Effects of Adding Blueberry Residue Powder and Extrusion Processing on Nutritional Components, Antioxidant Activity and Volatile Organic Compounds of Indica Rice Flour

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Material

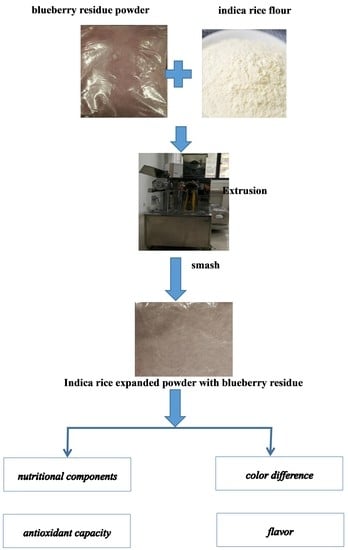

2.1.2. Preparation and Treatment of Samples

2.2. Methods

2.2.1. Determination of Nutritional Components

2.2.2. Determination of Color Difference

2.2.3. Determination of Antioxidant Capacity

2.2.4. Determination of Electronic Nose

2.2.5. Volatile Organic Compounds (VOCs) by GC-IMS

3. Statistical Analysis

4. Results and Discussion

4.1. Analysis of Nutritional Components

4.2. Color Difference

4.3. Antioxidant Capacity Analysis

4.4. Electronic Nose Analysis

4.5. Analysis of Volatile Organic Compounds (VOCs) by GC—IMS

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, W.; Zheng, Y.; Sun, W.; Chen, S.; Liu, D.; Zhang, H.; Fang, H.; Tian, J.; Ye, X. Effect of extrusion processing on the microstructure and in vitro digestibility of broken rice. LWT 2020, 119, 108835. [Google Scholar] [CrossRef]

- Wu, F.; Meng, Y.; Yang, N.; Tao, H.; Xu, X. Effects of mung bean starch on quality of rice noodles made by direct dry flour extrusion. LWT-Food Sci. Technol. 2015, 63, 1199–1205. [Google Scholar] [CrossRef]

- Li, X.Q.; Qin, L.K.; Zhang, X.J. The raw material ratio and quality evaluation of poria cocos compound nutrition powder. Food Mach. 2018, 34, 192–198. [Google Scholar]

- He, B.; Zhang, L.-L.; Yue, X.-Y.; Liang, J.; Jiang, J.; Gao, X.-L.; Yue, P.-X. Optimization of Ultrasound-Assisted Extraction of phenolic compounds and anthocyanins from blueberry ( Vaccinium ashei ) wine pomace. Food Chem. 2016, 204, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Wu, T.; Chu, X.; Tang, S.; Cao, W.; Liang, F.; Fang, Y.; Pan, S.; Xu, X. Fermented blueberry pomace with antioxidant properties improves fecal microbiota community structure and short chain fatty acids production in an in vitro mode. LWT 2019, 125, 109260. [Google Scholar] [CrossRef]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Zheng, Y.; Tian, J.; Ogawa, Y.; Yin, X.; Xu, E.; Chen, S.; Liu, D.; Kong, X.; Ye, X. Co-extrusion of proanthocyanins from Chinese bayberry leaves modifies the physicochemical properties as well as the in vitro digestion of restructured rice. Food Struct. 2021, 27, 100182. [Google Scholar] [CrossRef]

- Liu, G.; Ying, D.; Guo, B.; Cheng, L.J.; May, B.; Bird, T.; Sanguansri, L.; Cao, Y.; Augustin, M. Extrusion of apple pomace increases antioxidant activity upon in vitro digestion. Food Funct. 2019, 10, 951–963. [Google Scholar] [CrossRef]

- Wang, J.; Li, M.; Wang, C.; Dai, Y.; Sun, Y.; Li, X.; Heider, C.G.; Wu, X.; Liang, J. Effect of extrusion processing and addition of purple sweet potatoes on the structural properties and in vitro digestibility of extruded rice. Food Funct. 2021, 12, 739–746. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Peng, Z.; Zhao, Y.; Wu, K.; Zhou, N.; Yan, Y.; Ramaswamy, H.S.; Sun, J.; Bai, W. The impact of ultrasonic treatment on blueberry wine anthocyanin color and its In-vitro anti-oxidant capacity. Food Chem. 2020, 333, 127455. [Google Scholar] [CrossRef]

- Sun, X.; Yan, Z.; Zhu, T.; Zhu, J.; Wang, Y.; Li, B.; Meng, X. Effects on the color, taste, and anthocyanins stability of blueberry wine by different contents of mannoprotein. Food Chem. 2019, 279, 63–69. [Google Scholar] [PubMed]

- Sharma, O.; Bhat, T.K. DPPH antioxidant assay revisited. Food Chem. 2008, 113, 1202–1205. [Google Scholar] [CrossRef]

- Natthawuddhi Donlao, Y.O. Impacts of processing conditions on digestive recovery of polyphenolic compounds and stability of the antioxidant activity of green tea infusion during in vitro gastrointestinal digestion. LWT-Food Sci. Technol. 2018, 89, 648–656. [Google Scholar] [CrossRef]

- Jang, H.-H.; Kim, H.-W.; Kim, S.-Y.; Kim, S.-M.; Kim, J.-B.; Lee, Y.-M. In vitro and in vivo hypoglycemic effects of cyanidin 3-caffeoyl-p-hydroxybenzoylsophoroside-5-glucoside, an anthocyanin isolated from purple-fleshed sweet potato. Food Chem. 2019, 272, 688–693. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Zhang, Y.; Lü, Y.; Ma, G.; Chen, J.; Liu, D.; Ye, X. Phenolic compounds and antioxidant capacities of bayberry juices. Food Chem. 2008, 113, 884–888. [Google Scholar] [CrossRef]

- Li, W.; Beta, T. Evaluation of antioxidant capacity and aroma quality of anthograin liqueur. Food Chem. 2011, 127, 968–975. [Google Scholar] [CrossRef]

- Hotchkiss, A.T., Jr.; Chau, H.K.; Strahan, G.D.; Nuñez, A.; Simon, S.; White, A.K.; Dieng, S.; Heuberger, E.R.; Yadav, M.P.; Hirsch, J. Structure and composition of blueberry fiber pectin and xyloglucan that bind anthocyanins during fruit puree processing. Food Hydrocoll. 2021, 116, 106572. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional aspects of food extrusion: A review. Int. J. Food Ence Technol. 2010, 42, 916–929. [Google Scholar] [CrossRef]

- Arora, B.; Yoon, A.; Sriram, M.; Singha, P.; Rizvi, S.S. Reactive extrusion: A review of the physicochemical changes in food systems. Innov. Food Sci. Emerg. Technol. 2020, 64, 102429. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Extrusion effect on proximate composition, starch and dietary fibre of ready-to-eat products based on rice fortified with carob fruit and bean. LWT 2019, 111, 387–393. [Google Scholar] [CrossRef]

- Sun, X.; Shokri, S.; Gao, B.; Xu, Z.; Li, B.; Zhu, T.; Wang, Y.; Zhu, J. Improving effects of three selected co-pigments on fermentation, color stability, and anthocyanins content of blueberry wine. LWT 2022, 156, 113070. [Google Scholar] [CrossRef]

- Han, S.S.; Lo, S.C.; Choi, Y.W.; Kim, J.H.; Baek, S.H. Antioxidant activity of crude extract and pure compounds of Acer ginnala Max. Bull. Korean Chem. Soc. 2004, 25, 389–391. [Google Scholar]

- Ti, H.; Li, Q.; Zhang, R.; Zhang, M.; Deng, Y.; Wei, Z.; Chi, J.; Zhang, Y. Free and bound phenolic profiles and antioxidant activity of milled fractions of different indica rice varieties cultivated in southern China. Food Chem. 2014, 159, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Q.; Woo, M.W.; Hu, J.; Xiong, H.; Zhao, Q. The role of heating time on the characteristics, functional properties and antioxidant activity of enzyme-hydrolyzed rice proteins-glucose Maillard reaction products. Food Biosci. 2021, 43, 101225. [Google Scholar] [CrossRef]

- Ferreira, L.F.; Minuzzi, N.M.; Rodrigues, R.F.; Pauletto, R.; Rodrigues, E.; Emanuelli, T.; Bochi, V.C. Citric acid water-based solution for blueberry bagasse anthocyanins recovery: Optimization and comparisons with microwave-assisted extraction (MAE). LWT 2020, 133, 110064. [Google Scholar] [CrossRef]

- Cui, S.; Wang, J.; Yang, L.; Wu, J.; Wang, X. Qualitative and quantitative analysis on aroma characteristics of ginseng at different ages using E-nose and GC–MS combined with chemometrics. J. Pharm. Biomed. Anal. 2015, 102, 64–77. [Google Scholar] [CrossRef]

- Pfannhauser, W. Volatiles formed during extrusion cooking of cereals. Flavour Fragr. J. 1993, 8, 109–113. [Google Scholar] [CrossRef]

- Adelina, N.M.; Wang, H.; Zhang, L.; Zhao, Y. Comparative analysis of volatile profiles in two grafted pine nuts by headspace-SPME/GC–MS and electronic nose as responses to different roasting conditions. Food Res. Int. 2021, 140, 110026. [Google Scholar] [CrossRef]

- Jezussek, M.; Juliano, B.O.; Schieberle, P. Comparison of key aroma compounds in cooked brown rice varieties based on aroma extract dilution analyses. J. Agric. Food Chem. 2002, 50, 1101–1105. [Google Scholar]

- Goff, S.A.; Klee, H.J. Plant volatile compounds: Sensory cues for health and nutritional value? Science 2006, 311, 815–819. [Google Scholar] [CrossRef]

- Siegmund, B.; Murkovic, M. Changes in chemical composition of pumpkin seeds during the roasting process for production of pumpkin seed oil (Part 2: Volatile compounds). Food Chem. 2004, 84, 367–374. [Google Scholar] [CrossRef]

- Xiao, Y.; Huang, Y.; Chen, Y.; Fan, Z.; Chen, R.; He, C.; Li, Z.; Wang, Y. Effects of solid-state fermentation with Eurotium cristatum YL-1 on the nutritional value, total phenolics, isoflavones, antioxidant activity, and volatile organic compounds of black soybeans. Agronomy 2021, 11, 1029. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhu, Y.; Du, K.; Yang, H.B.; Ding, S.G.; Gao, Y.C.; Yang, L.J.; Du, X.F. Effects of hydrothermal treatment on quality characteristics and in vitro digestion of rice. J. Chin. Cereals Oils Assoc. 2022, 11, 1–15. [Google Scholar]

- Bi, W.Y.; Shi, T.Y.; Zhang, L.L. Changes of volatile components of yong you 15 during storage. J. Chin. Cereals Oils Assoc. 2020, 35, 137–143. [Google Scholar]

- Zhu, L.; Lin, X.D.; He, Y.; Shang, H.T.; Ling, J.G.; Tong, L.T. Analysis on volatile components of yongyou series indica-japonica hybrid rice. J. Chin. Cereals Oils Assoc. 2022, 37, 154–160. [Google Scholar]

- Liao, W.; Shen, J.; Manickam, S.; Li, S.; Tao, Y.; Li, D.; Liu, D.; Han, Y. Investigation of blueberry juice fermentation by mixed probiotic strains: Regression modeling, machine learning optimization and comparison with fermentation by single strain in the phenolic and volatile profiles. Food Chem. 2022, 405, 134982. [Google Scholar] [CrossRef]

| REP | REPBR | |

|---|---|---|

| Total starch (g per 100 g) | 74.80 ± 0.89 a | 68.50 ± 2.30 b |

| Protein (g per 100 g) | 6.72 ± 0.18 b | 7.91 ± 0.13 a |

| Fat (g per 100 g) | 0.56 ± 0.007 b | 0.11 ± 0.007 c |

| Total dietary fiber (mg per 100 g) | 1.03 ± 0.03 b | 2.28 ± 0.09 a |

| Anthocyanins (mg C3G/g) | ND | 0.14 ± 0.0005 |

| REP | REPBR | Indica Rice Flour | Blueberry Residue | Mixed Powder | |

|---|---|---|---|---|---|

| L* | 65.60 ± 0.42 b | 28.55 ± 1.07 d | 69.17 ± 2.25 a | 17.54 ± 0.26 e | 42.54 ± 0.32 c |

| a* | −0.34 ± 0.057 e | 8.59 ± 0.35 b | 0.053 ± 0.0015 d | 12.51 ± 0.095 a | 7.35 ± 0.030 c |

| b* | 5.71 ± 0.30 a | 0.84 ± 0.055 d | 4.03 ± 0.18 b | 3.99 ± 0.010 b | 2.16 ± 0.012 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Gao, Y.; Wang, R.; Sun, Y.; Li, X.; Liang, J. Effects of Adding Blueberry Residue Powder and Extrusion Processing on Nutritional Components, Antioxidant Activity and Volatile Organic Compounds of Indica Rice Flour. Biology 2022, 11, 1817. https://doi.org/10.3390/biology11121817

Zhang X, Gao Y, Wang R, Sun Y, Li X, Liang J. Effects of Adding Blueberry Residue Powder and Extrusion Processing on Nutritional Components, Antioxidant Activity and Volatile Organic Compounds of Indica Rice Flour. Biology. 2022; 11(12):1817. https://doi.org/10.3390/biology11121817

Chicago/Turabian StyleZhang, Xinzhen, Yang Gao, Ran Wang, Yue Sun, Xueling Li, and Jin Liang. 2022. "Effects of Adding Blueberry Residue Powder and Extrusion Processing on Nutritional Components, Antioxidant Activity and Volatile Organic Compounds of Indica Rice Flour" Biology 11, no. 12: 1817. https://doi.org/10.3390/biology11121817