A Novel Three-Step Extraction Strategy for High-Value Products from Red Algae Porphyridium purpureum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microorganisms and Culture Conditions

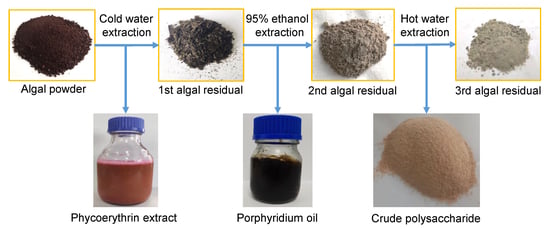

2.2. Fractional Extraction Process of Active Substances

2.2.1. Phycoerythrin

2.2.2. Crude Lipid

2.2.3. Intracellular Polysaccharide

2.3. Phycobiliprotein Content

2.4. Lipid Composition

2.5. Biochemical Composition of Biomass

2.6. Determination of Monosaccharide Composition

2.7. Determination of Uronic Acid and Sulfate Radical Content

2.8. Determination of Antioxidant Activity

2.8.1. ABTS Radical Scavenging Ability

2.8.2. DPPH Radical Scavenging Activity

2.8.3. Superoxide Anion Radical Scavenging Activity

2.9. Fourier-Transform Infrared Spectroscopy (FTIR)

2.10. Spectral Characteristics of Crude Phycoerythrin

2.11. Statistical Analysis

3. Results

3.1. Biomass Reduction during Three-Step Extraction

3.2. Biochemical Composition of the Reduced Biomass during Three-Step Extraction

3.3. Spectral Characteristics of Crude Phycoerythrin

3.4. Lipomics Analysis of Ethanol Extract

3.5. Characteristics of Polysaccharides in Porphyridium

3.6. Antioxidant Activity of the Respective Extracts of Porphyridium

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.H.; Ji, L.; Shi, Q.W.; Wu, H.Z.; Fan, J.H. Advances in the Production of Bioactive Substances from Marine Unicellular Microalgae Porphyridium spp. Bioresour. Technol. 2019, 292, 122048. [Google Scholar] [CrossRef] [PubMed]

- Dvir, I.; Moppes, D.; Arad, S. Foodomics: To Discover the Health Potential of Microalgae. In Comprehensive Foodomics; Elsevier: Oxford, UK, 2021; pp. 658–671. [Google Scholar]

- Pagels, F.; Guedes, A.C.; Amaro, H.M.; Kijjoa, A.; Vasconcelos, V. Phycobiliproteins from Cyanobacteria: Chemistry and Biotechnological Applications. Biotechnol. Adv. 2019, 37, 422–443. [Google Scholar] [CrossRef] [PubMed]

- Sekar, S.; Chandramohan, M. Phycobiliproteins as a Commodity: Trends in Applied Research, Patents and Commercialization. J. Appl. Phycol. 2008, 20, 113–136. [Google Scholar] [CrossRef]

- Li, T.; Xu, J.; Wu, H.; Jiang, P.; Chen, Z.; Xiang, W. Growth and Biochemical Composition of Porphyridium purpureum SCS-02 under Different Nitrogen Concentrations. Mar. Drugs 2019, 17, 124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- B-Phycoerythrin from Porphyridium cruentum. Available online: https://www.sigmaaldrich.cn/CN/en/product/sigma/p1286?context=product (accessed on 4 August 2021).

- Lauceri, R.; Chini Zittelli, G.; Torzillo, G. A Simple Method for Rapid Purification of Phycobiliproteins from Arthrospira platensis and Porphyridium cruentum Biomass. Algal Res. 2019, 44, 101685. [Google Scholar] [CrossRef]

- Munier, M.; Jubeau, S.; Wijaya, A.; Morancais, M.; Dumay, J.; Marchal, L.; Jaouen, P.; Fleurence, J. Physicochemical Factors Affecting the Stability of Two Pigments: R-Phycoerythrin of Grateloupia turuturu and B-Phycoerythrin of Porphyridium cruentum. Food Chem. 2014, 150, 400–407. [Google Scholar] [CrossRef]

- Durmaz, Y.; Monteiro, M.; Bandarra, N.; Gokpinar, S.; Isik, O. The Effect of Low Temperature on Fatty Acid Composition and Tocopherols of the Red Microalga, Porphyridium cruentum. J. Appl. Phycol. 2007, 19, 223–227. [Google Scholar] [CrossRef]

- Guiheneuf, F.; Stengel, D.B. Towards the Biorefinery Concept: Interaction of Light, Temperature and Nitrogen for Optimizing the Co-Production of High-Value Compounds in Porphyridium purpureum. Algal Res. 2015, 10, 152–163. [Google Scholar] [CrossRef]

- 75-Day-Premarket-Ndin-1995-to-Present-Aug132021. Available online: https://www.fda.gov/media/108748/download (accessed on 3 September 2021).

- Manufacturer Supply Nannochloropsis Powder. Available online: https://www.alibaba.com/product-detail/Manufacturer-Supply-Nannochloropsis-Powder-Supplier-Nannochloropsis_1600291553066.html?spm=a2700.galleryofferlist.normal_offer.d_title.505982f6CUvsZP&s=p (accessed on 3 September 2021).

- Callejon, M.J.J.; Medina, A.R.; Sanchez, M.D.M.; Cerdan, L.E.; Moreno, P.A.G.; Lopez, E.N.; Pena, E.H.; Grima, E.M. Obtaining Highly Pure EPA-rich Lipids from Dry and Wet Nannochloropsis gaditana Microalgal Biomass Using Ethanol, Hexane and Acetone. Algal Res. 2020, 45, 101729. [Google Scholar] [CrossRef]

- Yang, F.F.; Cheng, C.H.; Long, L.J.; Hu, Q.J.; Jia, Q.K.; Wu, H.L.; Xiang, W.Z. Extracting Lipids from Several Species of Wet Microalgae Using Ethanol at Room Temperature. Energy Fuel. 2015, 29, 2380–2386. [Google Scholar] [CrossRef]

- Nagle, V.; Gaikwad, M.; Pawar, Y.; Dasgupta, S. Marine Red Alga Porphyridium sp. As a Source of Sulfated Polysaccharides (SPs) for Combating against COVID-19. Preprints 2020, 2020040168, 1–18. [Google Scholar]

- Jonsson, M.; Allahgholi, L.; Sardari, R.R.R.; Hreggvidsson, G.O.; Karlsson, E.N. Extraction and Modification of Macroalgal Polysaccharides for Current and Next-Generation Applications. Molecules 2020, 25, 930. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, T.; Xu, J.; Wu, H.L.; Wang, G.H.; Dai, S.K.; Fan, J.W.; He, H.; Xiang, W.Z. A Saponification Method for Chlorophyll Removal from Microalgae Biomass as Oil Feedstock. Mar. Drugs. 2016, 14, 162. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Luo, G.; Wang, L.; Yuan, W. Optimization of Antioxidant Extraction from Edible Brown Algae Ascophyllum nodosum Using Response Surface Methodology. Food Bioprod. Process. 2019, 114, 205–215. [Google Scholar] [CrossRef]

- Schneedorferová, I.; Tomčala, A.; Valterová, I. Effect of Heat Treatment on the n-3/n-6 Ratio and Content of Polyunsaturated Fatty Acids in Fish Tissues. Food Chem. 2015, 176, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein Measurement with the Folin Phenol Reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Khozin-Goldberg, I.; Shrestha, P.; Cohen, Z. Mobilization of Arachidonyl Moieties from Triacylglycerols into Chloroplastic Lipids Following Recovery from Nitrogen Starvation of the Microalga Parietochloris incisa. BBA-Mol. Cell Biol. L. 2006, 1761, 501. [Google Scholar]

- Luo, J.G.; Liu, J.; Sun, Y.; Ye, H.; Zhou, C.H.; Zeng, X.X. Medium Optimization, Preliminary Characterization and Antioxidant Activity in Vivo of Mycelial Polysaccharide from Phellinus baumii Pilat. Carbohyd. Polym. 2010, 81, 533–540. [Google Scholar] [CrossRef]

- Blumenkr, N.; Asboehan, G. New Method for Quantitative-Determination of Uronic Acids. Anal. Chem. 1973, 54, 484–489. [Google Scholar]

- Zhang, L.; Wang, Y.; Jiang, S.; Han, L. Determination of SO42− Content of Polysaccharides Sulfate from Rhodiola saohalinensis A. Bor by Ion-Chromatography. J. Mol. Sci. 2000, 16, 161–164. [Google Scholar]

- Li, X.C.; Lin, J.; Gao, Y.X.; Han, W.J.; Chen, D.F. Antioxidant Activity and Mechanism of Rhizoma cimicifugae. Chem. Cent. J. 2012, 6, 140–150. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.X.; Liu, X.Y.; Wu, L.X.; Tong, A.J.; Zhao, L.N.; Liu, B.; Zhao, C. Physicochemical Characterization of Polysaccharides from Chlorella pyrenoidosa and Its Anti-Ageing Effects in Drosophila melanogaster. Carbohyd. Polym. 2018, 185, 120–126. [Google Scholar] [CrossRef]

- Mitra, M.; Mishra, S. Multiproduct Biorefinery from Arthrospira spp. Towards Zero Waste: Current Status and Future Trends. Bioresour. Technol. 2019, 291, 121928. [Google Scholar] [CrossRef] [PubMed]

- Gallego, R.; Martinez, M.; Cifuentes, A.; Ibanez, E.; Herrero, M. Development of a Green Downstream Process for the Valorization of Porphyridium cruentum Biomass. Molecules 2019, 24, 1564. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinez, J.M.; Delso, C.; Alvarez, I.; Raso, J. Pulsed Electric Field Permeabilization and Extraction of Phycoerythrin from Porphyridium cruentum. Algal Res. 2019, 37, 51–56. [Google Scholar] [CrossRef]

- Tran, T.; Denimal, E.; Lafarge, C.; Journaux, L.; Lee, J.A.; Winckler, P.; Perrier-Cornet, J.M.; Pradelles, R.; Loupiac, C.; Cayot, N. Effect of High Hydrostatic Pressure on Extraction of B-Phycoerythrin from Porphyridium cruentum: Use of Confocal Microscopy and Image Processing. Algal Res. 2019, 38, 101394. [Google Scholar] [CrossRef]

- Tang, Z.; Zhao, J.; Ju, B.; Li, W.; Wen, S.; Pu, Y.; Qin, S. One-Step Chromatographic Procedure for Purification of B-Phycoerythrin from Porphyridium cruentum. Protein Expres. Purif. 2016, 123, 70–74. [Google Scholar] [CrossRef] [PubMed]

- Blue Spirulina platensis Phycocyanin Powder. Available online: https://www.alibaba.com/product-detail/Phycocyanin-Phycocyanin-The-Powder-Blue-Spirulina_62128351642.html?spm=a2700.galleryofferlist.normal_offer.d_title.40e74c9cvE7oUg&s=p (accessed on 3 September 2021).

- Yang, X.H.; Li, Y.; Li, Y.H.; Ye, D.; Yuan, L.; Sun, Y.H.; Han, D.X.; Hu, Q. Solid Matrix-Supported Supercritical CO2 Enhances Extraction of Linolenic Acid from the Cyanobacterium Arthrospira (Spirulina) platensis and Bioactivity Evaluation of the Molecule in Zebrafish. Mar. Drugs 2019, 17, 203. [Google Scholar] [CrossRef] [Green Version]

- Khozin-Goldberg, I.; Yu, H.Z.; Adlerstein, D.; Didi-Cohen, S.; Heimer, Y.M.; Cohen, Z. Triacylglycerols of the Red Microalga Porphyridium cruentum Can Contribute to the Biosynthesis of Eukaryotic Galactolipids. Lipids 2000, 35, 881–889. [Google Scholar] [CrossRef]

- Han, D.X.; Jia, J.; Li, J.; Sommerfeld, M.; Xu, J.; Hu, Q. Metabolic Remodeling of Membrane Glycerolipids in the Microalga Nannochloropsis oceanica under Nitrogen Deprivation. Front. Mar. Sci. 2017, 4, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Remmers, I.M.; Martens, D.E.; Wijffels, R.H.; Lamers, P.P. Dynamics of Triacylglycerol and Epa Production in Phaeodactylum tricornutum under Nitrogen Starvation at Different Light Intensities. PLoS ONE 2017, 12, e0175630. [Google Scholar] [CrossRef] [PubMed]

- Murata, N.; Los, D.A. Membrane Fluidity and Temperature Perception. Plant Physiol. 1997, 115, 875–879. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bernaerts, T.M.M.; Kyomugasho, C.; Van Looveren, N.; Gheysen, L.; Foubert, I.; Hendrickx, M.E.; Van Loey, A.M. Molecular and Rheological Characterization of Different Cell Wall Fractions of Porphyridium cruentum. Carbohyd. Polym. 2018, 195, 542–550. [Google Scholar] [CrossRef]

- Ciocchini, A.E.; Guidolin, L.S.; Casabuono, A.C.; Couto, A.S.; De Iannino, N.I.; Ugalde, R.A. A Glycosyltransferase with a Length-Controlling Activity as a Mechanism to Regulate the Size of Polysaccharides. Proc. Natl. Acad. Sci. USA 2007, 104, 16492–16497. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qi, H.M.; Zhang, Q.B.; Zhao, T.T.; Chen, R.; Zhang, H.; Niu, X.Z.; Li, Z. Antioxidant Activity of Different Sulfate Content Derivatives of Polysaccharide Extracted from Ulva pertusa (Chlorophyta) in Vitro. Int. J. Biol. Macromol. 2005, 37, 195–199. [Google Scholar] [CrossRef] [PubMed]

- Levy-Ontman, O.; Arad, S.; Harvey, D.J.; Parsons, T.B.; Fairbanks, A.; Tekoah, Y. Unique N-Glycan Moieties of the 66-kDa Cell Wall Glycoprotein from the Red Microalga Porphyridium sp. J. Biol. Chem. 2011, 286, 21340–21352. [Google Scholar] [CrossRef] [Green Version]

- Li, S.Y.; Shabtai, Y.; Arad, S. Floridoside as a Carbon Precursor for the Synthesis of Cell-Wall Polysaccharide in the Red Microalga Porphyridium sp. (Rhodophyta). J. Phycol. 2002, 38, 931–938. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.; Shi, Q.; Ma, C. Preparation of Different Molecular Weight Polysaccharides from Porphyridium cruentum and Their Antioxidant Activities. Int. J. Biol. Macromol. 2009, 45, 42–47. [Google Scholar] [CrossRef]

- Safi, C.; Charton, M.; Pignolet, O.; Pontalier, P.-Y.; Vaca-Garcia, C. Evaluation of the Protein Quality of Porphyridium cruentum. J. Appl. Phycol. 2013, 25, 497–501. [Google Scholar] [CrossRef] [Green Version]

- Kavitha, M.D.; Shree, M.H.S.; Vidyashankar, S.; Sarada, R. Acute and Subchronic Safety Assessment of Porphyridium purpureum Biomass in the Rat Model. J. Appl. Phycol. 2016, 28, 1071–1083. [Google Scholar] [CrossRef]

| Algal Powder | Phycoerythrin | Lipid | Polysaccharide | |

|---|---|---|---|---|

| Content (% DW) | / | 4.9 ± 0.1 | 7.0 ±0.2 | 17.8 ± 0.05 |

| Theoretical weight (g) | 1.000 | 0.049 ± 0.001 | 0.070 ± 0.002 | 0.178 ± 0.001 |

| Actual weight (g) | 1.000 ± 0.002 | 0.031 ± 0.001 | 0.052 ± 0.003 | 0.134 ± 0.016 |

| Yield (%) | / | 63.3 ± 2.7 | 74.3 ± 4.0 | 75.2 ± 8.8 |

| Xylose | Glucose | Galactose | |

|---|---|---|---|

| Percentage (%total carbohydrate) | 38.83 ± 0.56 | 21.59 ± 0.79 | 39.58 ± 1.23 |

| Carbohydrate | Protein | Uronic Acid | SO42− | |

|---|---|---|---|---|

| Content (%DW) | 55.57 ± 0.85 | 8.01 ± 0.02 | 4.13 ± 0.05 | 8.31 ± 0.19 |

| IC50 (mg mL−1) | Phycoerythrin | Lipid | Polysaccharide | Vitamin C (Control) |

|---|---|---|---|---|

| ABTS | 0.53 ± 0.05 b1 | 1.53 ± 0.09 a1 | 1.43 ± 0.02 a1 | 0.01 ± 0.00 c1 |

| DPPH | 0.69 ± 0.02 c2 | 0.87 ± 0.06 b2 | 1.90 ± 0.09 a2 | 0.01 ± 0.00 d2 |

| Superoxide anion | 1.56 ± 0.01 c3 | 5.18 ± 0.16 b3 | 23.47 ± 1.65 a3 | 0.02 ± 0.00 d3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Xu, J.; Wang, W.; Chen, Z.; Li, C.; Wu, H.; Wu, H.; Xiang, W. A Novel Three-Step Extraction Strategy for High-Value Products from Red Algae Porphyridium purpureum. Foods 2021, 10, 2164. https://doi.org/10.3390/foods10092164

Li T, Xu J, Wang W, Chen Z, Li C, Wu H, Wu H, Xiang W. A Novel Three-Step Extraction Strategy for High-Value Products from Red Algae Porphyridium purpureum. Foods. 2021; 10(9):2164. https://doi.org/10.3390/foods10092164

Chicago/Turabian StyleLi, Tao, Jin Xu, Weinan Wang, Zishuo Chen, Chulin Li, Hualian Wu, Houbo Wu, and Wenzhou Xiang. 2021. "A Novel Three-Step Extraction Strategy for High-Value Products from Red Algae Porphyridium purpureum" Foods 10, no. 9: 2164. https://doi.org/10.3390/foods10092164