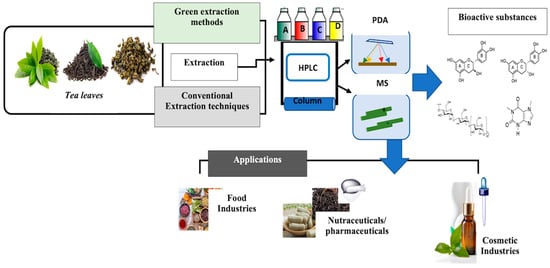

Green Extraction Techniques for the Determination of Active Ingredients in Tea: Current State, Challenges, and Future Perspectives

Abstract

:1. Introduction

2. Active Ingredients Contained in Tea

2.1. Alkaloids

Methylxanthines

2.2. Polyphenols

Catechins

2.3. Flavonols

2.4. Polysaccharides

2.5. Other Bioactive Molecules

3. Extraction of Natural Products

3.1. Conventional Extraction Methods

3.1.1. Conventional Maceration Extraction Using Water as Solvent

3.1.2. Conventional Maceration Extraction Using Organic Solvents

3.1.3. Decoction

3.1.4. Hydro Distillation

3.1.5. Reflux Extraction

3.1.6. Soxhlet Extraction

3.2. Non-Conventional or Green Extraction Methods

3.3. Green Solvents

Criteria of Green Solvent Selection

4. Analytical Techniques for the Separation of Active Ingredients of Tea

5. Conclusions

6. Future Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anastas, P.; Eghbali, N. Green chemistry: Principles and practice. Chem. Soc. Rev. 2010, 39, 301–312. [Google Scholar] [CrossRef] [PubMed]

- Luczynska, G.; Pena-Pereira, F.; Tobiszewski, M.; Namieśnik, J. Expectation-maximization model for substitution of missing values characterizing greenness of organic solvents. Molecules 2018, 28, 1292–1300. [Google Scholar] [CrossRef] [PubMed]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Zhang, J.R.; Li, H.B.; Wu, D.T.; Geng, F.; Corke, H.; Wei, X.L.; Ren-You Gan, R.Y. Green Extraction of Antioxidant Polyphenols from Green Tea (Camellia sinensis). Antioxidants 2020, 9, 785–799. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhou, Z.X. Variations of main quality components of tea genetic resources (Camellia sinensis (L.) O. Kuntze) preserved in the China national germplasm tea repository. Plant Food Hum. Nutr. 2005, 60, 31–35. [Google Scholar] [CrossRef]

- Li, F.; Wei, Y.L.; Liang, L.; Huang, L.L.; Yu, G.Y.; Li, Q.H. A novel low-molecular-mass pumpkin polysaccharide: Structural characterization, antioxidant activity, and hypoglycemic potential. Carbohydr. Polym. 2021, 251, 117090. [Google Scholar] [CrossRef]

- Banerjee, S.; Chatterjee, J. Efficient extraction strategies of tea (Camellia sinensis) biomolecules. J. Food Sci. Technol. 2015, 52, 3158–3168. [Google Scholar] [CrossRef]

- Fujioka, K.; Salaheldin, T.A.; Godugu, K.; Meyers, H.V.; Mousa, S.A. Edible Green Solvent for Optimized Catechins Extraction from Green Tea Leaves: Anti-Hypercholesterolemia. J Pharm. Pharmacol. Res. 2022, 6, 80–92. [Google Scholar] [CrossRef]

- Kanwar, J.; Taskeen, M.; Mohammad, I.; Huo, C.; Chan, T.H.; Dou, Q.P. Recent advances on tea polyphenols. Front Biosci. 2012, 4, 111–131. [Google Scholar] [CrossRef]

- van Heerden, F.R.; van Wyk, B.E.; Viljoen, A.M.; Steenkamp, P.A. Phenolic variation in wild populations of Aspalathus linearis (rooibos tea). Biochem. Syst. Ecol. 2003, 31, 885–895. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, B.; Row, K. Extraction of Catechin Compounds from Green Tea with a New Green Solvent. Chem. Res. Chin. Univ. 2014, 30, 37–41. [Google Scholar] [CrossRef]

- Sereshti, H.; Khosraviani, M.; Samadi, S.; Amini-Fazl, M.S. Simultaneous determination of theophylline, theobromine and caffeine in different tea beverages by graphene-oxide based ultrasonic-assisted dispersive micro solid-phase extraction combined with HPLC-UV. RSC Adv. 2014, 4, 47114–47120. [Google Scholar] [CrossRef]

- Botten, D.; Fugallo, G.; Fraternali, F.; Molteni, C. Structural Properties of Green Tea Catechins. J. Phys. Chem. B 2015, 119, 12860–12867. [Google Scholar] [CrossRef]

- Chin, J.M.; Merves, M.L.; Goldberger, B.A.; Sampson-Cone, A.; Cone, E.J. Caffeine content of brewed teas. J. Anal. Toxicol. 2008, 32, 702–704. [Google Scholar] [CrossRef]

- Ng, K.W.; Cao, Z.J.; Chen, H.B.; Zhao, Z.Z.; Zhu, L.; Yi, T. Oolong tea: A critical review of processing methods, chemical composition, health effects, and risk. Crit. Rev. Food Sci. Nutr. 2017, 58, 2957–2980. [Google Scholar] [CrossRef]

- Unachukwu, U.J.; Ahmed, S.; Kavalier, A.; Lyles, J.T.; Kennelly, E.J. White and green teas (Camellia sinensis var. sinensis): Variation in phenolic, methylxanthine, and antioxidant profiles. J. Food Sci. 2010, 75, 541–548. [Google Scholar]

- Peng, L.; Song, X.; Shi, X.; Li, J.; Ye, C. An improved HPLC method for simultaneous determination of Phenolic compounds purine alkaloids and theanine in Camellia species. J. Food Compos. Anal. 2008, 21, 559–563. [Google Scholar] [CrossRef]

- Carrageta, D.F.; Dias, T.R.; Alves, M.G.; Oliveira, P.F.; Monteiro, M.P.; Silva, B.M. Anti-obesity potential of natural methylxanthines. J. Funct. Foods 2018, 43, 84–94. [Google Scholar] [CrossRef]

- Aqel, A.; Almulla, A.; Al-Rifai, A.; Wabaidur, S.M.; ALOthman, Z.A.; Badjah-Hadj-Ahmed, A.-Y. Rapid and Sensitive Determination of Methylxanthines in Commercial Brands of Tea Using Ultra-High-Performance Liquid Chromatography-Mass Spectrometry. Int. J. Anal. Chem. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Cappelletti, S.; Daria, P.; Sani, G.; Aromatario, M. Caffeine: Cognitive and Physical Performance Enhancer or Psychoactive Drug? Curr. Neuropharmacol. 2015, 13, 71–88. [Google Scholar] [CrossRef]

- Bernatoniene, J.; Kopustinskiene, D.M. The Role of Catechins in Cellular Responses to Oxidative Stress. Molecules 2018, 23, 965–975. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reckziegel, P.; Dias, V.T.; Benvegnú, D.M.; Boufleur, N.; Barcelos, R.C.S.; Segat, H.J.; Pase, C.S.; dos Santos, C.M.M.; Flores, É.M.M.; Bürger, M.E. Antioxidant protection of gallic acid against toxicity induced by Pb in blood, liver and kidney of rats. Toxicol. Rep. 2016, 3, 351–356. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Y.; Zeng, L.; Dong, F.; Tu, Y.; Yang, Z. Occurrence of Functional Molecules in the Flowers of Tea (Camellia sinensis) Plants: Evidence for a Second Resource. Molecules 2018, 23, 790–806. [Google Scholar] [CrossRef] [PubMed]

- Nie, S.P.; Xie, M.Y. A review on the isolation and structure of tea polysaccharides and their bioactivities. Food Hydrocoll. 2011, 25, 144–149. [Google Scholar] [CrossRef]

- Yao, J.; Liu, H.; Ma, C.; Pu, L.; Yang, W.; Lei, Z. A Review on the Extraction, Bioactivity, and Application of Tea Polysaccharides. Molecules 2022, 27, 4679–4691. [Google Scholar] [CrossRef]

- Yang, K.; Gao, Z.Y.; Li, T.Q.; Song, W.; Xiao, W.; Zheng, J.; Chen, H.; Chen, G.H.; Zou, H.Y. Anti-tumor activity and the mechanism of a green tea (Camellia sinensis) polysaccharide on prostate cancer. Int. J. Biol. Macromol. 2019, 122, 95–103. [Google Scholar] [CrossRef]

- Wang, H.S.; Chen, J.R.; Ren, P.F.; Zhang, Y.W.; Onayango, S.O. Ultrasound irradiation alters the spatial structure and improves the antioxidant activity of the yellow tea polysaccharide. Ultrason. Sonochem. 2021, 70, 105355. [Google Scholar] [CrossRef]

- Lv, Y.; Yang, X.B.; Zhao, Y.; Ruan, Y.; Yang, Y.; Wang, Z.Z. Separation and quantification of component monosaccharides of the tea polysaccharides from Gynostemma pentaphyllum by HPLC with indirect UV detection. Food Chem. 2009, 112, 742–746. [Google Scholar] [CrossRef]

- Gramza-Michałowska, A. Caffeine in tea Camellia sinensis-Content, absorption, benefits and risks of consumption. J. Nutr. Health Aging 2013, 18, 143–149. [Google Scholar] [CrossRef]

- Williams, J.; Sergi, D.; McKune, A.J.; Georgousopoulou, E.N.; Mellor, D.D.; Naumovski, N. The beneficial health effects of green tea amino acid l-theanine in animal models: Promises and prospects for human trials. Phytother. Res. 2019, 33, 571–583. [Google Scholar] [CrossRef]

- Sheng, Y.Y.; Xiang, J.; Wang, K.R.; Li, Z.Y.; Li, K.; Lu, J.L.; Ye, J.H.; Liang, Y.R.; Zheng, X.Q. Extraction of Squalene from Tea Leaves (Camellia sinensis) and Its Variations with Leaf Maturity and Tea Cultivar. Front Nutr. 2022, 9, 755514. [Google Scholar] [CrossRef]

- Kim, S.K.; Karadeniz, F. Biological importance and applications of squalene and squalane. Adv. Food Nutr. Res. 2012, 65, 223–233. [Google Scholar]

- Kotelevets, L.; Chastre, E.; Caron, J.; Mougin, J.; Bastian, G.; Pineau, A. A squalene-based nanomedicine for oral treatment of colon cancer. Cancer Res. 2017, 77, 2964–2975. [Google Scholar] [CrossRef]

- Lou-Bonafonte, J.M.; Martinez-Beamonte, R.; Sanclemente, T.; Surra, J.C.; Herrera-Marcos, L.V.; Sanchez-Marco, J. Current insights into the biological action of squalene. Mole Nutr. Food Res. 2018, 62, 1800136–1800152. [Google Scholar] [CrossRef]

- Wambulwa, M.C.; Meegahakumbura, M.K.; Kamunya, S.; Wachira, F.N. From the wild to the cup: Tracking footprints of the tea species in time and space. Front Nutr. 2021, 8, 706770–706778. [Google Scholar] [CrossRef]

- Mason, T.J.; Chemat, F.; Vinatoru, M. The Extraction of Natural Products using Ultrasound or Microwaves. Curr. Org. Chem 2011, 15, 237–247. [Google Scholar] [CrossRef]

- Zhang, Q.W.; Lin, L.G.; Ye, W.C. Techniques for extraction and isolation of natural products: A comprehensive review. Chin. Med. 2018, 13, 20–46. [Google Scholar] [CrossRef]

- Ameer, K.; Shahbaz, H.M.; Kwon, J.H. Green Extraction Methods for Polyphenols from Plant Matrices and Their Byproducts: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 295–315. [Google Scholar] [CrossRef]

- García, S.L.R.; Raghavan, V. Green extraction techniques from fruit and vegetable waste to obtain bioactive compounds—A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 6446–6466. [Google Scholar] [CrossRef]

- Mena- García, A.; Ruiz-Matute, A.I.; Soria, A.C.; Sanz, M.L. Green techniques for extraction of bioactive carbohydrates. TrAC Trend Anal. Chem. 2019, 119, 115612–115622. [Google Scholar]

- Li, H.; Guo, H.; Luo, Q.; Wu, D.T.; Zou, L.; Liu, Y.; Li, H.B.; Gan, R.Y. Current extraction, purification, and identification techniques of tea polyphenols: An updated review. Crit. Rev. Food Sci. Nutr. 2021, 1–19. [Google Scholar] [CrossRef]

- Bindes, M.M.M.; Cardoso, V.L.; Reis, M.H.M.; Boffito, D.C. Maximisation of the polyphenols extraction yield from green tea leaves and sequential clarification. J. Food Eng. 2019, 241, 97–104. [Google Scholar] [CrossRef]

- Calderón-Oliver, M.; Ponce-Alquicira, E. Environmentally Friendly Techniques and Their Comparison in the Extraction of Natural Antioxidants from Green Tea, Rosemary, Clove, and Oregano. Molecules 2021, 26, 1869–1889. [Google Scholar] [CrossRef]

- Panja, P. Green extraction methods of food polyphenols from vegetable materials. Curr. Opin. Food Sci. 2018, 23, 173–182. [Google Scholar] [CrossRef]

- Vinatoru, M.; Mason, T.J.; Calinescu, I. Ultrasonically assisted extraction (UAE) and microwave assisted extraction (MAE) of functional compounds from plant materials. Trend Anal. Chem. 2017, 97, 159–178. [Google Scholar] [CrossRef]

- Tiwari, B.K. Ultrasound: A clean, green extraction technology. Trend Anal. Chem. 2015, 71, 100–109. [Google Scholar] [CrossRef]

- Both, S.; Chemat, F.; Strube, J. Extraction of polyphenols from black tea—Conventional and ultrasound assisted extraction. Ultrason. Sonochem. 2014, 21, 1030–1034. [Google Scholar] [CrossRef]

- Choi, Y.H.; Verpoorte, R. Metabolomics: What you see is what you extract. Phytochem. Anal. 2014, 25, 289–290. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Ravi, H.K.; Khadhraoui, B.; Hilali, S.; Perino, S.; Tixier, A.S.F. Review of Alternative Solvents for Green Extraction of Food and Natural Products: Panorama, Principles, Applications and Prospects. Molecules 2019, 24, 3007–3034. [Google Scholar] [CrossRef]

- Jessop, P.G. Searching for green solvents. Green Chem. 2011, 13, 1391–1398. [Google Scholar] [CrossRef]

- Wu, L.; Li, L.; Chen, S.; Wang, L.; Lin, X. Deep eutectic solvent-based ultrasonic-assisted extraction of phenolic compounds from Moringa oleifera L. leaves: Optimization, comparison and antioxidant activity. Sep. Purif. Technol. 2020, 247, 117014–117025. [Google Scholar] [CrossRef]

- Mihaylova, D.; Lante, A. Water an Eco-Friendly Crossroad in Green Extraction: An Overview. Open Biotechnol. J. 2019, 13, 155–162. [Google Scholar] [CrossRef]

- Carr, A.G.; Mammucari, R.; Foster, N.R. A review of subcritical water as a solvent and its utilization for the processing of hydrophobic organic compounds. Chem. Eng. J. 2011, 172, 1–17. [Google Scholar] [CrossRef]

- Zakaria, S.M.; Kamal, S.M.M.; Harun, M.R.; Omar, R.; Siajam, S.I. Subcritical water technology for extraction of phenolic compounds from Chlorella sp. microalgae and assessment on its antioxidant activity. Molecules 2017, 22, 1105–1119. [Google Scholar] [CrossRef]

- Li, J.; Han, Z.; Zou, Y.; Yu, B. Efficient extraction of major catechins in Camellia sinensis leaves using green choline chloride-based deep eutectic solvents. RSC Adv. 2015, 5, 93937–93944. [Google Scholar] [CrossRef]

- Cai, C.; Li, F.; Liu, L.; Tan, Z. Deep eutectic solvents used as the green media for the efficient extraction of caffeine from Chinese dark tea. Sep. Purif. Technol. 2019, 227, 115723–115731. [Google Scholar] [CrossRef]

- Dai, Y.; Van Spronsen, J.; Witkamp, G.-J.; Verpoorte, R.; Choi, Y.H. Natural deep eutectic solvents as new potential media for green technology. Anal. Chim. Acta 2013, 766, 61–68. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, M. Optimization of deep eutectic solvent-based ultrasound-assisted extraction of polysaccharides from Dioscorea opposita Thunb. Int. J. Biol. Macromol. 2017, 95, 675–681. [Google Scholar] [CrossRef]

- Espino, M.; Fernández, M.A.; Gomez, F.J.V.; Silva, M.F. Natural designer solvents for greening analytical chemistry. TRaC Trend Anal. Chem. 2016, 76, 126–136. [Google Scholar] [CrossRef]

- Paiva, A.; Craveiro, R.; Aroso, I.; Martins, M.; Reis, R.L.; Duarte, A.R.C. Natural Deep Eutectic Solvents—Solvents for the 21st Century. ACS Sustain. Chem. Eng. 2014, 2, 1063–1071. [Google Scholar] [CrossRef]

- Neil Winterton, N. The green solvent: A critical perspective. Clean Technol. Environ. Policy 2021, 23, 2499–2522. [Google Scholar] [CrossRef]

- Lavaud, A.; Laguerre, M.; Bitric, S.; Fabiano Tixier, A.-S.; Roller, M.; Chemat, F. International. Patent WO 2016/162703 Al, 10 April 2015. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&II=4&ND=3&adjacent=true&locale=fr_EP&FT=D&date=20180406&CC=CN&NR=107889468A&KC=A# (accessed on 17 August 2019).

- Kerton, F.M.; Mariotte, R. Alternative Solvents for Green Chemistry, 2nd ed.; Royal Society of Chemistry: Croydon, UK, 2013; pp. 1–325. [Google Scholar]

- Zuo, Y.; Chen, H.; Deng, Y. Simultaneous determination of catechins, caffeine and gallic acids in green, oolong, black and pu-erh teas using HPLC with a photodiode array detector. Talanta 2002, 57, 307–316. [Google Scholar] [CrossRef] [PubMed]

- Komes, D.; Horžić, D.; Belščak, A.; Kovačević Ganič, K.; Baljak, A. Determination of caffeine content in tea and maté tea by using different methods. Czech J. Food Sci. 2009, 27, S213–S216. [Google Scholar] [CrossRef] [Green Version]

- Sereshti, H.; Samadi, S.; Jalali-Heravi, M. Determination of volatile components of green, black, oolong and white tea by optimized ultrasound-assisted extraction-dispersive liquid–liquid microextraction coupled with gas chromatography. J. Chromatogr. A 2013, 1280, 1–7. [Google Scholar] [CrossRef]

- Rostagno, M.A.; Manchón, N.; D’Arrigo, M.; Guillamón, E.; Villares, A.; García-Lafuente, A.; Ramos, A.; Martínez, J.A. Fast and simultaneous determination of phenolic compounds and caffeine in teas, mate, instant coffee, soft drink and energetic drink by high-performance liquid chromatography using a fused-core column. Anal. Chim. Acta 2011, 685, 204–211. [Google Scholar] [CrossRef]

- Wei, K.; Wang, L.Y.; Zhou, J.; He, W.; Zeng, J.M.; Jiang, Y.W.; Cheng, H. Comparison of catechins and purine alkaloids in albino and normal green tea cultivars (Camellia sinensis L.) by HPLC. Food Chem. 2012, 130, 720–724. [Google Scholar] [CrossRef]

- Lee, K.J.; Lee, S.H. Extraction behavior of caffeine and EGCG from green and black tea. Biotechn. Bioprocess. Eng. 2008, 13, 646–649. [Google Scholar] [CrossRef]

- Bae, I.K.; Ham, H.M.; Jeong, M.H.; Kim, D.H.; Kim, H.J. Simultaneous determination of 15 phenolic compounds and caffeine in teas and mate using RP-HPLC/UV detection: Method development and optimization of extraction process. Food Chem. 2015, 172, 469–475. [Google Scholar] [CrossRef]

- Rahim, A.A.; Nofrizal, S.; Saad, B. Rapid tea catechins and caffeine determination by HPLC using microwave-assisted extraction and silica monolithic column. Food Chem. 2014, 147, 262–268. [Google Scholar] [CrossRef]

- Novak, I.; Šeruga, M.; Komorsky-Lovrić, Š. Characterisation of catechins in green and black teas using square-wave voltammetry and RP-HPLC-ECD. Food Chem. 2010, 122, 1283–1289. [Google Scholar] [CrossRef]

- Scoparo, C.T.; de Souza, L.M.; Dartora, N.; Sassaki, G.L.; Gorin, P.A.J.; Iacomini, M. Analysis of Camellia sinensis green and black teas via ultra high performance liquid chromatography assisted by liquid–liquid partition and two-dimensional liquid chromatography (size exclusion × reversed phase). J. Chromatogr., A 2012, 1222, 29–37. [Google Scholar] [CrossRef]

- Yuda, N.; Tanaka, M.; Suzuki, M.; Asano, Y.; Ochi, H.; Iwatsuki, K. Polyphenols Extracted from Black Tea (Camellia sinensis) Residue by Hot-Compressed Water and Their Inhibitory Effect on Pancreatic Lipasein vitro. J. Food Sci. 2012, 77, H254–H261. [Google Scholar] [CrossRef]

- Jiang, H.; Engelhardt, U.H.; Thräne, C.; Maiwald, B.; Stark, J. Determination of flavonol glycosides in green tea, oolong tea and black tea by UHPLC compared to HPLC. Food Chem. 2015, 183, 30–35. [Google Scholar] [CrossRef]

- Fernando, C.D.; Soysa, P. Extraction Kinetics of phytochemicals and antioxidant activity during black tea (Camellia sinensis L.) brewing. Nutr. J. 2015, 31, 14–74. [Google Scholar] [CrossRef]

- Xu, L.L.; Chen, Y.; Chen, Z.Q.; Gao, X.D.; Wang, C.L.; Panichayupakaranant, P.; Chen, H.X. Ultrafiltration isolation, physicochemical characterization, and antidiabetic activities analysis of polysaccharides from green tea, oolong tea, and black tea. J. Food Sci. 2020, 85, 4025–4032. [Google Scholar] [CrossRef]

- Wang, H.; Helliwell, K.; You, X. Isocratic elution system for the determination of catechins, caffeine and gallic acid in green tea using HPLC. Food Chem. 2000, 68, 115–121. [Google Scholar] [CrossRef]

- Vuong, Q.V.; Tan, S.P.; Stathopoulos, C.E.; Roach, P.D. Improved extraction of green tea components from teabags using the microwave oven. J. Food Compos. Anal. 2012, 27, 95–101. [Google Scholar] [CrossRef]

- He, X.; Li, J.; Zhao, W.; Liu, R.; Zhang, L.; Kong, X. Chemical fingerprint analysis for quality control and identification of Ziyang green tea by HPLC. Food Chem. 2015, 171, 405–411. [Google Scholar] [CrossRef]

- Demir, E.; Serdar, G.; Sökmen, M. Comparison of Some Extraction Methods for Isolation of Catechins and Caffeine from Turkish Green Tea. Int. J. Second. Metab. 2015, 2, 16–25. [Google Scholar] [CrossRef]

- Hwang, H.J.; Kim, Y.G.; Chung, M.S. Improving the Extraction of Catechins of Green Tea (Camellia sinensis) by Subcritical Water Extraction (SWE) Combined with Pulsed Electric Field (PEF) or Intense Pulsed Light (IPL) Pretreatment. Foods 2021, 10, 3092–3105. [Google Scholar] [CrossRef]

- Perva-Uzunalic, A.; Skerget, M.; Knez, Z.; Weinreich, B.; Otto, F.; Gruner, S. Extraction of active ingredients from green tea (Camellia sinensis): Extraction efficiency of major catechins and caffeine. Food Chem. 2006, 96, 597–605. [Google Scholar] [CrossRef]

- Selvi, I.K.; Nagarajan, S. Separation of catechins from green tea (Camellia sinensis L.) by microwave assisted acetylation, evaluation of antioxidant potential of individual components and spectroscopic analysis. Food Sci. Technol. 2018, 91, 391–397. [Google Scholar]

- Pan, X.; Niu, G.; Liu, H. Microwave-assisted extraction of tea polyphenols and tea caffeine from green tea leaves. Chem. Eng. Process 2003, 42, 129–133. [Google Scholar] [CrossRef]

- Ayyildiz, S.S.; Karadeniz, B.; Sagcan, N.; Bahar, B.; Abdullah, A.; Alasalvar, C. Optimizing the extraction parameters of epigallocatechin gallate using conventional hot water and ultrasound assisted methods from green tea. Food Bioprod. Process. 2018, 111, 37–44. [Google Scholar] [CrossRef]

- Jun, X.; Deji, S.; Shou, Z.; Bingbing, L.; Ye, L.; Rui, Z. Characterization of polyphenols from green tea leaves using a high hydrostatic pressure extraction. Int. J. Pharm. 2009, 382, 139–143. [Google Scholar]

- Das, P.R.; Eun, J.B. A comparative study of ultra-sonication and agitation extraction techniques on bioactive metabolites of green tea extract. Food Chem. 2018, 253, 22–29. [Google Scholar] [CrossRef]

- Xiang, B.; Zhou, X.; Qin, D.; Xi, J. Vesicle-enhanced liquid-phase pulsed discharge extraction of polyphenols from green tea leaves. Innov. Food Sci. Emerg. 2021, 74, 102839. [Google Scholar] [CrossRef]

- Sökmen, M.; Demir, E.; Alomar, S.Y. Optimization of sequential supercritical fluid extraction (SFE) of caffeine and catechins from green tea. J. Supercrit. Fluids 2018, 133, 171–176. [Google Scholar] [CrossRef]

- Bermejo, D.V.; Ibánez, E.; Reglero, G.; Fornari, T. Effect of cosolvents (ethyl lactate, ethyl acetate and ethanol) on the supercritical CO2 extraction of caffeine from green tea. J. Supercrit. Fluids 2016, 107, 507–512. [Google Scholar] [CrossRef]

- Edwards, Q.A.; Hinkson, S.A.S.; Garner-O’Neale, L.D.; Kulikov, S.M. Quantification of caffeine in selected beverages via gas chromatography-mass spectroscopy. Int. J. Chem. Sci. 2015, 13, 133–142. [Google Scholar]

- Sharif, R.; Ahmad, S.W.; Anjum, H.; Ramzan, N.; Malik, S.R. Effect of infusion time and temperature on decaffeination of tea using liquid-liquid extraction technique. J. Food Process. Eng. 2014, 37, 46–52. [Google Scholar] [CrossRef]

- Ghasemzadeh-Mohammadi, V.; Zamani, B.; Afsharpour, M.; Mohammadi, A. Extraction of caffeine and catechins using microwave-assisted and ultrasonic extraction from green tea leaves: An optimization study by the IV-optimal design. Food Sci. Biotechnol. 2017, 26, 1281–1290. [Google Scholar] [CrossRef]

- Silva, A.S.; Reboredo-Rodríguez, P.; Sanchez-Machado, D.I.; López-Cervantes, J.; Barreca, D.; Pittala, V.; Samec, D.; Orhan, I.E.; Gulcan, H.O.; Forbes-Hernandez, T.Y.; et al. Evaluation of the status quo of polyphenols analysis: Part II—Analysis methods and food processing effects. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3219–3240. [Google Scholar] [CrossRef]

- Molina, G.A.; González-Fuentes, F.; Loske, A.M.; Fernández, F.; Estevez, M. Shock wave-assisted extraction of phenolic acids and flavonoids from Eysenhardtia polystachya heartwood: A novel method and its comparison with conventional methodologies. Ultrason. Sonochem. 2020, 61, 104809. [Google Scholar] [CrossRef]

| ||||

|---|---|---|---|---|

| Substitute | Derivatives of Flavonols | |||

| R1 | R2 | R3 | R4 | |

| OH | OH | H | H | Quercetin |

| Gal | OH | H | H | Quercetin 3-O-β-d-galactopyranoside |

| Glc | OH | H | H | Quercetin 3-O-β-d-glucopyranoside |

| Gal | OH | OH | H | Myricetin 3-O-β-d-galactopyranoside |

| OH | H | H | H | Kaempferol |

| Glc-Rha | OH | H | H | Rutin |

| Gal | H | H | H | Kaempferol-3-O-β-d-galactopyranoside |

| Glc | H | H | H | Kaempferol-3-O-β-d-glucopyranoside |

| Glc-Rha | H | H | H | Kaempferol-3-O-α-l-rhamnopyranosyl-(1→6)-β-d-glucopyranoside |

| Glc-Rha-Glc | H | H | H | Kaempferol-3-O-β-l-glucopyranosyl-(1→3)-α-l-rhamnopyranosyl-β-d-glucopyranoside |

| Gal-Rha-Glc | H | H | H | Kaempferol-3-O-β-l-glucopyranosyl-(1→3)-α-l-rhamnopyranosyl-β-d-galactopyranoside |

| S1 | H | H | OCH3 | Chakaflavonoside B |

| Method Classification | Extraction Method | Solvents | Pressure | Temperature | Extraction Time |

|---|---|---|---|---|---|

| Conventional extraction techniques | Soxhlet method | Organic solvents (ethanol, methanol, chloroform, acetone, etc.) | Atmospheric | Under heat (The range of temperature alters according to the used solvents) | Long time |

| Maceration | Water, aqueous, and organic solvents | Atmospheric | Room temperature | Long time | |

| Reflux extraction | Aqueous and organic solvents | Atmospheric | Under heat (The range of temperature alters according to the used solvents) | Moderate time | |

| Hydro-distillation | Water | Atmospheric | Under heat (100 °C) | Long time | |

| Decoction | Water | Atmospheric | Under heat (100 °C) | Moderate time | |

| Non-conventional extraction techniques or green extraction methods | Supercritical fluid extraction (SFE) | Supercritical fluid (usually S-CO2)/modifier | High (For example, CO2 is the most used solvent for SFE, with pressure at 74 bars) | Near room temperature (For CO2, a critical temperature at 31 °C) | Short time |

| Ultrasound-assisted extraction (UAE) | Water, aqueous, and organic solvents | Atmospheric | Room temperature or under heat (The range of temperature alters according to the used solvents) | Short time | |

| Microwave-assisted extraction (MAE) | Water, aqueous, and organic solvents | Atmospheric | Room temperature | Short time (15–30 min) | |

| Pressurized liquid extraction (PLE) | Water, aqueous, and organic solvents | High (For example, water is the most common solvent in PLE, whereby the boiling point of water at 0.1 MPa is obtained at the critical point of water at 22.1 MPa) | Under heat (Water: temperature ranging from 100 °C to 374 °C) | Short time | |

| Enzyme-assisted extraction (EAE) | Water, aqueous, and organic solvents | Atmospheric | Room temperature, or heated after enzyme treatment (For example, when using a pectinolytic method, the temperature is 50 °C) | Moderate time | |

| Pulsed electric field extraction (PEFE) | Water, aqueous, and organic solvents | Atmospheric | Room temperature or under heat (The range of temperature alters according to the used solvents) | Short time |

| Techniques | Main Operative Conditions | Advantages | Disadvantages |

|---|---|---|---|

| Ultrasound-assisted extraction (UAE) | The frequency range is 20 to 40 kHz; in addition, the intensities range from 10–1000 W/cm2. |

|

|

| Microwave-assisted extraction (MAE) | Magnetic and electric fields oscillate between 0.3 to 300 GHz. |

|

|

| Supercritical fluid extraction (SFE) | CO2, with ethanol as a co-solvent, at 40–60 °C and a range of 350–500 bar. CO2, which is the most utilized solvent for the SFE method, is used with a pressure at 7.39 MPa and a critical temperature at 31.3 °C. |

|

|

| Enzyme-assisted extraction (EAE) | Enzymes that are required for the method: cellulase, pectinesterase, hemicellulase, fructosyltransferase, pectinase, a-amylase, and protease in the solvent extraction. Examples of the method use celluzyme at 2500 ppm, as well as pectinolytic enzymes at 50 °C, 5000 ppm. |

|

|

| Pressurized liquid extraction (PLE) | Elevated temperatures under reduced pressures are used (thus, elevating the temperatures of employed solvents above their atmospheric boiling points). The range of temperature is dependent on the solvent used. |

|

|

| Pulsed electric field extraction (PEF) and high-voltage electrical discharges (HVED) | It is a non-thermal process. High-voltage pulses in the range of 20–80 kV/cm |

|

|

| High-hydrostatic pressure extraction (HHPE) | Introduction of a sample in a chamber with a high pressure, which is 100 to 1000 MPa, or higher (depending on the exposure time), at temperatures from 50–200 °C for short time periods (i.e., 5–10 min). |

|

|

| Deep eutectic solvents (DESs) | Using solvents with melting points that are lower than 100 °C, at a low pressure with high viscosity. |

|

|

| Solvent | Application | Solvent Polarity |

|---|---|---|

| Water/subcritical H2O | Steam distillation (essential oils); Microwave-assisted distillation (essential oils); Extraction by sub-critical water (aromas) | Polar, weakly polar, and non-polar |

| CO2/supercritical CO2 | Supercritical fluid extraction (extraction of tea) | Weakly polar and non-polar |

| Ionic liquids (ILs)/Eutectic solvents (DES, NADES) | Ultrasound-assisted extraction | Polar and non-polar |

| Natural solvents from biomass/Agrosolvents | Ethanol (pigments and antioxidants); Glycerol (polyphenols) terpenes, such as d-limonene (fats and oils) | Polar, weakly polar, and non-polar |

| Solvent-free | Microwave hydro-diffusion and gravity (antioxidants and essential oils); Pulse electric field (antioxidants and pigments) | Polar and weakly polar |

| Type of Tea | Extraction Method | Analysis Method | References |

|---|---|---|---|

| White tea (Camellia Sinensis, Theaceae) | MAE; UAE; DLLME; Extraction with a hydro-alcoholic solution and evaporation. | HPLC-UV; HPLC-PDA; RP-HPLC; GLC; GC/MS. | [6,12,64,65,66,67,68] |

| Black tea (Camellia Sinensis, Theaceae) | MAE; UAE; DLLME; HRE. Heating extraction with hydro-alcoholic solution and evaporation | HPLC/UV; HPLC/PDA; RP-HPLC/ECD; HPLC/DAD; HPLC/MS; UV-Vis; GLC; GC/MS; UHPLC/PDA or DAD; GC/FID. | [12,14,64,65,66,67,69,70,71,72,73,74,75,76,77] |

| Green tea (Camellia Sinensis, Theaceae) | MAE; UAE; DLLME; HRE; Heating extraction; Stirring extraction; Extraction with a hydro-alcoholic solution and evaporation; Citric acid water extraction; WE-HT; SWE; PEF; IPL; Microwave mediated acetylation; SE; UPE; US and agitation extraction techniques; Conventional hot water/UAE; UAE-DES; V-LPD; SFE; SCCO2 extraction.High hydrostatic pressure extraction. | HPLC/UV; HPLC/PDA; HPLC/MS; UV-Vis; GLC; GC/MS; RP-HPLC/ECD. UHPLC/PDA or DAD; HPLC-MS/MS; SEM; GC-FID; TLC; HRMS; FT-IR; 1H and 13C NMR; Colorimetric analysis. | [4,8,11,12,14,47,64,65,66,67,68,69,70,71,72,73,75,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91] |

| Red tea (Rooibos *) (Aspalathus Linearis, Fabaceae) | MAE | HPLC/PDA | [10] |

| Green mate tea (Ilex Paraguariensis) | MAE | RP-HPLC/PDA | [65] |

| Roasted mate tea ((Ilex Paraguariensis) | MAE | RP-HPLC/PDA | [65] |

| Yellow tea (Camellia sinensis L.) | MAE; UAE. | RP-HPLC/PDA | [27,65] |

| Oolong tea (Camellia Sinensis, Theaceae) | MAE; UAE; HRE; Thermal extraction; Extraction with a hydro-alcoholic solution and evaporation. | HPLC/PDA; GC/MS; UHPLC/DAD; GC/FID. | [64,66,70,75,77,88] |

| Fujian oolong tea (Camellia Sinensis) (produced in the Wuyi Mountain of northern Fujian) | MAE UAE | HPLC/PDA | [64,66] |

| Jiangxi oolong tea (Camellia Sinsensis) | MAE UAE | HPLC/PDA | [64,70] |

| Pu-erh tea (Camellia Sinensis var. assamica) | MAE | HPLC/PDA; UV-Vis. | [64] |

| Jasmine tea (a mixture of leaves of Camellia Sinsensis with jasmine flowers (Jasminum officinale). | MAE | HPLC/PDA; UV-Vis. | [64] |

| Lipton tea (decaffeinated green tea and green tea lemon and ginseng) | MAE | UV-Vis; GC/MS. | [92,93] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koina, I.M.; Sarigiannis, Y.; Hapeshi, E. Green Extraction Techniques for the Determination of Active Ingredients in Tea: Current State, Challenges, and Future Perspectives. Separations 2023, 10, 121. https://doi.org/10.3390/separations10020121

Koina IM, Sarigiannis Y, Hapeshi E. Green Extraction Techniques for the Determination of Active Ingredients in Tea: Current State, Challenges, and Future Perspectives. Separations. 2023; 10(2):121. https://doi.org/10.3390/separations10020121

Chicago/Turabian StyleKoina, Ioulia Maria, Yiannis Sarigiannis, and Evroula Hapeshi. 2023. "Green Extraction Techniques for the Determination of Active Ingredients in Tea: Current State, Challenges, and Future Perspectives" Separations 10, no. 2: 121. https://doi.org/10.3390/separations10020121