Advances in Fault Detection and Diagnosis for Thermal Power Plants: A Review of Intelligent Techniques

Abstract

:1. Introduction

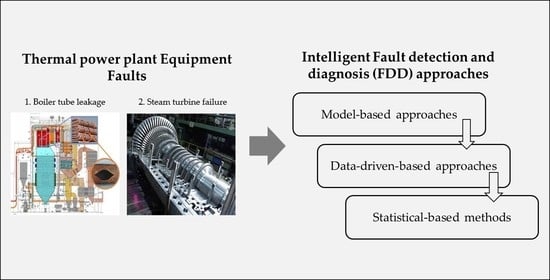

2. TPP Equipment and Common Faults: An Overview

2.1. Major Equipment in TPPs

- Boiler

- 2.

- Steam Turbine

- 3.

- Generator

- 4.

- Condenser

2.2. Common Faults in TPPs

2.2.1. Steam Turbine Faults

- Unbalancing and misalignment

- 2.

- Mechanical looseness

- 3.

- Actuator Fault

- 4.

- Thermocouple sensors fault

- 5.

- Fouling fault

- Vibration analysis: This involves measuring the vibration levels of the steam turbine components, and analyzing the data to detect any deviations from the normal operating conditions. Vibration analysis can help identify faults, such as unbalance, misalignment, or mechanical looseness [48].

- Thermography: This involves using thermal cameras to measure the temperature of the steam turbine components and detect any anomalies. Thermography can help to identify faults, such as a broken spindle or fouling [49].

- Acoustic monitoring: This involves listening for changes in the sound produced by the steam turbine, and analyzing the data to detect any deviations from the normal operating conditions. Acoustic monitoring can help to identify faults, such as mechanical looseness or bearing damage [50].

- Oil analysis: This involves testing the lubricating oil for contaminants or other signs of wear and tear, and analyzing the data to detect any anomalies. Oil analysis can help identify faults, such as actuator malfunction or a thermocouple sensor fault [51].

2.2.2. Boiler Tube Leakage

- Ultrasonic Testing: High-frequency sound waves are used to detect faults in the tubes. The location and size of the leak can be determined by transmitting sound waves through the tube wall [63].

- Eddy Current Testing: Magnetic fields are used to detect faults in the tubes. The location and size of the leak can be determined by inducing an eddy current in the tube wall [64].

- Leak Detection Dye: A water-soluble dye is injected into the steam system, and the location of the dye observed as it leaks out of the tubes. This can provide visual indication of the location and size of the leak [65].

- Pressure Testing: The pressure drop in the steam system is measured over time. A sudden drop in pressure can indicate a leak in the tubes.

- Thermographic Imaging: Infrared cameras are used to detect changes in temperature in the tubes. The location and size of the leak can be determined by detecting changes in temperature [66].

3. FDD Approaches in Intelligent TPPs

3.1. FDD Approaches for Steam Turbine

3.1.1. Model-Based Fault Detection

3.1.2. Data-Driven Based Fault Detection

3.1.3. Statistical Method-Based Fault Detection

3.2. Application of FDD Approaches in Boiler Tube Leakage Detection

3.2.1. Model-Based Methods

3.2.2. Data-Driven-Based Methods

3.2.3. Statistical Analysis Method

3.2.4. Comparative Analysis of Intelligent Techniques for TPPs

4. Challenges, Limitations, and Future Research Directions

4.1. Current Challenges and Limitations of FDD Techniques in TPPs

- One of the main challenges of FDD in TPPs is the complexity of the systems involved. Boilers and turbines are highly complex systems that involve a large number of components and processes, which can make it difficult to identify faults and diagnose problems. Additionally, the variability in the performance of these systems can make it difficult to establish normal operating conditions, which is essential for effective FDD.

- Another challenge of FDD in TPPs is the limited availability of data. In many cases, the data used for FDD are based on sensor readings, and these readings are often limited by the frequency and accuracy of the sensors. This can make it difficult to accurately diagnose problems and identify faults, especially when the data are incomplete or noisy.

- A third challenge of FDD in TPPs is the complexity of the algorithms used for analysis. Many of the FDD algorithms used in TPPs are based on artificial intelligence and machine learning techniques, which can be complex and difficult to implement. Additionally, these algorithms require significant computational resources, which can limit their ability to be applied in real-time.

- The limitations of FDD in TPPs also include issues related to maintenance and repair. In some cases, FDD algorithms may identify faults that are difficult to repair, or the cost of repair may be high. Additionally, the time required to repair faults may be longer than the time required to detect the faults, which can reduce the effectiveness of FDD.

- Another limitation of FDD in TPPs is the potential for false alarms. FDD algorithms can sometimes generate false alarms, which can result in unnecessary maintenance and repair activities. This can lead to increased costs, decreased efficiency, and reduced reliability of the power plant.

- Finally, FDD algorithms may not always be effective in detecting faults in all components of a TPP. For example, some faults may not be detectable by current FDD algorithms, or the algorithms may not be effective in detecting faults in certain types of equipment or processes.

4.2. Future Research Directions for FDD Techniques in TPPs

- ▪ Big Data and Advanced Analytics: With the increasing availability of data from sensors, SCADA systems, and other sources, advanced analytics techniques are needed to process these data and improve the accuracy of FDD algorithms. This could involve the use of machine learning and artificial intelligence algorithms, as well as the development of new approaches to data analysis that can better handle the complexity and variability of the data generated by TPPs.

- ▪ Real-Time Monitoring: To ensure the timely detection of faults and the effective diagnosis of problems, real-time monitoring techniques are required that can process data from sensors and other sources in near real-time. This will require the development of new algorithms and techniques that can process large amounts of data quickly and accurately, and the deployment of these algorithms in real-world TPPs.

- ▪ Integration of Multiple Sensors: To improve the accuracy of FDD algorithms, there is a need for the integration of multiple sensors and sources of data. This could involve the use of sensor fusion techniques, which can combine data from multiple sources to provide a more comprehensive view of the state of a system, as well as the development of new sensors and measurement techniques that can provide additional information about the operation of boilers and turbines.

- ▪ Predictive Maintenance: To improve the efficiency and reliability of TPPs, predictive maintenance techniques are required that can anticipate faults and problems before they occur. This could involve the use of machine learning and artificial intelligence algorithms to analyze data from sensors and other sources, as well as the development of new approaches to data analysis that can identify patterns and trends in the data.

- ▪ Energy Efficiency: To improve the energy efficiency of TPPs, FDD techniques are needed that can identify inefficiencies and opportunities for improvement. This could involve the use of advanced analytics techniques to analyze data from sensors and other sources, as well as the development of new algorithms and approaches that can better identify inefficiencies and improve the energy efficiency of boilers and turbines.

- ▪ Context-Aware FDD: To improve the accuracy of FDD algorithms, there is a need for context-aware techniques that can take into account the specific context of a TPP. This could involve the use of machine learning and artificial intelligence algorithms to analyze data from sensors and other sources, as well as the development of new algorithms that can better understand the context of a system and identify faults and problems more effectively.

- ▪ Cybersecurity: To ensure the security of TPPs, FDD techniques are needed that can detect and respond to cyber threats. These could involve the use of machine learning and artificial intelligence algorithms to detect and respond to cyberattacks, as well as the development of new techniques that can better protect TPPs from cyber threats.

- ▪ Cost-Effective Solutions: To ensure the widespread adoption of FDD techniques in TPPs, cost-effective solutions are necessary that can be implemented in real-world scenarios. These will require the development of new algorithms and techniques that can be implemented with limited computational resources, and the deployment of these algorithms in real-world TPPs.

5. Conclusions

- ▪ Model-based algorithms have become increasingly important in the operation of TPPs. These algorithms, which are based on mathematical models and simulations, allow power plants to analyze large amounts of data, and identify patterns and anomalies that may indicate faults. The use of model-based algorithms in conjunction with other digital technologies, such as artificial intelligence and machine learning, has enabled the development of sophisticated systems for continuous monitoring of the health of power plants and the detection of potential faults in real-time.

- ▪ Data-driven algorithms, such as statistical process control and condition monitoring, are also playing an important role in FDD. These algorithms allow power plants to collect and analyze vast amounts of data, providing insights into the performance and health of the system.

- ▪ Statistical methods, such as principal component analysis (PCA) and multivariate statistical analysis, are used to identify patterns and correlations in the data that can be used to detect faults. These methods can provide a quantitative measure of the relationship between different variables, and can be combined with other techniques, such as pattern recognition or machine learning algorithms, to enhance their performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial neural network |

| EMA | Exponential moving average filter |

| FDD | Fault detection and diagnosis |

| MPCA | Multiway PCA |

| PCA | Principal component analysis |

| SVM | Support vector machine |

| TPP | Thermal Power Plant |

References

- Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N.; Valdez, R. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques—Part I: Fault Diagnosis with Model-Based and Signal-Based Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef] [Green Version]

- Eguchi, S.; Takayabu, H.; Lin, C. Sources of Inefficient Power Generation by Coal-Fired Thermal Power Plants in China: A Metafrontier DEA Decomposition Approach. Renew. Sustain. Energy Rev. 2021, 138, 110562. [Google Scholar] [CrossRef]

- Mayadevi, N.; Vinodchandra, S.; Ushakumari, S. A Review on Expert System Applications in Power Plants. Int. J. Electr. Comput. Eng. 2014, 4, 116. [Google Scholar]

- Chen, H.; Pan, P.; Chen, X.; Wang, Y.; Zhao, Q. Fouling of the Flue Gas Cooler in a Large-Scale Coal-Fired Power Plant. Appl. Therm. Eng. 2017, 117, 698–707. [Google Scholar] [CrossRef]

- Shen, C.; Cirone, C.; Jacobi, A.M.; Wang, X. Fouling of Enhanced Tubes for Condensers Used in Cooling Tower Systems: A Literature Review. Appl. Therm. Eng. 2015, 79, 74–87. [Google Scholar] [CrossRef]

- Rahmani, K.; Jadidian, R.; Haghtalab, S. Evaluation of Inhibitors and Biocides on the Corrosion, Scaling and Biofouling Control of Carbon Steel and Copper–Nickel Alloys in a Power Plant Cooling Water System. Desalination 2016, 393, 174–185. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, X.; Qiao, J.; Tan, L.; Xu, W.; Li, W. Generator Stator Windings Ground Fault Diagnosis for Generator–Grid Directly Connected System of Floating Nuclear Power Plant. Energy Rep. 2021, 7, 460–469. [Google Scholar] [CrossRef]

- Ciupek, B.; Gołoś, K.; Jankowski, R.; Nadolny, Z. Effect of Hard Coal Combustion in Water Steam Environment on Chemical Composition of Exhaust Gases. Energies 2021, 14, 6530. [Google Scholar] [CrossRef]

- Shahzad Baig, K.; Yousaf, M. Coal Fired Power Plants: Emission Problems and Controlling Techniques. J. Earth Sci. Clim. Chang. 2017, 8, 2. [Google Scholar]

- Chen, J.; Patton, R.J. Robust. Model-Based Fault Diagnosis for Dynamic Systems; Springer Science & Business Media: Berlin, Germany, 2012; Volume 3, ISBN 1-4615-5149-8. [Google Scholar]

- Ding, S.X. Model-Based Fault Diagnosis Techniques: Design Schemes, Algorithms, and Tools; Springer Science & Business Media: Berlin, Germany, 2008; ISBN 3-540-76304-X. [Google Scholar]

- Xu, G.; Liu, M.; Wang, J.; Ma, Y.; Wang, J.; Li, F.; Shen, W. Data-Driven Fault Diagnostics and Prognostics for Predictive Maintenance: A Brief Overview. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 103–108. [Google Scholar]

- Gangsar, P.; Tiwari, R. Signal Based Condition Monitoring Techniques for Fault Detection and Diagnosis of Induction Motors: A State-of-the-Art Review. Mech. Syst. Signal. Process. 2020, 144, 106908. [Google Scholar] [CrossRef]

- Khalid, S.; Lim, W.; Kim, H.S.; Oh, Y.T.; Youn, B.D.; Kim, H.-S.; Bae, Y.-C. Intelligent Steam Power Plant Boiler Waterwall Tube Leakage Detection via Machine Learning-Based Optimal Sensor Selection. Sensors 2020, 20, 6356. [Google Scholar] [CrossRef]

- Ali, J.B.; Fnaiech, N.; Saidi, L.; Chebel-Morello, B.; Fnaiech, F. Application of Empirical Mode Decomposition and Artificial Neural Network for Automatic Bearing Fault Diagnosis Based on Vibration Signals. Appl. Acoust. 2015, 89, 16–27. [Google Scholar]

- Zhou, P.; Zhang, R.; Xie, J.; Liu, J.; Wang, H.; Chai, T. Data-Driven Monitoring and Diagnosing of Abnormal Furnace Conditions in Blast Furnace Ironmaking: An Integrated PCA-ICA Method. IEEE Trans. Ind. Electron. 2020, 68, 622–631. [Google Scholar] [CrossRef]

- Chemweno, P.K.; Pintelon, L. Towards E-Maintenance: An Exploration Approach for Aircraft Maintenance Data. In Applications and Challenges of Maintenance and Safety Engineering in Industry 4.0; IGI Global: Hershey, PA, USA, 2020; pp. 189–212. [Google Scholar]

- Razmi-Farooji, A.; Kropsu-Vehkaperä, H.; Härkönen, J.; Haapasalo, H. Advantages and Potential Challenges of Data Management in E-Maintenance. J. Qual. Maint. Eng. 2019, 25, 378–396. [Google Scholar] [CrossRef]

- Sohaib, M.; Kim, J.-M. Data Driven Leakage Detection and Classification of a Boiler Tube. Appl. Sci. 2019, 9, 2450. [Google Scholar] [CrossRef] [Green Version]

- Sohaib, M.; Islam, M.; Kim, J.; Jeon, D.-C.; Kim, J.-M. Leakage Detection of a Spherical Water Storage Tank in a Chemical Industry Using Acoustic Emissions. Appl. Sci. 2019, 9, 196. [Google Scholar] [CrossRef] [Green Version]

- Khalid, S.; Hwang, H.; Kim, H.S. Real-World Data-Driven Machine-Learning-Based Optimal Sensor Selection Approach for Equipment Fault Detection in a Thermal Power Plant. Mathematics 2021, 9, 2814. [Google Scholar] [CrossRef]

- Nurbanasari, M. Abdurrachim Investigation of Leakage on Water Wall Tube in a 660 MW Supercritical Boiler. J. Fail. Anal. Preven. 2014, 14, 657–661. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Kim, J.; Kim, J.-M. Leakage Detection of a Boiler Tube Using a Genetic Algorithm-like Method and Support Vector Machines. In Proceedings of the 10th International Conference on Soft Computing and Pattern Recognition (SoCPaR 2018), Porto, Portugal, 13–15 December 2018. [Google Scholar] [CrossRef]

- Kokkinos, A. Coal R&D Beyond 2020. In DOE-NETL-EPRI Technical Exchange Meeting; EPRI: Pittsburgh, PA, USA, 2019. [Google Scholar]

- Lang, F.D.; Rodgers, D.A.; Mayer, L.E. Detection of Tube Leaks and Their Location Using Input/Loss Methods; AMSE: New York, NY, USA, 2004; Volume 41626, pp. 143–150. [Google Scholar]

- Qiu, J.; Wu, Q.; Ding, G.; Xu, Y.; Feng, S. A Survey of Machine Learning for Big Data Processing. EURASIP J. Adv. Signal. Process. 2016, 2016, 1–16. [Google Scholar]

- Zhou, L.; Pan, S.; Wang, J.; Vasilakos, A.V. Machine Learning on Big Data: Opportunities and Challenges. Neurocomputing 2017, 237, 350–361. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Fu, Z.; Zhen, L. Thermal Power Generation Fault Diagnosis and Prediction Model Based on Deep Learning and Multimedia Systems. Multimed. Tools Appl. 2019, 78, 4673–4692. [Google Scholar] [CrossRef]

- Hundi, P.; Shahsavari, R. Comparative Studies among Machine Learning Models for Performance Estimation and Health Monitoring of Thermal Power Plants. Appl. Energy 2020, 265, 114775. [Google Scholar] [CrossRef]

- Cui, Y.; Xia, L.; Huang, Y.; Ma, X. Research on Fault Diagnosis and Early Warning of Power Plant Boiler Reheater Temperature Deviation Based on Machine Learning Algorithm. In Proceedings of the 2020 IEEE 6th International Conference on Control Science and Systems Engineering (ICCSSE), Beijing, China, 17–19 July 2020; pp. 212–216. [Google Scholar]

- Dhini, A.; Surjandari, I.; Kusumoputro, B.; Kusiak, A. Extreme Learning Machine–Radial Basis Function (ELM-RBF) Networks for Diagnosing Faults in a Steam Turbine. J. Ind. Prod. Eng. 2022, 39, 572–580. [Google Scholar] [CrossRef]

- Ghiasi, M.; Niknam, T.; Dehghani, M.; Baghaee, H.R.; Wang, Z.; Ghanbarian, M.M.; Blaabjerg, F.; Dragicevic, T. Multipurpose FCS Model Predictive Control of VSC-Based Microgrids for Islanded and Grid-Connected Operation Modes. IEEE Syst. J. 2022, 1–12. [Google Scholar] [CrossRef]

- Ghiasi, M.; Wang, Z.; Mehrandezh, M.; Jalilian, S.; Ghadimi, N. Evolution of Smart Grids towards the Internet of Energy: Concept and Essential Components for Deep Decarbonisation. IET Smart Grid 2023, 6, 86–102. [Google Scholar] [CrossRef]

- Ghiasi, M. Detailed Study, Multi-Objective Optimization, and Design of an AC-DC Smart Microgrid with Hybrid Renewable Energy Resources. Energy 2019, 169, 496–507. [Google Scholar] [CrossRef]

- Alobaid, F.; Mertens, N.; Starkloff, R.; Lanz, T.; Heinze, C.; Epple, B. Progress in Dynamic Simulation of Thermal Power Plants. Prog. Energy Combust. Sci. 2017, 59, 79–162. [Google Scholar] [CrossRef]

- Dmitrienko, M.A.; Strizhak, P.A. Coal-Water Slurries Containing Petrochemicals to Solve Problems of Air Pollution by Coal Thermal Power Stations and Boiler Plants: An Introductory Review. Sci. Total Environ. 2018, 613, 1117–1129. [Google Scholar] [CrossRef]

- Chaibakhsh, A.; Ghaffari, A. Steam Turbine Model. Simul. Model. Pract. Theory 2008, 16, 1145–1162. [Google Scholar] [CrossRef]

- Drbal, L.; Westra, K.; Boston, P. Power Plant Engineering; Springer Science & Business Media: Berlin, Germany, 2012; ISBN 1-4613-0427-X. [Google Scholar]

- Attia, S.I. The Influence of Condenser Cooling Water Temperature on the Thermal Efficiency of a Nuclear Power Plant. Ann. Nucl. Energy 2015, 80, 371–378. [Google Scholar] [CrossRef]

- Lakzian, E.; Yazdani, S.; Lee, B.J. Passive Control Optimization of Condensation Flow in Steam Turbine Blades. Int. J. Mech. Sci. 2022, 237, 107804. [Google Scholar] [CrossRef]

- Dhini, A.; Kusumoputro, B.; Surjandari, I. Neural Network Based System for Detecting and Diagnosing Faults in Steam Turbine of Thermal Power Plant. In Proceedings of the 2017 IEEE 8th International Conference on Awareness Science and Technology (iCAST), Taichung, Taiwan, 8–10 November 2017; pp. 149–154. [Google Scholar]

- Cai, W.; Lu, S.; Wu, Z.; Ying, G.; Wu, W. Strategy and Technique of High Efficiency Balancing in Field for Turbo-Generator Units with Large Capacity. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 2101, p. 012011. [Google Scholar]

- Hou, P.; Ma, H.; Liu, B.; Chen, X.; Zhu, C.; Tan, F. Mechanical Fault Diagnosis of Reactor Core Winding Looseness Based on Multi-Feature Fusion and Improved KELM. In Proceedings of the 2021 IEEE Sustainable Power and Energy Conference (iSPEC), Nanjing, China, 23–25 December 2021; pp. 3927–3932. [Google Scholar]

- Reyes-Martínez, J.; Astorga-Zaragoza, C.-M.; Madrigal-Espinosa, G.; Chadli, M.; Vargas-Méndez, R.-A.; Osorio-Gordillo, G.-L.; Reyes-Reyes, J. Actuator Fault Compensation Based on a Takagi-Sugeno PI Observer: Application to a Thermoelectric Steam Generator. Int. J. Fuzzy Syst. 2022, 24, 855–866. [Google Scholar] [CrossRef]

- Weigel, B.V.; Odenbach, S.; Uffrecht, W.; Polklas, T. Thermal Characterization of a Steam Turbine Casing Including Measuring of Adiabatic Wall Temperatures Using Proprietary Sensors. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2021; Volume 85017, p. V008T22A011. [Google Scholar]

- Nayeri, M.R.; Araabi, B.; Moshiri, B. Fault Detection and Isolation of Gas Turbine: Hierarchical Classification and Confidence Rate Computation. J. Frankl. Inst. 2022, 17, 10120–10144. [Google Scholar] [CrossRef]

- Zhao, W.; Li, Y.; Xue, M.; Wang, P.; Jiang, J. Vibration Analysis for Failure Detection in Low Pressure Steam Turbine Blades in Nuclear Power Plant. Eng. Fail. Anal. 2018, 84, 11–24. [Google Scholar] [CrossRef]

- Talai, S.M.; Desai, D.A.; Heyns, P.S. Infrared Thermography Applied to the Prediction of Structural Vibration Behaviour. Alex. Eng. J. 2019, 58, 603–610. [Google Scholar] [CrossRef]

- Uekita, M.; Takaya, Y. Tool Condition Monitoring for Form Milling of Large Parts by Combining Spindle Motor Current and Acoustic Emission Signals. Int. J. Adv. Manuf. Technol. 2017, 89, 65–75. [Google Scholar] [CrossRef]

- Pondini, M.; Colla, V.; Signorini, A. Models of Control Valve and Actuation System for Dynamics Analysis of Steam Turbines. Appl. Energy 2017, 207, 208–217. [Google Scholar] [CrossRef]

- Szymański, K.; Hernas, A.; Moskal, G.; Myalska, H. Thermally Sprayed Coatings Resistant to Erosion and Corrosion for Power Plant Boilers—A Review. Surf. Coat. Technol. 2015, 268, 153–164. [Google Scholar] [CrossRef]

- Singh, P.M.; Mahmood, J. Stress Assisted Corrosion of Waterwall Tubes in Recovery Boiler Tubes: Failure Analysis. J. Fail. Anal. Preven. 2007, 7, 361–370. [Google Scholar] [CrossRef]

- Lee, N.-H.; Kim, S.; Choe, B.-H.; Yoon, K.-B.; Kwon, D. Failure Analysis of a Boiler Tube in USC Coal Power Plant. Eng. Fail. Anal. 2009, 16, 2031–2035. [Google Scholar] [CrossRef]

- Indrawan, N.; Shadle, L.J.; Breault, R.W.; Panday, R.; Chitnis, U.K. Data Analytics for Leak Detection in a Subcritical Boiler. Energy 2021, 220, 119667. [Google Scholar] [CrossRef]

- Che, C.; Qian, G.; Yang, X.; Liu, X. Fatigue Damage of Waterwall Tubes in a 1000 MW USC Boiler. In Proceedings of the 7th International Conference on Fracture Fatigue and Wear; Lecture Notes in Mechanical Engineering; Abdel Wahab, M., Ed.; Springer: Singapore, 2019; pp. 314–324. ISBN 9789811304101. [Google Scholar]

- Singh, W.S.; Rao, B.P.; Mukhopadhyay, C.K.; Jayakumar, T. Detection of Localized Damage in Water Wall Tubes of Thermal Power Plants Using GMR Sensor Array Based Magnetic Flux Leakage Technique. J. Nondestruct. Eval. 2015, 34, 19. [Google Scholar] [CrossRef]

- Yang, G.; Gou, Y.; Liu, X.; Zhang, X.; Zhang, T. Failure Analysis of the Corroded Water Wall Tube in a 50MW Thermal Power Plant. High Temp. Mater. Process. 2018, 37, 995–999. [Google Scholar] [CrossRef]

- Xue, S.; Guo, R.; Hu, F.; Ding, K.; Liu, L.; Zheng, L.; Yang, T. Analysis of the Causes of Leakages and Preventive Strategies of Boiler Water-Wall Tubes in a Thermal Power Plant. Eng. Fail. Anal. 2020, 110, 104381. [Google Scholar] [CrossRef]

- Purbolaksono, J.; Ahmad, J.; Beng, L.; Rashid, A.; Khinani, A.; Ali, A. Failure Analysis on a Primary Superheater Tube of a Power Plant. Eng. Fail. Anal. 2010, 17, 158–167. [Google Scholar] [CrossRef]

- Ranjbar, K. Failure Analysis of Boiler Cold and Hot Reheater Tubes. Eng. Fail. Anal. 2007, 14, 620–625. [Google Scholar] [CrossRef]

- Ahmad, J.; Purbolaksono, J.; Beng, L.C.; Rashid, A.Z.; Khinani, A.; Ali, A.A. Failure Investigation on Rear Water Wall Tube of Boiler. Eng. Fail. Anal. 2009, 16, 2325–2332. [Google Scholar] [CrossRef]

- Mandeliya, M.; Vishwakarma, M. A Review on Boiler Tube Assessment in Power Plant Using Ultrasonic Testing. Int. Res. J. Eng. Technol. 2018, 5, 708–714. [Google Scholar]

- Thekkuden, D.T.; Mourad, A.-H.I.; Bouzid, A.-H. Failures and Leak Inspection Techniques of Tube-to-Tubesheet Joints: A Review. Eng. Fail. Anal. 2021, 130, 105798. [Google Scholar] [CrossRef]

- Erenburg, B.; Zilberberg, A.; Iskevitch, E. Cracking of AISI T22 Reheater Pendant Assembly Tubing of Steam Boiler. J. Fail. Anal. Prev. 2019, 19, 320–327. [Google Scholar] [CrossRef]

- Guan, H.; Xiao, T.; Luo, W.; Gu, J.; He, R.; Xu, P. Automatic Fault Diagnosis Algorithm for Hot Water Pipes Based on Infrared Thermal Images. Build. Environ. 2022, 218, 109111. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, G.; An, L. Online Monitoring of Furnace Exit Gas Temperature in Power Plants. Appl. Therm. Eng. 2019, 147, 917–926. [Google Scholar] [CrossRef]

- Zhang, C.; Li, D.; Mu, Y.; Song, D. An Interval-Valued Hesitant Fuzzy Multigranulation Rough Set over Two Universes Model for Steam Turbine Fault Diagnosis. Appl. Math. Model. 2017, 42, 693–704. [Google Scholar] [CrossRef]

- Sun, X.; Chen, T.; Marquez, H.J. Boiler Leak Detection Using a System Identification Technique. Ind. Eng. Chem. Res. 2002, 41, 5447–5454. [Google Scholar] [CrossRef]

- Que, Z.; Xu, Z. A Data-Driven Health Prognostics Approach for Steam Turbines Based on Xgboost and Dtw. IEEE Access 2019, 7, 93131–93138. [Google Scholar] [CrossRef]

- Ko, J.U.; Na, K.; Oh, J.-S.; Kim, J.; Youn, B.D. A New Auto-Encoder-Based Dynamic Threshold to Reduce False Alarm Rate for Anomaly Detection of Steam Turbines. Expert Syst. Appl. 2022, 189, 116094. [Google Scholar] [CrossRef]

- Diatte, K.; O’Halloran, B.; Van Bossuyt, D.L. The Integration of Reliability, Availability, and Maintainability into Model-Based Systems Engineering. Systems 2022, 10, 101. [Google Scholar] [CrossRef]

- Cano, S.; Rodríguez, J.; Rodríguez, J.; García, J.; Sierra, F.; Casolco, S.; Herrera, M. Detection of Damage in Steam Turbine Blades Caused by Low Cycle and Strain Cycling Fatigue. Eng. Fail. Anal. 2019, 97, 579–588. [Google Scholar] [CrossRef]

- Salahshoor, K.; Kordestani, M.; Khoshro, M.S. Fault Detection and Diagnosis of an Industrial Steam Turbine Using Fusion of SVM (Support Vector Machine) and ANFIS (Adaptive Neuro-Fuzzy Inference System) Classifiers. Energy 2010, 35, 5472–5482. [Google Scholar] [CrossRef]

- Salahshoor, K.; Khoshro, M.S.; Kordestani, M. Fault Detection and Diagnosis of an Industrial Steam Turbine Using a Distributed Configuration of Adaptive Neuro-Fuzzy Inference Systems. Simul. Model. Pract. Theory 2011, 19, 1280–1293. [Google Scholar] [CrossRef]

- Li, G.; Zhao, Q. Minimum Entropy Deconvolution Optimized Sinusoidal Synthesis and Its Application to Vibration Based Fault Detection. J. Sound Vib. 2017, 390, 218–231. [Google Scholar] [CrossRef]

- Hassan Shah, M.Z.; Ahmed, Z.; Hu, L. Feature Extraction and Fault Detection Scheme via Improved Locality Preserving Projection and SVDD. Trans. Inst. Meas. Control 2022, 45, 01423312221099855. [Google Scholar] [CrossRef]

- Huang, B.; Hu, L.-S. A Geometrically Inspired Quantification Approach for Valve Stiction Using Riemannian Logarithmic Map. Measurement 2022, 199, 111562. [Google Scholar] [CrossRef]

- Salahshoor, K.; Kordestani, M. Design of an Active Fault Tolerant Control System for a Simulated Industrial Steam Turbine. Appl. Math. Model. 2014, 38, 1753–1774. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Yuan, Y.; Hu, L.-S. Fault Detection Based on Graph Model for Dead Zone of Steam Turbine Control Valve. Int. J. Control Autom. Syst. 2022, 20, 2759–2767. [Google Scholar] [CrossRef]

- Shah, M.Z.H.; Hu, L.; Ahmed, Z. Modified LPP Based on Riemannian Metric for Feature Extraction and Fault Detection. Measurement 2022, 193, 110923. [Google Scholar] [CrossRef]

- Yan, J.; Lv, M.; Wang, P.; Wang, M. Kalman Filter Based Neural Network Methodology for Predictive Maintenance: A Case Study on Steam Turbine Blade Performance Prognostics. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Chicago, IL, USA, 5–10 November 2006; Volume 47748, pp. 271–276. [Google Scholar]

- Baraldi, P.; Di Maio, F.; Rigamonti, M.; Zio, E.; Seraoui, R. Clustering for Unsupervised Fault Diagnosis in Nuclear Turbine Shut-down Transients. Mech. Syst. Signal Process. 2015, 58, 160–178. [Google Scholar] [CrossRef]

- Jiang, J.; Ma, X.; Ouyang, D.; Williams, R.O. Emerging Artificial Intelligence (AI) Technologies Used in the Development of Solid Dosage Forms. Pharmaceutics 2022, 14, 2257. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Wu, J.; Deng, C.; Jiang, W. Wide Residual Relation Network-Based Intelligent Fault Diagnosis of Rotating Machines with Small Samples. Sensors 2022, 22, 4161. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.-Y.; Chen, L.-S.; Chen, M.-C.; Lee, C.-L. Using SVM Based Method for Equipment Fault Detection in a Thermal Power Plant. Comput. Ind. 2011, 62, 42–50. [Google Scholar] [CrossRef]

- Ashraf, W.M.; Rafique, Y.; Uddin, G.M.; Riaz, F.; Asim, M.; Farooq, M.; Hussain, A.; Salman, C.A. Artificial Intelligence Based Operational Strategy Development and Implementation for Vibration Reduction of a Supercritical Steam Turbine Shaft Bearing. Alex. Eng. J. 2022, 61, 1864–1880. [Google Scholar] [CrossRef]

- Que, Z.J.; Xiong, Y.; Xu, Z.G. A Semi-Supervised Approach for Steam Turbine Health Prognostics Based on GAN and PF. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 1476–1480. [Google Scholar]

- Fang, M.; Xu, Z. Vibration Fault Diagnosis for Steam Turbine-Generators Based on History Cases and Artificial Neural Network. In Proceedings of the 2018 2nd IEEE Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Xi’an, China, 25–27 May 2018; pp. 747–753. [Google Scholar]

- Wang, C.; Zhang, D.; Xie, Y. Research on Fault Diagnosis of Steam Turbine Rotor Unbalance and Parallel Misalignment Based on Numerical Simulation and Convolutional Neural Network. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2021; Volume 85017, p. V008T22A019. [Google Scholar]

- Helin, M. Fault Detection in Steam Turbines Using Data-Driven Methods. Master’s Thesis, Aalto University, Espoo, Finland, 2020. [Google Scholar]

- Satyanarayana, K.; Sarcar, M.M.M.; Purushothaman, S. Implementation of Locally Weighted Projection Regression Network for Condition Monitoring of a Steam Turbine. Artif. Intell. Syst. Mach. Learn. 2012, 4, 574–577. [Google Scholar]

- Komatsu, K.; Miyazawa, H.; Yiran, C.; Sato, M.; Furusawa, T.; Yamamoto, S.; Kobayashi, H. Detection of Machinery Failure Signs From Big Time-Series Data Obtained by Flow Simulation of Intermediate-Pressure Steam Turbines. J. Eng. Gas Turbines Power 2022, 144, 011007. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Sheng, D.; Chen, J.; Yu, Z. Fault Diagnosis Method of Peak-Load-Regulation Steam Turbine Based on Improved PCA-HKNN Artificial Neural Network. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2021, 235, 1026–1040. [Google Scholar] [CrossRef]

- Zhao, G.; Jiang, D.; Diao, J.; Qian, L. Application of Wavelet Time-Frequency Analysis on Fault Diagnosis for Steam Turbine. In Proceedings of the 5th International Conference of Acoustical and Vibratory Surveillance Methods and Diagnostic Techniques, Senlis, France, 11–13 October 2004. [Google Scholar]

- Ajami, A.; Daneshvar, M. Data Driven Approach for Fault Detection and Diagnosis of Turbine in Thermal Power Plant Using Independent Component Analysis (ICA). Int. J. Electr. Power Energy Syst. 2012, 43, 728–735. [Google Scholar] [CrossRef]

- Mubaraali, L.; Kuppuswamy, N.; Muthukumar, R. Intelligent Fault Diagnosis in Microprocessor Systems for Vibration Analysis in Roller Bearings in Whirlpool Turbine Generators Real Time Processor Applications. Microprocess. Microsyst. 2020, 76, 103079. [Google Scholar] [CrossRef]

- Lin, W.-M.; Wu, C.-H.; Lin, C.-H.; Su, C.-H. Grey Clustering Analysis Based Classifier for Steam Turbine-Generator Fault Diagnosis. In Proceedings of the 2007 International Conference on Intelligent Systems Applications to Power Systems, Kaohsiung, Taiwan, 5–8 November 2007; pp. 1–6. [Google Scholar]

- Zhang, X.; Chen, S.; Zhu, Y.; Yan, W. Fault Detection and Diagnosis for Steam Turbine Based on Kernel GDA. In Proceedings of the Proceedings of 2011 International Conference on Modelling, Identification and Control, Shanghai, China, 26–29 June 2011; pp. 58–62. [Google Scholar]

- Bae, S.J.; Mun, B.M.; Chang, W.; Vidakovic, B. Condition Monitoring of a Steam Turbine Generator Using Wavelet Spectrum Based Control Chart. Reliab. Eng. Syst. Saf. 2019, 184, 13–20. [Google Scholar] [CrossRef]

- Panday, R.; Indrawan, N.; Shadle, L.J.; Vesel, R.W. Leak Detection in a Subcritical Boiler. Appl. Therm. Eng. 2021, 185, 116371. [Google Scholar] [CrossRef]

- Sun, X.; Chen, T.; Marquez, H.J. Efficient Model-Based Leak Detection in Boiler Steam-Water Systems. Comput. Chem. Eng. 2002, 26, 1643–1647. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Upadhyaya, B.R.; Coffey, L.A. Model-Based Monitoring and Fault Diagnosis of Fossil Power Plant Process Units Using Group Method of Data Handling. ISA Trans. 2009, 48, 213–219. [Google Scholar] [CrossRef]

- David, N.P.; Swaminathan, B. Modeling, Identification and Detection of Faults in Industrial Boiler(July2015). In Proceedings of the 2015 IEEE Technological Innovation in ICT for Agriculture and Rural Development (TIAR), Chennai, India, 10–12 July 2015; pp. 197–201. [Google Scholar]

- Afgan, N.; Coelho, P.J.; Carvalho, M.G. Boiler Tube Leakage Detection Expert System. Appl. Therm. Eng. 1998, 18, 317–326. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Xiong, J.; Xiao, M.; Sun, G.; He, J. Fault Diagnosis of a Rolling Bearing Using Wavelet Packet Denoising and Random Forests. IEEE Sens. J. 2017, 17, 5581–5588. [Google Scholar] [CrossRef]

- Swiercz, M.; Mroczkowska, H. Multiway PCA for Early Leak Detection in a Pipeline System of a Steam Boiler—Selected Case Studies. Sensors 2020, 20, 1561. [Google Scholar] [CrossRef] [Green Version]

- Rostek, K.; Morytko, Ł.; Jankowska, A. Early Detection and Prediction of Leaks in Fluidized-Bed Boilers Using Artificial Neural Networks. Energy 2015, 89, 914–923. [Google Scholar] [CrossRef]

- Ramezani, M.G.; Hasanian, M.; Golchinfar, B.; Saboonchi, H. Automatic Boiler Tube Leak Detection with Deep Bidirectional LSTM Neural Networks of Acoustic Emission Signals. Sens. Smart Struct. Technol. Civ. Mech. Aerosp. Syst. 2020, 11379, 113791I. [Google Scholar] [CrossRef]

- Rakhshani, E.; Sariri, I.; Rouzbehi, K. Application of Data Mining on Fault Detection and Prediction in Boiler of Power Plant Using Artificial Neural Network. In Proceedings of the 2009 International Conference on Power Engineering, Energy and Electrical Drives, Lisbon, Portugal, 18–20 March 2009; pp. 473–478. [Google Scholar]

- Jing, C.; Hou, J. SVM and PCA Based Fault Classification Approaches for Complicated Industrial Process. Neurocomputing 2015, 167, 636–642. [Google Scholar] [CrossRef]

- Yu, J.; Yoo, J.; Jang, J.; Park, J.H.; Kim, S. A Novel Plugged Tube Detection and Identification Approach for Final Super Heater in Thermal Power Plant Using Principal Component Analysis. Energy 2017, 126, 404–418. [Google Scholar] [CrossRef]

- Sun, X.; Marquez, H.J.; Chen, T.; Riaz, M. An Improved PCA Method with Application to Boiler Leak Detection. ISA Trans. 2005, 44, 379–397. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Jang, J.; Yoo, J.; Park, J.H.; Kim, S. A Clustering-Based Fault Detection Method for Steam Boiler Tube in Thermal Power Plant. J. Electr. Eng. Technol. 2016, 11, 848–859. [Google Scholar] [CrossRef] [Green Version]

- Tian, Z.; Xu, L.; Yuan, J.; Zhang, X.; Wang, J. Online Performance Monitoring Platform Based on the Whole Process Models of Subcritical Coal-Fired Power Plants. Appl. Therm. Eng. 2017, 124, 1368–1381. [Google Scholar] [CrossRef]

- Cai, J.; Ma, X.; Li, Q. On-Line Monitoring the Performance of Coal-Fired Power Unit: A Method Based on Support Vector Machine. Appl. Therm. Eng. 2009, 29, 2308–2319. [Google Scholar] [CrossRef]

- Duong, B.P.; Kim, J.; Kim, C.-H.; Kim, J.-M. Deep Learning Object-Impulse Detection for Enhancing Leakage Detection of a Boiler Tube Using Acoustic Emission Signal. Appl. Sci. 2019, 9, 4368. [Google Scholar] [CrossRef] [Green Version]

- Moradi, M.; Chaibakhsh, A.; Ramezani, A. An Intelligent Hybrid Technique for Fault Detection and Condition Monitoring of a Thermal Power Plant. Appl. Math. Model. 2018, 60, 34–47. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Hu, L.-S. Fault Propagation Inference Based on a Graph Neural Network for Steam Turbine Systems. Energies 2021, 14, 309. [Google Scholar] [CrossRef]

- Brkovic, A.; Gajic, D.; Gligorijevic, J.; Savic-Gajic, I.; Georgieva, O.; Di Gennaro, S. Early Fault Detection and Diagnosis in Bearings for More Efficient Operation of Rotating Machinery. Energy 2017, 136, 63–71. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, S.; Gao, W.; Shen, T. Vibration Fault Diagnosis of Steam Turbine Shafting Based on Probability Neural Networks. In Proceedings of the 2008 Congress on Image and Signal Processing, Sanya, China, 27–30 May 2008; Volume 5, pp. 582–585. [Google Scholar]

| Fault Detection Approach | Fault/Consequence | Outcome |

|---|---|---|

| Integrated SVM with ANFIS [74] | List of different faults, such as, fouling, TS, boiler pressure. | The proposed FDD system is primarily appealing due to the potential advantages of lowering maintenance costs, increased productivity, and enhanced steam turbine accessibility. |

| ANFIS technique [75] | Various faults: Boiler pressure, fouling, TS, etc. | The proposed FDD model showed the generalization capabilities for variable operating conditions, such as alteration in the fault behavior over time. |

| MEDSS model using Kalman filter [76] | Rotor-to-stator rubbing fault. | The MEDSS filter has demonstrated promise in detecting distinctive uncontrollable fault attributes in rotating machines, particularly in low SNR scenarios. |

| Kalman filter [82] | Turbine blade fault due to fatigue. | By assessing deterioration severity and replacement scheduling, overall performance and reliability prediction can be used to enhance accessibility and implement maintenance until failure happens. |

| ILPP scheme using Riemannian metric [77] | Fouling fault. | The performance of the proposed approached is effective, as compared to the other conventional techniques. |

| Riemannian algorithm [78] | Valve stiction fault of the steam turbine. | Applicability of the approach in both single control loop and cascaded control loop. |

| FTC approach [45] | Actuator fault. | Applicable to use in broader range of situations with strong nonlinear dynamics. |

| FTC approach based on ANFIS [79] | Various faults: actuator fault, TS fault, fouling, etc. | Applicability of the proposed FTC approach under various types of steam turbine fault circumstances. |

| Graph model approach [80] | Control valve fault | Effectively applicable in the real industrial environment, enhancing economic advantages and execution safety. |

| MLPP based on Riemannian [81] | Blades fouled fault | Applicable under variable operating conditions (validated using various noisy conditions). |

| Unsupervised fuzzy C-means (FCM) algorithm [83] | Misaligned and amplified data | Generalization and capable of working on unseen data. |

| Approach | Fault | Outcomes |

|---|---|---|

| Neural network with PCA [42] | Various faults, such as misalignment, robot bowing, blade erosion. | Good classification performance under real industrial applications. |

| SVM based fault classification [86] | Various faults such as flow, erosion of blade, failure of bearing, etc. | The presented work is capable of real application. |

| Extreme learning machine-radial basis function networks (ELMRBF) approach [32] | Various faults in the turbine, such as case cracking, blade cracking, rotor bowing, misalignment. | This study identifies characteristics that have a significant impact on the given specification. |

| ANN and SVM based FDD [87] | Bearing fault of the steam turbine | Vibration reduction of the bearing of the steam turbine’s high-speed shaft can inhibit downtimes and costly maintenance, contributing to the machinery’s safe and constant execution. |

| Semi-supervised model based on GAN and PF [88] | Anomaly detection: generator power is used as a health indicator (HI) | Applicable in the real application, and can be used to determine the HI and RUL. |

| Feature extraction based on ANN [89] | Imbalance and rubbing | The extracted feature outperforms the conventional feature based on EMD. |

| Residual network [90] | Misalignment and imbalance | This solves the limitations of traditional techniques, and reduces the computational cost. |

| Various approaches, such as unsupervised, PCA, and NN based autoencoder [91] | Anomaly detection of steam turbine | Long-term data are utilized; hence, the problem evaluation on big data (two years) is considered, which effectively detects anomalies in the steam turbine. |

| ANN approach [92] | Steam turbine bearing fault | Computationally less expensive model, as compared to previous models. |

| Deep learning based wide residual relation network (WRRN) [85] | Imbalance, misalignment | It is demonstrated that the WRRN can reliably detect rotating machine fault types using small, or even single, samples. |

| FDD Approach | Fault/Signal Type | Advantages |

|---|---|---|

| CWT approach [95] | Vibration signal with various kinds of faults, such as rubbing, oil whip, looseness, loss of component, unbalance. | The proposed model is effective, and can potentially be used in real-world application. |

| CWT based SF and HT combined with M-PH [97] | Vibration data, bearing fault. | The proposed method outperforms other approaches in terms of fault signal extraction and fault diagnosis of low-speed bearings. |

| Kernel generalized discriminant analysis (KGDA) [99] | Vibration data/various kind of fault; unbalance, misalignment, oil whip, radial rubbing. | This approach captures the nonlinear correlation, and proficiently synthesizes changing information in multiple process factors. |

| ICA based statistical approach [96] | Different thermal parameters related to the flow. | The model can compensate for environmental and model uncertainty. |

| GCA analysis based on FFT [98] | Vibration signal. | Ease of implementation, practical application with high accuracy. |

| Wavelet spectrum based FDD of turbine generator [100] | Thermal signal measurement. | The early fault can be detected using the energy profile based on wavelet spectrum. |

| FDD Approach | Fault | Advantages |

|---|---|---|

| Exponential Moving average filter and Kalman Filter [101] | Economizer tube leakage detection. | The proposed technique was simple, and can be extended to other sections of the boiler. |

| Least square algorithm [69,102,103] | Complete boiler. | Provided a simple and effective solution based on heat and mass balance relationships. |

| GMDH Model [103] | High-pressure feed water heater. | Simple and effective methods based on heat mass balance relationships. |

| Input/loss method [26] | Generator tubes and heat ex-changers. | Ease of implementation in real power plant, and effective in predicting tube leaks. |

| Kalman filter algorithm [104] | Complete Subsystems of the boiler. | Practical application with high accuracy. |

| Approach | Fault | Outcomes |

|---|---|---|

| ANN [42] | Various faults, including 12 faults of fluidized bed boiler. | Real world industrial applicability. |

| Expert system [105] | Waterwall tube leakage. | High accuracy using radiation heat flux measurements and three-dimensional model of furnace. |

| LSTM-based Model [109] | Various subsystems of the boiler. | High performance of the proposed model utilizing acoustic emission signals. |

| Machine learning-based optimal sensor selection algorithm [15] | Waterwall tube leakage detection. | Developed algorithm showed higher performance and ease of implementation in real power plant. |

| Deep neural network [20] | For all boiler tubes components. | High classification accuracy and applicable for practical implementation. |

| Multiplayer back propagation neural network [110] | Boiler burner system. | Used data mining technology to develop intelligent alarm. |

| Approach | Fault | Outcomes |

|---|---|---|

| PCA [112] | Final superheater tube leakage. | Successful in detecting and identifying tube plugging and prevented severe failures by avoiding overheating. |

| Improved PCA [113] | Boiler water/Steam leak. | The proposed method was tested on real data from a utility plant in Fort McMurray, Canada, for boiler water and steam leak detection. |

| Multiway PCA [107] | Riser and downcomer tube leakage. | High performance of the proposed Multiway PCA. |

| Clustering-based method [114] | Boiler tube leakage. | The proposed approach leverages unsupervised learning, and does not require labeled training samples. |

| Intelligent Technique | Key Findings and Conclusions | Performance Metrics | TPP Application |

|---|---|---|---|

| Deep neural network (DNN) [20] | Proposed classification mechanism using wavelet packet transform analysis of the acoustic emission signal | 99.2% (classification accuracy) | Boiler tube leakage detection |

| Whole Process model [115] | Developed monitoring platform with the functions of online estimation of key state variables | 1.1 % (mean relative deviation) | Boiler tube leak detection |

| SVM [116] | Prediction of the unburned carbon content of fly ash in the boiler and the exhaust steam enthalpy in turbine | 0.068 % (mean relative error) | Online monitoring of 300 MW TPP |

| Deep learning flexible boundary regression [117] | Proposed impulse detection methodology that employs deep learning methodology | 99.8% (classification accuracy) | Boiler tube leak detection |

| Hybrid intelligent system [118] | A Hybrid fault detection approach based on Decision fusion technique | 99.99% (classification accuracy) | Steam generator unit transient condition |

| Residual network [90] | Proposed a fault diagnosis method based on Knowledge Graph and Bayesian Network | 99.1% detection accuracy | Steam turbine rotor fault diagnosis |

| Graph neural network [119] | Fault representation through Graph neural network | 86% inference accuracy | Steam turbine system |

| Vibration signal analysis [120] | Wavelet transform and statistical pattern recognition employed in the proposed approach | 100% fault detection accuracy | Rolling element bearing in rotating machinery |

| Probability neural networks (PNNs) [121] | Proposed approach based on PNNs to fuse three information entropy | 100% classification accuracy on training data and 80% accuracy on unseen data | Steam turbine rotor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalid, S.; Song, J.; Raouf, I.; Kim, H.S. Advances in Fault Detection and Diagnosis for Thermal Power Plants: A Review of Intelligent Techniques. Mathematics 2023, 11, 1767. https://doi.org/10.3390/math11081767

Khalid S, Song J, Raouf I, Kim HS. Advances in Fault Detection and Diagnosis for Thermal Power Plants: A Review of Intelligent Techniques. Mathematics. 2023; 11(8):1767. https://doi.org/10.3390/math11081767

Chicago/Turabian StyleKhalid, Salman, Jinwoo Song, Izaz Raouf, and Heung Soo Kim. 2023. "Advances in Fault Detection and Diagnosis for Thermal Power Plants: A Review of Intelligent Techniques" Mathematics 11, no. 8: 1767. https://doi.org/10.3390/math11081767