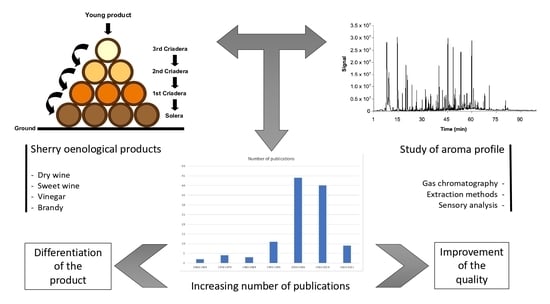

Aroma of Sherry Products: A Review

Abstract

:1. Introduction

2. Study of the Aroma of Dry Sherry Wines

3. Study of the Aroma of Natural Sweet Wines

4. Study of the Aroma of Sherry Vinegar

5. Study of the Aroma of Sherry Brandy

- (1)

- (2)

- The fermentation and production conditions of the base wine [112];

- (3)

- (4)

- (5)

- The preconditioning of the cask with wine, i.e., the type of wine that it has previously contained and for how long [13];

- (6)

- The previous length or frequency of use of the barrel, i.e., whether it is used to produce brandy for the first time after its preconditioning with wine or it has been used several times to hold and produce brandy [117].

6. Final Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pardo-Calle, C.; Segovia-Gonzalez, M.M.; Paneque-Macias, P.; Espino-Gonzalo, C. An approach to zoning in the wine growing regions of “Jerez-Xérès-Sherry” and “Manzanilla-Sanlúcar de Barrameda” (Cádiz, Spain). INIA Span. J. Agric. Res. 2011, 9, 831–843. [Google Scholar] [CrossRef] [Green Version]

- Johnson, H.; Robinson, J. The World Atlas of Wine, 8th ed.; Mitchell Beazley: London, UK, 2019. [Google Scholar]

- Pozo-Bayón, M.A.; Moreno-Arribas, M.V. Sherry Wines: Manufacture, Composition and Analysis. In Encyclopedia of Food and Health; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 779–784. [Google Scholar]

- Marin-Menguiano, M.; Romero-Sanchez, S.; Barrales, R.R.; Ibeas, J.I. Population analysis of biofilm yeasts during fino sherry wine aging in the Montilla-Moriles, D.O. region. Int. J. Food Microbiol. 2017, 244, 67–73. [Google Scholar] [CrossRef]

- Pozo-Bayón, M.A.; Moreno-Arribas, M.V. Sherry Wines. In Advances in Food and Nutrition Research; Academic Press Inc.: Cambridge, MA, USA, 2011; Volume 63, pp. 17–40. [Google Scholar]

- Consejería de Agricultura y Pesca. Orden de 13 de Mayo de 2010, Por La Que se Aprueba el Reglamento de las Denominaciones de Origen «Jerez-Xérès-Sherry» y «Manzanilla de Sanlúcar de Barrameda», así Como sus Correspondientes Pliegos de Condiciones; Boletín Oficial de la Junta de Andalucía (BOJA): Sevilla, Spain, 2010; Volume 103, pp. 53–74. [Google Scholar]

- Council of the European Union. Council Regulation (EEC) No 4252/88 of 21 December 1988 on the Preparation and Marketing of Liqueur Wines Produced in the Community; European Union: Brussels, Belgium, 1988. [Google Scholar]

- Ministerio de Agricultura, Pesca y Alimentación. Orden de 26 de Diciembre de 2000 por la que se Ratifica el Reglamento de la Denominación de Origen «Vinagre de Jerez»; Boletín Oficial del Estado (BOE): Madrid, Spain, 2000; p. 24477. [Google Scholar]

- Council of the European Union. Council Regulation (EC) No 510/2006 of 20 March 2006 on the Protection of Geographical Indications and Designations of Origin for Agricultural Products and Foodstuffs; European Union: Brussels, Belgium, 2006. [Google Scholar]

- Dodero, M.C.R.; Sánchez, D.A.G.; Rodríguez, M.S.; Barroso, C.G. Phenolic compounds and furanic derivatives in the characterization and quality control of Brandy de Jerez. J. Agric. Food Chem. 2010, 58, 990–997. [Google Scholar] [CrossRef] [PubMed]

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine aging technology: Fundamental role of wood barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef]

- Pérez-Prieto, L.J.; López-Roca, J.M.; Martínez-Cutillas, A.; Pardo Mínguez, F.; Gómez-Plaza, E. Maturing wines in oak barrels. Effects of origin, volume, and age of the barrel on the wine volatile composition. J. Agric. Food Chem. 2002, 50, 3272–3276. [Google Scholar] [CrossRef]

- Sánchez-Guillén, M.M.; Schwarz-Rodríguez, M.; Rodríguez-Dodero, M.C.; García-Moreno, M.V.; Guillén-Sánchez, D.A.; García-Barroso, C. Discriminant ability of phenolic compounds and short chain organic acids profiles in the determination of quality parameters of Brandy de Jerez. Food Chem. 2019, 286, 275–281. [Google Scholar] [CrossRef]

- Martínez Montero, C.; Rodríguez Dodero, M.D.C.; Guillén Sánchez, D.A.; García Barroso, C. Sugar contents of Brandy de Jerez during its aging. J. Agric. Food Chem. 2005, 53, 1058–1064. [Google Scholar] [CrossRef]

- Ruiz-Muñoz, M.; Cordero-Bueso, G.; Benítez-Trujillo, F.; Martínez, S.; Pérez, F.; Cantoral, J.M. Rethinking about flor yeast diversity and its dynamic in the “criaderas and soleras” biological aging system. Food Microbiol. 2020, 92. [Google Scholar] [CrossRef]

- Palacios, V.; Valcárcel, M.; Caro, I.; Pérez, L. Chemical and biochemical transformations during the industrial process of sherry vinegar aging. J. Agric. Food Chem. 2002, 50, 4221–4225. [Google Scholar] [CrossRef]

- Schwarz, M.; Rodríguez, M.C.; Guillén, D.A.; Barroso, C.G. Analytical characterisation of a Brandy de Jerez during its ageing. Eur. Food Res. Technol. 2011, 232, 813–819. [Google Scholar] [CrossRef]

- Cejudo Bastante, M.J.; Durán Guerrero, E.; Castro Mejías, R.; Natera Marín, R.; Rodríguez Dodero, M.C.; Barroso, C.G. Study of the polyphenolic composition and antioxidant activity of new sherry vinegar-derived products by maceration with fruits. J. Agric. Food Chem. 2010, 58, 11814–11820. [Google Scholar] [CrossRef]

- Delgado-González, M.J.; García-Moreno, M.V.; Sánchez-Guillén, M.M.; García-Barroso, C.; Guillén-Sánchez, D.A. Colour evolution kinetics study of spirits in their ageing process in wood casks. Food Control 2021, 119. [Google Scholar] [CrossRef]

- Recamales, A.F.; Hernanz, D.; Álvarez, C.; González-Miret, M.L.; Heredia, F.J. Colour of Amontillado wines aged in two oak barrel types. Eur. Food Res. Technol. 2007, 224, 321–327. [Google Scholar] [CrossRef]

- Ding, Y.; Ma, Y.; Li, S.; Liang, J.; Xi, X.; Wang, J.; Sun, J.; Yu, H.; Guo, S. Characterization of biochemical compositions, volatile compounds and sensory profiles of cabernet sauvignon wine in successive vintages (2008–2017). Am. J. Biochem. Biotechnol. 2020, 16, 380–391. [Google Scholar] [CrossRef]

- Pati, S.; Crupi, P.; Savastano, M.L.; Benucci, I.; Esti, M. Evolution of phenolic and volatile compounds during bottle storage of a white wine without added sulfite. J. Sci. Food Agric. 2020, 100, 775–784. [Google Scholar] [CrossRef] [PubMed]

- Niimi, J.; Tomic, O.; Næs, T.; Bastian, S.E.P.; Jeffery, D.W.; Nicholson, E.L.; Maffei, S.M.; Boss, P.K. Objective measures of grape quality: From Cabernet Sauvignon grape composition to wine sensory characteristics. LWT Food Sci. Technol. 2020, 123. [Google Scholar] [CrossRef]

- Zea, L.; Ruiz, M.J.; Moyano, L. Using Odorant Series as an Analytical Tool for the Study of the Biological Ageing of Sherry Wines. In Gas Chromatography in Plant Science, Wine Technology, Toxicology and Some Specific Applications; InTechOpen: Rijeka, Croatia, 2012. [Google Scholar]

- Dunkel, A.; Steinhaus, M.; Kotthoff, M.; Nowak, B.; Krautwurst, D.; Schieberle, P.; Hofmann, T. Nature’s chemical signatures in human olfaction: A foodborne perspective for future biotechnology. Angew. Chem. 2014, 53, 7124–7143. [Google Scholar] [CrossRef]

- Souza Gonzaga, L.; Capone, D.L.; Bastian, S.E.P.; Jeffery, D.W. Defining wine typicity: Sensory characterisation and consumer perspectives. Aust. J. Grape Wine Res. 2020, 27, 246–256. [Google Scholar] [CrossRef]

- Welke, J.E.; Hernandes, K.C.; Nicolli, K.P.; Barbará, J.A.; Biasoto, A.C.T.; Zini, C.A. Role of gas chromatography and olfactometry to understand the wine aroma: Achievements denoted by multidimensional analysis. J. Sep. Sci. 2021, 44, 135–168. [Google Scholar] [CrossRef]

- Marín-San Román, S.; Rubio-Bretón, P.; Pérez-Álvarez, E.P.; Garde-Cerdán, T. Advancement in analytical techniques for the extraction of grape and wine volatile compounds. Food Res. Int. 2020, 137. [Google Scholar] [CrossRef]

- Pérez-Elortondo, F.J.; Symoneaux, R.; Etaio, I.; Coulon-Leroy, C.; Maître, I.; Zannoni, M. Current status and perspectives of the official sensory control methods in protected designation of origin food products and wines. Food Control 2018, 88, 159–168. [Google Scholar] [CrossRef]

- Cruces-Montes, S.J.; Merchán-Clavellino, A.; Romero-Moreno, A.; Paramio, A. Perception of the attributes of sherry wine and its consumption in young people in the South of Spain. Foods 2020, 9, 417. [Google Scholar] [CrossRef] [Green Version]

- Cortes, M.B.; Moreno, J.J.; Zea, L.; Moyano, L.; Medina, M. Response of the aroma fraction in Sherry wines subjected to accelerated biological aging. J. Agric. Food Chem. 1999, 47, 3297–3302. [Google Scholar] [CrossRef] [PubMed]

- Zea, L.; Moyano, L.; Moreno, J.; Cortes, B.; Medina, M. Discrimination of the aroma fraction of Sherry wines obtained by oxidative and biological ageing. Food Chem. 2001, 75, 79–84. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Moreno, J.A.; Medina, M. Aroma series as fingerprints for biological ageing in fino sherry-type wines. J. Sci. Food Agric. 2007, 87, 2319–2326. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Ruiz, M.J.; Medina, M. Chromatography-Olfactometry Study of the Aroma of Fino Sherry Wines. Int. J. Anal. Chem. 2010, 2010, 1–5. [Google Scholar] [CrossRef]

- Moyano, L.; Zea, L.; Moreno, J.; Medina, M. Analytical study of aromatic series in sherry wines subjected to biological aging. J. Agric. Food Chem. 2002, 50, 7356–7361. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J.A.; Zea, L.; Moyano, L.; Medina, M. Aroma compounds as markers of the changes in sherry wines subjected to biological ageing. Food Control 2005, 16, 333–338. [Google Scholar] [CrossRef]

- Moyano, L.; Zea, L.; Moreno, J.A.; Medina, M. Evaluation of the active odorants in Amontillado sherry wines during the aging process. J. Agric. Food Chem. 2010, 58, 6900–6904. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Ruiz, M.J.; Medina, M. Odor descriptors and aromatic series during the oxidative aging of oloroso sherry wines. Int. J. Food Prop. 2013, 16, 1534–1542. [Google Scholar] [CrossRef]

- García-Moreno, M.V.; Sánchez-Guillén, M.M.; Delgado-González, M.J.; Durán-Guerrero, E.; Rodríguez-Dodero, M.C.; Guillén-Sánchez, D.A.; García-Barroso, C. Chemical content and sensory changes of Oloroso Sherry wine when aged with four different wood types. LWT Food Sci. Technol. 2021, 140, 110706. [Google Scholar] [CrossRef]

- Garcia-Maiquez, E. Les levures de voile dans l’élaboration des vins de Xéres. In Proceedings of the Application a l’Oenologie des Progres Recents en Microbiologie et en Fermentation; OIV (Ed.): Paris, France, 1988; pp. 341–351. [Google Scholar]

- Martínez, P.; Pérez Rodríguez, L.; Benítez, T. Velum formation by flor yeast isolated from Sherry wine. Am. J. Enol. Vitic. 1997, 48, 55–62. [Google Scholar]

- Zea, L.; Serratosa, M.P.; Mérida, J.; Moyano, L. Acetaldehyde as Key Compound for the Authenticity of Sherry Wines: A Study Covering 5 Decades. Compr. Rev. Food Sci. Food Saf. 2015, 14, 681–693. [Google Scholar] [CrossRef]

- Muñoz, D.; Peinado, R.A.; Medina, M.; Moreno, J. Biological aging of sherry wines under periodic and controlled microaerations with Saccharomyces cerevisiae var. capensis: Effect on odorant series. Food Chem. 2007, 100, 1188–1195. [Google Scholar] [CrossRef]

- Hevia, K.; Castro, R.; Natera, R.; González-García, J.A.; Barroso, C.G.; Durán-Guerrero, E. Optimization of Head Space Sorptive Extraction to Determine Volatile Compounds from Oak Wood in Fortified Wines. Chromatographia 2016, 79, 763–771. [Google Scholar] [CrossRef]

- Herrera, P.; Durán-Guerrero, E.; Sánchez-Guillén, M.M.; García-Moreno, M.V.; Guillén, D.A.; Barroso, C.G.; Castro, R. Effect of the type of wood used for ageing on the volatile composition of Pedro Ximénez sweet wine. J. Sci. Food Agric. 2020, 100, 2512–2521. [Google Scholar] [CrossRef]

- Ruiz, M.J.; Moyano, L.; Zea, L. Changes in aroma profile of musts from grapes cv. Pedro Ximenez chamber-dried at controlled conditions destined to the production of sweet Sherry wine. LWT Food Sci. Technol. 2014, 59, 560–565. [Google Scholar] [CrossRef]

- Ruiz, M.J.; Moyano, L.; Zea, L. Sweet wines produced by an innovative winemaking procedure: Colour, active odorants and sensory profile. S. Afr. J. Enol. Vitic. 2014, 35, 205–216. [Google Scholar] [CrossRef] [Green Version]

- Franco, M.; Peinado, R.A.; Medina, M.; Moreno, J. Off-vine grape drying effect on volatile compounds and aromatic series in must from Pedro Ximénez grape variety. J. Agric. Food Chem. 2004, 52, 3905–3910. [Google Scholar] [CrossRef]

- López De Lerma, N.; García-Martínez, T.; Moreno, J.; Mauricio, J.C.; Peinado, R.A. Volatile composition of partially fermented wines elaborated from sun dried Pedro Ximénez grapes. Food Chem. 2012, 135, 2445–2452. [Google Scholar] [CrossRef]

- Ruiz, M.J.; Zea, L.; Moyano, L.; Medina, M. Aroma active compounds during the drying of grapes cv. Pedro Ximenez destined to the production of sweet Sherry wine. Eur. Food Res. Technol. 2010, 230, 429–435. [Google Scholar] [CrossRef]

- Lopez De Lerma, N.; Bellincontro, A.; Mencarelli, F.; Moreno, J.; Peinado, R.A. Use of electronic nose, validated by GC-MS, to establish the optimum off-vine dehydration time of wine grapes. Food Chem. 2012, 130, 447–452. [Google Scholar] [CrossRef]

- Márquez, R.; Castro, R.; Natera, R.; García-Barroso, C. Characterisation of the volatile fraction of Andalusian sweet wines. Eur. Food Res. Technol. 2008, 226, 1479–1484. [Google Scholar] [CrossRef]

- García-Martínez, T.; Bellincontro, A.; De Lerma, M.D.L.N.L.; Peinado, R.A.; Mauricio, J.C.; Mencarelli, F.; Moreno, J.J. Discrimination of sweet wines partially fermented by two osmo-ethanol-tolerant yeasts by gas chromatographic analysis and electronic nose. Food Chem. 2011, 127, 1391–1396. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Bejarano, M.J.; Castro-Mejías, R.; del Carmen Rodríguez-Dodero, M.; García-Barroso, C. Volatile composition of Pedro Ximénez and Muscat sweet Sherry wines from sun and chamber dried grapes: A feasible alternative to the traditional sun-drying. J. Food Sci. Technol. 2016, 53, 2519–2531. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Bejarano, M.J.; Castro-Mejías, R.; Rodríguez-Dodero, M.d.C.; García-Barroso, C. Study of the content in volatile compounds during the aging of sweet Sherry wines obtained from grapes cv. Muscat and fermented under different conditions. Eur. Food Res. Technol. 2013, 237, 905–922. [Google Scholar] [CrossRef]

- Campo, E.; Cacho, J.; Ferreira, V. The chemical characterization of the aroma of dessert and sparkling white wines (Pedro Ximénez, Fino, Sauternes, and Cava) by gas chromatography-olfactometry and chemical quantitative analysis. J. Agric. Food Chem. 2008, 56, 2477–2484. [Google Scholar] [CrossRef]

- Chaves, M.; Zea, L.; Moyano, L.; Medina, M. Changes in color and odorant compounds during oxidative aging of Pedro Ximenez sweet wines. J. Agric. Food Chem. 2007, 55, 3592–3598. [Google Scholar] [CrossRef]

- García-Martínez, T.; Moreno-García, J. Alternativas a la elaboración tradicional de vinos dulces de uva Pedro Ximénez pasificada. In Proceedings of the Grupos de Investigación Enológica, Tarragona, Spain, 9–12 June 2015; pp. 240–243. [Google Scholar]

- Flanzy, C. Anaerobic grape metabolism. In Enology: Scientific and Technological Base; Mundi-Prensa: Madrid, Spain, 2000. [Google Scholar]

- Cabañares, F.J.; Accensi, F.; Bragulat, M.R.; Abarca, M.L.; Castella, G.; Mínguez, S.; Pons, A. What is the source of ochratoxin A in wine? Int. J. Food Microbiol. 2002, 79, 213–215. [Google Scholar] [CrossRef]

- Serratosa, M.P.; Marquez, A.; Lopez-Toledano, A.; Merida, J. Sensory analysis of sweet musts in pedro ximenez cv. grapes dried using different methods. S. Afr. J. Enol. Vitic. 2012, 33, 14–20. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Bejarano, M.J.; Durán-Guerrero, E.; Castro, R.; Barroso, C.G.; Rodríguez-Dodero, M.C. Use of sensory analysis to investigate the influence of climate chambers and other process variables in the production of sweet wines. Foods 2020, 9, 424. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruíz Bejarano, M.J.; Rodríguez Dodero, M.C.; Barroso, C.G. Optimizing the process of making sweet wines to minimize the content of ochratoxin A. J. Agric. Food Chem. 2010, 58, 13006–13012. [Google Scholar] [CrossRef]

- Ruiz-Bejarano, M.J.; Castro-Mejías, R.; Rodríguez-Dodero, M.C.; García-Barroso, C. Effect of ageing of sweet Sherry wines obtained from cvs Muscat and Pedro Ximénez on ethyl carbamate concentration. Aust. J. Grape Wine Res. 2015, 21, 396–403. [Google Scholar] [CrossRef]

- Espejo, F.; Armada, S. Effect of Enzyme Addition in the Making of Pedro Ximenez Sweet Wines Using Dynamic Pre-fermentative Maceration. S. Afr. J. Enol. Vitic. 2016, 31. [Google Scholar] [CrossRef] [Green Version]

- García-Martínez, T.; De Lerma, N.L.; Moreno, J.; Peinado, R.A.; Millán, M.C.; Mauricio, J.C. Sweet Wine Production by Two Osmotolerant Saccharomyces cerevisiae Strains. J. Food Sci. 2013, 78, 874–879. [Google Scholar] [CrossRef]

- Ruiz-Bejarano, M.J.; Rodríguez-Dodero, M.C.; Castro, R.; García-Barroso, C. Empleo de Torulaspora delbrueckii en la elaboración de vinos dulces andaluces. Caracterización química y sensorial. In Proceedings of the Grupos de Investigación Enológica, Tarragona, Spain, 9–12 June 2015; pp. 352–355. [Google Scholar]

- Santiago Hurtado, J.I.; López de Lerma, N.; Moreno, J.; Peinado, R.A. Effect of thermal treatment and oak chips on the volatile composition of pedro ximénez sweet wines. Am. J. Enol. Vitic. 2010, 61, 91–95. [Google Scholar]

- López de Lerma, N.; Peinado, J.; Moreno, J.; Peinado, R.A. Antioxidant activity, browning and volatile Maillard compounds in Pedro Ximénez sweet wines under accelerated oxidative aging. LWT Food Sci. Technol. 2010, 43, 1557–1563. [Google Scholar] [CrossRef]

- Chinnici, F.; Guerrero, E.D.; Sonni, F.; Natali, N.; Marín, R.N.; Riponi, C. Gas chromatography-mass spectrometry (GC-MS) characterization of volatile compounds in quality vinegars with protected European geographical indication. J. Agric. Food Chem. 2009, 57, 4784–4792. [Google Scholar] [CrossRef]

- Callejón, R.M.; González, A.G.; Troncoso, A.M.; Morales, M.L. Optimization and validation of headspace sorptive extraction for the analysis of volatile compounds in wine vinegars. J. Chromatogr. A 2008, 1204, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Ríos-Reina, R.; Morales, M.L.; García-González, D.L.; Amigo, J.M.; Callejón, R.M. Sampling methods for the study of volatile profile of PDO wine vinegars. A comparison using multivariate data analysis. Food Res. Int. 2018, 105, 880–896. [Google Scholar] [CrossRef]

- Durán-Guerrero, E.; Schwarz, M.; Fernández-Recamales, M.Á.; Barroso, C.G.; Castro, R. Characterization and Differentiation of Spanish Vinegars from Jerez and Condado de Huelva Protected Designations of Origin. Foods 2019, 8, 341. [Google Scholar] [CrossRef] [Green Version]

- Aceña, L.; Vera, L.; Guasch, J.; Busto, O.; Mestres, M. Chemical characterization of commercial sherry vinegar aroma by headspace solid-phase microextraction and gas chromatography-olfactometry. J. Agric. Food Chem. 2011, 59, 4062–4070. [Google Scholar] [CrossRef]

- Callejón, R.M.; Morales, M.L.; Troncoso, A.M.; Silva Ferreira, A.C. Targeting key aromatic substances on the typical aroma of Sherry vinegar. J. Agric. Food Chem. 2008, 56, 6631–6639. [Google Scholar] [CrossRef] [PubMed]

- Marrufo-Curtido, A.; Cejudo-Bastante, M.J.; Rodríguez-Dodero, M.C.; Natera-Marín, R.; Castro-Mejías, R.; García-Barroso, C.; Durán-Guerrero, E. Novel vinegar-derived product enriched with dietary fiber: Effect on polyphenolic profile, volatile composition and sensory analysis. J. Food Sci. Technol. 2015, 52, 7608–7624. [Google Scholar] [CrossRef] [Green Version]

- Pizarro, C.; Esteban-Díez, I.; Sáenz-González, C.; González-Sáiz, J.M. Vinegar classification based on feature extraction and selection from headspace solid-phase microextraction/gas chromatography volatile analyses: A feasibility study. Anal. Chim. Acta 2008, 608, 38–47. [Google Scholar] [CrossRef]

- Jiménez-Sánchez, M.; Durán-Guerrero, E.; Rodríguez-Dodero, M.C.; Barroso, C.G.; Castro, R. Use of ultrasound at a pilot scale to accelerate the ageing of sherry vinegar. Ultrason. Sonochem. 2020, 69. [Google Scholar] [CrossRef] [PubMed]

- Marrufo-Curtido, A.; Cejudo-Bastante, M.J.; Durán-Guerrero, E.; Castro-Mejías, R.; Natera-Marín, R.; Chinnici, F.; García-Barroso, C. Characterization and differentiation of high quality vinegars by stir bar sorptive extraction coupled to gas chromatography-mass spectrometry (SBSE-GC-MS). LWT Food Sci. Technol. 2012, 47, 332–341. [Google Scholar] [CrossRef]

- Ríos-Reina, R.; Segura-Borrego, M.P.; Morales, M.L.; Callejón, R.M. Characterization of the aroma profile and key odorants of the Spanish PDO wine vinegars. Food Chem. 2020, 311. [Google Scholar] [CrossRef]

- Natera Marín, R.; Castro Mejías, R.; de Valme García Moreno, M.; García Rowe, F.; García Barroso, C. Headspace solid-phase microextraction analysis of aroma compounds in vinegar: Validation study. J. Chromatogr. A 2002, 967, 261–267. [Google Scholar] [CrossRef]

- Callejón, R.M.; Morales, M.L.; Ferreira, A.C.S.; Troncoso, A.M. Defining the Typical Aroma of Sherry Vinegar: Sensory and Chemical Approach. J. Agric. Food Chem. 2008, 56, 8086–8095. [Google Scholar] [CrossRef]

- Blanch, G.P.; Tabera, J.; Herraiz, M.; Sanz, J.; Reglero, G. Volatile Composition of Vinegars. Simultaneous Distillation-Extraction and Gas Chromatographic-Mass Spectrometric Analysis. J. Agric. Food Chem. 1992, 40, 1046–1049. [Google Scholar] [CrossRef]

- Morales, M.L.L.; Troncoso, A.M.M. Note: Evaluation of Aroma Compounds in Wine Vinegars: Effect of Previous Neutralisation of Samples. Food Sci. Technol. Int. 2003, 9, 397–402. [Google Scholar] [CrossRef]

- Morales, M.L.; González, G.A.; Casas, J.A.; Troncoso, A.M. Multivariate analysis of commercial and laboratory produced Sherry wine vinegars: Influence of acetification and aging. Eur. Food Res. Technol. 2001, 212, 676–682. [Google Scholar] [CrossRef]

- Morales, M.L.; Tesfaye, W.; Carmen García-Parrilla, M.; Casas, J.A.; Troncoso, A.M. Evolution of the aroma profile of sherry wine vinegars during an experimental aging in wood. J. Agric. Food Chem. 2002, 50, 3173–3178. [Google Scholar] [CrossRef]

- Bruna-Maynou, F.J.; Castro, R.; Rodríguez-Dodero, M.C.; Barroso, C.G.; Durán-Guerrero, E. Flavored Sherry vinegar with citric notes: Characterization and effect of ultrasound in the maceration of orange peels. Food Res. Int. 2020, 133. [Google Scholar] [CrossRef] [PubMed]

- Morales, M.L.; Tesfaye, W.; García-Parrilla, M.C.; Casas, J.A.; Troncoso, A.M. Sherry wine vinegar: Physicochemical changes during the acetification process. J. Sci. Food Agric. 2001, 81, 611–619. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Durán, E.; Castro, R.; Rodríguez-Dodero, M.C.; Natera, R.; García-Barroso, C. Study of the volatile composition and sensory characteristics of new Sherry vinegar-derived products by maceration with fruits. LWT Food Sci. Technol. 2013, 50, 469–479. [Google Scholar] [CrossRef]

- Ríos-Reina, R.; Segura-Borrego, M.P.; García-González, D.L.; Morales, M.L.; Callejón, R.M. A comparative study of the volatile profile of wine vinegars with protected designation of origin by headspace stir bar sorptive extraction. Food Res. Int. 2019, 123, 298–310. [Google Scholar] [CrossRef]

- Casale, M.; Armanino, C.; Casolino, C.; Oliveros, C.C.; Forina, M. A chemometrical approach for vinegar classification by headspace mass spectrometry of volatile compounds. Food Sci. Technol. Res. 2006, 12, 223–230. [Google Scholar] [CrossRef] [Green Version]

- Chanivet, M.; Durán-Guerrero, E.; Barroso, C.G.; Castro, R. Suitability of alternative wood types other than American oak wood for the ageing of Sherry vinegar. Food Chem. 2020, 316. [Google Scholar] [CrossRef]

- Chanivet, M.; Durán-Guerrero, E.; Rodríguez-Dodero, M.D.C.; Barroso, C.G.; Castro, R. Application of accelerating energies to the maceration of sherry vinegar with citrus fruits. J. Sci. Food Agric. 2020, 101, 2235–2246. [Google Scholar] [CrossRef]

- Durán-Guerrero, E.; Chinnici, F.; Natali, N.; Riponi, C. Evaluation of volatile aldehydes as discriminating parameters in quality vinegars with protected European geographical indication. J. Sci. Food Agric. 2015, 95, 2395–2403. [Google Scholar] [CrossRef]

- Troncoso-González, A.M.; Guzmán-Chozas, M. Volatile components in Andalusian vinegars. Z. Lebensm.-Unters. Forsch. 1987, 185, 130–133. [Google Scholar] [CrossRef]

- Guerrero, M.I.; Heredia, F.J.; Troncoso, A.M. Characterisation and differentiation of wine vinegars by multivariate analysis. J. Sci. Food Agric. 1994, 66, 209–212. [Google Scholar] [CrossRef]

- Guerrero, E.D.; Marín, R.N.; Mejías, R.C.; Barroso, C.G. Optimisation of stir bar sorptive extraction applied to the determination of volatile compounds in vinegars. J. Chromatogr. A 2006, 1104, 47–53. [Google Scholar] [CrossRef]

- Guerrero, E.D.; Marín, R.N.; Mejías, R.C.; Barroso, C.G. Stir bar sorptive extraction of volatile compounds in vinegar: Validation study and comparison with solid phase microextraction. J. Chromatogr. A 2007, 1167, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Ríos-Reina, R.; Callejón, R.M.; Oliver-Pozo, C.; Amigo, J.M.; García-González, D.L. ATR-FTIR as a potential tool for controlling high quality vinegar categories. Food Control 2017, 78, 230–237. [Google Scholar] [CrossRef]

- Guerrero, E.D.; Mejías, R.C.; Marín, R.N.; Lovillo, M.P.; Barroso, C.G. A new FT-IR method combined with multivariate analysis for the classification of vinegars from different raw materials and production processes. J. Sci. Food Agric. 2010, 90, 712–718. [Google Scholar] [CrossRef]

- Benito, M.J.; Ortiz, M.C.; Sánchez, M.S.; Sarabia, L.A.; Iñiguez, M. Typification of vinegars from Jerez and Rioja using classical chemometric techniques and neural network methods. Analyst 1999, 124, 547–552. [Google Scholar] [CrossRef]

- Durán, E.; Palma, M.; Natera, R.; Castro, R.; Barroso, C.G. New FT-IR method to control the evolution of the volatile constituents of vinegar during the acetic fermentation process. Food Chem. 2010, 121, 575–579. [Google Scholar] [CrossRef]

- González-Viñas, M.A.; Salvador, M.D.; Cabezudo, M.D. Taste group thresholds and sensory evaluation of spanish wine vinegars. J. Sens. Stud. 1996, 11, 129–140. [Google Scholar] [CrossRef]

- Tesfaye, W.; García-Parrilla, M.C.; Troncoso, A.M. Sensory evaluation of Sherry wine vinegar. J. Sens. Stud. 2002, 17, 133–144. [Google Scholar] [CrossRef]

- Tesfaye, W.; Morales, M.L.; Callejón, R.M.; Cerezo, A.B.; González, A.G.; García-Parrilla, M.C.; Troncoso, A.M. Descriptive sensory analysis of wine vinegar: Tasting procedure and reliability of new attributes. J. Sens. Stud. 2010, 25, 216–230. [Google Scholar] [CrossRef]

- Morales Gómez, M.L.; Bellido, B.B.; Tesfaye, W.; Callejón Fernandez, R.M.; Valencia, D.V.; Fernandez-Pachón, M.S.; García-Parrilla, M.D.C.; Troncoso González, A.M. Sensory evaluation of sherry vinegar: Traditional compared to accelerated aging with oak chips. J. Food Sci. 2006, 71. [Google Scholar] [CrossRef]

- Durán Guerrero, E.; Mejías, R.C.; Marín, R.N.; Bejarano, M.J.R.; Dodero, M.C.R.; Barroso, C.G. Accelerated aging of a Sherry wine vinegar on an industrial scale employing microoxygenation and oak chips. Eur. Food Res. Technol. 2011, 232, 241–254. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Rodríguez Dodero, M.C.; Durán Guerrero, E.; Castro Mejías, R.; Natera Marín, R.; García Barroso, C. Development and optimisation by means of sensory analysis of new beverages based on different fruit juices and sherry wine vinegar. J. Sci. Food Agric. 2013, 93, 741–748. [Google Scholar] [CrossRef]

- Consejería de Agriculura, Pesca y Desarrollo Rural. Orden de 28 de Junio de 2018, Por La Que Se Aprueba el Expediente Técnico de Indicación Geográfica “Brandy de Jerez.”; Boletin Oficial Junta Andalucía (BOJA): Sevilla, Spain, 2018; Volume 127, pp. 19–20. [Google Scholar]

- Schwarz, M.; Rodríguez-Dodero, M.C.; Jurado, M.S.; Puertas, B.; Barroso, C.G.; Guillén, D.A. Analytical Characterization and Sensory Analysis of Distillates of Different Varieties of Grapes Aged by an Accelerated Method. Foods 2020, 9, 277. [Google Scholar] [CrossRef] [Green Version]

- Trillo, L.M.; Álvarez, M.A.; Pinedo, J.M.; Arnedo, R.; Casas, J.A.; Sanz, J. Influencia de la selección varietal en la composición química de los aguardientes de vino destinados a la elaboración de Brandy de Jerez. In Proceedings of the XI Congreso Nacional de Enólogos, Toledo, Spain, 14–16 April 2005. [Google Scholar]

- Álvarez, M.A.; Trillo, L.M.; Pinedo, J.M.; Casas, J.A.; García-Maíquez, E. Influencia de la temperatura de fermentación y el contenido de SO2 en la elaboración de vinos de “La Mancha”, destinados a la obtención de aguardientes vínicos de bajo grado (Holandas). In Proceedings of the VI Congreso Nacional de Enólogos, Jerez de la Frontera, Spain, 7–9 April 2000. [Google Scholar]

- Trillo, L.M.; Pinedo, J.M.; Arnedo, R.; Casas, J.A.; Sanz, J.; Roselló, A.; Cota, J.; Carrillo, F. Estudio comparativo de los procesos de destilación discontinuos en alambique charentais y en columna de platos para la obtención de aguardientes de vino destinados a la elaboración de Brandy de Jerez. In Proceedings of the XII Congreso Nacional de Enólogos, Santa Cruz de Tenerife, Spain, 5–7 May 2006. [Google Scholar]

- Delgado-González, M.J.; Sánchez-Guillén, M.M.; García-Moreno, M.d.V.; Rodríguez-Dodero, M.C.; García-Barroso, C.; Guillén-Sánchez, D.A. Estudio del envejecimiento de destilados vínicos (holandas) monovarietales obtenidos mediante destilación de conos rotatorios. In Proceedings of the XIV Congreso Nacional de Investigación Enológica, Ciudad Real, Spain, 26–29 June 2019; pp. 204–207. [Google Scholar]

- Guerrero-Chanivet, M.; Valcárcel-Muñoz, M.J.; García-Moreno, M.V.; Guillén-Sánchez, D.A. Characterization of the Aromatic and Phenolic Profile of Five Different Wood Chips Used for Ageing Spirits and Wines. Foods 2020, 9, 1613. [Google Scholar] [CrossRef]

- Valme García-Moreno, M.; Sánchez-Guillén, M.M.; de Mier, M.R.; Delgado-González, M.J.; Carmen Rodríguez-Dodero, M.; García-Barroso, C.; Guillén-Sánchez, D.A. Use of alternative wood for the ageing of brandy de Jerez. Foods 2020, 9, 250. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valcárcel-Muñoz, M.J.; Guerrero-Chanivet, M.; García-Moreno, M.V.; Rodríguez-Dodero, M.C.; Guillén-Sánchez, D.A. Comparative Evaluation of Brandy de Jerez Aged in American Oak Barrels with Different Times of Use. Foods 2021, 10, 288. [Google Scholar] [CrossRef] [PubMed]

- Delgado, R.; Durán, E.; Castro, R.; Natera, R.; Barroso, C.G. Development of a stir bar sorptive extraction method coupled to gas chromatography-mass spectrometry for the analysis of volatile compounds in Sherry brandy. Anal. Chim. Acta 2010, 672, 130–136. [Google Scholar] [CrossRef]

- Durán Guerrero, E.; Cejudo Bastante, M.J.; Castro Mejías, R.; Natera Marín, R.; García Barroso, C. Characterization and differentiation of sherry brandies using their aromatic profile. J. Agric. Food Chem. 2011, 59, 2410–2415. [Google Scholar] [CrossRef]

- Schwarz, M.; Rodríguez, M.C.; Guillén, D.A.; Barroso, C.G. Development and validation of UPLC for the determination of phenolic compounds and furanic derivatives in Brandy de Jerez. J. Sep. Sci. 2009, 32, 1782–1790. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Dodero, M.C.; García-Barroso, C.; Pérez-Bustamante-De Monasterio, J.A. Análisis de cumarinas en brandys de Jerez mediante el uso de HPLC con detección en fluorescencia. In Proceedings of the Jornadas de Viticultura y Enología en Tierra de Barros, Almendralejo, Spain, 6–10 May 1997. [Google Scholar]

- Rodríguez-Dodero, M.C.; Guillén-Sánchez, D.A.; García-Barroso, C. La nariz electrónica como herramienta para la diferenciación de tipos de Brandy de Jerez. In Proceedings of the Congreso Nacional de Enólogos, Bilbao, Spain, 15–17 February 2003. [Google Scholar]

- Consejo Regulador de la IGP Brandy de Jerez Bodegas y Marcas de Brandy de Jerez. Available online: https://www.brandydejerez.es/bodegas-y-marcas (accessed on 1 April 2021).

- Delgado-González, M.J.; Sánchez-Guillén, M.M.; García-Moreno, M.V.; Rodríguez-Dodero, M.C.; García-Barroso, C.; Guillén- Sánchez, D.A. Study of a laboratory-scaled new method for the accelerated continuous ageing of wine spirits by applying ultrasound energy. Ultrason. Sonochem. 2017, 36, 226–235. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, M.; Rodríguez, M.C.; Sánchez, M.; Guillén, D.A.; Barroso, C.G. Development of an accelerated aging method for Brandy. LWT Food Sci. Technol. 2014, 59, 108–114. [Google Scholar] [CrossRef]

- Sánchez-Guillén, M.M.; Rodríguez-Dodero, M.C.; Schwarz-Rodríguez, M.; Guillén-Sánchez, D.A.; García-Barroso, C. Aplicación del análisis sensorial durante la optimización del test patentado sobre envejecimiento acelerado de aguardientes. In Proceedings of the XII Congreso de los Grupos de Investigación Enológica GIENOL 2013, Madrid, Spain, 18–21 June 2013; pp. 555–558. [Google Scholar]

- Trillo-Ollero, R.; García-Moreno, M.d.V.; Delgado-González, M.J.; Rodríguez-Dodero, M.C.; García-Barroso, C.; Guillén-Sánchez, D.A. Caracterización de cinco tipos de maderas para su uso en el envejecimiento de destilados. In Proceedings of the XIV Congreso Nacional de Investigación Enológica, Ciudad Real, Spain, 26–29 June 2018; pp. 200–203. [Google Scholar]

| Volatile Compounds | Sensory Descriptors | Concentration (mg/L) | References Fino | References Amontillado | References Oloroso |

|---|---|---|---|---|---|

| Carbonyls | |||||

| Acetaldehyde | Overripe apple | 85–545 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| Acetoin | Butter | 0.011–74 | [31,32,33,34,35,36] | [32,37] | [32] |

| Benzaldehyde | Bitter almond/cherry | 0.013–0.076 | [33,36] | [39] | |

| 2,3-Butanedione | Butter-cookie | 0.170–2.1 | [33,34,36] | [37] | [38] |

| Furfural | Sweet/woody/almond/baked/bread | 0.179–7.14 | [32] | [32] | [32] |

| β-Ionone | Balsamic/rose/violet/berry/phenolic | 0.062 | [32,35] | [32] | |

| Neral | Sweet/citrus/lemon peel | [33] | |||

| Octanal | Herbaceous | 0.090–0.390 | [32,33,34,35,36] | [37] | |

| Acids | |||||

| Butanoic acid | Cheese/butter | 0.607–14.6 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| Decanoic acid | Rancid | 0.004–0.370 | [31,33,36] | [39] | |

| Dodecanoic acid | Mild fatty/coconut/bay oil | [33,36] | |||

| Hexanoic acid | Fatty/sweat/cheese | 0.635–2.39 | [31,32,33,34,35,36] | [32] | [32] |

| Isobutanoic acid | Acidic/cheese/dairy/buttery/rancid | 2.2–22.1 | [31,33,36] | ||

| Isobutyric acid | Acidic/cheese/dairy/buttery/rancid | 0.002–4.58 | [32] | [32,39] | |

| 3-Methylbutanoic acid | Cheese | 1.5–679 | [31,32,33,35,36] | [32,37] | [38] |

| Nonanoic acid | Waxy/cheesy/dairy | 0.003–0.011 | [39] | ||

| Octanoic acid | Fatty/waxy/rancid/oily/cheesy | 0.001–1.6 | [31,33,34,36] | [39] | |

| Alcohols | |||||

| Benzyl alcohol | Floral/rose/phenolic/balsamic | 0.045–3.3 | [31,32,33,36] | [32] | [32] |

| 1-Butanol | Fusel oil/sweet/balsam/whiskey | 0.001–19.9 | [31,32,33,34,35,36] | [32] | [32,39] |

| 2-Butanol | Sweet/apricot | 1.1–4.4 | [31,32,33,35,36] | [32] | [32] |

| 2,3-Butanediol | Fruity/creamy/buttery | [33,36] | |||

| 1-Decanol | Fatty/waxy/floral | 0.124–1.26 | [32,33,35,36] | [32] | [32] |

| 3-Ethoxy-1-propanol | 0.250–0.490 | [31,33,35] | |||

| 1-Heptanol | Musty/pungent/leafy green/apple/banana | 0.300–0.870 | [33] | [32] | [32] |

| Hexanol | Fusel oil/fruity/alcoholic/sweet/green | 0.001–2.5 | [31,32,33,35,36] | [32] | [32,39] |

| E-3-Hexenol | Green/cortex/floral/oily/earthy | 0.055–0.085 | [31,32,35] | ||

| Z-3-Hexenol | Green/grassy/melon rind | 0.055–0.085 | [31,32,33,35] | ||

| Isoamyl alcohols | Vinous/solvent | 0.020–444 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| Isobutanol | Vinous/solvent | 25.7–102 | [31,32,33,34,35,36] | [32,37] | [32] |

| Isopropyl alcohol | Alcohol/musty/woody | 1.4–2.7 | [31] | ||

| Methanol | Slight alcoholic | [33,36] | |||

| 2-Methyl-1-butanol | Roasted/fruity/fusel oil/alcoholic/wine/whiskey | [39] | |||

| 2-Methyl-1-pentanol | 0.020–0.090 | [32] | [32] | [32] | |

| 3-Methyl-1-pentanol | Pungent/fusel oil/brandy/wine/cocoa | 0.110–18 | [31,32,33,35,36] | [32] | [32] |

| 4-Methyl-1-pentanol | Nutty | 0.029–0.135 | [31,32,33,36] | [32] | |

| 1-Octanol | Waxy/green/citrus/aldehydic/floral/coconut | [33,36] | |||

| 1-Pentanol | Pungent/fermented/bready/yeasty/fusel oil/winey/solvent | 0.060–102 | [32,33] | [32] | [32] |

| Phenethyl alcohol | Rose | 0.003–99 | [31,32,33,34,35,36] | [32,37] | [32,38,39] |

| Propanol | Alcoholic/fermented/musty/yeasty/apple/pear | 12.3–16.3 | [31,33,35,36] | ||

| Volatile phenols | |||||

| 4-Ethylguaiacol | Toasted/clove | 0.002–0.740 | [32,33,34,35,36] | [32,37] | [32,39] |

| 4-Ethylphenol | Smoke/phenolic/creosote | 0.004–0.094 | [33,36] | [32,39] | |

| Eugenol | Cinnamon/clove | 0.002–0.477 | [31,32,33,34,35,36] | [32,37] | [32,39] |

| Guaiacol | Phenolic/smoke/spice/vanilla/woody | 0.280–0.434 | [39] | ||

| Methyleugenol | Spicy/cinnamon/clove/musty/waxy/phenolic | 0.157 | [32] | ||

| Esters | |||||

| Butyl acetate | Fruity/solvent/banana | 0.091–0.161 | [33] | [32,39] | |

| Diethyl malate | Brown sugar/sweet/wine/fruity/herbal | 0.800–23.6 | [31,32,33,35,36] | [32] | [32] |

| Diethyl succinate | Mild fruity/cooked apple/ylang | 0.001–55.4 | [31,32,33,35,36] | [32] | [32,39] |

| Ethyl acetate | Pineapple/varnish | 13.9–260 | [31,32,33,34,35,36] | [32,37] | [32] |

| Ethyl benzoate | Fruity/dry/musty/sweet/wintergreen | 0.180–0.215 | [32] | [32] | |

| Ethyl butanoate | Banana/apple | 0.172–3.5 | [31,32,33,34,35,36] | [37] | [32,38,39] |

| Ethyl decanoate | Sweet/waxy/fruity/apple/grape/oily/brandy | 0.22 | [32] | ||

| Ethyl furoate | Balsamic | [33,36] | |||

| Ethyl heptanoate | Fruity/pineapple/brandy/rum/wine | 0.021–0.109 | [32,35] | [32] | [32] |

| Ethyl hexanoate | Almond/apple | 0.078–0.280 | [31,33,34,35,36] | [37] | [38,39] |

| Ethyl 3-hydroxybutanoate | Fruity/green grape/tropical | 0.030–0.747 | [31,33,35,36] | ||

| Ethyl 3-hydroxyhexanoate | Rubber | [33] | [37] | ||

| Ethyl isobutanoate | Apple/pineapple | 0.028–1.660 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| Ethyl isovalerate | Fruity/sweet/apple/pineapple/tutti frutti | 0.001–0.009 | [39] | ||

| Ethyl lactate | Raspberry/milky | 12–854 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| Ethyl laurate | Sweet/waxy/floral/soapy/clean | 0.024–0.140 | [32,35] | [32] | [32] |

| Ethyl myristate | Mild waxy/soapy | 0.099–0.119 | [32,33,35,36] | [32] | |

| Ethyl octanoate | Pear | 0.008–1.3 | [31,32,33,34,35,36] | [32,37] | [39] |

| Ethyl propanoate | Sweet/fruity/rum/juicy fruit/grape/pineapple | 0.109–1.92 | [31,32,33,35,36] | [32] | [32] |

| Ethyl palmitate | Mild waxy | 0.042–0.070 | [32,35] | [32] | |

| Ethyl pyruvate | Fruity/sweet/rum | 0.081–0.201 | [31,32,33,35,36] | [32] | [32] |

| Ethyl valerate | Sweet/fruity/apple/pineapple/green/tropical | 0.001–0.010 | [39] | ||

| Hexyl acetate | Green/fruity/sweet/fatty/fresh/apple/pear | 0.001–0.008 | [39] | ||

| Hexyl hexanoate | Green/sweet/waxy/fruity/berry | 0.247 | [32] | ||

| Hexyl lactate | Sweet/floral/green/fruity | 1.1 | [32] | ||

| Isoamyl acetate | Banana | 0.050–0.855 | [31,33,34,36] | [37] | [38,39] |

| Isoamyl laurate | Winey/alcoholic/fatty/creamy/yeasty/fusel oil | 0.357 | [32] | ||

| Isobutyl acetate | Sweet/fruity/banana | 0.025–0.137 | [31,33] | [32,39] | |

| Isobutyl isobutanoate | Fruity tropical/fruit pineapple/grape skin/banana | 0.066 | [32] | ||

| Isobutyl lactate | Faint buttery/fruity/caramel | 0.034–0.242 | [32,33,35,36] | [32] | |

| Methyl acetate | Solvent/fruity/winey/brandy/rum | 6.6 | [32] | ||

| Methyl butanoate | Strawberry/butter | 0.486–4.86 | [33,34,36] | [37] | [32,38] |

| Monoethyl succinate | Odorless | [33,36] | |||

| Phenethyl acetate | Flowers | 0.100–1.1 | [31,33,36] | [37] | [38] |

| Phenethyl octanoate | Sweet/waxy/slightly cocoa/caramel/winey/brandy | 0.190–0.275 | [32,33,36] | [32] | |

| Propyl acetate | Solvent/fusel oil/sweet/fruity | 0.042–0.162 | [31,32,33,36] | [32] | [32] |

| Propyl butanoate | Pungent/rancid | 0.112–0.150 | [32,35] | [32] | |

| Terpenes | |||||

| β-Citronellol | Rose | 0.280–1.33 | [31,32,33,35,36] | [32] | |

| Farnesol | Sweet/floral | 0.282–5.79 | [32,35] | [32] | [32] |

| Linalool | Citrus/orange/floral/terpy/waxy/rose | 0.009–0.032 | [31] | [38] | |

| Nerol | Floral/green | 0.151–0.176 | [32,35] | [32] | |

| E-Nerolidol | Floral/green/citrus/woody/waxy | 0.076–0.213 | [32,35] | [32] | [32] |

| Z-Nerolidol | Waxy/floral | 0.696 | [32,33,36] | ||

| 4-Terpineol | Pine | 0.777 | [32] | ||

| α-Terpineol | Pine/woody/resinous/lemon/citrus | 0.006–0.015 | [32,33,35] | [39] | |

| Lactones | |||||

| γ-Butyrolactone | Creamy/oily | 0.004–40.8 | [31,32,33,34,35,36] | [32] | [32,39] |

| γ-Decalactone | Peach | 0.043 | [32,33,34,35,36] | ||

| Pantolactone | 0.470–5.22 | [31,32,33,35,36] | [32] | [32] | |

| Sotolon | Walnut/cotton candy/curry | 0.100–0.670 | [33,34,36] | [37] | [38] |

| cis-Whiskeylactone | Burnt/wood/vanilla/coconut | 0.009–0.410 | [31,34,36] | [37] | [38,39] |

| trans-Whiskeylactone | Sweet/spicy/coconut/vanilla | [33] | [39] | ||

| Miscellaneous | |||||

| Methionol | Cooked potato/cut hay | 0.063–3.4 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| p-Cymene | Citrus/terpene/woody/spice | [33,36] | |||

| 1,1-Diethoxyethane | Green fruit/liquorice | 8.4–58.8 | [31,32,33,34,35,36] | [32,37] | [32,38] |

| Volatile Compounds | Sensory Descriptors | Concentration (mg/L) | References |

|---|---|---|---|

| Alcohols | |||

| (E)-2-Hexenol | Herbaceous/green/green tomato | 0.001–0.36 | [46,47,48,49,50,51] |

| 2,3-Butanediol (levo/meso) | Ripe fruit/butter | 0.001–4015.0 | [47,49,52,53] |

| 2-Butanol | Vinous/medicinal | 0.003–0.12 | [46,47,48,49,50,51] |

| 2-Methylbutanol | Roasted/fruity/ alcoholic/fusel oil/ wine/whiskey | 1.40–1.66 | [45] |

| 2-Phenylethanol | Rose/talc/honey | 0.12–78.88 | [45,47,48,49,51,52,53,54,55] |

| 2-phenylethyl alcohol | Rose/honey | 0.002–25.91 | [46,50,56,57] |

| 3-Ethoxypropanol | Overripe pear | 0.30–17.37 | [47,49] |

| 3-Hexenol (E/Z) | Herbaceous/green/grass | 0.001–0.079 | [46,47,48,49,52,56] |

| 3-Methyl-2-butanol | [54] | ||

| 3-Methylpentanol | Pungent/fusel oil/brandy/wine/cocoa | 0.022–0.030 | [47] |

| Benzyl alcohol | Roasted/toasted/disifectant/fruity/walnut/floral/rose/phenolic/balsamic | 0.001–0.772 | [45,46,47,48,49,50,51,52] |

| Butanol | Vinous/medicinal | 0.001–1.76 | [45,46,47,48,49,50,51] |

| Heptanol | Oily | 0.006–0.037 | [46,57] |

| Hexanol | Cut grass/resinous/herbaceous/wood | 0.001–1.02 | [45,46,47,48,49,50,51,54,55,57] |

| Isoamyl alcohols | Solvent/cake/fusel alcohols/nail polish/ripe fruit | 0.003–146.72 | [46,47,48,49,50,51,52,53,55,56,57] |

| Isobutanol | Alcohol/solvent/vinous/nail polish | 0.003–40.90 | [45,46,47,48,49,50,51,53,56,57] |

| Methanol | Solvent/pungent fruity | 57.5–163.0 | [49,53,57] |

| Pentanol | Bitter almond/synthetic | 0.001–0.014 | [49,51] |

| Propanol | Fusel alcohol/ripe fruit | 8.4–88.0 | [49,53,57] |

| Aldehydes | |||

| (E)-2-Hexenal | Herbaceous | 0.012–0.308 | [48,51,55] |

| 2-Hexanal | [54] | ||

| 3-Methylbutanal | Ethereal/aldehydic/chocolate/peach/fatty | 0.094 | [56] |

| Acetaldehyde | Stewed apple/pungent | 13.29–347.0 | [49,53,56,57] |

| Benzaldehyde | Roasted/bitter almond/nutty/smoky | 0.003–0.151 | [45,46,47,48,49,50,54,55] |

| Decanal | Soapy/green lemon | [57] | |

| Hexanal | Fatty/herbaceous/green apple | 0.004–0.444 | [46,47,48,49,50,52,54,55] |

| Nonanal | Waxy/aldehydic/rose/orange peel fatty | [54,55] | |

| Octanal | Herbaceous | 0.046–0.127 | [47,54,55] |

| Phenylacetaldehyde | 0.068 | [56] | |

| Ketones | |||

| 2,3-Butanedione | Buttery/ripe fruit/yogurt/cake | 0.004–5.07 | [46,47,48,49,50,51,56,57] |

| 2,3-Pentanedione | Buttery/cream/cake | 0.004–0.435 | [46,47,48,50,57] |

| 2-Octanone | Floral/over ripe fruit | 0.002–0.022 | [51] |

| 6-Methyl-5-hepten-2-one | [54,55] | ||

| Acetoin | Buttery/cream/sour yogurt/sour milk | 0.070–1228.52 | [46,47,48,49,50,51,53,57] |

| Furans | |||

| 2-Furaldehyde | Fusel alcohol/cake/burnt/almond/ripe fruit/toasted bread/incense/floral | 0.001–5.002 | [45,46,47,48,49,50,51,52,54,55,56,57] |

| 5-Hydroxymethyl-2-furaldehyde | Rancid/toasted | 0.003–102.40 | [45,51] |

| 5-Methyl-2-furaldehyde | Toasted/bitter almond/cake/burnt/caramel | 2.4 | [45,46,47,48,49,50,51,52,54,55,57] |

| Ethyl 2-furoate | Balsamic | [57] | |

| Furfuryl alcohol | Varnish | 0.005–0.023 | [47,49,57] |

| Acids | |||

| 2-Ethyl-hexanoic acid | [54,55] | ||

| 2-Methylbutanoic acid | Rancid | 0.003–0.009 | [48] |

| 3-Methylbutanoic acid | Lactic/rancid/cheese | 0.001–2.495 | [45,46,47,48,50,56,57] |

| Acetic acid | Fatty | 3.31–4.08 | [52] |

| Butanoic acid | Aged cheese/rancid | 0.003–0.627 | [46,47,48,49,50,56] |

| Decanoic acid | Rancid/cheese/wax/plasticine | 0.005–0.185 | [45,47,49,51,52,54,55,57] |

| Dodecanoic acid | Fatty/coconut/bay | [54,55] | |

| Hexadecanoic acid | Waxy/fatty | [54,55] | |

| Hexanoic acid | Cheese/rancid | 0.030–0.069 | [49] |

| Isobutanoic acid | Cheese/rancid/fat | 0.003–5.623 | [45,49] |

| Nonanoic acid | Waxy/dirty/cheese/dairy | 0.011–0.033 | [45,54,55] |

| Octanoic acid | Rancid/cheese/fatty | 0.002–0.506 | [45,47,48,49,51,52,54,55,57] |

| Propanoic acid | Fat | 0.080–1.371 | [49] |

| Tetradecanoic acid | Waxy | [54,55] | |

| Esters | |||

| 2-Phenylethyl acetate | Fruity/honeyed/floral/rose | 0.001–0.094 | [46,47,48,49,50,52,54,55,56,57,58] |

| 2-Phenylethyl hexanoate | 0.007–0.015 | [47] | |

| 2-Phenylethyl octanoate | Cocoa/caramel/winey/brandy | [57] | |

| 3-Methylpropyl acetate | 0.037 | [56] | |

| 4-Methyl-2-pentyl acetate | 0.181 | [52,55] | |

| Benzyl acetate | Floral/fruity/jasmine/fresh | 0.0416 | [45] |

| Butyl acetate | Solvent/fruity/banana | 0.016–0.154 | [45,47,54,55] |

| Butyl lactate | [57] | ||

| cis-3-Hexenyl acetate | 0.001–0.002 | [45] | |

| Diethyl malate | Green | 0.003–0.531 | [47,49,51] |

| Diethyl pentanedioate | [55] | ||

| Diethyl succinate | Overripe fruit/lavender | 0.101–1.76 | [45,47,49,52,54,55,57,58] |

| Ethyl 2-methylbutanoate | 0.0041 | [56] | |

| Ethyl 2-methylpentanoate | [56] | ||

| Ethyl 2-methylpropanoate | 0.054 | [56] | |

| Ethyl 3-hydroxybutanoate | Grape/green apple/marshmallows | 0.005–0.062 | [47,49,57] |

| Ethyl 3-methylbutanoate | 0.0075 | [45,54,55,56] | |

| Ethyl 3-methylpentanoate | 0.001 | [56] | |

| Ethyl 4-methylpentanoate | 0.001 | [56] | |

| Ethyl acetate | Pineapple/varnish/balsamic/fruity/solvent/pungent/glue | 0.031–113.33 | [46,47,48,49,50,52,53,57] |

| Ethyl benzoate | Fruity/medicinal/wintergreen/anise | 0.002–0.005 | [49,57] |

| Ethyl butanoate | Banana/pineapple/strawberry | 0.012–0.386 | [45,52,54,55,56,57,58] |

| Ethyl cyclohexanoate | [56] | ||

| Ethyl decanoate | Synthetic/rancid | 0.015–0.162 | [52,54,55,57,58] |

| Ethyl dihydrocinnamate | 0.001 | [56] | |

| Ethyl dodecanoate | Waxy/floral/soapy/clean | 0.077–0.106 | [54,55,58] |

| Ethyl furoate | Plum/floral | 0.0001 | [49] |

| Ethyl heptanoate | Strawberry/banana | 0.005–0.046 | [46,47,58] |

| Ethyl hexadecanoate | 0.008 | [54,55,58] | |

| Ethyl hexanoate | Banana/green apple | 0.005–0.147 | [45,47,49,54,55,56,57,58] |

| Ethyl isobutanoate | Apple/pineapple | 0.002–3.869 | [45,58] |

| Ethyl lactate | Lactic/yogurt/strawberry/raspberry/buttery | 0.001–93.8 | [46,47,48,50,51,52,57] |

| Ethyl octadecanoate | [54,55] | ||

| Ethyl octanoate | Pineapple/pear/soapy/banana | 0.002–0.174 | [45,49,52,54,55,56,57,58] |

| Ethyl pentanoate | Fruity/apple/pineapple/green/tropical | 0.005–0.071 | [45,52] |

| Ethyl propanoate | Banana/apple | 0.005–0.152 | [46,47,58] |

| Ethyl succinate | Toffee/coffee | 0.029–70.0 | [47,49] |

| Ethyl tetradecanoate | Mild waxy/soapy | 0.002 | [54,55,58] |

| Hexyl acetate | Apple/pear/banana/floral | 0.001–2.14 | [45,46,47,48,50,52,57] |

| Isoamyl acetate | Banana | 0.008–0.019 | [49,54,55] |

| Isoamyl butanoate | Banana/fruity | 0.012–0.089 | [47,48] |

| Isobutyl lactate | Faint buttery/fruity/caramel | [57] | |

| Methyl acetate | Solvent/fruity/winey/brandy/rum | 0.064–0.085 | [58] |

| Methyl butanoate | Strawberry/butter | [57] | |

| Methyl octanoate | 0.001 | [52] | |

| Terpenes | |||

| 4-Terpineol | Moldy | 0.002 | [48,54,55] |

| Carvacrol | Thyme | [54,55] | |

| Farnesol | Floral/fruity/balsamic/clove | 0.002–0.080 | [46,47,48,50,54,57] |

| Geranial | Citrus | 0.002–0.078 | [46,47,50] |

| Geraniol | Floral/fruity/rose/waxy/citrus | [54] | |

| γ-Terpineol | 0.034–2.99 | [52] | |

| Linalool | Muscat/rose/lavender | 0.006–1.62 | [52,54,55,56,57] |

| Linalool oxide | [54,55] | ||

| Nerol | Citrus/magnolia | 0.013 | [47,54,55] |

| Nerol oxide | [54,55] | ||

| Nerolidol | Floral/green/citrus/woody/waxy | [54,55] | |

| p-Cymene | Fresh/citrus/lemon/woody/spicy | 0.23–0.58 | [52] |

| Thymol | Herbal/thyme/phenolic/medicinal/camphor | [54,55] | |

| α-Terpineol | Lily/cake | 0.004–0.016 | [45,47,48,54,55] |

| β-Citronellol | Rose | [54,55] | |

| β-Myrcene | [54,55] | ||

| Lactones | |||

| 4-Caprolactone | Herbaceous/coconut | 0.001–0.005 | [49] |

| γ-Butyrolactone | Cake/caramel/fruity/empyreumatic/coconut/toasted | 0.003–37.90 | [45,46,47,48,49,50,51,57] |

| γ-Decalactone | Peach/coconut | 0.001–0.129 | [46,47,48,49,50,58] |

| γ-Heptalactone | Fruity/coconut/herbaceous/caramel | 0.001–0.120 | [46,47,48,50] |

| γ-Hexalactone | Cake/fruity/peach | 0.003–0.023 | [47,48] |

| γ-Nonalactone | Over-ripe fruit | 0.015–0.372 | [51,58] |

| γ-Pentalactone | Cut hay | 0.002–0.006 | [49] |

| Pantolactone | Toasted bread/smoked | 0.065–0.190 | [47,49,57] |

| Sotolon | walnut/cotton candy/curry | 0.176 | [56] |

| cis-Whiskeylactone | Burnt/wood/vanilla/coconut | 0.011–0.028 | [47,56,57] |

| trans-Whiskeylactone | Spicy/coconut/vanilla | 0.004–0.049 | [45,47,57] |

| Mercaptans | |||

| 2-Methyl-3-furanthiol | Fried | 0.035 | [56] |

| 3-Mercaptohexanol | Green/lemon | [56] | |

| 4-Mercapto-4-methyl-2-pentanone | Broom/cat urine/black currant sprout | [56] | |

| Dimethyl disulphide (DMDS) | 0.0098 | [56] | |

| Methional | Boiled vegetables/oxidized | 0.02 | [56] |

| Methionol | Cooked potato/cut hay | 0.001–0.070 | [46,47] |

| Methoxypyrazines | |||

| 3-Isobutyl-2-methoxypyrazine | Green pepper/asparagus/potato | [56] | |

| 3-Isopropyl-2-methoxypyrazine | [56] | ||

| 3-sec-Butyl-2-methoxypyrazine | [56] | ||

| Miscellaneous | |||

| 1,1,6-Trimethyl-1,2-dihydronaphthalene (TDN) | Gasoline | [54,55] | |

| 1,1-Diethoxyethane | Green fruit/licorice/cake/fruity/over-ripe fruit | 0.023–4.795 | [46,47,48,50,51,57] |

| β-Damascenone | Fruity/rose/plum/grape/raspberry | 0.01 | [56] |

| Volatile Compounds | Sensory Descriptors | Concentration (mg/L) | References |

|---|---|---|---|

| Acetates | |||

| Benzyl acetate | Sweet/floral/fruity/jasmine/fresh | 0.013–0.224 | [70,71,72,73,74,75,76,77,78] |

| Bornyl acetate | Woody/pine/herbal cedar/spice | [79] | |

| 2,3-Butanediol diacetate | [79,80] | ||

| n-Butyl acetate | Solvent/fruity/banana | 0.1–2.8 | [71,73,75,77,80,81,82] |

| Ethyl acetate | Fruity/sweet/weedy/green | 0.1–3.9 | [16,72,73,75,79,80,82,83,84,85,86,87,88] |

| Ethyl 2-phenyl acetate | Sweet/floral/honey/rose/balsamic/cocoa | 25–132 | [70,71,73,74,79,80,81,82,87,89] |

| Geranyl acetate | Floral/rose/lavender/ green/waxy | [79,89] | |

| (E)-2-Hexen-1-ol acetate | Green/fruity | [79,90] | |

| (Z)-3-Hexen-1-ol acetate | Green/fruity/banana/apple/grassy | 0.01–0.03 | [73,78,79,80,91] |

| Hexyl acetate | Fruity/green apple/banana/sweet | 0.007–0.09 | [71,72,73,75,78,79,83,87,92,93] |

| Isoamyl acetate | Sweet/fruity/banana | 2.7–16.3 | [71,72,73,74,75,78,79,80,82,83,86,93] |

| Isobutyl acetate | Sweet/fruity/banana | 1.0–4.3 | [71,72,73,75,78,79,80,82,83,87] |

| Methyl acetate | Sweet/fruity | 0.011–0.05 | [71,72,75,82,84,85,86,88,90] |

| 4-Methyl-2-pentyl acetate | Sweet/fruity/banana | [79,87,89,93] | |

| 2-Methyl-1-propyl acetate | Sweet/fruity/apple banana | 9.97 | [84,89] |

| Neryl acetate | Floral/rose/citrus/pear | [79] | |

| 3-Oxobutan-2-yl acetate | Pungent/sweet/creamy/buttery | [90] | |

| Phenylethyl acetate | Floral/rose/sweet/honey/fruity/tropical | 0.5–4.8 | [70,71,72,74,75,79,80,81,82,83,87,93] |

| Phenyl methyl acetate | Sweet/floral/honey/ spicy/waxy/almond | [79,94] | |

| 1,2-Propanediol diacetate | Fruity/acetic | [79] | |

| Propyl acetate | Solvent/fruity/fusel/raspberry/pear | 0.06–0.2 | [71,72,73,75,78,82,85] |

| Esters | |||

| Diethyl succinate | Mild fruity/cooked apple | 0.007–2.44 | [70,71,72,73,75,78,79,80,81,82,83,84,86,87,88,89,92,93] |

| Dihydroxymethyl jasmonate | [79] | ||

| Ethyl benzoate | Fruity/dry musty/sweet | 0.006–0.013 | [71,72,75,77,80] |

| Ethyl butanoate | Sweet/fruity/tutti frutti | 0.05–0.3 | [71,72,73,74,75,78,79,80,83,84,87,93] |

| Ethyl ciclohexanoate | [80] | ||

| Ethyl decanoate | Sweet/waxy/fruity/apple/grape/oily | 0.008–0.054 | [72,73,79,81,83,89,93] |

| Ethyl dodecanoate | Sweet/waxy/floral/soapy/clean | [72] | |

| Ethyl-3-ethoxypropanoate | [72,90] | ||

| Ethyl formate | Green/alcohol/rose/cognac | 24.3–194 | [85,86,88] |

| Ethyl heptanoate | Fruity/pineapple/cognac/rum/wine | [80] | |

| Ethyl hexanoate | Sweet/fruity/pineapple/waxy/green banana | 0.05–75 | [70,71,72,73,75,78,79,81,83,87,92,93] |

| Ethyl hydrogensuccinate | [70,72] | ||

| Ethyl isobutyrate | Sweet/ethereal/fruity/alcoholic/fusel | 0.006–1 | [71,72,73,74,75,77,78,82,92] |

| Ethyl isovalerate | Fruity/sweet/apple/pineapple/tutti frutti | 0.03–1.1 | [71,72,73,74,75,78,79,80,82,87,89,92] |

| Ethyl lactate | Sharp/tart/fruity/buttery/butterscotch | 0.007–63 | [70,71,73,82,85,86,88] |

| Ethyl levulinate | Sweet/fruity/floral/ berry/green pineapple/rhubarb | [79] | |

| Ethyl 2-methyl butanoate | Sharp/sweet/green/apple/fruity | 0.07–0.15 | [71,72,73,74,75,79,80,82,83,87,89,93] |

| Ethyl 3-methylpentanoate | Pineapple/fruity/tropical | [80] | |

| Ethyl nonanoate | Fruity/rose/waxy/rum/wine/tropical | [80] | |

| Ethyl octanoate | Fruity/wine/waxy/sweet/apricot/banana/brandy/pear | 0.02–0.05 | [71,72,73,75,79,80,83,89,92] |

| Ethyl propanoate | Fruity/banana/pineapple | 0.6–1.5 | [71,72,75,79,80,82,83] |

| Ethyl vanillate | Phenolic/burnt/smoky/powdery/metallic | [70,79] | |

| Ethyl valerate | Sweet/fruity/apple/pineapple/green | 0.002–0.67 | [71,72,73,75,78,79,81,82,92,93] |

| Isobutyl isothiocyanate | Green | [79] | |

| Methyl butyrate | Fruity/apple/sweet/ banana/pineapple | [80] | |

| Methyl hexadecanoate | Oil/waxy/fatty | [89,90] | |

| Methyl hexanoate | Fruity/pineapple | [79] | |

| Methyl nonanoate | Sweet/fruity/pear/waxy/tropical/wine | [90] | |

| Methyl 9-octadecanoate | [90] | ||

| Methyl salicylate | Mint | [70,72,77,79,87] | |

| Acids | |||

| Acetic acid | Sharp/pungent/sour/vinegar | [16,72,79,80,83,87,89,93] | |

| Benzoic acid | faint balsam/urine | [70,79,80,89] | |

| Butanoic acid | Sharp/cheesy/rancid/butter | [70,72,77,79,80,83] | |

| Decanoic acid | Unpleasant/ rancid/sour/fatty | 0.03–0.5 | [70,71,72,73,74,75,78,79,81,82,83,87,89,92,93] |

| Dodecanoic acid | Fatty/coconut/bay | [90,93] | |

| 2-Ethylhexanoic acid | [72] | ||

| Formic acid | Pungent/vinegar | [79] | |

| Heptanoic acid | Rancid/sour/cheesy/sweat | 0.10–0.15 | [71,77] |

| Hexadecanoic acid | Waxy/fatty | [70,72,79,89] | |

| 9-Hexadecenoic acid | [79,89] | ||

| Hexanoic acid | Sour/fatty/sweat/cheese | 1.3–2.2 | [70,71,72,73,75,77,79,80,81,82,83] |

| (4-Hexyl-2,5-dioxo-2,5- dihydro-3-furanyl) acetic acid | [90] | ||

| Isobutyric acid | Acidic/sour/cheese/dairy/buttery/rancid | 0.06–0.15 | [72,73,74,78,80,90,92] |

| Isopentanoic acid | Stinky feet/sweaty/cheese | 49–60 | [70,71,72,73,74,75,78,79,80,81,82,83,87,89,90,92] |

| Nonanoic acid | Waxy/dirty/cheese/dairy | 0.01–0.04 | [71,72,77,78,79,87,92,93] |

| Octadecanoic acid | Fatty/waxy | [79] | |

| 9-Octadecenoic acid | [79] | ||

| Octanoic acid | Fatty/waxy/rancid/oily/vegetable/cheesy | 0.7–2.6 | [70,71,72,73,75,78,79,80,81,82,83,87,89,92] |

| Oleic acid | Faint fatty/waxy | [79] | |

| Pentadecanoic acid | Waxy | [72,79,89] | |

| Pentanoic acid | Acidic/sweaty/rancid | [70,72] | |

| Phenylacetic acid | Sweet/honey/floral/honeysuckle/sour/waxy/ | [70] | |

| Propanoic acid | Pungent/acidic/cheesy/vinegar | [70,72,80] | |

| Sorbic acid | [72] | ||

| Tetradecanoic acid | Waxy | [70,72,79,89] | |

| Alcohols | |||

| 2-Acetoxy-1-propanol | [70] | ||

| Benzyl alcohol | Floral/rose/phenolic/balsamic | 81–1980 | [70,71,75,78,79,80,81,82,83,92,93] |

| Borneol | Balsamic/camphoreous/herbal/woody | [79] | |

| 2,3-Butanediol | Fruity/creamy/buttery | 353–95 | [80,81,85,88,91] |

| 1-Butanol | Fusel/oily/sweet/ balsamic/whiskey | [70,93] | |

| Butoxyethoxyethanol | [70] | ||

| Ethanol | Alcoholic/medical/strong | 1.03–9000 | [72,75,80,82,85,86,88] |

| 3-Ethoxy-1-propanol | Fruit | [70,79] | |

| 4-Ethyl resorcinol | [76] | ||

| γ-Eudesmol (2-naphthalene methanol) | Waxy/sweet | [77,93] | |

| Eugenol | Sweet/spicy/clove/woody | 0.01–0.1 | [70,71,73,75,77,78,92] |

| Fenchyl alcohol | Camphoreous/pine/woody/dry/rooty/sweet/lemon | [79,89] | |

| 1-Heptanol | Musty/leafy/violet/herbal/green/sweet/woody/peony | [90] | |

| 2-Heptanol | Fresh/lemon/grass/herbal/sweet/floral/fruity/green | [90] | |

| 3-Heptanol | Herbal | [90] | |

| 1-Hexanol | Ethereal/fusel/oily/fruity/alcoholic/sweet/green | 0.002–0.4 | [71,72,73,78,87,92] |

| 2-Hexanol | Chemical/winey/fruity/fatty/cauliflower | [89,93] | |

| trans 2-Hexen-1-ol | Fresh/green/leafy/fruity/unripe banana | [73,90] | |

| cis 3-Hexen-1-ol | Fresh/green/grassy/foliage/vegetable/ herbal/oily | 0.04–0.05 | [71,75,80,82,87] |

| Methanol | Alcoholic | 11–67 | [16,75,82,85,86,88] |

| 2-Methyl-1-butanol | Roasted winey onion/fruity/fusel/alcoholic/whiskey | 560–13,000 | [71,72,73,74,75,78,79,81,82,83,84,85,86,88,89,92,93] |

| 3-Methyl-1-butanol | Fusel/alcoholic/pungent/cognac/fruity/banana | 5000–60,000 | [16,70,71,72,73,74,75,79,80,81,82,83,84,85,86,88,89,90,93] |

| 2-Methyl-1-hexadecanol | [90] | ||

| 2-Methyl-1-propanol | Winey/whiskey | 3.5–14.3 | [71,73,74,75,80,81,82,85,86,88,93] |

| 1-Nonanol | Fresh/clean/fatty/floral/rose/orange/dusty/wet/oily | [89,90] | |

| Phenylethyl alcohol | Sweet/floral/fresh/rose | 0.013–27.1 | [70,71,72,74,75,78,79,80,81,82,83,84,85,86,87,88,89,90,92,93] |

| 1-Propanol | Alcoholic/fermented/fusel/tequila/musty/ sweet/fruity/apple/pear | 0.66–13.1 | [75,80,82,84,86,88] |

| Propano-1,2,3-triol | 3200–21,600 | [16] | |

| Vanillyl alcohol | Sweet/creamy/vanilla/caramellic/cracker/milky/ | [80] | |

| Phenols | |||

| 4-Acetyl-2-methylphenol | [79] | ||

| 2/4-Ditertbutyl phenol | [79] | ||

| 4-Ethylguaiacol | Spicy/smoky/bacon/phenolic/clove | 0.6–2.9 | [70,71,72,73,74,78,79,80,81,89,92] |

| 4-Ethylphenol | Phenolic/smoky | 0.02–1.6 | [70,71,73,74,75,78,79,80,81,82,87,89,90,92,93] |

| Guaiacol | Phenolic/smoky/spicy/vanilla/woody | 0.009–0.016 | [75,78,80,82,90] |

| 4-Methylguaiacol | Spicy/clove/vanilla/phenolic/medicinal/leathery | [80] | |

| Phenol | Phenolic/plastic/rubber | [79,83] | |

| Terpenes | |||

| Camphene | Woody/herbal/fir needle/camphor | [89,90] | |

| Citronellene | Floral/rose/herbal/citrus/ | [79] | |

| β-Citronellol | Floral/leathery/waxy/ rose/citrus | [87,89] | |

| Cymene | Fresh/citrus/lemon/woody/spicy | [79] | |

| Eucalyptol | Eucalyptus/herbal/camphoreous/medicinal | [79,90] | |

| Geraniol | Sweet/floral/fruity/rose/waxy/citrus | [79,89] | |

| Limonene | Pine/herbal/peppery | [79,87,89] | |

| Linalool | Citrus/floral/sweet/bois de rose/woody/green/blueberry | [79,87,89] | |

| trans p-Mentha-2,8-dienol | [90] | ||

| Nerol | Sweet/citrus/magnolia | [79,89,93] | |

| Perillaldehyde | Fresh/green/oily/grassy/fatty/minty/cherry | [79] | |

| Safranal | Fresh/herbal/phenolic/metallic/rosemary/tobacco/spicy | [90] | |

| δ-Selinene | [79] | ||

| γ-Terpinene | Oily/woody/lemon/ lime/tropical/herbal | [79] | |

| 4-Terpineol | Peppery/woody/earthy/musty/sweet | [79,87,89] | |

| α-Terpineol | Pine/lilac/citrus/woody/floral | 0.007–0.1 | [71,73,77,78,79,87,89,90,92,93] |

| β-Terpineol | Pungent/earthy/woody | [89] | |

| Thymol | Herbal/thyme/phenolic/medicinal/camphor | [89] | |

| Aldehydes | |||

| Acetaldehyde | Pungent/ethereal/aldehydic/fruity | 5–61 | [16,75,84,85,88] |

| Benzaldehyde | Strong/sharp/sweet/bitter/almond/cherry | 0.05–1070 | [70,71,72,73,75,77,78,80,81,83,84,87,89,90,91,92,93,94] |

| Butanal | Pungent/cocoa/musty/green/malty/bready | [94] | |

| 2-Butenal | Floral | [94] | |

| Cuminaldehyde (4-(1-methylethyl)-benzaldehyde) | Spicy/cumin/green/herbal | [77] | |

| Decanal | Sweet/aldehydic/waxy/orange peel/citrus/floral | [94] | |

| trans 2-Decenal | Fatty/orange/rose/aldehydic/floral/green | [90] | |

| Dodecanal | Soapy/waxy/aldehydic/citrus/green/floral | [94] | |

| Heptanal | Fresh/aldehydic/fatty/green/herbal/cognac/ | [94] | |

| Hexanal | Fresh/green/fatty/aldehydic/grassy | 0.009–0.05 | [71,73,94] |

| Isobutyraldehyde | Fresh/aldehydic/floral/green | [94] | |

| Isovaleraldehyde | Aldehydic/chocolate/ peach/fatty | [79] | |

| 2-Methylbutanal | Musty/cocoa/coffee/nutty | [74,94] | |

| 3-Methylbutanal | Ethereal/aldehydic/chocolate/peach/fatty | [74,94] | |

| 3-Methylpropanal | [94] | ||

| Nonanal | Waxy/aldehydic/rose/orange peel/fatty | [74,87,89,93,94] | |

| (E)-2-Nonenal | Fatty/green/cucumber/aldehydic/citrus | [74,80,94] | |

| Octanal | Aldehydic/waxy/citrus/orange peel/green/fatty | 0.011–0.014 | [74,79,87,90,93,94] |

| 3-Octanal | [89] | ||

| Pentanal | Fermented bready/fruity/nutty/berry | [94] | |

| Propanal | Earthy/alcoholic/winey/whiskey/cocoa/nutty | [94] | |

| Undecanal | Waxy/soapy/floral/aldehydic/citrus/green/fatty/fresh laundry | [94] | |

| Vanillin | Sweet/vanilla/cream/chocolate | 2.5–4.4 | [70,71,75,80] |

| Furanic componds | |||

| 5-Acetoxymethyl-2-furaldehyde | Baked bread | [72,73,79] | |

| 2-Acetyl-2,5-dimethylfuran | [79] | ||

| 2-Acetylfuran | Sweet/balsamic/almond/cocoa/caramellic/coffee | 0.6 × 10−5–1.7 × 10−5 | [70,79,82,90] |

| 2-Acetyl-5-methylfuran | Musty/nutty/hay/coconut/milky | [70,73,79] | |

| 5-Ethoxymethylfurfural | [79] | ||

| Ethyl furoate | 0.03–0.2 | [71,72] | |

| Furfural | Sweet/woody/almond/fragrant/baked bread | 0.1–2.2 | [70,71,72,73,75,77,78,79,81,83,87,91,92,94] |

| Furfuryl alcohol | Alcoholic/chemical/musty/sweet/caramel/bread/coffee | 0.3–1.04 | [70,71,75,80,82] |

| 5-Hydroxymethylfurfural | Fatty/buttery/musty/waxy/caramellic | [70,72,79] | |

| 5-Methylfurfural | Sweet/caramellic/bready/coffee | 0.005–0.02 | [70,71,72,75,78,79,80,92] |

| 1-(5-Methyl-2-furyl)-1-propanone | [79] | ||

| Ketones | |||

| Acetoin | Sweet/buttery/creamy/dairy/milky/fatty | 0.28–708 | [16,70,71,72,73,75,77,79,80,81,83,84,85,86,88,90,93] |

| Benzophenone | Balsamic/rose/metallic/geranium | [79,90] | |

| 2,3-Butanodione | Buttery/sweet/creamy/pungent/caramellic | 17–42 | [71,72,74,75,80,86,90,91] |

| β-Damascenone | Sweet/fruity/rose/plum/grape/raspberry/sugar | [80,90] | |

| 3-Heptanone | Green/fatty/fruity | [90] | |

| 2-Heptanone | Fruity/spicy/sweet/herbal/coconut/woody | [90] | |

| Hydroxyacetone | Pungent/sweet/caramellic/ethereal | 5.34–70 | [86] |

| 3-Hydroxy-3-methyl-2-butanone | [70] | ||

| α-Ionone | Sweet/woody/floral/violet/tropical/fruity | 0.018–0.038 | [81] |

| β-Ionone | Floral/woody/sweet/ fruity/berry/tropical | [80] | |

| Isovalerone | Green/fruity/metallic/pineapple/banana | [79] | |

| 5-Methyl-3-hexanone | [79] | ||

| 3-Nonanone | Fresh/sweet/jasmin/spicy/herbal/fruity | [72] | |

| 1-Octen-3-one | Herbal/mushroom/earthy/musty/dirty | [74,80] | |

| 1-(2,3,6-Trimethylphenyl)-3-buten-2-one | [79] | ||

| Lactones | |||

| γ-Butyrolactone | Creamy/oily/fatty/caramellic | 0.005–0.38 | [70,71,75,78,82,84,85,86,88,92] |

| δ-Decalactone | Fresh/oily/waxy/peach/coconut/buttery/sweet | [79] | |

| δ-2-Decenolactone | [79] | ||

| γ-Dodecalactone | Fatty/peach/sweet/metallic/fruity | [80] | |

| γ-Heptalactone | Sweet/coconut/nutty/caramellic/ | [79] | |

| δ-Laurolactone | [79] | ||

| α-Methyl-γ-crotonolactone | [79] | ||

| Pantolactone | Cotton/candy | [80] | |

| Solerone | [70] | ||

| Sotolone | Sweet/caramellic/maple/sugar burnt/sugar/coffee | 0.748 | [75,80] |

| cis-Whiskeylactone | Coconut/toasted/nutty/burnt | 0.1–1.5 | [70,71,75,79,80,82] |

| trans-Whiskeylactone | Coconut/toasted/nutty/celery/burnt | 0..07–0.3 | [70,71,75,78,79,82,92] |

| Enolic derivatives | |||

| Cyclotene | Sweet/caramel/maple/sugar/coffee/woody | [70,79,90] | |

| 2,3-Dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one | [79] | ||

| 3-Ethyl-2-hydroxy-2-cyclopenten-1-one | Sweet/caramellic/maple | [70,79] | |

| Cyclotene | Sweet/caramel/maple/sugar/coffee/woody | [70,79,90] | |

| Miscellaneous | |||

| 2-Butyl-4-methyl-1,3-dioxolane | Nutty/fatty | [90] | |

| Cadalene (1,6-dimethyl-4-(1-methylethyl)-naphthalene) | [77] | ||

| Cyclotetradecane | [79] | ||

| Dibutyl formamide | [79] | ||

| N,N-Dimethylformamide | Slight amine | [79] | |

| Methyl styrene | [79] | ||

| N-(3-Methylbutyl) acetamide | [79] | ||

| Pentadecane | Waxy | [79] | |

| Styrene | Sweet/balsamic/ floral/plastic | [79] | |

| Tetradecane | Mild waxy | [79] | |

| Tridecane | [79] | ||

| 1,1,6-Trimethyl-1,2- dihydronaphthalene (TDN) | Gasoline | 4.4 × 10−5–10.5 × 10−5 | [72,82,90] |

| Vitispirane | Floral/fruity/earthy/woody | [89] |

| Volatile Compounds | Sensory Descriptors | Concentration (mg/L) | References |

|---|---|---|---|

| Alcohols | |||

| 2-Butanol | Vinous/medicinal | 1.8 | [117] |

| 2-Methylbutanol | Roasted/fruity/fusel oil/alcoholic/wine/whiskey | 80.9–181.8 | [117,118,119] |

| 2-Phenylethanol | Rose/talc/honey | 4.99–22.4 | [118,119] |

| 2-Phenylethyl alcohol | Rose/honey | 2.16–2.52 | [117] |

| 3-Hexenol (E/Z) | Herbaceous/green/grass | 0.238–2.245 | [118,119] |

| Butanol | Vinous/medicinal | 7.92–9.36 | [117] |

| Hexanol | Cut grass/resinous/herbaceous/wood | 3.99–10.44 | [117,118,119] |

| Isoamyl alcohols | Solvent/cake/fusel alcohols/nail polish/ripe fruit | 193–678 | [117,118,119] |

| Isobutanol | Alcohol/solvent/vinous/nail polish | 119.88–133.92 | [117] |

| Methanol | Solvent/pungent fruity | 238.32–245.16 | [117] |

| Aldehydes | |||

| Acetaldehyde | Stewed apple/pungent/ | 78.84–86.76 | [117] |

| Benzaldehyde | Roasted/bitter almond/nutty/smoky | 2.91–35.3 | [118,119] |

| Furans | |||

| 2-Furaldehyde | Fusel alcohol/cake/almond/toasted bread/incense/floral | 0.19–14.54 | [10,116,117,120] |

| 5-Hydroxymethyl-2-furaldehyde | Rancid/toasted | 0.072–87.09 | [10,116,117,120] |

| 5-Methyl-2-furaldehyde | Toasted/bitter almond/cake/burnt/caramel | 0.062–1.94 | [10,116,117,120] |

| Acids | |||

| Acetic acid | Fatty | 210.1–307.6 | [116] |

| Decanoic acid | Rancid/cheese/wax/plasticine | 5.12–15.1 | [118,119] |

| Dodecanoic acid | Fatty/coconut/bay | 1.51–7.18 | [118,119] |

| Octanoic acid | Rancid/cheese/fatty | 0.007–13.4 | [118,119] |

| Esters | |||

| 2-Phenylethyl acetate | Fruity/honeyed/floral/rose | 0.013–0.119 | [118,119] |

| Diethyl succinate | Overripe fruit/lavender | 0.071–5.40 | [118,119] |

| Ethyl 2-methylbutanoate | 0.103–0.241 | [119] | |

| Ethyl 2-methylpropanoate | 0.064–0.454 | [118] | |

| Ethyl acetate | Pineapple/varnish/balsamic/fruity/solvent/pungent/glue | 134.28–236.52 | [117] |

| Ethyl butanoate | Banana/pineapple/strawberry | 0.327–14.9 | [118,119] |

| Ethyl decanoate | Synthetic/rancid | 0.64–4.93 | [117,118,119] |

| Ethyl dodecanoate | Sweet/waxy/floral/soapy/clean | 0.160–1.08 | [117,118,119] |

| Ethyl heptanoate | Strawberry/banana | 0.057–0.104 | [118,119] |

| Ethyl hexadecanoate | Mild waxy | 1.44 | [117] |

| Ethyl hexanoate | Banana/green apple | 0.46–1.79 | [117,118,119] |

| Ethyl isopentanoate | Fruity/sweet/apple/pineapple/tutti frutti | 0.090–0.443 | [118,119] |

| Ethyl lactate | Lactic/yogurt/strawberry/raspberry/buttery | 48.24–50.76 | [117] |

| Ethyl nonanoate | Fruity/rose/waxy /rum/wine/tropical | [118,119] | |

| Ethyl octanoate | Pineapple/pear/soapy/banana | 0.63–5.4 | [117,118,119] |

| Ethyl pentanoate | Sweet/fruity/apple/pineapple/green | 0.041–0.398 | [118,119] |

| Ethyl succinate | Toffee/coffee | 3.96–7.2 | [117] |

| Ethyl tetradecanoate | Mild waxy/soapy | 0.36 | [117] |

| Hexyl acetate | Apple/pear/banana/floral | 0.0004–0.003 | [118,119] |

| Isoamyl octanoate | 0.002–0.018 | [118,119] | |

| Isoamyl acetate | Sweet/fruity/banana | 0.101–1.098 | [118,119] |

| (E)-Methyl-2-octenoate | 0.0007–0.0027 | [118,119] | |

| Methyl decanoate | 0.001–0.007 | [118,119] | |

| Terpenes | |||

| Linalool | Muscat/rose/lavender | 0.053–0.590 | [118,119] |

| Nerolidol | Floral/green/citrus/woody/waxy | 0.002–0.004 | [118,119] |

| α-Terpinene | 0.0017 | [118,119] | |

| α-Terpineol | Lily/cake | 0.007–0.097 | [118,119] |

| Volatile phenols | |||

| 4-Ethylguaiacol | Spicy/smoky/bacon/phenolic/clove | 0.046–0.210 | [118,119] |

| Eugenol | Cinnamon/clove | 0.007–0.071 | [118,119] |

| Vanillin | Vanilla | 0.13–5.94 | [10,116,117,120] |

| Miscellaneous | |||

| 1,1-Diethoxyethane | Green fruit/licorice/cake/fruity/overripe fruit | 105.84–115.56 | [117] |

| β-Damascenone | Fruity/rose/plum/ grape/ raspberry | 0.001–0.084 | [118,119] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durán-Guerrero, E.; Castro, R.; García-Moreno, M.d.V.; Rodríguez-Dodero, M.d.C.; Schwarz, M.; Guillén-Sánchez, D. Aroma of Sherry Products: A Review. Foods 2021, 10, 753. https://doi.org/10.3390/foods10040753

Durán-Guerrero E, Castro R, García-Moreno MdV, Rodríguez-Dodero MdC, Schwarz M, Guillén-Sánchez D. Aroma of Sherry Products: A Review. Foods. 2021; 10(4):753. https://doi.org/10.3390/foods10040753

Chicago/Turabian StyleDurán-Guerrero, Enrique, Remedios Castro, María de Valme García-Moreno, María del Carmen Rodríguez-Dodero, Mónica Schwarz, and Dominico Guillén-Sánchez. 2021. "Aroma of Sherry Products: A Review" Foods 10, no. 4: 753. https://doi.org/10.3390/foods10040753