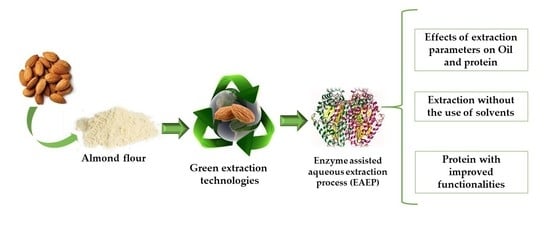

Effects of Processing Conditions on the Simultaneous Extraction and Distribution of Oil and Protein from Almond Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Enzyme Screening for the Enzyme-assisted Extraction Process (EAEP) of Almond Flour

2.3. Effects of Extraction Variables on the Enzyme-assisted Aqueous Extraction Process (EAEP) of Almond Flour

2.4. Proximate Analysis

2.5. Degree of Hydrolysis

2.6. Low Molecular Weight (MW) Polypeptide Profile Characterization of AEP and EAEP Skim Proteins by SDS-PAGE

2.7. AEP and EAEP Skim Protein Solubility

2.8. Statistical Analyses

3. Results and Discussion

3.1. Enzyme Selection for the Enzyme-assisted Extraction Process of Almond Flour

3.2. Effects of Extraction Parameters on the Enzyme-assisted Aqueous Extraction Process (EAEP) of Almond Flour

3.3. Experimental Validation of the Best Extraction Conditions

- (i)

- Condition 1: pH 6.5, 1:8 SLR, 45 °C and 0.5% of enzyme for the EAEP1, and without enzyme for the AEP1.

- (ii)

- Condition 2: pH 9.0, 1:10 SLR, 50 °C and 0.5% of enzyme for the EAEP2, and without enzyme for the AEP2.

3.4. Molecular Weight Polypeptide Profile, Degree of Hydrolysis (DH) and Solubility of AEP and EAEP Skims

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martínez, M.L.; Penci, M.C.; Marin, M.A.; Ribotta, P.D.; Maestri, D.M. Screw press extraction of almond (Prunus dulcis (Miller) D.A. Webb): Oil recovery and oxidative stability. J. Food Eng. 2013, 119, 40–45. [Google Scholar]

- Almond Board of California. Almond Board Research; Almond Board of California: Modesto, CA, USA, 2006. [Google Scholar]

- Shahidi, F.; Miraliakbari, H. Tree Nut Oils and Byproducts: Compositional Characteristics and Nutraceutical Applications. In (Chapter 9) Nutraceutical and Specialty Lipids and Their Co-Products; CRC Press: Boca Raton, FL, USA, 2006; pp. 159–166. ISBN 1-57444-499-9. [Google Scholar]

- United States Department of Agriculture. California Almond Forecast; United States Department of Agriculture National Agricultural Statistics Service: Washington, DC, USA, 2017.

- Almeida, N.M.; Moura Bell, J.M.L.N.; Johnson, L.A. Properties of Soy Protein Produced by Countercurrent, Two-Stage, Enzyme-Assisted Aqueous Extraction. J. Am. Oil Chem. Soc. 2014, 91, 1077–1085. [Google Scholar] [CrossRef]

- Moura, J.M.L.N.; Campbell, K.; Almeida, N.M.; Glatz, C.E.; Johnson, L.A. Protein extraction and membrane recovery in enzyme-assisted aqueous extraction processing of soybeans. JAOCS J. Am. Oil Chem. Soc. 2011, 88, 877–889. [Google Scholar] [CrossRef]

- Savoire, R.; Lanoisellé, J.-L.; Vorobiev, E. Mechanical Continuous Oil Expression from Oilseeds: A Review. Food Bioprocess Technol. 2013, 6, 1–16. [Google Scholar] [CrossRef]

- Johnson, L. Recovery of Fats and Oils from Plant and Animal Sources. Johnson. In Introduction to Fats and Oils Technology; O’Brien, R.D., Farr, W.E., Wan, P.J., Eds.; AOCS Press: Urbana, IL, USA, 2000; pp. 108–135. [Google Scholar]

- Environmental Protection Agency. 40 CFR Part 63 National Emissions Standards for Hazardous Air Pollutants: Solvent Extraction for Vegetable Oil Production, Final Rule, Federal Register; Environmental Protection Agency: Washington, DC, USA, 2001; pp. 19005–19026.

- Ndlela, S.C.; Moura, J.M.L.N.; Olson, N.K.; Johnson, L.A. Aqueous Extraction of Oil and Protein from Soybeans with Subcritical Water. J. Am. Oil Chem. Soc. 2012, 89, 1145–1153. [Google Scholar] [CrossRef]

- De Moura, J.M.L.N.; Maurer, D.; Jung, S.; Johnson, L.A. Integrated Countercurrent Two-Stage Extraction and Cream Demulsification in Enzyme-Assisted Aqueous Extraction of Soybeans. J. Am. Oil Chem. Soc. 2011, 88, 1045–1051. [Google Scholar] [CrossRef]

- Jung, S.; Moura, J.M.L.N.; Campbell, K.C.; Johnson, L.A. Enzyme-Assisted Aqueous Extraction of Oilseeds Jung; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Balvardi, M.; Rezaei, K.; Mendiola, J.A.; Ibáñez, E. Optimization of the Aqueous Enzymatic Extraction of Oil from Iranian Wild Almond. J. Am. Oil Chem. Soc. 2015, 92, 985–992. [Google Scholar] [CrossRef]

- Sharma, A.; Gupta, M.N. Ultrasonic pre-irradiation effect upon aqueous enzymatic oil extraction from almond and apricot seeds. Ultrason. Sonochem. 2006, 13, 529–534. [Google Scholar] [CrossRef] [PubMed]

- Moura, J.M.L.N.; Almeida, N.; Johnson, N.M. Scale-up of Enzyme-Assisted Aqueous Extraction Processing of Soybeans. JAOCS J. Am. Oil Chem. Soc. 2009, 86, 809–815. [Google Scholar] [CrossRef]

- Souza, T.S.P.; Dias, F.F.G.; Koblitz, M.G.B.; Bell, J.M.L.N.d.M. Aqueous and Enzymatic Extraction of Oil and Protein from Almond Cake: A Comparative Study. Processes 2019, 7, 472. [Google Scholar] [CrossRef]

- Rodrigues, M.I.; Iemma, A.F. Experimental Design and Process Optimization; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Rosenthal, A.; Pyle, D.L.; Niranjan, K.; Gilmour, S.; Trinca, L. Combined effect of operational variables and enzyme activity on aqueous enzymatic extraction of oil and protein from soybean. Enzym. Microb. Technol. 2001, 28, 499–509. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Method 922.06 Fat in Flour. Acid Hydrolysis Method, in: Official Methods of Analysis of AOAC International; Association of Official Analytical Chemists: Rockville, MD, USA, 2012. [Google Scholar]

- AACC International Approved Methods—AACC Method 44-40.01. Moisture—Modified Vacuum-Oven Method. Available online: https://methods.aaccnet.org/summaries/44-40-01.aspx (accessed on 17 August 2019).

- Nielsen, P.M.; Petersen, D.; Dambmann, C. Improved Method for Determining Food Protein Degree of Hydrolysis. J. Food Sci. 2001, 66, 642–646. [Google Scholar] [CrossRef]

- Liu, R.-L.; Ge, X.-L.; Gao, X.-Y.; Zhan, H.-Y.; Shi, T.; Su, N.; Zhang, Z.-Q. Two angiotensin-converting enzyme-inhibitory peptides from almond protein and the protective action on vascular endothelial function. Food Funct. 2016, 7, 3733–3739. [Google Scholar] [CrossRef] [PubMed]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef] [PubMed]

- Rickert, D.A.; Johnson, L.A.; Murphy, P.A. Functional Properties of Improved Glycinin and β-Conglycinin Fractions. Food Chem. Toxicol. 2004, 69, 303–311. [Google Scholar]

- Morr, C.V.; German, B.; Kinsella, J.E.; Regenstein, J.M.; Buren, J.P.V.; Kilara, A.; Lewis, B.A.; Mangino, M.E. A Collaborative Study to Develop a Standardized Food Protein Solubility Procedure. J. Food Sci. 1985, 50, 1715–1718. [Google Scholar] [CrossRef]

- Lamsal, B.; Murphy, P.; Johnson, L. Flaking and Extrusion as Mechanical Treatments for Enzyme-Assisted Aqueous Extraction of Oil from Soybeans. JAOCS J. Am. Oil Chem. Soc. 2006, 83, 973–979. [Google Scholar] [CrossRef]

- Campbell, K.A.; Glatz, C.E. Mechanisms of aqueous extraction of soybean oil. J. Agric. Food Chem. 2009, 57, 10904–10912. [Google Scholar] [CrossRef] [PubMed]

- Esteban, R.M.; López-Andréu, F.J.; Carpena, O. Protein extractability of almond (Prunus amygdalus, batsch) seed. J. Sci. Food Agric. 1985, 36, 485–490. [Google Scholar] [CrossRef]

- Wolf, W.J.; Sathe, S.K. Ultracentrifugal and polyacrylamide gel electrophoretic studies of extractability and stability of almond meal proteins. J. Sci. Food Agric. 1998, 78, 511–521. [Google Scholar] [CrossRef]

- Sathe, S.K. Solubilization, electrophoretic characterization and in vitro digestibility of almond (Prunus amygdalus) proteins. J. Food Biochem. 1992, 16, 249–264. [Google Scholar] [CrossRef]

- Amirshaghaghi, Z.; Rezaei, K.; Habibi Rezaei, M. Characterization and functional properties of protein isolates from wild almond. J. Food Meas. Charact. 2017, 11, 1725–1733. [Google Scholar] [CrossRef]

- Kinsella, J.E. Functional properties of soy proteins. J. Am. Oil Chem. Soc. 1979, 56, 242–258. [Google Scholar] [CrossRef]

- Li, P.; Zhang, W.; Han, X.; Liu, J.; Liu, Y.; Gasmalla, M.A.A.; Yang, R. Demulsification of oil-rich emulsion and characterization of protein hydrolysates from peanut cream emulsion of aqueous extraction processing. J. Food Eng. 2017, 204, 64–72. [Google Scholar] [CrossRef]

- Sari, Y.W.; Bruins, M.E.; Sanders, J.P.M. Enzyme assisted protein extraction from rapeseed, soybean, and microalgae meals. Ind. Crop. Prod. 2013, 43, 78–83. [Google Scholar] [CrossRef]

- Chabanon, G.; Chevalot, I.; Framboisier, X.; Chenu, S.; Marc, I. Hydrolysis of rapeseed protein isolates: Kinetics, characterization and functional properties of hydrolysates. Process Biochem. 2007, 42, 1419–1428. [Google Scholar] [CrossRef]

- Sathe, S.K.; Wolf, W.J.; Roux, K.H.; Teuber, S.S.; Venkatachalam, M.; Sze-Tao, K.W.C. Biochemical Characterization of Amandin, the Major Storage Protein in Almond (Prunus dulcis L.). J. Agric. Food Chem. 2002, 50, 4333–4341. [Google Scholar] [CrossRef] [PubMed]

- Derbyshire, E.; Wright, D.J.; Boulter, D. Legumin and vicilin, storage proteins of legume seeds. Phytochemistry 1976, 15, 3–24. [Google Scholar] [CrossRef]

- Jamdar, S.N.; Rajalakshmi, V.; Pednekar, M.D.; Juan, F.; Yardi, V.; Sharma, A. Influence of degree of hydrolysis on functional properties, antioxidant activity and ACE inhibitory activity of peanut protein hydrolysate. Food Chem. 2010, 121, 178–184. [Google Scholar] [CrossRef]

- Lacou, L.; Léonil, J.; Gagnaire, V. Functional properties of peptides: From single peptide solutions to a mixture of peptides in food products. Food Hydrocoll. 2016, 57, 187–199. [Google Scholar] [CrossRef]

| Experiment # | pH (x1) | Temperature (°C) (x2) | Solids-to-Liquid Ratio (SLR) (x3) | Enzyme (%) (x4) | ||||

|---|---|---|---|---|---|---|---|---|

| Coded Value | Real Value | Coded Value | Real Value | Coded Value | Real Value | Coded Value | Real Value | |

| 1 | −1 | 6.5 | −1 | 45 | −1 | 1:12 | −1 | 0.50 |

| 2 | 1 | 9.5 | −1 | 45 | −1 | 1:12 | 1 | 1.00 |

| 3 | −1 | 6.5 | 1 | 55 | −1 | 1:12 | 1 | 1.00 |

| 4 | 1 | 9.5 | 1 | 55 | −1 | 1:12 | −1 | 0.50 |

| 5 | −1 | 6.5 | −1 | 45 | 1 | 1:8 | 1 | 1.00 |

| 6 | 1 | 9.5 | −1 | 45 | 1 | 1:8 | −1 | 0.50 |

| 7 | −1 | 6.5 | 1 | 55 | 1 | 1:8 | −1 | 0.50 |

| 8 | 1 | 9.5 | 1 | 55 | 1 | 1:8 | 1 | 1.00 |

| 9 | 0 | 8.0 | 0 | 50 | 0 | 1:10 | 0 | 0.75 |

| 10 | 0 | 8.0 | 0 | 50 | 0 | 1:10 | 0 | 0.75 |

| 11 | 0 | 8.0 | 0 | 50 | 0 | 1:10 | 0 | 0.75 |

| Oil Extraction | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Extraction Time = 40 min | ||||||||||

| Factors | Effect | p-Value | Effect | p-Value | Effect | p-Value | Effect | p-Value | Effect | p-Value |

| TOE | OYC | OYS | OYI | FOY | ||||||

| Mean | 64.35 | 0.0000 | 49.51 | 0.0000 | 6.84 | 0.0000 | 35.64 | 0.0000 | 8.00 | 0.0006 |

| Curvature | 12.18 | 0.0340 | 9.77 | 0.2295 | 8.11 | 0.0053 | −12.17 | 0.0341 | −5.69 | 0.2066 |

| pH (x1) | 1.76 | 0.4599 | −2.83 | 0.4816 | 2.60 | 0.0341 | −1.76 | 0.4600 | 1.99 | 0.3757 |

| Temperature (°C) (x2) | −2.17 | 0.3686 | −7.05 | 0.1172 | 1.64 | 0.1277 | 2.17 | 0.3681 | 3.24 | 0.1745 |

| SLR* (x3) | −2.25 | 0.3520 | 6.19 | 0.1575 | −3.89 | 0.0076 | 2.25 | 0.3522 | −4.56 | 0.0766 |

| Enzyme (%) (w/w) (x4) | −1.53 | 0.5166 | −2.12 | 0.5937 | 1.02 | 0.3100 | 1.53 | 0.5165 | −0.43 | 0.8412 |

| Extraction Time = 180 min | ||||||||||

| Factors | TOE | OYC | OYS | OYI | FOY | |||||

| Effect | p-Value | Effect | p-Value | Effect | p-Value | Effect | p-Value | Effect | p-Value | |

| Mean | 67.27 | 0.0000 | 54.64 | 0.0000 | 7.18 | 0.0057 | 32.73 | 0.0000 | 5.46 | 0.0003 |

| Curvature | 10.39 | 0.0934 | 10.43 | 0.4224 | 0.66 | 0.9161 | −10.39 | 0.0934 | −0.71 | 0.7748 |

| pH (x1) | 1.69 | 0.5472 | 3.01 | 0.6496 | −2.14 | 0.5204 | −1.69 | 0.5473 | 0.82 | 0.5302 |

| Temperature (°C) (x2) | −1.74 | 0.5359 | 1.28 | 0.8448 | −5.91 | 0.1151 | 1.74 | 0.5360 | 2.88 | 0.0646 |

| SLR* (x3) | −4.12 | 0.1769 | 2.97 | 0.6544 | −6.31 | 0.0976 | 4.12 | 0.1769 | −0.78 | 0.5521 |

| Enzyme (%) (w/w) (x4) | −1.37 | 0.6244 | 2.31 | 0.7261 | −4.14 | 0.2391 | 1.37 | 0.6244 | 0.46 | 0.7202 |

| Protein Extraction | ||||||||

|---|---|---|---|---|---|---|---|---|

| Extraction Time = 40 min | ||||||||

| Factors | TPE | PYC | PYS | PYI | ||||

| Effect | p-Value | Effect | p-Value | Effect | p-Value | Effect | p-Value | |

| Mean | 69.75 | 0.0000 | 2.16 | 0.0000 | 67.59 | 0.0000 | 30.25 | 0.0000 |

| Curvature | 1.86 | 0.7727 | −0.36 | 0.3783 | 2.22 | 0.7314 | −1.86 | 0.7729 |

| pH (x1) | −4.83 | 0.1892 | 0.38 | 0.1121 | −5.21 | 0.1633 | 4.83 | 0.1890 |

| Temperature (°C) (x2) | 4.81 | 0.1913 | −1.16 | 0.0020 | 5.97 | 0.1206 | −4.81 | 0.1913 |

| SLR* (x3) | −0.84 | 0.8014 | −0.58 | 0.0332 | −0.27 | 0.9369 | 0.85 | 0.8010 |

| Enzyme (%) (w/w) (x4) | 0.71 | 0.8312 | 1.59 | 0.0005 | −0.88 | 0.7948 | −0.71 | 0.8312 |

| Extraction Time = 180 min | ||||||||

| Factors | TPE | PYC | PYS | PYI | ||||

| Effect | p-Value | Effect | p-Value | Effect | p-Value | Effect | p-Value | |

| Mean | 69.27 | 0.0000 | 2.09 | 0.0001 | 67.19 | 0.0000 | 30.73 | 0.0000 |

| Curvature | 13.78 | 0.0031 | 2.02 | 0.0248 | 11.75 | 0.0072 | −13.78 | 0.0031 |

| pH (x1) | −0.58 | 0.6838 | −1.02 | 0.0283 | 0.44 | 0.7679 | 0.58 | 0.6838 |

| Temperature (°C) (x2) | −1.46 | 0.3291 | 0.35 | 0.3383 | −1.81 | 0.2531 | 1.46 | 0.3291 |

| SLR* (x3) | −5.50 | 0.0096 | 0.36 | 0.3260 | −5.86 | 0.0087 | 5.50 | 0.0096 |

| Enzyme (%) (w/w) (x4) | 2.23 | 0.1595 | 0.09 | 0.7923 | 2.13 | 0.1892 | −2.23 | 0.1595 |

| Total Oil Extraction Yield (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 55.7 ± 1.6 e.f | 54.5 ± 3.4 e.f | 61.1 ± 1.7 c.d.e |

| AEP1 | 48.1 ± 2.4 f | 56.1 ± 2.8 e.f | 58.3 ± 4.7 d.e |

| EAEP2 | 62.0 ± 0.7 b.c.d.e | 68.6 ± 3.3 a.b.c | 74.5 ±2.2 a |

| AEP2 | 64.9 ± 2.6 b.c.d | 66.9 ± 5.1 a.b.c | 69.8 ± 0.9 a.b |

| Oil Yield in the Skim (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 2.5 ± 0.5 c | 3.8 ± 1.6 b.c | 7.8 ± 2.0 a |

| AEP1 | 3.7 ± 1.0 b.c | 4.6 ± 1.9 a.b.c | 4.0 ± 1.0 b.c |

| EAEP2 | 5.0 ± 1.0 a.b.c | 5.4 ± 1.3 a.b.c | 4.7 ± 1.8 a.b.c |

| AEP2 | 6.5 ± 0.6 a.b | 4.8 ± 0.9 a.b.c | 4.30 ± 0.9 a.b.c |

| Oil Yield in the Cream (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 44.6 ± 3.2 e.f | 45.0 ± 3.8 e.f | 47.0 ± 3.7 d.e.f |

| AEP1 | 41.0 ± 1.1 f | 48.2 ± 4.0 c.d.e.f | 51.0 ± 3.7 b.c.d.e.f |

| EAEP2 | 52.3 ± 1.5 b.c.d.e | 57.3 ± 4.8 a.b.c | 65.8 ± 4.4 a |

| AEP2 | 55.9 ± 3.3 a.b.c.d | 59.0 ± 6.1 a.b | 63.37 ± 1.6 a |

| Oil Yield in the Insoluble (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 44.3 ± 1.6 a.b | 45.6 ± 3.4 a.b | 38.9 ± 1.7 b.c.d |

| AEP1 | 51.9 ± 2.4 a | 43.9 ± 2.8 a.b | 41.7 ± 4.7 b.c |

| EAEP2 | 38.0 ± 0.7 b.c.d.e | 31.4 ± 3.3 d.e.f | 25.5 ± 2.2 f |

| AEP2 | 35.1 ± 2.6 c.d.e | 33.1 ± 5.d.e.f | 29.8 ± 1.3 e.f |

| Free Oil Yield (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 8.7 ± 1.5 a | 5.5 ± 1.7 a.b.c.d | 6.4 ± 1.0 a.b |

| AEP1 | 3.3 ± 1.7 b.c.d | 3.3 ± 0.5 b.c.d | 3.3 ± 0.2 b.c.d |

| EAEP2 | 4.6 ± 1.5 b.c.d | 5.9 ± 2.3 a.b.c | 6.4 ± 0.5 a.b |

| AEP2 | 2.5 ± 0.4 d | 3.2 ± 0.7 b.c.d | 2.6 ± 0.5 c.d |

| Total Protein Extraction Yield (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 55.1 ± 4.7 c | 63.3 ± 2.8 b.c | 68.1 ± 5.2 a.b |

| AEP1 | 55.7 ±2.6 c | 56.0 ± 0.5 c | 55.3 ± 3.9 c |

| EAEP2 | 69.3 ± 1.2 a.b | 71.9± 2.4 a | 72.3 ± 0.9 a |

| AEP2 | 65.0 ± 0.8 a.b | 66.5 ± 1.6 a.b | 64.8± 2.2 a.b |

| Protein Yield in the Skim (%) | |||

| Samples | 20 min | 40 min | 60 min |

| EAEP1 | 50.8 ± 5.3 d | 60.6 ± 2.1 b.c | 63.5 ± 4.0 a.b |

| AEP1 | 53.0 ± 2.9 c.d | 53.3 ± 0.8 c.d | 51.7 ± 4.4 d |

| EAEP2 | 67.7 ± 1.1 a.b | 70.4 ± 2.2 a | 70.94 ± 0.9 a |

| AEP2 | 63.2 ± 0.6 a.b | 64.6 ± 1.5 a.b | 65.7 ± 2.2 a.b.c |

| Protein Yield in the Cream (%) | |||

| EAEP1 | 4.3 ± 1.4 a | 2.7 ± 0.6 a | 4.5 ± 2.1 a |

| AEP1 | 2.7 ± 0.4 a | 2.7 ± 0.6 a | 3.6 ± 0.5 a |

| EAEP2 | 1.6 ± 0.1 a | 1.5 ± 0.1 a | 1.6 ± 0.1 a |

| AEP2 | 1.8 ± 0.2 a | 1.9 ± 0.2 a | 2.0 ± 0.3 a |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Almeida, N.M.; F. G. Dias, F.; Rodrigues, M.I.; L. N. de Moura Bell, J.M. Effects of Processing Conditions on the Simultaneous Extraction and Distribution of Oil and Protein from Almond Flour. Processes 2019, 7, 844. https://doi.org/10.3390/pr7110844

de Almeida NM, F. G. Dias F, Rodrigues MI, L. N. de Moura Bell JM. Effects of Processing Conditions on the Simultaneous Extraction and Distribution of Oil and Protein from Almond Flour. Processes. 2019; 7(11):844. https://doi.org/10.3390/pr7110844

Chicago/Turabian Stylede Almeida, Neiva M., Fernanda F. G. Dias, Maria I. Rodrigues, and Juliana M. L. N. de Moura Bell. 2019. "Effects of Processing Conditions on the Simultaneous Extraction and Distribution of Oil and Protein from Almond Flour" Processes 7, no. 11: 844. https://doi.org/10.3390/pr7110844