National Quality Infrastructure System and Its Application Progress in Photovoltaic Industry

Abstract

:1. Introduction

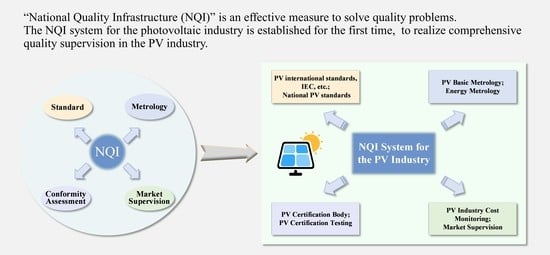

2. National Quality Infrastructure

2.1. NQI Core Elements

2.2. Metrology

2.3. Standard

2.4. Conformity Assessment

2.5. Integrated NQI Development

3. Applications of NQI in Photovoltaic Industry

3.1. Establishment of NQI System for Photovoltaic Industry

3.2. Metrology in Photovoltaic Industry

3.3. Conformity Assessment for Photovoltaic Industry

3.3.1. Conformity Assessment Agencies around the World

3.3.2. IEC Mutual Recognition System

3.4. Standard Construction of Photovoltaic Industry

3.5. Market Surveillance

4. Suggestions

4.1. At NQI Level

- Pay attention to the combination of theoretical research and practical application. It is necessary to organically integrate the metrology, standards, and conformity assessment in the NQI system with the existing enterprise quality management system. Actively organize and guide enterprises and projects to develop NQI and follow NQI-related requirements [47], making NQI construction more viable and targeted.

- Pay attention to national strategic needs. Determine the current development direction of the national NQI through top-level design and overall planning. Incorporate the current economic and social development needs, such as the “carbon peaking and carbon neutrality goals”, into the scope of NQI research, and form a scientific and reasonable NQI construction strategy, so that the NQI system can maximize its effectiveness.

- Pay attention to the construction of NQI. The essence of NQI is to serve quality management, serving people’s lives, industries, and enterprises. It is necessary to guide and promote the implementation of the NQI, improve the NQI evaluation system, and ensure that the NQI better serves the country, society and consumers.

- Actively participate in international exchanges and cooperation. The construction of the NQI system has received widespread attention from all countries in the world, and the practical experience and design ideas of NQI in all regions of the world are worth learning and researching. Actively participating in international conferences and participating in the construction of the international NQI system can help the NQI system that is under construction to achieve advancement and integration.

4.2. Recommendations for the Development of NQI System in Photovoltaic Industry

- In terms of metrology: (1) Strengthen the metrology service of key parameters and key equipment, formulate standard battery measurement and standard component measurement procedures, and build empirical test bases and public test platforms. (2) Strengthen on-site measurement and test services, especially outdoor photovoltaic measurement, improve the adaptability and flexibility of metrology methods and equipment, and provide customers with convenient services. (3) Provide measurement training services for technical personnel for enterprises. Research metering schemes suitable for distributed photovoltaics and develop more accurate electrical energy measurement instruments.

- In terms of standards: (1) Actively organize domestic experts to participate in meetings organized by IEC, and actively speak on standards proposed by member states to enhance international discourse power. (2) Pay attention to the development of international standards, increase communication with the standard-setting group, and summarize and highlight the revision and reporting direction of standards. (3) Realize the integrated and coordinated development of the photovoltaic industry from technology, products, applications to standards and testing, make full use of standards, and improve product quality. (4) It is necessary to speed up the formulation of safety standards and grid-connection requirements related to distributed photovoltaics, especially rooftop photovoltaic projects, starting from the aspects of design, construction, operation and maintenance. Especially in terms of design, it is essential to comprehensively consider site selection, electrical fire protection, engineering construction, etc., and set relevant specifications for the quality of engineering construction. In particular, China must give full play to its leading technological advantages and export volume advantages, transform technology into standards, lead the formulation of international standards, and enhance international competitiveness.

- In terms of certification, accreditation, inspection and testing: (1) Equipment should be optimized, testing capabilities should be enhanced, and the international credibility of testing data should be improved. (2) Form a certification and testing system covering the entire photovoltaic industry chain and the entire life cycle of photovoltaic equipment. (3) To increase grid-connected testing and certification capabilities, mandatory testing should be implemented for key content such as system security and actual operating efficiency. (4) For distributed photovoltaics, it is necessary to strengthen mandatory regulations such as leakage protection, arc detection protection, and rapid shutdown of photovoltaic modules.

- In terms of market supervision: (1) Strengthen the detection of changes in market costs and prices. In recent years, some silicon wafer manufacturers have been deliberately hoarding stocks, causing the price of raw materials to rise. It is necessary to strengthen the monitoring of prices and construction costs and report them to the National Energy Administration in a timely manner as the basis for industry policy adjustments. (2) Strengthen market supervision. Intensify the review of photovoltaic module suppliers and operation and maintenance companies to ensure the quality and warranty period of household photovoltaic products. Severely crack down on arbitrary charges in the construction of rooftop photovoltaic power stations. (3) Set up a standardized grid connection process. Help rooftop photovoltaic installers to connect to the grid easily and smoothly. Realize the transparency of the prices of all parts of the photovoltaic industry to help installers get the most benefits.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, L.; Huang, H.; Cai, L.-Y. On the Reform and Development of Quality Infrastructure under the New Situation in China. Qual. Explor. 2019, 16, 60–67. [Google Scholar]

- Department of Science and Technology, General Administration of Quality Supervision, Inspection and Quarantine. NQI: Consolidate the Strategy of Strengthening the Country through Quality, Leading Economic and Social Development. China Quality Certif. 2016, 4, 28–30. [Google Scholar]

- Xinhua News Agency Uiding Opinions of the Central Committee of the Communist Party of China and the State Council on Carrying out Quality Improvement Actions. 12 September 2017. Available online: http://www.gov.cn/zhengce/2017-09/12/content_5224580.htm (accessed on 28 January 2022).

- Liu, J.; Hu, B. The Evolution and Development Trend of National Quality Infrastructure (NQI). China Metrol. 2020, 10, 15–19. [Google Scholar]

- Jiang, J.-D.; Li, X.-Z.; Zheng, L.-W. National Quality Infrastructure: A Review. Ind. Eng. Manag. 2019, 24, 198–205. [Google Scholar]

- Physikalisch, T.B. The Relevance of Quality Infrastructure to Promote Innovation Systems in Developing Countries; PTB: Braunschweig, Germany, 2010. [Google Scholar]

- Physikalisch, T.B. Measurement of Quality Infrastructure; PTB: Braunschweig, Germany, 2011. [Google Scholar]

- Moljevic, S. Influence of quality infrastructure on regional development. Int. J. Qual. Res. 2016, 10, 433–452. [Google Scholar]

- Choi, D.G.; Hyun, O.-S.; Hong, J.-I.; Kang, B.-G. Standards as catalyst for national innovation and performance—A capability assessment framework for latecomer countries. Total Qual. Manag. Bus. Excel. 2014, 25, 969–985. [Google Scholar] [CrossRef] [Green Version]

- National Quality Forum. Strengthening the National Quality Infrastructure; NQF: Washington, DC, USA, 2010. [Google Scholar]

- Swedish International Development Cooperation Agency. Quality Infrastructure Development in Support of World Trade; Sida: Göteborg, Sweden, 2014.

- National Metrology Laboratory of the Philippines. Proposed Strategy for The National Metrology Infrastructure of the Philippines; National Metrology Laboratory: Manila, Philippines, 2016.

- Philippine Metrology, Standards, Testing and Quality. Study on National Quality Infrastructure (NQI) & Government Regulatory Processes (GRP); PhilMSTQ: Pasig City, Philippines, 2011. [Google Scholar]

- Xu, J.-H. The Foundation of National Quality Is an Important Support for a Strong Manufacturing Country. Stand. Life 2014, 9, 34–37. [Google Scholar]

- Xu, C.-H. Practice and Thinking on the Construction of National Quality Infrastructure Technology System. China Mark. Superv. Res. 2020, 1, 23–26. [Google Scholar]

- Chen, Y.-F.; Deng, S.-X. Analysis of Restrictive Factors in the Integrated Development of National Quality Infrastructure (NQI). China Insp. Test. 2021, 29, 6–8, 12. [Google Scholar]

- Yu, L.-C. On National Quality Infrastructure Development Policies and Their Legal System Construction. Stand. Sci. 2020, 9, 6–11. [Google Scholar]

- Shen, J.; Zhang, Y.; Zheng, S. A Methodological Framework of Assessing National Quality Infrastructure Efficacy for Quality Management. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 1573–1577. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, Y.; Zheng, X.-Y. The Importance of Metrology Research. Metrol. Test. Technol. 2019, 46, 104–106. [Google Scholar]

- Chen, Q. The Importance and Development Prospect of Metrology. Electromech. Technol. 2015, 6, 154–155. [Google Scholar]

- Kuang, B. Study on the Standardization Strategy Theory and Practice. Ph.D. Thesis, Wuhan University, Wuhan, China, 2011. [Google Scholar]

- Guo, T.-Q. Talking about the Importance of Standards. Sci. Chin. 2015, 15, 125. [Google Scholar]

- Wang, P. Looking at the Nature and Status of Standards and Standardization Organizations from Historical Development. China Stand. 2005, 6, 23–25. [Google Scholar]

- Fang, X.; Liu, Y.; Wang, Y.; Wang, J. Research on the Framework Design of NQI Service Cloud Platform in the Field of Smart Grid Measurement. J. Phys. Conf. Ser. 2020, 1676, 012230. [Google Scholar] [CrossRef]

- Liu, S.-G.; Sun, H.-G. Practical Exploration of Iterative Upgrade of National Quality Infrastructure Construction. China Mark. Superv. Res. 2021, 5, 64–66. [Google Scholar]

- Li, J. The Requirement Analysis of Photovoltaic Industry Measurement in Metrology Field. Metrol. Test. Technol. 2012, 39, 1–2. [Google Scholar]

- Physikalisch, T.B. Photovoltaic Metrology Center. Metrol. Test. Technol. 2020, 47, 66. [Google Scholar]

- Sun, H. Research on Calibration Methods of Solar Cells and Related Testing Equipments. Master’s Thesis, Chinese Academy of Metrology, Beijing, China, 2010. [Google Scholar]

- Rural Electrification Professional Committee of Chinese Society for Electrical Engineering, Research Report on Issues Related to the Development and Construction of Distributed Photovoltaics on the Roof of the Whole County. Rural. Power Manag. 2021, 10, 22–26.

- Tian, X.-Q. The Influence of DC Bias on Current Transformers and Power Metering. Master’s Thesis, North China Electric Power University, Beijing, China, 2014. [Google Scholar]

- Naik, R.; Mohan, N.; Rogers, M.; Bulawka, A. A novel grid interface, optimized for utility-scale applications of photovoltaic, wind-electric, and fuel-cell systems. IEEE Trans. Power Deliv. 1995, 10, 1920–1926. [Google Scholar] [CrossRef]

- Wu, T.-F.; Shen, C.-L.; Nein, H.-S.; Li, G.-F. A 1/spl phi/3W inverter with grid connection and active power filtering based on nonlinear programming and fast-zero-phase detection algorithm. IEEE Trans. Power Electron. 2005, 20, 218–226. [Google Scholar] [CrossRef]

- Teng, Z.-S.; Luo, Z.-K.; Sun, C.-Q.; Gao, Y.-P.; Tang, Q. Harmonic Energy Measurement Based on Wavelet Packet Decomposition and Reconstruction Algorithm. Trans. China Electrotech. Soc. 2010, 25, 200–206. [Google Scholar]

- Dou, X.-B.; Yang, L.; Ma, J.; Chen, K.-X.; Quan, X.-J. Improved model for power metering based on dynamic characteristics of distributed photovoltaic power generation. Power Autom. Equip. 2017, 37, 34–42. [Google Scholar]

- Li, S.-L.; Xue, Y.-S. Introduction to Domestic and Foreign Photovoltaic Product Testing and Certification Institutions. Sol. Energy 2010, 2, 62–64+23. [Google Scholar]

- Lin, X.-J.; Wu, B.-B.; Li, H.-T.; Bao, S.-J.; Zhang, J.-J. On—Site Testing Technology for Distributed Photovoltaic Power Plant. Electr. Meas. Instrum. 2014, 51, 79–82. [Google Scholar]

- Liu, H. Research on Current Detection Technology for Photovoltaic Grid-Connected System. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2014. [Google Scholar]

- Yu, J.-K. Research on the Technology of Photovoltaic MPPT and Islanding Detection. Master’s Thesis, AnHui University of Science and Technology, Huainan, China, 2017. [Google Scholar]

- Wang, M.; Li, M.-D.; Wang, X.-H. A simulation study of inverter island detection based on ant colony algorithm. J. Shanghai Dianji Univ. 2021, 24, 76–83. [Google Scholar]

- Menon, V.; Nehrir, M.H. A Hybrid Islanding Detection Technique Using Voltage Unbalance and Frequency Set Point. IEEE Trans. Power Syst. 2007, 22, 442–448. [Google Scholar] [CrossRef]

- Qiu, S. Photovoltaic Product Certification: A Race Against Time. Qual. Explor. 2015, 12, 27. [Google Scholar]

- Wang, Z. Golden Sun Photovoltaic Certification, Light Up Solar Energy. Sol. Energy 2008, 8, 46–47. [Google Scholar]

- The Energy Administration and CNCA issued the “Opinions”: Photovoltaic products connected to the grid need to obtain national certification. Power Gener. Air Cond. 2014, 35, 51.

- Pei, H.-C.; Zhang, J.-H.; Feng, Y.-B.; Wang, G.-Q. Review on Standardization in Photovoltaic Field at Home and Abroad. Stand. Res. 2020, 9, 11–15. [Google Scholar]

- Ministry of Industry and Information Technology of China, The General Office of the Ministry of Industry and Information Technology issued the Solar Photovoltaic Industry Comprehensive Standardization Technical System. China Natl. Build. Mater. 2017, 6, 59.

- Chen, X.-Y. Researching on the International Competitiveness. Ph.D. Thesis, NanKai University, Tianjin, China, 2010. [Google Scholar]

- Fang, X.; Liu, Y.; Wang, Y. Research on Data Processing Architecture of NQI Service Platform in Intelligent Measurement Domain. J. Phys. Conf. Ser. 2020, 1607, 012128. [Google Scholar] [CrossRef]

| Index | Certification Body | Country | Standard Basis | Main Business |

|---|---|---|---|---|

| 1 | Underwriter Laboratories (UL) | USA | UL 61703\UL 1741\IEC 61215\IEC 61646\IEC 61730\EN 61730, etc. | Cover the entire life cycle of the product, including aspects such as research and development, design, production, use and subsequent maintenance. Cover almost all components of the PV system and formulate standards for PV products. |

| 2 | Japan Electrical Safety and Environment Technology Laboratories | Japan | IEC 61730\JISC 61215\JISC 8993 | Certification of crystalline silicon and thin-film PV modules, and certification of operation and maintenance of PV power generation systems. |

| 3 | Intertek | UK | EN 50548\EN 50521\P10-0003\UL 3730\UL 3703\UL 2703, etc. | PV module product compliance testing and certification, PV product performance testing, PV component system balance, solar thermal product testing, solar cell bank subsidies. |

| 4 | VDE Testing and Certification Institute | Germany | IEC 62103\IEC 61646\EN 61000-6-2/VDE 0100\VDE 0126 | Product testing covers complete PV systems, PV modules, power inverters, installation systems, connectors and cables. Services include the following: safety testing, environmental testing, on-site compliance monitoring/inspection according to VDE and IEC standards. |

| 5 | TÜV SÜD | Germany | ULC/ORD-C1703\UL 1703\IEC 61730\IEC 61215\IEC 61646\EN 1090-2\EN 1090-3 | Provide a complete set of services from solar power plant design review to follow-up routine maintenance inspection, including PV system balance module testing and certification, PV module testing and certification, solar performance evaluation, PV power plant certification, construction project monitoring, etc. |

| 6 | TÜV Rheinland | Germany | UL 9540\UL 1741\CEC Guidelines\IEC 61683\EN 50530 et.al | Provide testing and certification of PV modules and components, supply chain management, and independent PV power station design services. Testable products include ground-use crystalline silicon battery modules, thin-film solar battery modules, concentrating solar battery modules, controllers, inverters, off-grid systems, grid-connected systems, etc. |

| 7 | China Quality Certification Centre (CQC) | China | IEC 62124\IEC 62125\GB 29196\GB 19964\NB 32004\CNCA 0004, etc. | Committed to building a national-level public service platform integrating solar energy (PV, solar thermal) testing, certification, and scientific research. The main business includes the certification of solar PV products (PV modules, PV inverters, PV combiner boxes, energy storage batteries, etc.), and supervision of the manufacturing of key PV components (PV modules, PV inverters, box transformers and main transformers, etc.). |

| 8 | China Classification Society Certification (CCSC) | China | IEC 61215\IEC 61730\GB 29848\GB 31034\NB 32004\CNCA 0003\CNCA 0002, etc. | The service covers the entire industrial chain from raw materials, key equipment of PV power plants to PV power plants. Provide third-party technical services such as PV station address and optical resource evaluation, design evaluation and optimization, power station quality and performance testing (power station acceptance, follow-up evaluation, follow-up monitoring), power station operation and maintenance capability evaluation and certification. |

| 9 | Ceprei Certification (Guangzhou) | China | IEC 62446\NB 32004, etc. | Certification of grid-connected inverters and grid-connected PV systems |

| 10 | Noah Testing Certification Group (NOA) | China | IEC 62124\IEC 62446\IEC 17025\GB 2828, etc. | Provide on-site inspection of PV modules for large-scale ground PV power stations, distributed PV power stations, and household PV power stations, provide full life cycle quality control services such as PV grid-connected inverters, combiner boxes, batteries, independent PV system testing and completion acceptance, etc., and issue third-party testing data and analysis reports. |

| 11 | China Testing and Certification International Group (CTC) | China | IEC 61646\IEC 61730\IEC 61724\GB 18911\GB 20047, etc. | The testing capabilities cover the entire PV industry chain including PV materials, PV modules, PV components, PV systems and inverters. Provide third-party technical services throughout the life cycle of PV power stations, such as PV station address and light resource evaluation, design evaluation and optimization of power station quality and performance testing, PV system certification, evaluation and certification of power station operation and maintenance capabilities. |

| 12 | China General Certification Center (CGC) | China | IEC 61215\IEC 61730\GB 37408\GB 37409\NB 32004\CGC-GF063, etc. | Business includes design optimization of PV power stations, optimization of key equipment selection, certification of key equipment such as PV modules, inverters, batteries, etc., acceptance testing of PV power stations, and post-evaluation of PV power station performance. |

| 13 | Shanghai Ingeer Certification Assessment Services (ICAS) | China | IEC 61730\IEC61215\GB 50794\CQC 9102\CNCA 0004, etc. | PV power plant inspection and acceptance, PV module certification and laboratory testing services, key equipment manufacturing supervision services, PV power plant due diligence and evaluation services. |

| 14 | Power (Beijing) Certification Centre (PCCC) | China | IEC 60904\IEC 61215\IEC 61730\GB 34396\CPIA 0006 etc. | Certification business for PV power generation and transmission systems and accessory products such as PV cells, PV cell modules, PV junction boxes and PV connectors, PV combiner boxes, back sheet, circuit breakers, etc. |

| 15 | Credit Builder Certification Wuxi (CBC) | China | IEC 62109\NB 32004\CNCA 0006 etc. | Certification of PV modules, independent PV systems, back sheet, battery performance, grid-connected inverters |

| Working Group | Title | Task |

|---|---|---|

| WG1 | Glossary | To prepare a glossary. |

| WG2 | Modules, non-concentrating | To develop international standards for non-concentrating, terrestrial photovoltaic modules. These standards will be in the general areas of photoelectric performance, environmental test, quality assurance and quality assessment criteria. |

| WG3 | Systems | To give general instructions for the photovoltaic system design, construction and maintenance. |

| WG6 | Balance-of-system components | To develop international standards for balance-of-system components for PV systems. These standards will be in the general areas of performance, safety, environmental durability (reliability), quality assurance and quality assessment criteria. |

| WG7 | Concentrator modules | To develop international standards for photovoltaic concentrators and receivers. These standards will be in the general areas of safety, photoelectric performance and environmental reliability tests. |

| WG8 | Photovoltaic (PV) cells | To develop international standards for non-concentrating, terrestrial photovoltaic cells. These standards will be in the general areas of photoelectric performance, environmental test, quality assurance and quality assessment criteria |

| WG9 | BOS Components—Support Structures | To develop international standards for photovoltaic support structures. These standards are in the general areas of safety, design qualification, engineering integrity, durability, and verification testing. |

| Index | Standard Number | Standard Name | Release Year |

|---|---|---|---|

| 1 | IEC 62788-1-6 | Measurement procedures for materials used in photovoltaic modules—Part 1–6: Encapsulants-Test methods for determining the degree of cure in Ethylene-Vinyl Acetate | 2017 |

| 2 | IEC 62805-1 | Method for measuring photovoltaic (PV) glass—Part 1: Measurement of total haze and spectral distribution of haze | 2017 |

| 3 | IEC 62805-2 | Method for measuring photovoltaic (PV) glass—Part 2: Measurement of transmittance and reflectance | 2017 |

| 4 | IEC 63202-1 | Photovoltaic cells—Part 1: Measurement of light-induced degradation of crystalline silicon photovoltaic cells | 2019 |

| 5 | IEC 62910 | Utility-interconnected photovoltaic inverters—Test procedure for under voltage ride-through measurements | 2020 |

| 6 | IEC 61327 | Utility-interconnected photovoltaic inverters—Test procedure for over voltage ride-through measurements | 2021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, R.; Xiao, H.-F.; Niu, C.-H.; Cao, Q.-W.; Yao, Z.-Y. National Quality Infrastructure System and Its Application Progress in Photovoltaic Industry. Electronics 2022, 11, 426. https://doi.org/10.3390/electronics11030426

Sun R, Xiao H-F, Niu C-H, Cao Q-W, Yao Z-Y. National Quality Infrastructure System and Its Application Progress in Photovoltaic Industry. Electronics. 2022; 11(3):426. https://doi.org/10.3390/electronics11030426

Chicago/Turabian StyleSun, Rui, Hua-Feng Xiao, Chen-Hui Niu, Qing-Wei Cao, and Zhong-Yuan Yao. 2022. "National Quality Infrastructure System and Its Application Progress in Photovoltaic Industry" Electronics 11, no. 3: 426. https://doi.org/10.3390/electronics11030426