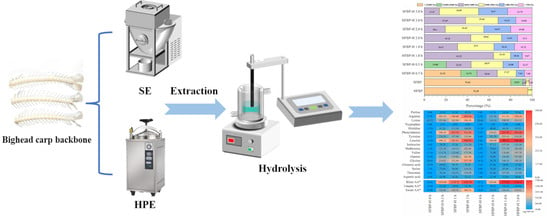

Steam Explosion-Assisted Extraction of Protein from Fish Backbones and Effect of Enzymatic Hydrolysis on the Extracts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of Fish Bone Protein

2.3. Preparation of Bone Protein Hydrolysates

2.4. Chemical Analysis of FBP

2.5. Determination of the Degree of Hydrolysis

2.6. Determination of Nitrogen Recovery

2.7. Fourier Transform Infrared Spectroscopy

2.8. Determination of Amino Acid Composition

2.9. Determination of Molecular Weight Distribution

2.10. Determination of Antioxidant Activity of Hydrolysates

2.10.1. DPPH Radical Scavenging Activity

2.10.2. ABTS Radical Scavenging Activity

2.11. Statistical Analysis

3. Results and Discussion

3.1. Proximate and Amino Acid Compositions of FBP

3.2. DH and NR

3.3. FTIR

3.4. Molecular Weight Distribution of FBP Hydrolysates

3.5. Free Amino Acid Composition of FBP Hydrolysates

3.6. Antioxidant Activities of FBP Hydrolysates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fishery and Fisheries Administration Bureau of the Ministry of Agriculture and Rural Areas of the People’s Republic of China; National Fisheries Technology Extension Center; China Society of Fisheries. China Fishery Statistical Yearbook; China Agricultural Press: Beijing, China, 2020. [Google Scholar]

- Luo, Y.; Pan, D.; Ji, B. Gel properties of surimi from bighead carp (Aristichthys nobilis): Influence of setting and soy protein isolate. J. Food Sci. 2004, 69, E374–E378. [Google Scholar] [CrossRef]

- Abdollahi, M.; Wu, H.; Undeland, I. Impact of processing technology on macro- and micronutrient profile of protein-enriched products from fish backbones. Foods 2021, 10, 950. [Google Scholar] [CrossRef]

- Wijayanti, I.; Singh, A.; Benjakul, S.; Sookchoo, P. Textural, sensory, and chemical characteristic of threadfin bream (Nemipterus sp.) surimi gel fortified with bio-calcium from bone of asian sea bass (Lates calcarifer). Foods 2021, 10, 976. [Google Scholar] [CrossRef] [PubMed]

- Steinsholm, S.; Oterhals, Å.; Underhaug, J.; Aspevik, T. Emulsion and surface-active properties of fish solubles based on direct extraction and after hydrolysis of atlantic cod and atlantic salmon backbones. Foods 2021, 10, 38. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, Y.; Dai, Z. Antioxidant and cryoprotective effects of bone hydrolysates from bighead carp (Aristichthys nobilis) in freeze-thawed fish fillets. Foods 2021, 10, 1409. [Google Scholar] [CrossRef]

- Yang, S.; Tu, Z.-C.; Wang, H.; Hu, Y.-M. Effects of coagulant promoter on the physical properties and microstructure of the mixed system of ultrafine fishbone and surimi. LWT 2020, 131, 109792. [Google Scholar] [CrossRef]

- Tkaczewska, J.; Morawska, M.; Kulawik, P.; Zając, M. Characterization of carp (Cyprinus carpio) skin gelatin extracted using different pretreatments method. Food Hydrocoll. 2018, 81, 169–179. [Google Scholar] [CrossRef]

- Liu, D.; Liang, L.; Regenstein, J.M.; Zhou, P. Extraction and characterisation of pepsin-solubilised collagen from fins, scales, skins, bones and swim bladders of bighead carp (Hypophthalmichthys nobilis). Food Chem. 2012, 133, 1441–1448. [Google Scholar] [CrossRef]

- Liao, W.; Chen, H.; Jin, W.; Yang, Z.; Cao, Y.; Miao, J. Three newly isolated calcium-chelating peptides from tilapia bone collagen hydrolysate enhance calcium absorption activity in intestinal Caco-2 cells. J. Agric. Food Chem. 2020, 68, 2091–2098. [Google Scholar] [CrossRef]

- Hong, H.; Fan, H.; Chalamaiah, M.; Wu, J. Preparation of low-molecular-weight, collagen hydrolysates (peptides): Current progress, challenges, and future perspectives. Food Chem. 2019, 301, 125222. [Google Scholar] [CrossRef]

- Rodrigues, D.P.; Calado, R.; Ameixa, O.M.; Valcarcel, J.; Vázquez, J.A. Valorisation of Atlantic codfish (Gadus morhua) frames from the cure-salting industry as fish protein hydrolysates with in vitro bioactive properties. LWT 2021, 149, 111840. [Google Scholar] [CrossRef]

- Lima, K.O.; de Quadros, C.D.C.; da Rocha, M.; de Lacerda, J.T.J.G.; Juliano, M.A.; Dias, M.; Mendes, M.A.; Prentice, C. Bioactivity and bioaccessibility of protein hydrolyzates from industrial byproducts of Stripped weakfish (Cynoscion guatucupa). LWT 2019, 111, 408–413. [Google Scholar] [CrossRef]

- Dong, X.-B.; Li, X.; Zhang, C.-H.; Wang, J.-Z.; Tang, C.-H.; Sun, H.-M.; Jia, W.; Li, Y.; Chen, L.-L. Development of a novel method for hot-pressure extraction of protein from chicken bone and the effect of enzymatic hydrolysis on the extracts. Food Chem. 2014, 157, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Thoresen, P.P.; Álvarez, R.G.; Vaka, M.R.; Rustad, T.; Sone, I.; Fernández, E.N. Potential of innovative pre-treatment technologies for the revalorisation of residual materials from the chicken industry through enzymatic hydrolysis. Innov. Food Sci. Emerg. Technol. 2020, 64, 102377. [Google Scholar] [CrossRef]

- Melgosa, R.; Marques, M.; Paiva, A.; Bernardo, A.; Fernández, N.; Sá-Nogueira, I.; Simões, P. Subcritical water extraction and hydrolysis of cod (Gadus morhua) frames to produce bioactive protein extracts. Foods 2021, 10, 1222. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Tu, D.; Shen, Q.; Dai, Z. Fish scale valorization by hydrothermal pretreatment followed by enzymatic hydrolysis for gelatin hydrolysate production. Molecules 2019, 24, 2998. [Google Scholar] [CrossRef] [Green Version]

- Min, S.-G.; Jo, Y.-J.; Park, S.H. Potential application of static hydrothermal processing to produce the protein hydrolysates from porcine skin by-products. LWT 2017, 83, 18–25. [Google Scholar] [CrossRef]

- Asaduzzaman, A.; Getachew, A.T.; Cho, Y.-J.; Park, J.-S.; Haq, M.; Chun, B.-S. Characterization of pepsin-solubilised collagen recovered from mackerel (Scomber japonicus) bone and skin using subcritical water hydrolysis. Int. J. Biol. Macromol. 2020, 148, 1290–1297. [Google Scholar] [CrossRef]

- Tan, X.; Qi, L.; Fan, F.; Guo, Z.; Wang, Z.; Song, W.; Du, M. Analysis of volatile compounds and nutritional properties of enzymatic hydrolysate of protein from cod bone. Food Chem. 2018, 264, 350–357. [Google Scholar] [CrossRef]

- Ahmed, R.; Chun, B.-S. Subcritical water hydrolysis for the production of bioactive peptides from tuna skin collagen. J. Supercrit. Fluids 2018, 141, 88–96. [Google Scholar] [CrossRef]

- de la Fuente, B.; Pallarés, N.; Barba, F.; Berrada, H. An integrated approach for the valorization of sea bass (Dicentrarchus labrax) Side Streams: Evaluation of contaminants and development of antioxidant protein extracts by pressurized liquid extraction. Foods 2021, 10, 546. [Google Scholar] [CrossRef]

- Guo, L.; Lu, L.; Yin, M.; Yang, R.; Zhang, Z.; Zhao, W. Valorization of refractory keratinous waste using a new and sustainable bio-catalysis. Chem. Eng. J. 2020, 397, 125420. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, B.; Yu, F.; Xu, G.; Song, A. A real explosion: The requirement of steam explosion pretreatment. Bioresour. Technol. 2012, 121, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Shen, Q.; Zhang, C.; Jia, W.; Qin, X.; Xu, X.; Ye, M.; Mo, H.; Richel, A. Liquefaction of chicken sternal cartilage by steam explosion to isolate chondroitin sulfate. Carbohydr. Polym. 2019, 215, 73–81. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, W.; Yang, R. Steam flash explosion assisted dissolution of keratin from feathers. ACS Sustain. Chem. Eng. 2015, 3, 2036–2042. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Elavarasan, K.; Shamasundar, B.; Badii, F.; Howell, N. Angiotensin I-converting enzyme (ACE) inhibitory activity and structural properties of oven- and freeze-dried protein hydrolysate from fresh water fish (Cirrhinus mrigala). Food Chem. 2016, 206, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Saisavoey, T.; Sangtanoo, P.; Reamtong, O.; Karnchanatat, A. Free radical scavenging and anti-inflammatory potential of a protein hydrolysate derived from salmon bones on RAW 264.7 macrophage cells. J. Sci. Food Agric. 2019, 99, 5112–5121. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Zhao, M.; Xiao, C.; Zhao, Q.; Su, G. Practical problems when using ABTS assay to assess the radical-scavenging activity of peptides: Importance of controlling reaction pH and time. Food Chem. 2016, 192, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Shakila, R.J.; Jeevithan, E.; Varatharajakumar, A.; Jeyasekaran, G.; Sukumar, D. Functional characterization of gelatin extracted from bones of red snapper and grouper in comparison with mammalian gelatin. LWT 2012, 48, 30–36. [Google Scholar] [CrossRef]

- Muyonga, J.H.; Cole, C.G.B.; Duodu, K.G. Extraction and physico-chemical characterisation of Nile perch (Lates niloticus) skin and bone gelatin. Food Hydrocoll. 2004, 18, 581–592. [Google Scholar] [CrossRef]

- Casanova, F.; Mohammadifar, M.A.; Jahromi, M.; Petersen, H.O.; Sloth, J.J.; Eybye, K.L.; Kobbelgaard, S.; Jakobsen, G.; Jessen, F. Physico-chemical, structural and techno-functional properties of gelatin from saithe (Pollachius virens) skin. Int. J. Biol. Macromol. 2020, 156, 918–927. [Google Scholar] [CrossRef]

- Ding, D.; Yu, T.; Du, B.; Huang, Y. Collagen hydrolysate from Thunnus orientalis bone induces osteoblast proliferation and differentiation. Chem. Eng. Sci. 2019, 205, 143–150. [Google Scholar] [CrossRef]

- Mirzapour-Kouhdasht, A.; Moosavi-Nasab, M.; Kim, Y.-M.; Eun, J.-B. Antioxidant mechanism, antibacterial activity, and functional characterization of peptide fractions obtained from barred mackerel gelatin with a focus on application in carbonated beverages. Food Chem. 2021, 342, 128339. [Google Scholar] [CrossRef] [PubMed]

- Cao, Q.; Lu, X.; Azad, B.B.; Pomper, M.; Smith, M.; He, J.; Pi, L.; Ren, B.; Ying, Z.; Sichani, B.S.; et al. cis-4-[18F]fluoro-L-proline molecular imaging experimental liver fibrosis. Front. Mol. Biosci. 2020, 7, 90. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Kuo, J.-M.; Wu, S.-J.; Tsai, H.-T. Isolation and characterization of fish scale collagen from tilapia (Oreochromis sp.) by a novel extrusion–hydro-extraction process. Food Chem. 2016, 190, 997–1006. [Google Scholar] [CrossRef] [PubMed]

- Abdollahi, M.; Rezaei, M.; Jafarpour, A.; Undeland, I. Sequential extraction of gel-forming proteins, collagen and collagen hydrolysate from gutted silver carp (Hypophthalmichthys molitrix), a biorefinery approach. Food Chem. 2018, 242, 568–578. [Google Scholar] [CrossRef]

- Aleman, A.; Giménez, B.; Santín, E.P.; Gómez-Guillén, M.C.; Montero, P. Contribution of Leu and Hyp residues to antioxidant and ACE-inhibitory activities of peptide sequences isolated from squid gelatin hydrolysate. Food Chem. 2011, 125, 334–341. [Google Scholar] [CrossRef] [Green Version]

- de la Fuente, B.; Pallarés, N.; Berrada, H.; Barba, F. Salmon (Salmo salar) side streams as a bioresource to obtain potential antioxidant peptides after applying pressurized liquid extraction (PLE). Marine Drugs 2021, 19, 323. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wang, K.; Gao, S.; Hong, H.; Zhang, L.; Liu, H.; Feng, L.; Luo, Y. Purification and characterization of antioxidant peptides from yak (Bos grunniens) bone hydrolysates and evaluation of cellular antioxidant activity. J. Food Sci. Technol. 2021, 58, 3106–3119. [Google Scholar] [CrossRef]

- Lassoued, I.; Mora, L.; Nasri, R.; Jridi, M.; Toldrá, F.; Aristoy, M.-C.; Barkia, A.; Nasri, M. Characterization and comparative assessment of antioxidant and ACE inhibitory activities of thornback ray gelatin hydrolysates. J. Funct. Foods 2015, 13, 225–238. [Google Scholar] [CrossRef]

- Liu, D.; Nikoo, M.; Boran, G.; Zhou, P.; Regenstein, J.M. Collagen and gelatin. Annu. Rev. Food Sci. Technol. 2015, 6, 527–557. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.; Hardacre, A.K.; Parker, M.E. Effects of enzymatic hydrolysis treatments on the physicochemical properties of beef bone extract using endo- and exoproteases. Int. J. Food Sci. Technol. 2019, 54, 111–120. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Fang, D.; Kimatu, B.M.; Chen, X.; Wu, X.; Du, J.; Yang, Q.; Chen, H.; Zheng, H.; An, X.; et al. Analysis of umami taste substances of morel mushroom (Morchella sextelata) hydrolysates derived from different enzymatic systems. Food Chem. 2021, 362, 130192. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ke, H.; Bai, T.; Chen, C.; Guo, T.; Mu, Y.; Li, H.; Liao, W.; Pan, Z.; Zhao, L. Characterization of umami compounds in bone meal hydrolysate. J. Food Sci. 2021, 86, 2264–2275. [Google Scholar] [CrossRef]

- Hou, H.; Li, B.; Zhao, X.; Zhang, Z.; Li, P. Optimization of enzymatic hydrolysis of Alaska pollock frame for preparing protein hydrolysates with low-bitterness. LWT 2011, 44, 421–428. [Google Scholar] [CrossRef]

- Jakubczyk, A.; Karaś, M.; Rybczyńska-Tkaczyk, K.; Zielińska, E.; Zieliński, D. Current trends of bioactive peptides—new sources and therapeutic effect. Foods 2020, 9, 846. [Google Scholar] [CrossRef]

- Girgih, A.T.; Chao, D.; Lin, L.; He, R.; Jung, S.; Aluko, R.E. Enzymatic protein hydrolysates from high pressure-pretreated isolated pea proteins have better antioxidant properties than similar hydrolysates produced from heat pretreatment. Food Chem. 2015, 188, 510–516. [Google Scholar] [CrossRef] [PubMed]

- Tkaczewska, J.; Borawska-Dziadkiewicz, J.; Kulawik, P.; Duda, I.; Morawska, M.; Mickowska, B. The effects of hydrolysis condition on the antioxidant activity of protein hydrolysate from Cyprinus carpio skin gelatin. LWT 2020, 117, 108616. [Google Scholar] [CrossRef]

- Ren, Y.; Wu, H.; Chi, Y.; Deng, R.; He, Q. Structural characterization, erythrocyte protection, and antifatigue effect of antioxidant collagen peptides from tilapia (Oreochromis nilotica L.) skin. Food Funct. 2020, 11, 10149–10160. [Google Scholar] [CrossRef] [PubMed]

- Neves, A.C.; Harnedy, P.A.; O’Keeffe, M.; FitzGerald, R.J. Bioactive peptides from Atlantic salmon (Salmo salar) with angiotensin converting enzyme and dipeptidyl peptidase IV inhibitory, and antioxidant activities. Food Chem. 2017, 218, 396–405. [Google Scholar] [CrossRef]

- Nikoo, M.; Regenstein, J.M.; Noori, F.; Gheshlaghi, S.P. Autolysis of rainbow trout (Oncorhynchus mykiss) by-products: Enzymatic activities, lipid and protein oxidation, and antioxidant activity of protein hydrolysates. LWT 2021, 140, 110702. [Google Scholar] [CrossRef]

- Xiao, F.; Chen, S.; Li, L.; He, J.; Cheng, W.; Ren, G. In Vitro Antioxidant activity of peptides from simulated gastro-intestinal digestion products of Cyprinus carpio haematopterus scale gelatin. Foods 2019, 8, 618. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Limpisophon, K.; Shibata, J.; Yasuda, Y.; Tanaka, M.; Osako, K. Optimization of hydrolysis conditions for production of gelatin hydrolysates from shark skin byproduct and evaluation of their antioxidant activities. J. Aquat. Food Prod. Technol. 2020, 29, 736–749. [Google Scholar] [CrossRef]

- Ketnawa, S.; Benjakul, S.; Alvarez, M.; Rawdkuen, S. Fish skin gelatin hydrolysates produced by visceral peptidase and bovine trypsin: Bioactivity and stability. Food Chem. 2017, 215, 383–390. [Google Scholar] [CrossRef]

| Amino Acids | SFBP | HFBP |

|---|---|---|

| Aspartic acid/asparagine | 54.2 | 57.3 |

| Glutamic acid/glutamine | 85.1 | 90.2 |

| Serine | 27.1 | 30.9 |

| Histidine | 4.2 | 5.9 |

| Glycine | 333.5 | 328.5 |

| Threonine | 20.8 | 21.7 |

| Arginine | 53.3 | 52.5 |

| Alanine | 123.4 | 123.1 |

| Tyrosine | 2.7 | 3.9 |

| Valine | 23.3 | 25.3 |

| Methionine | 11.2 | 13.6 |

| Phenylalanine | 14.4 | 16.3 |

| Isoleucine | 12.5 | 14.7 |

| Leucine | 24.1 | 27.3 |

| Lysine | 27.0 | 28.3 |

| Proline | 101.1 | 90.9 |

| Hydroxyproline | 82.2 | 69.7 |

| Total | 1000 | 1000 |

| Imino acids | 183.3 | 160.6 |

| Samples | β-Sheet/% | Random Coil/% | β-Turn/% | α-Helix/% |

|---|---|---|---|---|

| SFBP | 52.14 | 33.32 | 14.54 | - |

| HFBP | 51.40 | 33.36 | 11.88 | 3.35 |

| SFBP-H | 41.72 | 34.13 | 19.99 | 4.17 |

| HFBP-H | 35.62 | 36.46 | 20.85 | 7.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Yan, W.; Zhang, X.-D.; Dai, Z.-Y.; Zhang, Y.-Q. Steam Explosion-Assisted Extraction of Protein from Fish Backbones and Effect of Enzymatic Hydrolysis on the Extracts. Foods 2021, 10, 1942. https://doi.org/10.3390/foods10081942

Dong Y, Yan W, Zhang X-D, Dai Z-Y, Zhang Y-Q. Steam Explosion-Assisted Extraction of Protein from Fish Backbones and Effect of Enzymatic Hydrolysis on the Extracts. Foods. 2021; 10(8):1942. https://doi.org/10.3390/foods10081942

Chicago/Turabian StyleDong, Ye, Wen Yan, Xiao-Di Zhang, Zhi-Yuan Dai, and Yi-Qi Zhang. 2021. "Steam Explosion-Assisted Extraction of Protein from Fish Backbones and Effect of Enzymatic Hydrolysis on the Extracts" Foods 10, no. 8: 1942. https://doi.org/10.3390/foods10081942