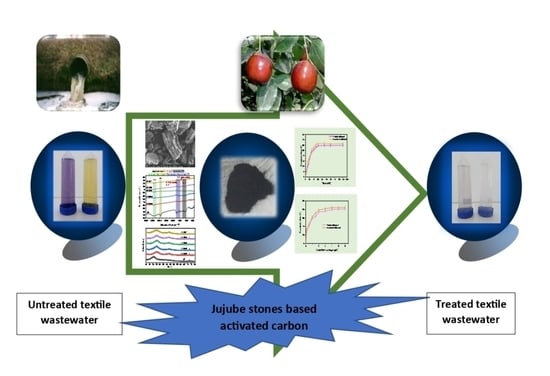

Study and Characterization of H3PO4 Activated Carbons Prepared from Jujube Stones for the Treatment of Industrial Textile Effluents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wastewater Samples

2.2. Preparation and Characterization of Activated Carbons

3. Results and Discussion

3.1. Effect of H3PO4 Concentration on the ACs Characteristics

3.2. Effect of the Temperature of Carbonization on the Characteristics of ACs

3.3. FTIR Analysis

3.4. SEM Analysis

3.5. XRD Analysis

3.6. Textile Effluents Treatment

3.6.1. Effect of Contact Time

3.6.2. Effect of Adsorbent Dosage

3.6.3. Physico-Chemical Characteristics of Wastewater before and after Treatment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mia, R.; Selim, M.; Shamim, A.; Chowdhury, M.; Sultana, S.; Armin, M.; Hossain, M.; Akter, R.; Dey, S.; Naznin, H. Review on various types of pollution problem in textile dyeing & printing industries of Bangladesh and recommandation for mitigation. J. Text. Eng. Fash. Technol. 2019, 5, 220–226. [Google Scholar]

- Bhagat, S.K.; Pilario, K.E.; Emmanuel, B.O.; Tiyasha, T.; Yaqub, M.; Onu, C.E.; Pyrgaki, K.; Falah, M.W.; Jawad, A.H.; Yaseen, D.A. Comprehensive review on machine learning methodologies for modeling dye removal processes in wastewater. J. Clean. Prod. 2023, 385, 135522. [Google Scholar]

- Solayman, H.; Hossen, M.A.; Abd Aziz, A.; Yahya, N.Y.; Hon, L.K.; Ching, S.L.; Monir, M.U.; Zoh, K.-D. Performance evaluation of dye wastewater treatment technologies: A review. J. Environ. Chem. Eng. 2023, 11, 109610. [Google Scholar]

- Zidane, F.; Kaba, N.; Bensaid, J.; Blais, J.F.; Drogui, P.; Rhazzar, A.; Lekhlif, B.; Benabdenbi, B. Contribution ā la dépollution d’un rejet textile par adsorption sur un coagulant ā base du mélange fer/aluminium préparé par électrocoagulation. Int. J. Biol. Chem. Sci. 2011, 5, 2094–2102. [Google Scholar] [CrossRef]

- Hassan, M.M.; Saifullah, K. Ultrasound-assisted sustainable and energy efficient pre-treatments, dyeing, and finishing of textiles–A comprehensive review. Sustain. Chem. Pharm. 2023, 33, 101109. [Google Scholar] [CrossRef]

- Donkadokula, N.Y.; Kola, A.K.; Naz, I.; Saroj, D. A review on advanced physico-chemical and biological textile dye wastewater treatment techniques. Rev. Environ. Sci. Bio/Technol. 2020, 19, 543–560. [Google Scholar] [CrossRef]

- Reddy, S.S.; Kotaiah, B.; Reddy, N.S.P. Color pollution control in textile dyeing industry effluents using tannery sludge derived activated carbon. Bull. Chem. Soc. Ethiop. 2008, 22, 369–378. [Google Scholar]

- Hassan, M.M.; Carr, C.M. A critical review on recent advancements of the removal of reactive dyes from dyehouse effluent by ion-exchange adsorbents. Chemosphere 2018, 209, 201–219. [Google Scholar] [CrossRef]

- Afroze, S.; Sen, T.K. A review on heavy metal ions and dye adsorption from water by agricultural solid waste adsorbents. Water Air Soil Pollut. 2018, 229, 225. [Google Scholar]

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.-G.; Elsamahy, T.; Jiao, H.; Fu, Y.; Sun, J. A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160. [Google Scholar] [CrossRef]

- Arslan, S.; Eyvaz, M.; Gürbulak, E.; Yüksel, E. A review of state-of-the-art technologies in dye-containing wastewater treatment–the textile industry case. In Textile Wastewater Treatment; IntechOpen: London, UK, 2016. [Google Scholar]

- Samsami, S.; Mohamadizaniani, M.; Sarrafzadeh, M.-H.; Rene, E.R.; Firoozbahr, M. Recent advances in the treatment of dye-containing wastewater from textile industries: Overview and perspectives. Process Saf. Environ. Prot. 2020, 143, 138–163. [Google Scholar] [CrossRef]

- Su, M.; Li, H.; He, X.; Xu, Z. Significant enhancement of pesticide and organic dyes degradation by ion-exchange within a metal–organic framework. Polyhedron 2022, 215, 115651. [Google Scholar] [CrossRef]

- Bouchelkia, N.; Tahraoui, H.; Amrane, A.; Belkacemi, H.; Bollinger, J.-C.; Bouzaza, A.; Zoukel, A.; Zhang, J.; Mouni, L. Jujube stones based highly efficient activated carbon for methylene blue adsorption: Kinetics and isotherms modeling, thermodynamics and mechanism study, optimization via response surface methodology and machine learning approaches. Process Saf. Environ. Prot. 2023, 170, 513–535. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Monash, P.; Velu, S.; Banat, F.; Naushad, M.; Arthanareeswaran, G.; Show, P.L. Effective treatment of dye polluted wastewater using nanoporous CaCl2 modified polyethersulfone membrane. Process Saf. Environ. Prot. 2019, 124, 266–278. [Google Scholar] [CrossRef]

- Bangari, R.S.; Yadav, A.; Bharadwaj, J.; Sinha, N. Boron nitride nanosheets incorporated polyvinylidene fluoride mixed matrix membranes for removal of methylene blue from aqueous stream. J. Environ. Chem. Eng. 2022, 10, 107052. [Google Scholar] [CrossRef]

- Hadadi, A.; Imessaoudene, A.; Bollinger, J.-C.; Cheikh, S.; Assadi, A.A.; Amrane, A.; Kebir, M.; Mouni, L. Parametrical Study for the Effective Removal of Mordant Black 11 from Synthetic Solutions: Moringa oleifera Seeds’ Extracts Versus Alum. Water 2022, 14, 4109. [Google Scholar] [CrossRef]

- Bilińska, L.; Gmurek, M.; Ledakowicz, S. Textile wastewater treatment by AOPs for brine reuse. Process Saf. Environ. Prot. 2017, 109, 420–428. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T.; Tong, L.; Gao, Y.; Zhang, H.; Zhang, Y.; Wang, Z.; Zhu, S. Non-free Fe dominated PMS activation for enhancing electro-Fenton efficiency in neutral wastewater. J. Electroanal. Chem. 2023, 928, 117062. [Google Scholar] [CrossRef]

- Yin, C.; Ma, J.; Qiu, J.; Liu, R.; Ba, L. Mass-producible low-cost flexible electronic fabrics for azo dye wastewater treatment by electrocoagulation. Chin. J. Chem. Eng. 2023, 59, 222–230. [Google Scholar] [CrossRef]

- Kalsoom, U.; Khalid, N.; Ibrahim, A.; Ashraf, S.S.; Bhatti, H.N.; Ahsan, Z.; Zdarta, J.; Bilal, M. Biocatalytic degradation of reactive blue 221 and direct blue 297 dyes by horseradish peroxidase immobilized on iron oxide nanoparticles with improved kinetic and thermodynamic characteristics. Chemosphere 2023, 312, 137095. [Google Scholar] [CrossRef]

- Amin, S.; Rastogi, R.P.; Chaubey, M.G.; Jain, K.; Divecha, J.; Desai, C.; Madamwar, D. Degradation and toxicity analysis of a reactive textile diazo dye-Direct Red 81 by newly isolated Bacillus sp. DMS2. Front. Microbiol. 2020, 11, 576680. [Google Scholar] [CrossRef] [PubMed]

- Cheikh, S.; Imessaoudene, A.; Bollinger, J.-C.; Hadadi, A.; Manseri, A.; Bouzaza, A.; Assadi, A.; Amrane, A.; Zamouche, M.; El Jery, A. Complete Elimination of the Ciprofloxacin Antibiotic from Water by the combination of Adsorption–Photocatalysis Process using Natural Hydroxyapatite and TiO2. Catalysts 2023, 13, 336. [Google Scholar] [CrossRef]

- Imessaoudene, A.; Cheikh, S.; Bollinger, J.-C.; Belkhiri, L.; Tiri, A.; Bouzaza, A.; El Jery, A.; Assadi, A.; Amrane, A.; Mouni, L. Zeolite Waste Characterization and Use as Low-Cost, Ecofriendly, and Sustainable Material for Malachite Green and Methylene Blue Dyes Removal: Box–Behnken Design, Kinetics, and Thermodynamics. Appl. Sci. 2022, 12, 7587. [Google Scholar] [CrossRef]

- Ileri, B.; Dogu, I. Sono–degradation of Reactive Blue 19 in aqueous solution and synthetic textile industry wastewater by nanoscale zero–valent aluminum. J. Environ. Manag. 2022, 303, 114200. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Ali, S.W.; Shahadat, M.; Sagadevan, S. Applications of polyaniline-impregnated silica gel-based nanocomposites in wastewater treatment as an efficient adsorbent of some important organic dyes. Green Process. Synth. 2022, 11, 617–630. [Google Scholar] [CrossRef]

- Hadadi, A.; Imessaoudene, A.; Bollinger, J.-C.; Cheikh, S.; Manseri, A.; Mouni, L. Dual Valorization of Potato Peel (Solanum tuberosum) as a Versatile and Sustainable Agricultural Waste in Both Bioflocculation of Eriochrome Black T and Biosorption of Methylene Blue. J. Polym. Environ. 2023, 31, 2983–2998. [Google Scholar] [CrossRef]

- Bouchelkia, N.; Mouni, L.; Belkhiri, L.; Bouzaza, A.; Bollinger, J.-C.; Madani, K.; Dahmoune, F. Removal of lead (II) from water using activated carbon developed from jujube stones, a low-cost sorbent. Sep. Sci. Technol. 2016, 51, 1645–1653. [Google Scholar] [CrossRef]

- Chedri Mammar, A.; Mouni, L.; Bollinger, J.-C.; Belkhiri, L.; Bouzaza, A.; Assadi, A.A.; Belkacemi, H. Modeling and optimization of process parameters in elucidating the adsorption mechanism of Gallic acid on activated carbon prepared from date stones. Sep. Sci. Technol. 2020, 55, 3113–3125. [Google Scholar] [CrossRef]

- Kausar, A.; Iqbal, M.; Javed, A.; Aftab, K.; Bhatti, H.N.; Nouren, S. Dyes adsorption using clay and modified clay: A review. J. Mol. Liq. 2018, 256, 395–407. [Google Scholar] [CrossRef]

- Karimi, S.; Yaraki, M.T.; Karri, R.R. A comprehensive review of the adsorption mechanisms and factors influencing the adsorption process from the perspective of bioethanol dehydration. Renew. Sustain. Energy Rev. 2019, 107, 535–553. [Google Scholar] [CrossRef]

- Patel, H. Fixed-bed column adsorption study: A comprehensive review. Appl. Water Sci. 2019, 9, 45. [Google Scholar] [CrossRef]

- Daniel, L.S.; Rahman, A.; Hamushembe, M.N.; Kapolo, P.; Uahengo, V.; Jonnalagadda, S.B. The production of activated carbon from Acacia erioloba seedpods via phosphoric acid activation method for the removal of methylene blue from water. Bioresour. Technol. Rep. 2023, 23, 101568. [Google Scholar] [CrossRef]

- Dias, J.M.; Alvim-Ferraz, M.C.; Almeida, M.F.; Rivera-Utrilla, J.; Sánchez-Polo, M. Waste materials for activated carbon preparation and its use in aqueous-phase treatment: A review. J. Environ. Manag. 2007, 85, 833–846. [Google Scholar] [CrossRef] [PubMed]

- Regti, A.; El Kassimi, A.; Laamari, M.R.; El Haddad, M. Competitive adsorption and optimization of binary mixture of textile dyes: A factorial design analysis. J. Assoc. Arab. Univ. Basic Appl. Sci. 2017, 24, 1–9. [Google Scholar] [CrossRef]

- Erto, A.; Chianese, S.; Lancia, A.; Musmarra, D. On the mechanism of benzene and toluene adsorption in single-compound and binary systems: Energetic interactions and competitive effects. Desalination Water Treat. 2017, 86, 259–265. [Google Scholar] [CrossRef]

- El Gamal, M.; Mousa, H.A.; El-Naas, M.H.; Zacharia, R.; Judd, S. Bio-regeneration of activated carbon: A comprehensive review. Sep. Purif. Technol. 2018, 197, 345–359. [Google Scholar] [CrossRef]

- Akkari, I.; Graba, Z.; Bezzi, N.; Kaci, M.M.; Merzeg, F.A.; Bait, N.; Ferhati, A.; Dotto, G.L.; Benguerba, Y. Effective removal of cationic dye on activated carbon made from cactus fruit peels: A combined experimental and theoretical study. Environ. Sci. Pollut. Res. 2023, 30, 3027–3044. [Google Scholar] [CrossRef]

- Bayomie, O.S.; Kandeel, H.; Shoeib, T.; Yang, H.; Youssef, N.; El-Sayed, M.M. Novel approach for effective removal of methylene blue dye from water using fava bean peel waste. Sci. Rep. 2020, 10, 7824. [Google Scholar] [CrossRef]

- Ramutshatsha-Makhwedzha, D.; Mavhungu, A.; Moropeng, M.L.; Mbaya, R. Activated carbon derived from waste orange and lemon peels for the adsorption of methyl orange and methylene blue dyes from wastewater. Heliyon 2022, 8, e09930. [Google Scholar] [CrossRef]

- Raji, Y.; Nadi, A.; Mechnou, I.; Saadouni, M.; Cherkaoui, O.; Zyade, S. High adsorption capacities of crystal violet dye by low-cost activated carbon prepared from Moroccan Moringa oleifera wastes: Characterization, adsorption and mechanism study. Diam. Relat. Mater. 2023, 135, 109834. [Google Scholar] [CrossRef]

- Amibo, T.A.; Beyn, S.M.; Bayu, A.B.; Kabeta, W.F. Optimization and Modeling of Cr (VI) Removal from Tannery Wastewater onto Activated Carbon Prepared from Coffee Husk and Sulfuric Acid (H2SO4) as Activating Agent by Using Central Composite Design (CCD). J. Environ. Public Health 2023, 2023, 5663261. [Google Scholar]

- Milanković, V.; Tasić, T.; Pejčić, M.; Pašti, I.; Lazarević-Pašti, T. Spent Coffee Grounds as an Adsorbent for Malathion and Chlorpyrifos—Kinetics, Thermodynamics, and Eco-Neurotoxicity. Foods 2023, 12, 2397. [Google Scholar] [CrossRef]

- Yusop, M.F.M.; Khan, M.N.N.; Zakaria, R.; Abdullah, A.Z.; Ahmad, M.A. Mass transfer simulation on remazol brilliant blue R dye adsorption by optimized teak wood Based activated carbon. Arab. J. Chem. 2023, 16, 104780. [Google Scholar] [CrossRef]

- Yusop, M.F.M.; Jaya, M.A.T.; Idris, I.; Abdullah, A.Z.; Ahmad, M.A. Optimization and mass transfer simulation of remazol brilliant blue R dye adsorption onto meranti wood based activated carbon. Arab. J. Chem. 2023, 16, 104683. [Google Scholar] [CrossRef]

- Agarwal, S.; Singh, A.P.; Mathur, S. Removal of COD and color from textile industrial wastewater using wheat straw activated carbon: An application of response surface and artificial neural network modeling. Environ. Sci. Pollut. Res. 2023, 30, 41073–41094. [Google Scholar] [CrossRef] [PubMed]

- Khan, T.A.; Nouman, M.; Dua, D.; Khan, S.A.; Alharthi, S.S. Adsorptive scavenging of cationic dyes from aquatic phase by H3PO4 activated Indian jujube (Ziziphus mauritiana) seeds based activated carbon: Isotherm, kinetics, and thermodynamic study. J. Saudi Chem. Soc. 2022, 26, 101417. [Google Scholar] [CrossRef]

- Hung, N.V.; Nguyet, B.T.M.; Nghi, N.H.; Thanh, N.M.; Quyen, N.D.V.; Nguyen, V.T.; Nhiem, D.N.; Khieu, D.Q. Highly effective adsorption of organic dyes from aqueous solutions on longan seed-derived activated carbon. Environ. Eng. Res. 2022, 28, 220116. [Google Scholar] [CrossRef]

- Wickramaarachchi, W.K.P.; Minakshi, M.; Gao, X.; Dabare, R.; Wong, K.W. Hierarchical porous carbon from mango seed husk for electro-chemical energy storage. Chem. Eng. J. Adv. 2021, 8, 100158. [Google Scholar] [CrossRef]

- Wickramaarachchi, K.; Minakshi, M.; Aravindh, S.A.; Dabare, R.; Gao, X.; Jiang, Z.-T.; Wong, K.W. Repurposing N-doped grape marc for the fabrication of supercapacitors with theoretical and machine learning models. Nanomaterials 2022, 12, 1847. [Google Scholar] [CrossRef]

- Zaharia, C. Application of a physico-chemical treatment based on adsorption for industrial effluents. A case study. In Proceedings of the 16th International Conference–Modern Technologies, Quality and Innovation–ModTech, Sinaia, Romania, 24–26 May 2012; pp. 1069–1072. [Google Scholar]

- Ahmed, M.J.; Dhedan, S.K. Equilibrium isotherms and kinetics modeling of methylene blue adsorption on agricultural wastes-based activated carbons. Fluid Phase Equilibria 2012, 317, 9–14. [Google Scholar] [CrossRef]

- Reffas, A.; Bernardet, V.; David, B.; Reinert, L.; Lehocine, M.B.; Dubois, M.; Batisse, N.; Duclaux, L. Carbons prepared from coffee grounds by H3PO4 activation: Characterization and adsorption of methylene blue and Nylosan Red N-2RBL. J. Hazard. Mater. 2010, 175, 779–788. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Wang, T.; Zhi, J.; Zheng, Q.; Chen, Q.; Zhang, C.; Li, Y. Utilization of Jujube biomass to prepare biochar by pyrolysis and activation: Characterization, adsorption characteristics, and mechanisms for nitrogen. Materials 2020, 13, 5594. [Google Scholar] [CrossRef]

- Rozada, F.; Otero, M.; Moran, A.; Garcia, A. Activated carbons from sewage sludge and discarded tyres: Production and optimization. J. Hazard. Mater. 2005, 124, 181–191. [Google Scholar] [CrossRef]

- Daoud, M.; Benturki, O.; Girods, P.; Donnot, A.; Fontana, S. Adsorption ability of activated carbons from Phoenix dactylifera rachis and Ziziphus jujube stones for the removal of commercial dye and the treatment of dyestuff wastewater. Microchem. J. 2019, 148, 493–502. [Google Scholar] [CrossRef]

- Msaada, A.; Belbahloula, M.; El Hajjajib, S.; Beakoua, B.H.; Houssainia, M.A.; Belhajjiaa, C.; Aassilac, H.; Zouhria, A.; Anouara, A. Industrial wastewater decolorization by activated carbon from Ziziphus lotus. Desalin. Water Treat. 2018, 126, 296–305. [Google Scholar] [CrossRef]

- Angın, D. Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake. Bioresour. Technol. 2013, 128, 593–597. [Google Scholar] [CrossRef] [PubMed]

- Adib, M.; Suraya, W.; Rafidah, H.; Amirza, A.; Attahirah, M.; Hani, M.; Adnan, M. Effect of phosphoric acid concentration on the characteristics of sugarcane bagasse activated carbon. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 012061. [Google Scholar] [CrossRef]

- Yakout, S.; El-Deen, G.S. Characterization of activated carbon prepared by phosphoric acid activation of olive stones. Arab. J. Chem. 2016, 9, S1155–S1162. [Google Scholar] [CrossRef]

- Girgis, B.S.; El-Hendawy, A.-N.A. Porosity development in activated carbons obtained from date pits under chemical activation with phosphoric acid. Microporous Mesoporous Mater. 2002, 52, 105–117. [Google Scholar] [CrossRef]

- Bahnes, Z.; Benderdouche, N.; Attouti, S.; Bestani, B.; Duclaux, L.; Reinert, L. Preparation of a novel activated carbon from jujube stones (Ziziphus jujuba) for the removal of basic and acid dyes. Desalination Water Treat. 2018, 102, 312–325. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Yang, G.; Wang, Q.; Li, R.; Lucia, L.A. Preparation and characterization of activated carbon from hydrochar by phosphoric acid activation and its adsorption performance in prehydrolysis liquor. BioResources 2017, 12, 5928–5941. [Google Scholar] [CrossRef]

- Shahrokhi-Shahraki, R.; Benally, C.; El-Din, M.G.; Park, J. High efficiency removal of heavy metals using tire-derived activated carbon vs commercial activated carbon: Insights into the adsorption mechanisms. Chemosphere 2021, 264, 128455. [Google Scholar] [CrossRef] [PubMed]

- Kundu, A.; Gupta, B.S.; Hashim, M.A.; Redzwan, G. Taguchi optimization approach for production of activated carbon from phosphoric acid impregnated palm kernel shell by microwave heating. J. Clean. Prod. 2015, 105, 420–427. [Google Scholar] [CrossRef]

- El-Hendawy, A.-N.A. Variation in the FTIR spectra of a biomass under impregnation, carbonization and oxidation conditions. J. Anal. Appl. Pyrolysis 2006, 75, 159–166. [Google Scholar] [CrossRef]

- Puziy, A.M.; Poddubnaya, O.I.; Martínez-Alonso, A.; Suárez-García, F.; Tascón, J.M.D. Synthetic carbons activated with phosphoric acid: I. Surface chemistry and ion binding properties. Carbon 2002, 40, 1493–1505. [Google Scholar] [CrossRef]

- Hesas, R.H.; Arami-Niya, A.; Daud, W.M.A.W.; Sahu, J. Preparation and characterization of activated carbon from apple waste by microwave-assisted phosphoric acid activation: Application in methylene blue adsorption. BioResources 2013, 8, 2950–2966. [Google Scholar]

- Solum, M.S.; Pugmire, R.J.; Jagtoyen, M.; Derbyshire, F. Evolution of carbon structure in chemically activated wood. Carbon 1995, 33, 1247–1254. [Google Scholar] [CrossRef]

- Njewa, J.B.; Vunain, E.; Biswick, T. Synthesis and characterization of activated carbons prepared from agro-wastes by chemical activation. J. Chem. 2022, 2022, 9975444. [Google Scholar] [CrossRef]

- Gunathilaka, H.; Thambiliyagodage, C.; Usgodaarchchi, L.; Angappan, S. Effect of surfactants on morphology and textural parameters of silica nanoparticles derived from paddy husk and their efficient removal of methylene blue. In Proceedings of the International Conference on Innovations in Energy Engineering & Cleaner Production (IEECP’21), San Francisco, CA, USA, 29–30 July 2021; pp. 29–30. [Google Scholar]

- Sher, F.; Iqbal, S.Z.; Albazzaz, S.; Ali, U.; Mortari, D.A.; Rashid, T. Development of biomass derived highly porous fast adsorbents for post-combustion CO2 capture. Fuel 2020, 282, 118506. [Google Scholar] [CrossRef]

- Köseoğlu, E.; Akmil-Başar, C. Preparation, structural evaluation and adsorptive properties of activated carbon from agricultural waste biomass. Adv. Powder Technol. 2015, 26, 811–818. [Google Scholar] [CrossRef]

- Djilani, C.; Zaghdoudi, R.; Modarressi, A.; Rogalski, M.; Djazi, F.; Lallam, A. Elimination of organic micropollutants by adsorption on activated carbon prepared from agricultural waste. Chem. Eng. J. 2012, 189, 203–212. [Google Scholar] [CrossRef]

- Soedarmanto, H.; Sudjito, S.; Wijayanti, W.; Hamidi, N.; Setiawati, E. The impact of water soaking on physicochemical activated carbon produced by various thermal cracking temperature. AIP Conf. Proc. 2020, 2278, 020008. [Google Scholar]

- Girgis, B.S.; Temerk, Y.M.; Gadelrab, M.M.; Abdullah, I.D. X-ray diffraction patterns of activated carbons prepared under various conditions. Carbon Sci. 2007, 8, 95–100. [Google Scholar] [CrossRef]

- Açıkyıldız, M.; Gürses, A.; Karaca, S. Preparation and characterization of activated carbon from plant wastes with chemical activation. Microporous Mesoporous Mater. 2014, 198, 45–49. [Google Scholar] [CrossRef]

- Rahman, A.; Hango, H.J.; Daniel, L.S.; Uahengo, V.; Jaime, S.J.; Bhaskaruni, S.V.; Jonnalagadda, S.B. Chemical preparation of activated carbon from Acacia erioloba seed pods using H2SO4 as impregnating agent for water treatment: An environmentally benevolent approach. J. Clean. Prod. 2019, 237, 117689. [Google Scholar] [CrossRef]

- Aragaw, T.A.; Asmare, A.M. Phycoremediation of textile wastewater using indigenous microalgae. Water Pract. Technol. 2018, 13, 274–284. [Google Scholar] [CrossRef]

- Hossain, M.S.; Sarker, P.; Rahaman, M.S.; Uddin, M.K. Integrated performance of Fenton process and filtration (Activated Charcoal and Sand) for textile wastewater treatment. Curr. J. Appl. Sci. Technol. 2020, 39, 21–31. [Google Scholar] [CrossRef]

- Farch, S.; Yahoum, M.M.; Toumi, S.; Tahraoui, H.; Lefnaoui, S.; Kebir, M.; Zamouche, M.; Amrane, A.; Zhang, J.; Hadadi, A. Application of Walnut Shell Biowaste as an Inexpensive Adsorbent for Methylene Blue Dye: Isotherms, Kinetics, Thermodynamics, and Modeling. Separations 2023, 10, 60. [Google Scholar] [CrossRef]

- Jawad, A.H.; Saber, S.E.M.; Abdulhameed, A.S.; Farhan, A.M.; ALOthman, Z.A.; Wilson, L.D. Characterization and applicability of the natural Iraqi bentonite clay for toxic cationic dye removal: Adsorption kinetic and isotherm study. J. King Saud Univ. -Sci. 2023, 35, 102630. [Google Scholar] [CrossRef]

- Karim, M.E.; Dhar, K.; Hossain, M.T. Physico-Chemical and Microbiological Analysis of Textile Dyeing Effluents. IOSR J. Environ. Sci. Toxicol. Food Technol. (IOSR-JESTFT) 2015, 9, 2319–2399. [Google Scholar]

- Prado, E.; Miranda, F.; de Araujo, L.; Fernandes, G.; Pereira, A.J.; Gomes, M.; da Silva Sobrinho, A.; Baldan, M.; Petraconi, G. Physicochemical Modifications and Decolorization of Textile Wastewater by Ozonation: Performance Evaluation of a Batch System. Ozone Sci. Eng. 2022, 45, 276–290. [Google Scholar] [CrossRef]

- Pavithra, M.; Kousar, H. Characterization of certain physico-chemical parameters of textile waste water. Int. J. Environ. Sci. 2016, 5, 39–41. [Google Scholar]

- Tafesse, T.; Yetemegne, A.; Kumar, S. BThe Physico-Chemical Studies of Wastewater in Hawassa Textile Industry. J. Environ. Anal. Chem. 2015, 2, 4. [Google Scholar] [CrossRef]

- Baral, A.; Das, D.P.; Minakshi, M.; Ghosh, M.K.; Padhi, D.K. Probing Environmental Remediation of RhB Organic Dye Using α-MnO2 under Visible-Light Irradiation: Structural, Photocatalytic and Mineralization Studies. ChemistrySelect 2016, 1, 4277–4285. [Google Scholar] [CrossRef]

- Ahmad, A.; Hameed, B. Reduction of COD and color of dyeing effluent from a cotton textile mill by adsorption onto bamboo-based activated carbon. J. Hazard. Mater. 2009, 172, 1538–1543. [Google Scholar] [CrossRef]

- Tebeje, A.; Worku, Z.; Nkambule, T.; Fito, J. Adsorption of chemical oxygen demand from textile industrial wastewater through locally prepared bentonite adsorbent. Int. J. Environ. Sci. Technol. 2021, 19, 1893–1906. [Google Scholar] [CrossRef]

- Zaharia, C.; Suteu, D. Coal fly ash as adsorptive material for treatment of a real textile effluent: Operating parameters and treatment efficiency. Environ. Sci. Pollut. Res. 2013, 20, 2226–2235. [Google Scholar] [CrossRef]

- Khellouf, M.; Chemini, R.; Salem, Z.; Khodja, M.; Zeriri, D.; Jada, A. A new activated carbon prepared from cypress cones and its application in the COD reduction and colour removal from industrial textile effluent. Environ. Dev. Sustain. 2021, 23, 7756–7771. [Google Scholar] [CrossRef]

- Elayadi, F.; Achak, M.; Boumya, W.; Elamraoui, S.; Barka, N.; Lamy, E.; Beniich, N.; El Adlouni, C. Factorial Design Statistical Analysis and Optimization of the Adsorptive Removal of COD from Olive Mill Wastewater Using Sugarcane Bagasse as a Low-Cost Adsorbent. Water 2023, 15, 1630. [Google Scholar] [CrossRef]

- Santhy, K.; Selvapathy, P. Removal of reactive dyes from wastewater by adsorption on coir pith activated carbon. Bioresour. Technol. 2006, 97, 1329–1336. [Google Scholar] [CrossRef]

| Particle Size (µm) | pHpzc | Moisture Content (%) | Ash Content (%) | Volatile Matter (%) | Fixed Carbon (%) |

|---|---|---|---|---|---|

| <100 | 6.60 | 7.66 | 0.86 | 75.25 | 16.23 |

| AC30/5 | AC50/5 | AC85/5 | AC85/6 | AC85/7 | |

|---|---|---|---|---|---|

| pHpzc | 6.34 | 6.10 | 4.86 | 5.00 | 5.90 |

| Moisture content (%) | 6.3 | 6.5 | 6.9 | 6.5 | 5.5 |

| Ash content (%) | 3.42 | 2.97 | 0.99 | 1.03 | 3.81 |

| Volatile matter (%) | 71.65 | 69.37 | 49.52 | 45.06 | 16.04 |

| Fixed carbon (%) | 18.63 | 21.16 | 42.59 | 47.41 | 74.65 |

| Iodine number (mg/g) | 663.08 | 709.21 | 860.95 | 867.54 | 833.48 |

| Methylene blue index (mg/g) | 166.86 | 315.04 | 338.40 | 387.61 | 324.56 |

| SMB (m2/g) | 408.46 | 771.19 | 828.37 | 948.84 | 794.50 |

| Carboxylic groups (mmol/g) | 0.43 | 0.55 | 0.62 | 0.6 | 0.57 |

| Lactonic groups (mmol/g) | 0.16 | 0.27 | 0.2 | 0.25 | 0.24 |

| Phenolic groups (mmol/g) | 0.31 | 0.38 | 0.43 | 0.51 | 0.41 |

| Total acid (mmol/g) | 0.9 | 1.2 | 1.25 | 1.36 | 1.22 |

| Total basic (mmol/g) | 0.11 | 0.14 | 0.12 | 0.15 | 0.15 |

| Adsorbent | Activating Agent | Preparation Conditions | Methylene Blue Index (mg/g) | SMB (m2/g) | Iodine Number (mg/g) | Reference |

|---|---|---|---|---|---|---|

| Pine sawdust (PS)-based activated carbon | ZnCl2 | 1.5/1 Imp. ratio (w/w)/carbonization at 400 °C/2 h | 300 | / | / | [77] |

| Rose seed (RS)-based activated carbon | ZnCl2 | 1.5/1 Imp. ratio (w/w); carbonization at 500 °C/3 h | 297 | / | / | [77] |

| Cornel seed (CS)-based activated carbon | ZnCl2 | 1.5/1 Imp. ratio (w/w); carbonization at 500 °C/2 h | 299 | / | [77] | |

| Jujube stone-based activated carbon | KOH | 1/2 Imp. ratio (w/w); carbonization at 700 °C/3 h | 299.02 | / | 1358.05 | [62] |

| Jujube stone-based activated carbon | H3PO4 | 1/1 Imp. ratio (w/w); carbonization at 600 °C/1 h | 387.61 | 948.84 | 867.54 | This study |

| Acacia erioloba seed pods-based activated carbon (<50 µm) | H2SO4 | 25 g + 150 mL 10% H2SO4; carbonization at 600 °C/1 h | / | 10.47 | 528 ± 2.9 | [78] |

| Acacia erioloba seed pods-based activated carbon (<75 µm) | H2SO4 | / | 10.34 | 638 ± 3.1 | [78] | |

| Acacia erioloba seed pods-based activated carbon (<100 µm) | H2SO4 | / | 10.31 | 554 ± 2.4 | [78] |

| Parameter | Mustard Effluent | Violet Effluent | Algerian Standard * N° 06-141, 2006 | Textile Factory’s Internal Specifications | World Health Organization (WHO) Standard [57] |

|---|---|---|---|---|---|

| Temperature (°C) | 17.95 | 17.31 | 35 | <30 | / |

| pH | 9.19 | 9.24 | 6.0–9.0 | 6.5–8.5 | 6.5–8.5 |

| turbidity (FTU) | 7.52 | 8.09 | - | - | - |

| COD (mg O2/L) | 302.72 | 230.68 | 300 | 120 | <90 |

| BOD (mg O2/L) | 80.00 | 60.00 | 200 | 40 | <30 |

| COD/BOD | 3.78 | 3.84 | - | - | - |

| suspended solids (mg/L) | 63.00 | 45.00 | 40 | 40 | <20 |

| Total dissolved solids (mg/L) | 1864.00 | 1397.00 | - | - | - |

| Total solid (mg/L) | 1927.00 | 1442.00 | - | - | - |

| Parameter | Mustard Effluent | Violet Effluent | ||

|---|---|---|---|---|

| before Treatment | after Treatment with AC85/6 | before Treatment | after Treatment with AC85/6 | |

| Temperature (°C) | 17.95 | 16.59 ± 0.54 | 17.31 | 16.10 ± 1.01 |

| pH | 9.19 | 7.38 ± 0.21 | 9.24 | 7.44 ± 0.43 |

| turbidity (FTU) | 7.52 | 0.22 ± 0.07 | 8.09 | 0.51 ± 0.13 |

| turbidity removal (%) | / | 97.07 ± 0.93 | / | 93.70 ± 1.61 |

| COD (mg O2/L) | 302.72 | 96.04 ± 2.57 | 230.68 | 80.51 ± 3.61 |

| COD removal (%) | / | 68.27 ± 0.85 | / | 65.10 ± 1.56 |

| BOD (mg O2/L) | 80.00 | 40.00 | 60.00 | 20.00 |

| BOD removal (%) | / | 50.00 | / | 66.67 |

| suspended solids (mg/L) | 63.00 | 0.26 ± 0.04 | 45.00 | 0.43 ± 0.09 |

| suspended solids removal (%) | / | 99.59 ± 0.06 | / | 99.04 ± 0.20 |

| Total dissolved solids (mg/L) | 1864.00 | 767.00 ± 7.00 | 1397.00 | 635.00 ± 5.00 |

| Total dissolved solids removal (%) | / | 58.85 ± 0.38 | / | 54.55 ± 0.36 |

| Total solid (mg/L) | 1927.00 | 767.26 ± 7.04 | 1442.00 | 635.43 ± 5.09 |

| Total solids removal (%) | / | 60.18 ± 0.37 | / | 55.93 ± 0.25 |

| Adsorbent | Adsorbent Dosage (g/L) | COD before Treatment (mg O2/L) | COD Removal (%) | Reference |

|---|---|---|---|---|

| Bamboo-based activated carbon | 3 | 251.65 | 75.21 | [88] |

| wheat straw activated carbon | 2.045 | 1313 | 90.92 | [46] |

| Sphagnum moss peat | 20 | 665 | 44.128 | [51] |

| Sulfuric acid activated bentonite | 2 | 569 ± 23 | 76.5 | [89] |

| Jujube stone-based activated carbon | 4 | 302.72 | 84.65 | This study |

| 4 | 230.68 | 81.03 | This study | |

| Coal fly ash | 40 | 665 | 61.11 | [90] |

| Cypress cones activated carbon | 2 | 865 | 19 | [91] |

| Sugarcane bagasse | 10 | 347.8 | 55.07 | [92] |

| Coir pith activated carbon (CPC) | 5 | 528 | 46.5 | [93] |

| Granular coir pith carbon (GCPC) | 5 | 528 | 35 | [93] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouchelkia, N.; Benazouz, K.; Mameri, A.; Belkhiri, L.; Hamri, N.; Belkacemi, H.; Zoukel, A.; Amrane, A.; Aoulmi, F.; Mouni, L. Study and Characterization of H3PO4 Activated Carbons Prepared from Jujube Stones for the Treatment of Industrial Textile Effluents. Processes 2023, 11, 2694. https://doi.org/10.3390/pr11092694

Bouchelkia N, Benazouz K, Mameri A, Belkhiri L, Hamri N, Belkacemi H, Zoukel A, Amrane A, Aoulmi F, Mouni L. Study and Characterization of H3PO4 Activated Carbons Prepared from Jujube Stones for the Treatment of Industrial Textile Effluents. Processes. 2023; 11(9):2694. https://doi.org/10.3390/pr11092694

Chicago/Turabian StyleBouchelkia, Nasma, Kheira Benazouz, Amal Mameri, Lazhar Belkhiri, Nadia Hamri, Hayet Belkacemi, Abdelhalim Zoukel, Abdeltif Amrane, Fodil Aoulmi, and Lotfi Mouni. 2023. "Study and Characterization of H3PO4 Activated Carbons Prepared from Jujube Stones for the Treatment of Industrial Textile Effluents" Processes 11, no. 9: 2694. https://doi.org/10.3390/pr11092694