Improving the pressing extraction of polyphenols of orange peel by pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2013, 17, 79–84. [Google Scholar] [CrossRef]

- Parniakov, O.; Barba, F.J.; Grimi, N.; Lebovka, N.; Vorobiev, E. Impact of pulsed electric fields and high voltage electrical discharges on extraction of high-added value compounds from papaya peels. Food Res. Int. 2014, 65, 337–343. [Google Scholar] [CrossRef]

- Yu, X.; Bals, O.; Grimi, N.; Vorobiev, E. A new way for the oil plant biomass valorization: Polyphenols and proteins extraction from rapeseed stems and leaves assisted by pulsed electric fields. Ind. Crops Prod. 2015, 74, 309–318. [Google Scholar] [CrossRef]

- Barba, F.J.; Boussetta, N.; Vorobiev, E. Emerging technologies for the recovery of isothiocyanates, protein and phenolic compounds from rapeseed and rapeseed press-cake: Effect of high voltage electrical discharges. Innov. Food Sci. Emerg. Technol. 2015, 31, 67–72. [Google Scholar] [CrossRef]

- López, N.; Puértolas, E.; Condón, S.; Álvarez, I.; Raso, J. Effects of pulsed electric fields on the extraction of phenolic compounds during the fermentation of must of Tempranillo grapes. Innov. Food Sci. Emerg. Technol. 2008, 9, 477–482. [Google Scholar] [CrossRef]

- Barba, F.J.; Brianceau, S.; Turk, M.; Boussetta, N.; Vorobiev, E. Effect of Alternative Physical Treatments (Ultrasounds, Pulsed Electric Fields, and High-Voltage Electrical Discharges) on Selective Recovery of Bio-compounds from Fermented Grape Pomace. Food Bioprocess Technol. 2015, 8, 1139–1148. [Google Scholar] [CrossRef]

- Boussetta, N.; Vorobiev, E.; Le, L.H.; Cordin-Falcimaigne, A.; Lanoisellé, J.L. Application of electrical treatments in alcoholic solvent for polyphenols extraction from grape seeds. LWT Food Sci. Technol. 2012, 46, 127–134. [Google Scholar] [CrossRef]

- Zia, S.; Khan, M.R.; Shabbir, M.A.; Aslam Maan, A.; Khan, M.K.I.; Nadeem, M.; Khalil, A.A.; Din, A.; Aadil, R.M. An Inclusive Overview of Advanced Thermal and Nonthermal Extraction Techniques for Bioactive Compounds in Food and Food-related Matrices. Food Rev. Int. 2020, 1–31. [Google Scholar] [CrossRef]

- Brianceau, S.; Turk, M.; Vitrac, X.; Vorobiev, E. Combined densification and pulsed electric field treatment for selective polyphenols recovery from fermented grape pomace. Innov. Food Sci. Emerg. Technol. 2015, 29, 2–8. [Google Scholar] [CrossRef]

- Barba, F.J.; Zhu, Z.; Koubaa, M.; Sant’Ana, A.S.; Orlien, V. Green alternative methods for the extraction of antioxidant bioactive compounds from winery wastes and by-products: A review. Trends Food Sci. Technol. 2016, 49, 96–109. [Google Scholar] [CrossRef]

- Delsart, C.; Cholet, C.; Ghidossi, R.; Grimi, N.; Gontier, E.; Gény, L.; Vorobiev, E.; Mietton-Peuchot, M. Effects of Pulsed Electric Fields on Cabernet Sauvignon Grape Berries and on the Characteristics of Wines. Food Bioprocess Technol. 2014, 7, 424–436. [Google Scholar] [CrossRef]

- Rajha, H.N.; Boussetta, N.; Louka, N.; Maroun, R.G.; Vorobiev, E. A comparative study of physical pretreatments for the extraction of polyphenols and proteins from vine shoots. Food Res. Int. 2014, 65, 462–468. [Google Scholar] [CrossRef]

- El Kantar, S.; Boussetta, N.; Lebovka, N.; Foucart, F.; Rajha, H.N.; Maroun, R.G.; Louka, N.; Vorobiev, E. Pulsed electric field treatment of citrus fruits: Improvement of juice and polyphenols extraction. Innov. Food Sci. Emerg. Technol. 2018, 46, 153–161. [Google Scholar] [CrossRef]

- Palma, M.; Taylor, L.T. Extraction of polyphenolic compounds from grape seeds with near critical carbon dioxide. J. Chromatogr. A 1999, 849, 117–124. [Google Scholar] [CrossRef]

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and opportunities for ultrasound assisted extraction in the food industry—A review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169. [Google Scholar] [CrossRef]

- Pataro, G.; Bobinaitė, R.; Bobinas, Č.; Šatkauskas, S.; Raudonis, R.; Visockis, M.; Ferrari, G.; Viškelis, P. Improving the Extraction of Juice and Anthocyanins from Blueberry Fruits and Their By-products by Application of Pulsed Electric Fields. Food Bioprocess Technol. 2017, 10, 1595–1605. [Google Scholar] [CrossRef]

- Arruda, H.S.; Silva, E.K.; Peixoto Araujo, N.M.; Pereira, G.A.; Pastore, G.M.; Marostica Junior, M.R. Anthocyanins Recovered from Agri-Food By-Products Using Innovative Processes: Trends, Challenges, and Perspectives for Their Application in Food Systems. Molecules 2021, 26, 2632. [Google Scholar] [CrossRef]

- Bobinaitė, R.; Pataro, G.; Raudonis, R.; Vškelis, P.; Bobinas, Č.; Šatkauskas, S.; Ferrari, G. Improving the Extraction of Juice and Anthocyanin Compounds from Blueberry Fruits and Their by-Products by Pulsed Electric Fields; Springer: Singapore, 2016; pp. 363–366. [Google Scholar]

- Medina-Meza, I.G.; Barbosa-Cánovas, G.V. Assisted extraction of bioactive compounds from plum and grape peels by ultrasonics and pulsed electric fields. J. Food Eng. 2015, 166, 268–275. [Google Scholar] [CrossRef]

- Corrales, M.; Toepfl, S.; Butz, P.; Knorr, D.; Tauscher, B. Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: A comparison. Innov. Food Sci. Emerg. Technol. 2008, 9, 85–91. [Google Scholar] [CrossRef]

- Corrales, M.; García, A.F.; Butz, P.; Tauscher, B. Extraction of anthocyanins from grape skins assisted by high hydrostatic pressure. J. Food Eng. 2009, 90, 415–421. [Google Scholar] [CrossRef]

- Bobinaitė, R.; Pataro, G.; Lamanauskas, N.; Šatkauskas, S.; Viškelis, P.; Ferrari, G. Application of pulsed electric field in the production of juice and extraction of bioactive compounds from blueberry fruits and their by-products. J. Food Sci. Technol. 2015, 52, 5898–5905. [Google Scholar] [CrossRef]

- Lončarić, A.; Celeiro, M.; Jozinović, A.; Jelinić, J.; Kovač, T.; Jokić, S.; Babić, J.; Moslavac, T.; Zavadlav, S.; Lores, M. Green Extraction Methods for Extraction of Polyphenolic Compounds from Blueberry Pomace. Foods 2020, 9, 1521. [Google Scholar] [CrossRef] [PubMed]

- Plazzotta, S.; Ibarz, R.; Manzocco, L.; Martín-Belloso, O. Modelling the recovery of biocompounds from peach waste assisted by pulsed electric fields or thermal treatment. J. Food Eng. 2021, 290, 110196. [Google Scholar] [CrossRef]

- Lamanauskas, N.; Pataro, G.; Bobinas, Č.; Šatkauskas, S.; Viškelis, P.; Bobinaitė, R.; Ferrari, G. Impact of pulsed electric field treatment on juice yield and recovery of bioactive compounds from raspberries and their by-products. Zemdirbyste 2016, 103, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Kurtulbaş Şahin, E.; Bilgin, M.; Şahin, S. Recovery of anthocyanins from sour cherry (Prunus cerasus L.) peels via microwave assisted extraction: Monitoring the storage stability. Prep. Biochem. Biotechnol. 2021, 51, 686–696. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Bobinaiu, R.; Donsì, G.; Ferrari, G. Improving the Extraction Yield of Juice and Bioactive Compounds from Sweet Cherries and Their By-products by Pulsed Electric Fields. Chem. Eng. Trans. 2017, 57, 1717–1722. [Google Scholar]

- El Darra, N.; Grimi, N.; Maroun, R.G.; Louka, N.; Vorobiev, E. Pulsed electric field, ultrasound, and thermal pretreatments for better phenolic extraction during red fermentation. Eur. Food Res. Technol. 2013, 236, 47–56. [Google Scholar] [CrossRef]

- El Darra, N.; Grimi, N.; Vorobiev, E.; Maroun, R.G.; Louka, N. Pulsed Electric Field-Assisted Cold Maceration of Cabernet franc and Cabernet Sauvignon Grapes. Am. J. Enol. Vitic. 2013, 64, 476–484. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, X.; Huang, H. Effects of Pulsed Electric Fields on Anthocyanin Extraction Yield of Blueberry Processing By-Products. J. Food Processing Preserv. 2015, 39, 1898–1904. [Google Scholar] [CrossRef]

- Bleve, M.; Ciurlia, L.; Erroi, E.; Lionetto, G.; Longo, L.; Rescio, L.; Schettino, T.; Vasapollo, G. An innovative method for the purification of anthocyanins from grape skin extracts by using liquid and sub-critical carbon dioxide. Sep. Purif. Technol. 2008, 64, 192–197. [Google Scholar] [CrossRef]

- Gadioli Tarone, A.; Keven Silva, E.; Dias de Freitas Queiroz Barros, H.; Baú Betim Cazarin, C.; Roberto Marostica Junior, M. High-intensity ultrasound-assisted recovery of anthocyanins from jabuticaba by-products using green solvents: Effects of ultrasound intensity and solvent composition on the extraction of phenolic compounds. Food Res. Int. 2021, 140, 110048. [Google Scholar] [CrossRef] [PubMed]

- Albuquerque, B.R.; Pinela, J.; Barros, L.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R. Anthocyanin-rich extract of jabuticaba epicarp as a natural colorant: Optimization of heat- and ultrasound-assisted extractions and application in a bakery product. Food Chem. 2020, 316, 126364. [Google Scholar] [CrossRef] [PubMed]

- More, P.R.; Arya, S.S. Intensification of bio-actives extraction from pomegranate peel using pulsed ultrasound: Effect of factors, correlation, optimization and antioxidant bioactivities. Ultrason. Sonochem. 2021, 72, 105423. [Google Scholar] [CrossRef] [PubMed]

- Barba, F.J.; Putnik, P.; Bursać Kovačević, D.; Poojary, M.M.; Roohinejad, S.; Lorenzo, J.M.; Koubaa, M. Impact of conventional and non-conventional processing on prickly pear (Opuntia spp.) and their derived products: From preservation of beverages to valorization of by-products. Trends Food Sci. Technol. 2017, 67, 260–270. [Google Scholar] [CrossRef]

- Koubaa, M.; Barba, F.J.; Grimi, N.; Mhemdi, H.; Koubaa, W.; Boussetta, N.; Vorobiev, E. Recovery of colorants from red prickly pear peels and pulps enhanced by pulsed electric field and ultrasound. Innov. Food Sci. Emerg. Technol. 2016, 37, 336–344. [Google Scholar] [CrossRef]

- Amiri-Rigi, A.; Abbasi, S. Microemulsion-based lycopene extraction: Effect of surfactants, co-surfactants and pretreatments. Food Chem. 2016, 197, 1002–1007. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Falcone, M.; Ferrari, G. Recovery of lycopene from industrially derived tomato processing by-products by pulsed electric fields-assisted extraction. Innov. Food Sci. Emerg. Technol. 2020, 63, 102369. [Google Scholar] [CrossRef]

- de Andrade Lima, M.; Kestekoglou, I.; Charalampopoulos, D.; Chatzifragkou, A. Supercritical Fluid Extraction of Carotenoids from Vegetable Waste Matrices. Molecules 2019, 24, 466. [Google Scholar] [CrossRef] [Green Version]

- Wani, F.A.; Rashid, R.; Jabeen, A.; Brochier, B.; Yadav, S.; Aijaz, T.; Makroo, H.A.; Dar, B.N. Valorisation of food wastes to produce natural pigments using non-thermal novel extraction methods: A review. Int. J. Food Sci. Technol. 2021, 56, 4823–4833. [Google Scholar] [CrossRef]

- Shahram, H.; Dinani, S.T. Optimization of ultrasonic-assisted enzymatic extraction of β-carotene from orange processing waste. J. Food Process Eng. 2019, 42, e13042. [Google Scholar] [CrossRef]

- Kumar, K.; Srivastav, S.; Sharanagat, V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrason. Sonochem. 2021, 70, 105325. [Google Scholar] [CrossRef] [PubMed]

- Luengo, E.; Condón-Abanto, S.; Condón, S.; Álvarez, I.; Raso, J. Improving the extraction of carotenoids from tomato waste by application of ultrasound under pressure. Sep. Purif. Technol. 2014, 136, 130–136. [Google Scholar] [CrossRef]

- Marić, M.; Grassino, A.N.; Zhu, Z.; Barba, F.J.; Brnčić, M.; Rimac Brnčić, S. An overview of the traditional and innovative approaches for pectin extraction from plant food wastes and by-products: Ultrasound-, microwaves-, and enzyme-assisted extraction. Trends Food Sci. Technol. 2018, 76, 28–37. [Google Scholar] [CrossRef]

- Wikiera, A.; Mika, M.; Grabacka, M. Multicatalytic enzyme preparations as effective alternative to acid in pectin extraction. Food Hydrocoll. 2015, 44, 156–161. [Google Scholar] [CrossRef]

- Yuliarti, O.; Goh, K.K.; Matia-Merino, L.; Mawson, J.; Brennan, C. Extraction and characterisation of pomace pectin from gold kiwifruit (Actinidia chinensis). Food Chem. 2015, 187, 290–296. [Google Scholar] [CrossRef]

- Liew, S.Q.; Chin, N.L.; Yusof, Y.A.; Sowndhararajan, K. Comparison of Acidic and Enzymatic Pectin Extraction from Passion Fruit Peels and Its Gel Properties. J. Food Process Eng. 2016, 39, 501–511. [Google Scholar] [CrossRef]

- Dominiak, M.; Søndergaard, K.M.; Wichmann, J.; Vidal-Melgosa, S.; Willats, W.G.T.; Meyer, A.S.; Mikkelsen, J.D. Application of enzymes for efficient extraction, modification, and development of functional properties of lime pectin. Food Hydrocoll. 2014, 40, 273–282. [Google Scholar] [CrossRef]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Serna-Saldivar, S.O.; Welti-Chanes, J. Dietary Fiber Concentrates from Fruit and Vegetable By-products: Processing, Modification, and Application as Functional Ingredients. Food Bioprocess Technol. 2018, 11, 1439–1463. [Google Scholar] [CrossRef]

- Tejada-Ortigoza, V.; Garcia-Amezquita, L.E.; Serna-Saldívar, S.O.; Martín-Belloso, O.; Welti-Chanes, J. High Hydrostatic Pressure and Mild Heat Treatments for the Modification of Orange Peel Dietary Fiber: Effects on Hygroscopic Properties and Functionality. Food Bioprocess Technol. 2018, 11, 110–121. [Google Scholar] [CrossRef]

- de Oliveira, C.F.; Giordani, D.; Gurak, P.D.; Cladera-Olivera, F.; Marczak, L.D.F. Extraction of pectin from passion fruit peel using moderate electric field and conventional heating extraction methods. Innov. Food Sci. Emerg. Technol. 2015, 29, 201–208. [Google Scholar] [CrossRef]

- Ninčević Grassino, A.; Ostojić, J.; Miletić, V.; Djaković, S.; Bosiljkov, T.; Zorić, Z.; Ježek, D.; Rimac Brnčić, S.; Brnčić, M. Application of high hydrostatic pressure and ultrasound-assisted extractions as a novel approach for pectin and polyphenols recovery from tomato peel waste. Innov. Food Sci. Emerg. Technol. 2020, 64, 102424. [Google Scholar] [CrossRef]

- Wang, W.; Ma, X.; Xu, Y.; Cao, Y.; Jiang, Z.; Ding, T.; Ye, X.; Liu, D. Ultrasound-assisted heating extraction of pectin from grapefruit peel: Optimization and comparison with the conventional method. Food Chem. 2015, 178, 106–114. [Google Scholar] [CrossRef]

- Encalada, A.M.I.; Pérez, C.D.; Flores, S.K.; Rossetti, L.; Fissore, E.N.; Rojas, A.M. Antioxidant pectin enriched fractions obtained from discarded carrots (Daucus carota L.) by ultrasound-enzyme assisted extraction. Food Chem. 2019, 289, 453–460. [Google Scholar] [CrossRef]

- Artés, F.; Allende, A. Minimal Processing of Fresh Fruit, Vegetables, and Juices. In Emerging Technologies for Food Processing, 2nd ed.; Sun, D.-W., Ed.; Academic Press: San Diego, CA, USA, 2014; Chapter 31; pp. 583–597. [Google Scholar] [CrossRef]

- Ruiz Rodríguez, L.G.; Zamora Gasga, V.M.; Pescuma, M.; Van Nieuwenhove, C.; Mozzi, F.; Sánchez Burgos, J.A. Fruits and fruit by-products as sources of bioactive compounds. Benefits and trends of lactic acid fermentation in the development of novel fruit-based functional beverages. Food Res. Int. 2021, 140, 109854. [Google Scholar] [CrossRef]

- Lavelli, V.; Sri Harsha, P.S.C.; Torri, L.; Zeppa, G. Use of winemaking by-products as an ingredient for tomato puree: The effect of particle size on product quality. Food Chem. 2014, 152, 162–168. [Google Scholar] [CrossRef]

- Ning, X.; Wu, J.; Luo, Z.; Chen, Y.; Mo, Z.; Luo, R.; Bai, C.; Du, W.; Wang, L. Cookies fortified with purple passion fruit epicarp flour: Impact on physical properties, nutrition, in vitro starch digestibility, and antioxidant activity. Cereal Chem. 2021, 98, 328–336. [Google Scholar] [CrossRef]

- Marinelli, V.; Lucera, A.; Incoronato, A.L.; Morcavallo, L.; Del Nobile, M.A.; Conte, A. Strategies for fortified sustainable food: The case of watermelon-based candy. J. Food Sci. Technol. 2021, 58, 894–901. [Google Scholar] [CrossRef]

- Mandha, J.; Shumoy, H.; Matemu, A.O.; Raes, K. Valorization of Mango By-Products to Enhance the Nutritional Content of Maize Complementary Porridges. Foods 2021, 10, 1635. [Google Scholar] [CrossRef] [PubMed]

- Cedola, A.; Cardinali, A.; D’Antuono, I.; Conte, A.; Del Nobile, M.A. Cereal foods fortified with by-products from the olive oil industry. Food Biosci. 2020, 33, 100490. [Google Scholar] [CrossRef]

- Wang, J.; Brennan, M.A.; Brennan, C.S.; Serventi, L. Effect of Vegetable Juice, Puree, and Pomace on Chemical and Technological Quality of Fresh Pasta. Foods 2021, 10, 1931. [Google Scholar] [CrossRef]

- Mohd Basri, M.S.; Abdul Karim Shah, N.N.; Sulaiman, A.; Mohamed Amin Tawakkal, I.S.; Mohd Nor, M.Z.; Ariffin, S.H.; Abdul Ghani, N.H.; Mohd Salleh, F.S. Progress in the Valorization of Fruit and Vegetable Wastes: Active Packaging, Biocomposites, By-Products, and Innovative Technologies Used for Bioactive Compound Extraction. Polymers 2021, 13, 3503. [Google Scholar] [CrossRef]

- Bayram, B.; Ozkan, G.; Kostka, T.; Capanoglu, E.; Esatbeyoglu, T. Valorization and Application of Fruit and Vegetable Wastes and By-Products for Food Packaging Materials. Molecules 2021, 26, 4031. [Google Scholar] [CrossRef] [PubMed]

- Tauferova, A.; Pospiech, M.; Javurkova, Z.; Tremlova, B.; Dordevic, D.; Jancikova, S.; Tesikova, K.; Zdarsky, M.; Vitez, T.; Vitezova, M. Plant Byproducts as Part of Edible Coatings: A Case Study with Parsley, Grape and Blueberry Pomace. Polymers 2021, 13, 2578. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhang, L.; Ser, S.L.; Cumming, J.R.; Ku, K.-M. Comparative Phytonutrient Analysis of Broccoli By-Products: The Potentials for Broccoli By-Product Utilization. Molecules 2018, 23, 900. [Google Scholar] [CrossRef] [Green Version]

- Espro, C.; Paone, E.; Mauriello, F.; Gotti, R.; Uliassi, E.; Bolognesi, M.L.; Rodríguez-Padrón, D.; Luque, R. Sustainable production of pharmaceutical, nutraceutical and bioactive compounds from biomass and waste. Chem. Soc. Rev. 2021, 50, 11191–11207. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano-Lamadrid, M.; Artés-Hernández, F. By-Products Revalorization with Non-Thermal Treatments to Enhance Phytochemical Compounds of Fruit and Vegetables Derived Products: A Review. Foods 2022, 11, 59. https://doi.org/10.3390/foods11010059

Cano-Lamadrid M, Artés-Hernández F. By-Products Revalorization with Non-Thermal Treatments to Enhance Phytochemical Compounds of Fruit and Vegetables Derived Products: A Review. Foods. 2022; 11(1):59. https://doi.org/10.3390/foods11010059

Chicago/Turabian StyleCano-Lamadrid, Marina, and Francisco Artés-Hernández. 2022. "By-Products Revalorization with Non-Thermal Treatments to Enhance Phytochemical Compounds of Fruit and Vegetables Derived Products: A Review" Foods 11, no. 1: 59. https://doi.org/10.3390/foods11010059