Effect of Adding Phragmites-Australis Fiber on the Mechanical Properties and Volume Stability of Mortar

Abstract

:1. Introduction

2. Materials and Testing Methods

2.1. Materials

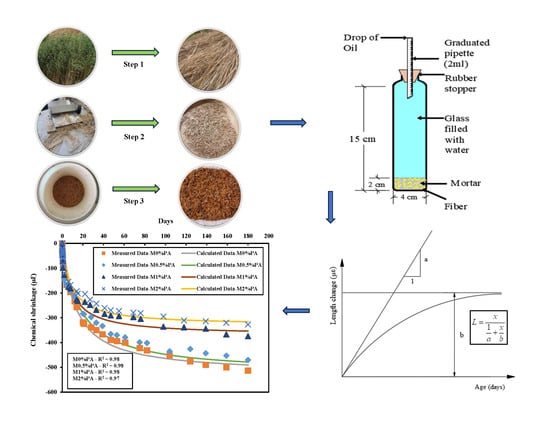

2.1.1. Phragmites-Australis Fiber

2.1.2. Mix Proportions

- (1)

- Ordinary Portland cement type I conforming to the Lebanese norms: PA-L 42.5N with a density, specific gravity and Blaine surface area of 1440 kg/m3, 3.15 and 399.8 m2/kg respectively.

- (2)

- Siliceous sand with a specific gravity, water absorption and fineness modulus of 2.65, 2.33% and 2.8, respectively.

2.1.3. Samples Preparation

2.2. Testing Methods

2.2.1. Mechanical Properties

2.2.2. Length Change Test

Drying Shrinkage, Autogenous Shrinkage, and Expansion Tests

Chemical Shrinkage Test

2.3. Estimation of Length Change

- L = Predicted length change (i.e., chemical, autogenous, drying shrinkage, or expansion)

- a = Initial rate of length change (IRL)

- a = Initial rate of length change (IRL)

- x = Age (days)

- b = Ultimate length change (UL)

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Compressive Strength

3.1.2. Flexural Strength

3.2. Length Change

3.2.1. Chemical Shrinkage

3.2.2. Autogenous Shrinkage

3.2.3. Drying Shrinkage

3.2.4. Expansion

4. Correlations between Different Length Change

5. Conclusions

- Generally, the presence of fibers shows a slight reduction in compressive strength, except at 90 days, where the 1% PA mix shows a higher value. However, the flexural strength shows a reduction in the presence of fibers except in the mortar mix containing 1% fiber where a noticeable increase was observed at curing ages beyond 3 days and up to 180 days.

- The incorporation of PA fibers up to 2% significantly contributes to reducing length change of mortar. The chemical shrinkage, autogenous shrinkage, drying shrinkage and expansion are reduced, compared to the control, by 37%, 19%, 15%, and 20%, respectively, at 180 days.

- The hyperbolic model demonstrates a good fit with the experimental data across all length change parameters with a high coefficient of correlation (R2 > 0.98). The predicted ultimate length change is systematically reduced with the increase in the % of PA fibers. However, the initial rate of length change has a maximum value at 1% PA fibers. Also, there is a strong linear correlation between chemical shrinkage and other length change parameters supported by a high coefficient of determination (R2 > 0.97).

- Future research on PA fibers in cementitious systems may include other properties such as sorptivity, water absorption, permeability, sulfate attack, chloride ingress, and abrasion resistance. Mortar can also be used in masonry blocks and plastering. Including fibers in the mortar can improve the shrinkage characteristics of the bonded masonry blocks and plaster. Therefore, further research can include relevant testing on masonry and plaster. This should allow the development of guidelines for using PA fibers in construction applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Holden, E.; Linnerud, K.; Banister, D. Sustainable development: Our common future revisited. Glob. Environ. Chang. 2014, 26, 130–139. [Google Scholar] [CrossRef]

- Grybaite, V.; Tvaronavičiene, M. Estimation of sustainable development: Germination on institutional level. J. Bus. Econ. Manag. 2008, 9, 327–334. [Google Scholar] [CrossRef]

- Taleb, H.M.; Sharples, S. Developing sustainable residential buildings in Saudi Arabia: A case study. Appl. Energy 2011, 88, 383–391. [Google Scholar] [CrossRef]

- Thanu, H.P.; Kanya Kumari, H.G.; Rajasekaran, C. Sustainable building management by using alternative materials and techniques. In Sustainable Construction and Building Materials: Select Proceedings of ICSCBM; Springer: Singapore, 2018; pp. 583–593. [Google Scholar] [CrossRef]

- Alabi, B.; Fapohunda, J. Criteria to Be Considered in the Selection of Building Materials for Sustainable Housing Delivery. In The Construction Industry in the Fourth Industrial Revolution: Proceedings of 11th Construction Industry Development Board (CIDB) Postgraduate Research Conference; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; Volume 11, pp. 412–418. [Google Scholar] [CrossRef]

- Nguyen, N.L. Comparison of autogenous shrinkage measurements by different methods in case of fast-hardening mortar. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 16–17 September 2020; IOP Publishing: Bristol, UK, 2020; Volume 869, p. 032041. [Google Scholar] [CrossRef]

- Zeng, H.; Li, Y.; Zhang, J.; Chong, P.; Zhang, K. Effect of limestone powder and fly ash on the pH evolution coefficient of concrete in a sulfate-freeze–thaw environment. J. Mater. Res. Technol. 2022, 16, 1889–1903. [Google Scholar] [CrossRef]

- Ahmad, S.; Al-Amoudi, O.S.B.; Khan, S.M.; Maslehuddin, M. Effect of silica fume inclusion on the strength, shrinkage and durability characteristics of natural pozzolan-based cement concrete. Case Stud. Constr. Mater. 2022, 17, e01255. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, B.; Hu, X.; Liu, J.; Zhang, Z.; Pan, X.; Xie, Z.; Chang, J.; Zhang, T.; Nehdi, M.L.; et al. Effect of CO2 surface treatment on penetrability and microstructure of cement-fly ash–slag ternary concrete. Cem. Concr. Compos. 2021, 123, 104194. [Google Scholar] [CrossRef]

- Vilaplana, F.; Strömberg, E.; Karlsson, S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stab. 2010, 95, 2147–2161. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Santos, S.F.; Schmidt, R.; Almeida, A.E.; Tonoli, G.H.; Savastano, H., Jr. Supercritical carbonation treatment on extruded fibre–cement reinforced with vegetable fibres. Cem. Concr. Compos. 2015, 56, 84–94. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Coutts, R.S. A review of Australian research into natural fibre cement composites. Cem. Concr. Compos. 2005, 27, 518–526. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Y. Novel lignocellulosic hybrid particleboard composites made from rice straws and coir fibers. Mater. Des. 2014, 55, 19–26. [Google Scholar] [CrossRef]

- Ganiron, T.U., Jr. Influence of polymer fiber on strength of concrete. Int. J. Adv. Sci. Technol. 2013, 55, 53–66. [Google Scholar]

- El Messiry, M.; Fadel, N. Tailoring the mechanical properties of jute woven/cement composite for innovation in the architectural constructions. J. Nat. Fibers 2021, 18, 1181–1193. [Google Scholar] [CrossRef]

- Palanikumar, K.; Ramesh, M.; Hemachandra Reddy, K. Experimental investigation on the mechanical properties of green hybrid sisal and glass fiber reinforced polymer composites. J. Nat. Fibers 2016, 13, 321–331. [Google Scholar] [CrossRef]

- Palanisamy, E.; Ramasamy, M. Dependency of sisal and banana fiber on mechanical and durability properties of polypropylene hybrid fiber reinforced concrete. J. Nat. Fibers 2022, 19, 3147–3157. [Google Scholar] [CrossRef]

- Rajendran, M.; Nagarajan, C.K. Experimental investigation on bio-composite using jute and banana fiber as a potential substitute of solid wood based materials. J. Nat. Fibers 2022, 19, 4557–4566. [Google Scholar] [CrossRef]

- Jaballi, S.; Miraoui, I.; Hassis, H. Long-unidirectional palm and sisal fibers reinforced composite: An experimental investigation. J. Nat. Fibers 2017, 14, 368–378. [Google Scholar] [CrossRef]

- Prasanthi, P.P.; Babu, K.S.; Niranjan Kumar, M.S.R.; Kumar, A.E. Analysis of sisal fiber waviness effect on the elastic properties of natural composites using analytical and experimental methods. J. Nat. Fibers 2021, 18, 1675–1688. [Google Scholar] [CrossRef]

- Zakaria, M.; Ahmed, M.; Hoque, M.; Shaid, A. A comparative study of the mechanical properties of jute fiber and yarn reinforced concrete composites. J. Nat. Fibers 2018, 17, 676–687. [Google Scholar] [CrossRef]

- Ede, A.N.; Agbede, J.O. Use of coconut husk fiber for improved compressive and flexural strength of concrete. Int. J. Sci. Eng. Res. 2015, 6, 968–974. [Google Scholar]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental investigation of the physical and mechanical properties of sisal fiber-reinforced concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Eller, F.; Skálová, H.; Caplan, J.S.; Bhattarai, G.P.; Burger, M.K.; Cronin, J.T.; Guo, W.Y.; Guo, X.; Hazelton, E.L.; Kettenring, K.M.; et al. Cosmopolitan species as models for ecophysiological responses to global change: The common reed Phragmites australis. Front. Plant Sci. 2017, 8, 1833. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, R.; Khatib, J.; Ghorbel, E.; Elkordi, A. Effect of Adding Phragmites-Australis Plant on the Chemical Shrinkage and Mechanical Properties of Mortar. In International Conference on Bio-Based Building Materials; Springer Nature: Cham, Switzerland, 2023; pp. 573–584. [Google Scholar]

- Packer, J.G.; Meyerson, L.A.; Skálová, H.; Pyšek, P.; Kueffer, C. Biological flora of the British Isles: Phragmites australis. J. Ecol. 2017, 105, 1123–1162. [Google Scholar] [CrossRef]

- Mal, T.K.; Narine, L. The biology of Canadian weeds. 129. Phragmites australis (Cav.) Trin. ex Steud. Can. J. Plant Sci. 2004, 84, 365–396. [Google Scholar] [CrossRef]

- Machaka, M.; Khatib, J.; Baydoun, S.; Elkordi, A.; Assaad, J.J. The effect of adding phragmites australis fibers on the properties of concrete. Buildings 2022, 12, 278. [Google Scholar] [CrossRef]

- Ramadan, R.; Jahami, A.; Khatib, J.; El-Hassan, H.; Elkordi, A. Improving Structural Performance of Reinforced Concrete Beams with Phragmites Australis Fiber and Waste Glass Additives. Appl. Sci. 2023, 13, 4206. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Compressive and flexural properties of hemp fiber reinforced concrete. Fibers Polym. 2004, 5, 187–197. [Google Scholar] [CrossRef]

- Bentz, D.P. Influence of water-to-cement ratio on hydration kinetics: Simple models based on spatial considerations. Cem. Concr. Res. 2006, 36, 238–244. [Google Scholar] [CrossRef]

- Chand, N.; Fahim, M. Tribology of Natural Fiber Polymer Composites; Woodhead Publishing: Sawston, UK, 2020. [Google Scholar]

- EN 1015-11. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. British Standards Institution (BSI): London, UK, 2007.

- ASTM C 490-04; Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete. 2004 Annual Book of ASTM standards, Section 4. vol. 04.02 (Concrete and Aggregates). ASTM: Philadelphia, PA, USA, 2004; p. 5.

- ASTM C 1608. Standard Test Method for Chemical Shrinkage of Hydraulic Cement Paste. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Volume stability of cement paste containing limestone fines. Buildings 2021, 11, 366. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; ElKordi, A. Effect of using limestone fines on the chemical shrinkage of pastes and mortars. Environ. Sci. Pollut. Res. 2023, 30, 25287–25298. [Google Scholar] [CrossRef] [PubMed]

- Khatib, J.M.; Ramadan, R.; Ghanem, H.; Elkordi, A.; Baalbaki, O.; Kırgız, M. Chemical shrinkage of paste and mortar containing limestone fines. Mater. Today Proc. 2022, 61, 530–536. [Google Scholar] [CrossRef]

- Khatib, J.M.; Ramadan, R.; Ghanem, H.; Elkordi, A.; Sonebi, M. Effect of limestone fines as a partial replacement of cement on the chemical, autogenous, drying shrinkage and expansion of mortars. Mater. Today Proc. 2022, 58, 1199–1204. [Google Scholar] [CrossRef]

- Ghanem, H.; Ramadan, R.; Khatib, J.; Elkordi, A. A Review on Chemical and Autogenous Shrinkage of Cementitious Systems. Materials 2024, 17, 283. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.I.; Jang, S.Y.; Kwon, S.J.; Lee, B.Y. Tensile behavior and cracking pattern of an ultra-high-performance mortar reinforced by polyethylene fiber. Adv. Mater. Sci. Eng. 2017, 2017, 5383982. [Google Scholar] [CrossRef]

- Suryawanshi, Y.R.; Dalvi, M.J.D. Study of Sisal Fibre as Concrete Reinforcement Material in Cement Based Composites. Int. J. Eng. Res. Technol. 2013, 2, 1–4. [Google Scholar]

- Ramirez, A. Physical-Mechanical Properties of Fiber Cement Elements made of Rice Straw, Sugercane, Bagass requis and Cocunt Husk Fibers. In Fibre Reinforced Cement and Concrete; CRC Press: Boca Raton, FL, USA, 1992; pp. 1203–1215. [Google Scholar]

- Rokbi, M.; Osmani, H.; Imad, A.; Benseddiq, N. Effect of chemical treatment on flexure properties of natural fiber-reinforced polyester composite. Procedia Eng. 2011, 10, 2092–2097. [Google Scholar] [CrossRef]

- Bessadok, A.; Roudesli, S.; Marais, S.; Follain, N.; Lebrun, L. Alfa fibres for unsaturated polyester composites reinforcement: Effects of chemical treatments on mechanical and permeation properties. Compos. Part A Appl. Sci. Manuf. 2009, 40, 184–195. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, P. Investigation of the hydrogen-bond structure of cellulose diacetate by two-dimensional infrared correlation spectroscopy. Carbohydr. Polym. 2008, 74, 509–513. [Google Scholar] [CrossRef]

- De La Grée, G.D.; Yu, Q.L.; Brouwers, H.J.H. Assessing the effect of CaSO4 content on the hydration kinetics, microstructure and mechanical properties of cements containing sugars. Constr. Build. Mater. 2017, 143, 48–60. [Google Scholar] [CrossRef]

- Jongvisuttisun, P.; Leisen, J.; Kurtis, K.E. Key mechanisms controlling internal curing performance of natural fibers. Cem. Concr. Res. 2018, 107, 206–220. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Effect of flax fibers on early age shrinkage and cracking of earth concrete. Constr. Build. Mater. 2020, 254, 119315. [Google Scholar] [CrossRef]

- Alzebdeh, K.I.; Nassar, M.M.; Arunachalam, R. Effect of fabrication parameters on strength of natural fiber polypropylene composites: Statistical assessment. Measurement 2019, 146, 195–207. [Google Scholar] [CrossRef]

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984. [Google Scholar] [CrossRef]

- Brahim, S.B.; Cheikh, R.B. Influence of fibre orientation and volume fraction on the tensile properties of unidirectional Alfa-polyester composite. Compos. Sci. Technol. 2007, 67, 140–147. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Murugananthan, K.; Sanjay, M.R. Physicochemical properties of new cellulosic fibers from Azadirachta indica plant. J. Nat. Fibers 2018, 15, 29–38. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Zuo, Y.; Wei, X. Relations among electrical resistivity, chemical and autogenous shrinkage of cement pastes. Adv. Cem. Res. 2015, 27, 175–183. [Google Scholar] [CrossRef]

| kg/m3 | |||||||

|---|---|---|---|---|---|---|---|

| Mortar Code | Cement (C) | Sand (S) | Water | PA Fibers | PA Fibers (% by vol) | W/C | S/C |

| M-0%PA | 616.5 | 1233 | 339.1 | 0 | 0 | 0.55 | 2 |

| M-0.5%PA | 616.5 | 1233 | 339.1 | 3.33 | 0.5 | 0.55 | 2 |

| M-1%PA | 616.5 | 1233 | 339.1 | 6.65 | 1 | 0.55 | 2 |

| M-2%PA | 616.5 | 1233 | 339.1 | 13.3 | 2 | 0.55 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Effect of Adding Phragmites-Australis Fiber on the Mechanical Properties and Volume Stability of Mortar. Fibers 2024, 12, 14. https://doi.org/10.3390/fib12020014

Khatib J, Ramadan R, Ghanem H, Elkordi A. Effect of Adding Phragmites-Australis Fiber on the Mechanical Properties and Volume Stability of Mortar. Fibers. 2024; 12(2):14. https://doi.org/10.3390/fib12020014

Chicago/Turabian StyleKhatib, Jamal, Rawan Ramadan, Hassan Ghanem, and Adel Elkordi. 2024. "Effect of Adding Phragmites-Australis Fiber on the Mechanical Properties and Volume Stability of Mortar" Fibers 12, no. 2: 14. https://doi.org/10.3390/fib12020014