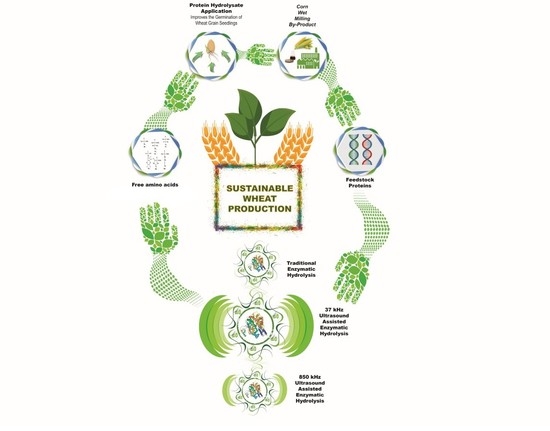

Integration of Ultrasound into the Development of Plant-Based Protein Hydrolysate and Its Bio-Stimulatory Effect for Growth of Wheat Grain Seedlings In Vivo

Abstract

:1. Introduction

2. Materials and Methods

2.1. Corn Processing By-Products and Their Analysis

2.2. CSL Ultrasound Pre-Treatment Procedure

2.3. Enzymatic Treatment of CSL

2.4. Extraction and Determination of Free Amino Acids

2.5. Biostimulatory Effect of CSL on Wheat Seed Treatment and Germination

2.6. Statistical Analysis

3. Results and Discussion

3.1. Effect of CSL Ultrasonication on the Enzymatic Treatment

3.2. Influence of Ultrasonic Pre-Treatment for Enzymatic Hydrolysis of CSL on FAA Profile

3.3. The Impact of CSL Protein Hydrolysate Application on Wheat Grain Seedlings Germination

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hristov, J.; Toreti, A.; Perez Dominguez, I.; Dentener, F.; Fellmann, T.; Elleby, C.; Ceglar, A.; Fumagalli, D.; Niemeyer, S.; Cerrani, I.; et al. Analysis of Climate Change Impacts on EU Agriculture by 2050; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-10617-3. [Google Scholar] [CrossRef]

- Rouphael, Y.; Colla, G. Biostimulants in Agriculture. Front. Plant Sci. 2020, 11, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, X.; Zheng, X.; Song, Z.; Liu, X.; Kopparapu, N.K.; Wang, X.; Zheng, Y. Preparation of enzymatic pretreated corn gluten meal hydrolysate and in vivo evaluation of its antioxidant activity. J. Funct. Foods 2015, 18, 1147–1157. [Google Scholar] [CrossRef]

- Amir, R.; Galili, G.; Cohen, H. The metabolic roles of free amino acids during seed development. Plant Sci. 2018, 275, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Kocira, S.; Kocira, A.; Szmigielski, M.; Piecak, A.; Sagan, A.; Malaga-Tobola, U. Effect of an amino acids-containing biostimulator on common bean crop. U Malaga-Tobola Przemysl Chem. 2015, 94, 1732–1736. [Google Scholar]

- Popko, M.; Michalak, I.; Wilk, R.; Górecki, H. Effect of the New Plant Growth Biostimulants Based on Amino Acids on Yield and Grain Quality of Winter Wheat. Molecules 2018, 23, 470. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.; Yu, H.; Li, Q.; Gao, Y.; Sallam, B.N.; Wang, H.; Liu, P.; Jiang, W. Exogenous Application of Amino Acids Improves the Growth and Yield of Lettuce by Enhancing Photosynthetic Assimilation and Nutrient Availability. Agronomy 2019, 9, 266. [Google Scholar] [CrossRef] [Green Version]

- Kocira, S. Effect of amino acid biostimulant on the yield and nutraceutical potential of soybean. Chil. J. Agric. Res. 2019, 79, 17–25. [Google Scholar] [CrossRef]

- Li, S.; Yang, X.; Zhang, Y.; Maa, H.; Qua, W.; Ye, X.; Muatasim, R.; Oladejo, A.O. Enzymolysis kinetics and structural characteristics of rice protein with energy-gathered ultrasound and ultrasound assisted alkali pretreatments. Ultrason. Sonochem. 2016, 31, 85–92. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Vaquero, M.; Ummat, V.; Tiwari, B.; Rajauria, G. Exploring Ultrasound, Microwave and Ultrasound–Microwave Assisted Extraction Technologies to Increase the Extraction of Bioactive Compounds and Antioxidants from Brown Macroalgae. Mar. Drugs 2020, 18, 172. [Google Scholar] [CrossRef] [Green Version]

- Qu, W.; Ma, H.; Jia, J.; He, R.; Luo, L.; Pan, Z. Enzymolysis kinetics and activities of ACE inhibitory peptides from wheat germ protein prepared with SFP ultrasound-assisted processing. Ultrason. Sonochem. 2012, 19, 1021–1026. [Google Scholar] [CrossRef]

- Jin, J.; Ma, H.; Qu, W.; Wang, K.; Zhou, C.; He, R.; Luo, L.; Owusu, J. Effects of multi-frequency power ultrasound on the enzymolysis of corn gluten meal: Kinetics and thermodynamics study. Ultrason. Sonochem. 2015, 27, 46–53. [Google Scholar] [CrossRef] [PubMed]

- AACC. Approved Methods of the American Association of Cereal Chemists; AACC International: St. Paul, MN, USA, 2010; Volume 11. [Google Scholar]

- ISO. Native Starch. Determination of Starch Content—Ewers Polarimetric Method. Method 10520; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- Bartkiene, E.; Bartkevics, V.; Ikkere, L.E.; Pugajeva, I.; Zavistanaviciute, P.; Lele, V.; Ruzauskas, M.; Bernatoniene, J.; Jakstas, V.; Klupsaite, D.; et al. The effects of ultrasonication, fermentation with Lactobacillus sp., and dehydration on the chemical composition and microbial contamination of bovine colostrum. Int. J. Dairy Sci. 2018, 101, 6787–6798. [Google Scholar] [CrossRef]

- Juodeikiene, G.; Zadeike, D.; Trakselyte-Rupsiene, K.; Gasauskaite, K.; Bartkiene, E.; Lele, V.; Viskelis, P.; Bernatoniene, J.; Ivanauskas, L.; Jakstas, V. Functionalisation of flaxseed proteins assisted by ultrasonication to produce coatings enriched with raspberries phytochemicals. LWT Food Sci. Technol. 2020, 124, 109180. [Google Scholar] [CrossRef]

- Bradford, M.M. A rapid and sensitive for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Jukonyte, R.; Zadeike, D.; Bartkiene, E.; Lele, V.; Cernauskas, D.; Suproniene, S.; Juodeikiene, G. A potential of brown rice polish as a substrate for the lactic acid and bioactive compounds production by the lactic acid bacteria newly isolated from cereal-based fermented products. LWT Food Sci. Technol. 2018, 97, 323–331. [Google Scholar] [CrossRef]

- Dabkevičius, Z.; Gaurilčkienė, I.; Semaškienė, R. Varpinių Javų Ligos. Žemes ŪKio Augalų Kenkėjai, Ligos ir Jų Apskaita; Arx-Baltica: Akademija, Lithuania, 2002; pp. 80–134. ISBN 9986-527-88-0. [Google Scholar]

- Salem, N.M.; Al-banna, L.; Awwad, A. Seed Germination and Growth of Cucumber (Cucumis sativus): Effect of Nano-Crystalline Sulfur. J. Agric. Sci. 2016, 8, 219. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, Y.; Zhangad, Z.; Wang, Y.; Mintah, B.K.; Dabbour, M.; Jiang, H.; He, R.; Ma, H. Modification of rapeseed protein by ultrasound-assisted pH shift treatment: Ultrasonic mode and frequency screening, changes in protein solubility and structural characteristics. Ultrason. Sonochem. 2020, 69, 105240. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Murray, B.; Flynn, C.; Norton, I. The effect of ultrasound treatment on the structural, physical and emulsifying properties of animal and vegetable proteins. Food Hydrocoll. 2016, 53, 141–154. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Huang, L.; Jia, J.; He, R.; Luo, L.; Zhu, W. Effect of energy-gathered ultrasound on Alcalase. Ultrason. Sonochem. 2011, 18, 419–424. [Google Scholar] [CrossRef]

- Ying, Z.; Han, X.; Li, J. Ultrasound-assisted extraction of polysaccharides from mulberry leaves. Food Chem. 2011, 127, 1273–1279. [Google Scholar] [CrossRef]

- El-Saied, H.M.; Hegazi, S.M.; El-Marsafy, M.K. Amino Acid Patterns of Different Brands of Corn Steep Liquor. Starch-Stärke 1975, 27, 413–416. [Google Scholar] [CrossRef]

- Xiao, X.; Hou, Y.; Liu, Y.; Liu, Y.; Zhao, H.; Dong, L.; Du, J.; Wang, Y.; Bai, G.; Luo, G. Classification and analysis of corn steep liquor by UPLC/Q-TOFMS and HPLC. Talanta 2013, 107, 344–348. [Google Scholar] [CrossRef]

- Shukla, R.; Cheryan, M. Zein: The industrial protein from corn. Ind. Crops Prod. 2001, 13, 171–192. [Google Scholar] [CrossRef]

- Wu, Y.; Messing, J. Proteome balancing of the maize seed for higher nutritional value. Front. Plant Sci. 2014, 30, 240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, C.; Uygun, S.; Shiu, S.H.; Last, R.L. The impact of the branched-Chain ketoaciddehydrogenase complex on amino acid homeostasis in Arabidopsis. Plant Physiol. 2015, 169, 1807–1820. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cohen, H.; Israeli, H.; Matityahu, I.; Amir, R. Seed-specific expression of a feedbackinsensitive form of CYSTATHIONINE-gamma-SYNTHASE in Arabidopsis stimulates metabolic and transcriptomic responses associated with desiccation stress. Plant Physiol. 2014, 166, 1575–1592. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Funck, D.; Winter, G.; Baumgarten, L.; Forlani, G. Requirement of proline synthesis during Arabidopsis reproductive development. BMC Plant Biol. 2012, 12, 191. [Google Scholar] [CrossRef] [Green Version]

- Colla, G.; Rouphael, Y.; Canaguier, R.; Svecova, E.; Cardarelli, M. Biostimulant action of a plant-derived protein hydrolysate produced through enzymatic hydrolysis. Front. Plant Sci. 2014, 5, 448. [Google Scholar] [CrossRef] [Green Version]

| Component | Concentrations |

|---|---|

| Dry matter (%) | 51.7 ± 0.29 |

| Crude protein (%) | 44.4 ± 0.57 |

| Starch (%) | 1.3 ± 0.02 |

| V0 (g/L * min−1) | kM/(kAE0) | 1/(kAE0) | kM (g/L) | kA (min−1) | |

|---|---|---|---|---|---|

| Traditional hydrolysis | 0.267 ± 0.01 a | 113.34 ± 0.27 a | 3.21 ± 0.07 a | 35.35 ± 0.91 a | 0.30 ± 0.005 a |

| 37 kHz pretreated hydrolysis | 0.367 ± 0.01 b | 57.63 ± 0.23 c | 2.45 ± 0.03 b | 23.50 ± 0.40 c | 0.39 ± 0.002 b |

| 850 kHz pretreated hydrolysis | 0.360 ± 0.01 b | 66.26 ± 0.34 b | 2.59 ± 0.04 b | 28.74 ± 0.38 b | 0.37 ± 0.004 b |

| Free Amino Acid, g/100 mL CSL | CSL | CSL1 | CSL2 | CSL3 |

|---|---|---|---|---|

| Aspartic Acid | 0.04 ± 0.01 a | 0.09 ± 0.04 a | 0.12 ± 0.06 a | 0.11 ± 0.06 a |

| Glutamic acid | 0.11 ± 0.11 a | 0.13 ± 0.02 a | 0.18 ± 0.04 a | 0.17 ± 0.03 a |

| Serine | 0.28 ± 0.03 a | 0.43 ± 0.05 a | 0.59 ± 0.12 b | 0.55 ± 0.05 b |

| Histidine | 0.04 ± 0.05 a | 0.03 ± 0.05 a | 0.04 ± 0.07 a | 0.04 ± 0.07 a |

| Glycine | 0.19 ± 0.02 a | 0.24 ± 0.02 a | 0.33 ± 0.06 c | 0.31 ± 0.01 b |

| Threonine | 0.25 ± 0.01 a | 0.39 ± 0.05 a | 0.51 ± 0.11 c | 0.52 ± 0.05 b |

| Arginine | 0.01 ± 0.02 a | 0.06 ± 0.06 a | 0.09 ± 0.09 a | 0.09 ± 0.08 a |

| Alanine | 1.39 ± 0.02 a | 1.84 ± 0.32 a | 2.58 ± 0.60 c | 2.41 ± 0.37 b |

| Tyrosine | 0.02 ± 0.01 a | 0.07 ± 0.05 a | 0.09 ± 0.07 a | 0.09 ± 0.07 a |

| Cysteine | 0.21 ± 0.03 a | 0.32 ± 0.03 b | 0.49 ± 0.04 c | 0.50 ± 0.04 c |

| Valine | 0.34 ± 0.11 a | 0.62 ± 0.02 b | 0.89 ± 0.12 c | 0.83 ± 0.04 c |

| Methionine | 0.32 ± 0.08 a | 0.45 ± 0.05 a | 0.62 ± 0.20 a | 0.61 ± 0.14 a |

| Tryptophan | 0.39 ± 0.06 a | 0.68 ± 0.09 b | 0.98 ± 0.17 c | 0.95 ± 0.04 c |

| Phenylalanine | 0.27 ± 0.02 a | 0.47 ± 0.20 a | 0.67 ± 0.16 b | 0.63 ± 0.10 b |

| Isoleucine | 0.91 ± 0.16 a | 1.36 ± 0.20 a | 1.96 ± 0.42 b | 1.89 ± 0.22 b |

| Leucine | 0.03 ± 0.05 a | 0.07 ± 0.04 a | 0.10 ± 0.06 a | 0.10 ± 0.06 a |

| Lysine | 0.06 ± 0.08 a | 0.12 ± 0.14 a | 0.15 ± 0.22 a | 0.15 ± 0.21 a |

| Proline | 0.82 ± 0.60 a | 1.99 ± 0.60 b | 2.46 ± 0.63 c | 2.23 ± 1.03 b |

| Total FAA | 5.67 ± 0.19 a | 9.34 ± 1.21 a | 12.87 ± 1.40 b | 12.18 ± 2.32 b |

| GP (%) | Root Length (cm) | Stem Length (cm) | Root Fresh Wt. (g) | Root Dry Wt. (g) | Stem Fresh Wt. (g) | Stem Dry Wt. (g) | |

|---|---|---|---|---|---|---|---|

| Control | 85.3 ± 0.58 a | 8.48 ± 0.52 a | 5.38 ± 0.49 a | 0.0115 ± 0.0002 a | 0.0558 ± 0.0005 a | 0.0053 ± 0.0005 a | 0.0055 ± 0.0027 a |

| CSL | 93.3 ± 1.15 b | 8.77 ± 0.69 a,b | 6.04 ± 0.74 a | 0.0165 ± 0.0004 b | 0.0650 ± 0.0004 a | 0.0066 ± 0.0006 b | 0.0063 ± 0.0004 a |

| CSL1 | 90.7± 0.58 b | 9.76 ± 0.54 b,c | 6.32 ± 0.65 a | 0.0180 ± 0.0015 b,c | 0.0690 ± 0.0015 a,b | 0.0078 ± 0.00212 | 0.0068 ± 0.0002 a |

| CSL2 | 95.7± 0.58 c | 11.03 ± 0.47 c | 7.20 ± 1.22 a | 0.0195 ± 0.0005 c | 0.0732 ± 0.0002 b | 0.0083 ± 0.0004 c | 0.0071 ± 0.0002 b |

| CSL3 | 92.3± 0.58 b | 10.14 ± 0.29 c | 6.90 ± 0.52 a | 0.0190 ± 0.0020 c | 0.0705 ± 0.0003 c | 0.0081 ± 0.0002 c | 0.0069 ± 0.0001 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trakselyte-Rupsiene, K.; Juodeikiene, G.; Cernauskas, D.; Bartkiene, E.; Klupsaite, D.; Zadeike, D.; Bendoraitiene, J.; Damasius, J.; Ignatavicius, J.; Sikorskaite-Gudziuniene, S. Integration of Ultrasound into the Development of Plant-Based Protein Hydrolysate and Its Bio-Stimulatory Effect for Growth of Wheat Grain Seedlings In Vivo. Plants 2021, 10, 1319. https://doi.org/10.3390/plants10071319

Trakselyte-Rupsiene K, Juodeikiene G, Cernauskas D, Bartkiene E, Klupsaite D, Zadeike D, Bendoraitiene J, Damasius J, Ignatavicius J, Sikorskaite-Gudziuniene S. Integration of Ultrasound into the Development of Plant-Based Protein Hydrolysate and Its Bio-Stimulatory Effect for Growth of Wheat Grain Seedlings In Vivo. Plants. 2021; 10(7):1319. https://doi.org/10.3390/plants10071319

Chicago/Turabian StyleTrakselyte-Rupsiene, Karolina, Grazina Juodeikiene, Darius Cernauskas, Elena Bartkiene, Dovile Klupsaite, Daiva Zadeike, Joana Bendoraitiene, Jonas Damasius, Jonas Ignatavicius, and Sidona Sikorskaite-Gudziuniene. 2021. "Integration of Ultrasound into the Development of Plant-Based Protein Hydrolysate and Its Bio-Stimulatory Effect for Growth of Wheat Grain Seedlings In Vivo" Plants 10, no. 7: 1319. https://doi.org/10.3390/plants10071319