Co-Firing of Sawdust and Liquid Petroleum Gas in the Application of a Modified Rocket Stove

Abstract

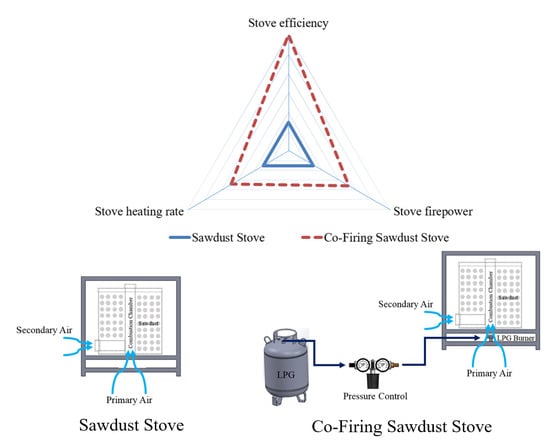

:1. Introduction

2. Materials and Methods

2.1. Biomass Sample

2.2. Experimental Setup

3. Results and Discussion

3.1. Stove Heating Rate and Firepower

3.2. Stove Efficiency

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raman, P.; Murali, J.; Sakthivadivel, D.; Vigneswaran, V.S. Evaluation of domestic cookstove technologies implemented across the world to identify possible options for clean and efficient cooking solutions. J. Energy Chem. Eng. 2013, 1, 15–26. [Google Scholar]

- Bryden, M.; Still, D.; Scott, P.; Hoffa, G.; Ogle, D.; Bailis, R. Design Principles for Wood Burning Cookstoves; US Environmental Protection Agency: Washington, DC, USA, 2005.

- Schumack, M. A computational model for a rocket mass heater. Appl. Therm. Eng. 2016, 93, 763–778. [Google Scholar] [CrossRef]

- Gandigude, A.; Nagarhalli, M. Review of rocket cook-stove geometrical aspects for its performance improvement. Mater. Today Proc. 2018, 5, 4743–4747. [Google Scholar] [CrossRef]

- Pundle, A.; Sullivan, B.; Means, P.; Posner, J.D.; Kramlich, J.C. Predicting and analyzing the performance of biomass-burning natural draft rocket cookstoves using computational fluid dynamics. Biomass Bioenergy 2019, 131, 105402. [Google Scholar] [CrossRef]

- Mukunda, H.S.; Dasappa, S.; Swati, B.; Shrinivasa, U. Studies on a stove for powdery biomass. Int. J. Energy Res. 1993, 17, 281–291. [Google Scholar] [CrossRef]

- Grimsby, L.K.; Borgenvik, E.J.L. Fuelling sawdust stoves with jatropha fruit coats. Sustain. Energy Technol. Assess. 2013, 2, 12–18. [Google Scholar] [CrossRef]

- Varma, A.K.; Thakur, L.S.; Shankar, R.; Mondal, P. Pyrolysis of wood sawdust: Effects of process parameters on products yield and characterization of products. Waste Manag. 2019, 89, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Bhaskar Dixit, C.S.; Paul, P.J.; Mukunda, H.S. Part I: Experimental studies on a pulverised fuel stove. Biomass Bioenergy 2006, 30, 673–683. [Google Scholar] [CrossRef]

- Ohlemiller, T.J. Modeling of smouldering combustion propagation. Prog. Energy Combust. Sci. 1985, 11, 277–310. [Google Scholar] [CrossRef]

- Ohlemiller, T.J. Smouldering combustion. In Society of Fire Protection Engineers’ Hand Book of Fire Protection Engineering; National Fire Protection Association: Quincy, MA, USA, 1995. [Google Scholar]

- Suresh, R.; Singh, V.K.; Malik, J.K.; Datta, A.; Pal, R.C. Evaluation of the performance of improved biomass cooking stoves with different solid biomass fuel types. Biomass Bioenergy 2016, 95, 27–34. [Google Scholar] [CrossRef]

- Jugjai, S. Thermal efficiency improvement of an LPG gas cooker by a swirling central flame. Int. J. Energy Res. 2001, 25, 657–674. [Google Scholar] [CrossRef]

| LHV (MJ/kg) | Ultimate Analysis (Weight Percentages) | Loading Mass into Stove (kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Ash | C | H | O | N | Stove 1 (225 mm) | Stove 2 (385 mm) | Stove 3 (550 mm) | ||

| Sawdust | 12.91 | 0.63 | 51.32 | 7.52 | 40.18 | 0.34 | 3.5 | 11 | 24 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Comsawang, P.; Nanetoe, S.; Soponpongpipat, N. Co-Firing of Sawdust and Liquid Petroleum Gas in the Application of a Modified Rocket Stove. Processes 2020, 8, 112. https://doi.org/10.3390/pr8010112

Comsawang P, Nanetoe S, Soponpongpipat N. Co-Firing of Sawdust and Liquid Petroleum Gas in the Application of a Modified Rocket Stove. Processes. 2020; 8(1):112. https://doi.org/10.3390/pr8010112

Chicago/Turabian StyleComsawang, Paisan, Suwat Nanetoe, and Nitipong Soponpongpipat. 2020. "Co-Firing of Sawdust and Liquid Petroleum Gas in the Application of a Modified Rocket Stove" Processes 8, no. 1: 112. https://doi.org/10.3390/pr8010112