Effect of Dairy, Season, and Sampling Position on Physical Properties of Trentingrana Cheese: Application of an LMM-ASCA Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling Procedure

2.2. Analytic Determinations

2.2.1. Color

2.2.2. Textural Properties

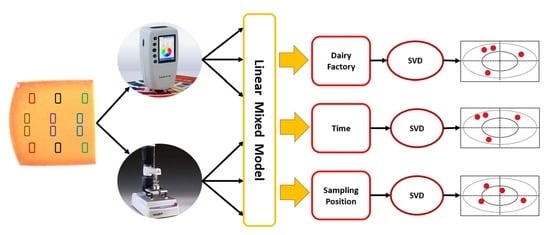

2.3. Statistical Analysis

2.4. Model Selection

2.5. Permutation Test for Linear Mixed Models’ Significance

2.6. Estimation of the Model

2.7. Statistical Software

3. Results and Discussion

3.1. Linear Mixed Models

3.2. Simultaneous Component Analysis: LMM-ASCA Results

3.2.1. Dairy Factory

3.2.2. Time

3.2.3. Sampling Position

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- EUR-lex. Commission Regulation (EC) No 1107/96 of 12 June 1996. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:01996R1107-20081120 (accessed on 19 November 2021).

- Endrizzi, I.; Aprea, E.; Biasioli, F.; Corollaro, M.L.; Demattè, L.; Penasa, M.; Bittante, G.; Gasperi, F. Implementing sensory analysis principles in the quality control of PDO products: A critical evaluation of a real-world case study. J. Sens. Stud. 2013, 28, 14–24. [Google Scholar] [CrossRef]

- Ministero delle Politiche Agricole Alimentari e Forestali. Disciplinare Grana Padano 07.10.2019. 2019. Available online: https://www.politicheagricole.it/flex/cm/pages/ServeAttachment.php/L/IT/D/e%252F7%252F7%252FD.fd9b8410457c0a5b2a84/P/BLOB%3AID%3D3340/E/pdf (accessed on 19 November 2021).

- Fox, P.F.; Cogan, T.M. Factors that Affect the Quality of Cheese. In Cheese: Chemistry, Physics and Microbiology, III ed.; Elsevier: Amsterdam, Netherlands, 2004; Volume 1, pp. 583–608. [Google Scholar]

- Bittante, G.; Cecchinato, A.; Cologna, N.; Penasa, M.; Tiezzi, F.; de Marchi, M. Factors affecting the incidence of first-quality wheels of Trentingrana cheese. J. Dairy Sci. 2011, 94, 3700–3707. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McDermott, A.; Visentin, G.; McParland, S.; Berry, D.P.; Fenelon, M.A.; De Marchi, M. Effectiveness of mid-infrared spectroscopy to predict the color of bovine milk and the relationship between milk color and traditional milk quality traits. J. Dairy Sci. 2016, 99, 3267–3273. [Google Scholar] [CrossRef] [PubMed]

- Mucchetti, G.; Gatti, M.; Nocetti, M.; Reverberi, P.; Bianchi, A.; Galati, F.; Petroni, A. Segmentation of Parmigiano Reggiano dairies according to cheese-making technology and relationships with the aspect of the cheese curd surface at the moment of its extraction from the cheese vat. J. Dairy Sci. 2014, 97, 1202–1209. [Google Scholar] [CrossRef] [PubMed]

- Banks, J.M. What general factors affect the texture of hard and semihard cheeses? In Cheese Problems Solved; McSweeney, P.L.H., Ed.; Woodhead Publishing Limited: Sawston, UK, 2007; pp. 200–201. [Google Scholar]

- Cipolat-Gotet, C.; Cecchinato, A.; de Marchi, M.; Bittante, G. Factors affecting the variation of different measures of cheese yield and milk nutrient recovery from an individual model cheese-manufacturing process. J. Dairy Sci. 2013, 96, 7952–7965. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bellesia, F.; Pinetti, A.; Pagnoni, U.M.; Rinaldi, R.; Zucchi, C.; Caglioti, L.; Palyi, G. Volatile components of Grana Par-mi-giano-Reggiano type hard cheese. Food Chem. 2003, 83, 55–61. [Google Scholar] [CrossRef]

- Careri, M.; Spagnoli, S.; Panari, G.; Zannoni, M.; Barbieri, G. Chemical parameters of the non-volatile fraction of ripened Parmigiano-Reggiano cheese. Int. Dairy J. 1996, 6, 147–155. [Google Scholar] [CrossRef]

- Franceschi, P.; Malacarne, M.; Formaggioni, P.; Cipolat-Gotet, C.; Stocco, G.; Summer, A. Effect of Season and Factory on Cheese-Making Efficiency in Parmigiano Reggiano Manufacture. Foods 2019, 8, 315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting Linear Mixed-Effects Models Using lme4. J. Stat. Softw. 2015, 67, 1–48. [Google Scholar] [CrossRef]

- Smilde, A.K.; Timmerman, M.E.; Hendriks, M.M.W.B.; Jansen, J.J.; Hoefsloot, H.C.J. Generic framework for high-dimensional fixed-effects ANOVA. Brief. Bioinform. 2012, 13, 524–535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stamirova, I.; Kazura, M.; De Beer, D.; Joubert, E.; Schulze, A.E.; Beelders, T.; de Villiers, A.; Walczak, B. High-dimensional nested analysis of variance to assess the effect of production season, quality grade and steam pas-teuri-zation on the phenolic composition of fermented rooibos herbal tea. Talanta 2013, 115, 590–599. [Google Scholar] [CrossRef] [PubMed]

- Martin, M.; Govaerts, B. LiMM-PCA: Combining ASCA+ and linear mixed models to analyse high-dimensional de-signed data. J. Chemom. 2020, 34, e3232. [Google Scholar] [CrossRef]

- Janos, S. CIE Colorimetry in Colorimetry: Understanding the CIE System; Janos, S., Ed.; Wiley-Interscience: Hoboken, NJ, USA, 2007. [Google Scholar]

- Noël, Y.; Zannoni, M.; Hunter, E.A. Texture of Parmigiano Reggiano cheese: Statistical relationships between rheological and sensory variates. Lait 1996, 76, 243–254. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021; Available online: https://www.R-project.org/ (accessed on 28 November 2021).

- Kassambara, A. Ggpubr: ‘ggplot2’ Based Publication Ready Plots. R Package Version 0.4.0. 2020. Available online: https://CRAN.R-project.org/package=ggpubr (accessed on 28 November 2021).

- Kassambara, A.; Mundt, F. Factoextra: Extract and Visualize the Results of Multivariate Data Analyses. R Package Version 1.0.7. 2020. Available online: https://CRAN.R-project.org/package=factoextra (accessed on 28 November 2021).

- Kassambara, A. Practical Guide to Principal Component Methods in R; STHDA: Marseille, France, 2017. [Google Scholar]

- Hartigan, J.A.; Wong, M.A. Algorithm AS 136: A K-Means Clustering Algorithm. J. R. Stat. Soc. 1979, 28, 100–108. [Google Scholar] [CrossRef]

- Kassambara, A. Multivariate Analysis I: Practical Guide to Cluster Analysis in R. Unsupervised Machine Learning; STHDA: Marseille, France, 2017. [Google Scholar]

- Prentice, J.H. Dairy Rheology—A Concise Guide; VCH: Weinheim, Germany, 1992. [Google Scholar]

- Milovanovic, B.; Djekic, I.; Miocinovic, J.; Djordjevic, V.; Lorenzo, J.M.; Barba, F.J.; Mörlein, D.; Tomasevic, I. What Is the Color of Milk and Dairy Products and How Is It Measured? Foods 2020, 9, 1629. [Google Scholar] [CrossRef] [PubMed]

- Bley, M.E.; Johnson, M.E.; Olson, N.F. Factors Affecting Nonenzymatic Browning of Process Cheese. J. Dairy Sci. 1985, 68, 555–561. [Google Scholar] [CrossRef]

- Adachi, K.; Igoshi, A.; Murata, M. Analyses of factors affecting the browning of model processed cheese during storage. J. Nutr. Sci. Vitaminol. 2020, 66, 364–369. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Description | Measure Unit |

|---|---|---|

| Maximum Force (Fmax) | The maximum amount of force applied by the uniaxial probe to the sample. | N |

| Area under the curve (Ac) | The whole area under the force/strain curve during the compression of the sample until the endpoint. | N*mm |

| Elastic modulus (El) | The slope of the linear part of the stress-strain curve. | N/mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricci, M.; Gasperi, F.; Endrizzi, I.; Menghi, L.; Cliceri, D.; Franceschi, P.; Aprea, E. Effect of Dairy, Season, and Sampling Position on Physical Properties of Trentingrana Cheese: Application of an LMM-ASCA Model. Foods 2022, 11, 127. https://doi.org/10.3390/foods11010127

Ricci M, Gasperi F, Endrizzi I, Menghi L, Cliceri D, Franceschi P, Aprea E. Effect of Dairy, Season, and Sampling Position on Physical Properties of Trentingrana Cheese: Application of an LMM-ASCA Model. Foods. 2022; 11(1):127. https://doi.org/10.3390/foods11010127

Chicago/Turabian StyleRicci, Michele, Flavia Gasperi, Isabella Endrizzi, Leonardo Menghi, Danny Cliceri, Pietro Franceschi, and Eugenio Aprea. 2022. "Effect of Dairy, Season, and Sampling Position on Physical Properties of Trentingrana Cheese: Application of an LMM-ASCA Model" Foods 11, no. 1: 127. https://doi.org/10.3390/foods11010127