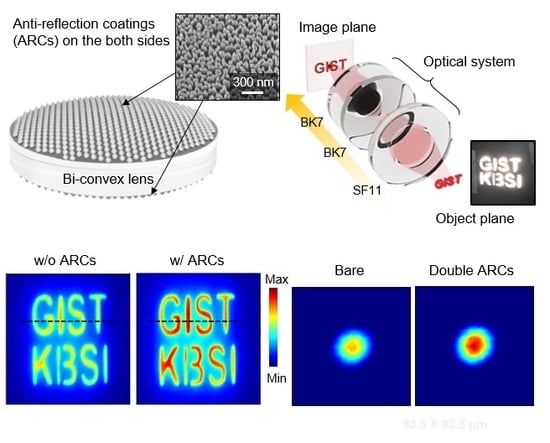

Double-Sided Anti-Reflection Nanostructures on Optical Convex Lenses for Imaging Applications

Abstract

:1. Introduction

2. Optical Imaging of Bi-Convex Lenses with Double-Side Antireflection Coatings

3. Simulation and Optimization of Geometry of Nanostructures

4. Fabrication of Nanostructures on Both Sides of the Bi-Convex Lens

5. Imaging Properties of Fabricated Single Lens

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Potyrailo, R.A.; Ghiradella, H.; Vertiatchikh, A.; Dovidenko, K.; Cournoyer, J.R.; Olson, E. Morpho butterfly wing scales demonstrate highly selective vapour response. Nat. Photonics 2007, 1, 123–128. [Google Scholar] [CrossRef]

- Nakata, K.; Sakai, M.; Ochiai, T.; Murakami, T.; Takagi, K.; Fujishima, A. Antireflection and self-cleaning properties of a moth-eye-like surface coated with TiO2 particles. Langmuir 2011, 27, 3275–3278. [Google Scholar] [CrossRef] [PubMed]

- Aizenberg, J.; Tkachenko, A.; Weiner, S.; Addadi, L.; Hendler, G. Calcitic microlenses as part of the photoreceptor system in brittlestars. Nature 2001, 412, 819–822. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Xie, Y.; Malyarchuk, V.; Xiao, J.; Jung, I.; Choi, K.J.; Liu, Z.; Park, H.; Lu, C.; Kim, R.H.; et al. Digital cameras with designs inspired by the arthropod eye. Nature 2013, 497, 95–99. [Google Scholar] [CrossRef] [PubMed]

- Bernhard, C.G. Structural and functional adaptation in a visual system. Endeavour 1967, 26, 79–84. [Google Scholar]

- Huang, Y.F.; Chattopadhyay, S.; Jen, Y.J.; Peng, C.Y.; Liu, T.A.; Hsu, Y.K.; Pan, C.L.; Lo, H.C.; Hsu, C.H.; Chang, Y.H.; et al. Improved broadband and quasi-omnidirectional anti-reflection properties with biomimetic silicon nanostructures. Nat. Nanotechnol. 2007, 2, 770–774. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.J.; Lee, Y.; Kim, H.G.; Choi, K.J.; Kweon, H.S.; Park, S.; Jeong, K.H. Biologically inspired LED lens from cuticular nanostructures of firefly lantern. PNAS 2012, 109, 18674–18678. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tavakoli, M.M.; Tsui, K.H.; Zhang, Q.; He, J.; Yao, Y.; Li, D.; Fan, Z. Highly efficient flexible perovskite solar cells with antireflection and self-cleaning nanostructures. ACS Nano 2015, 9, 10287–10295. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.J.; Lee, G.J.; Kim, S.; Min, J.W.; Jeong, S.Y.; Yoo, Y.J.; Lee, S.; Song, Y.M. Efficient light absorption by GaN truncated nanocones for high performance water splitting applications. ACS Appl. Mater. Interfaces 2018, 10, 28672–28678. [Google Scholar] [CrossRef]

- Kadakia, L.; Naczas, S.; Bakhru, H.; Huang, M. Fabrication of surface textures by ion implantation for antireflection of silicon crystals. Appl. Phys. Lett. 2010, 97, 191912. [Google Scholar] [CrossRef]

- Song, Y.M.; Jang, S.J.; Yu, J.S.; Lee, Y.T. Bioinspired parabola subwavelength structures for improved broadband antireflection. Small 2010, 6, 984–987. [Google Scholar] [CrossRef] [PubMed]

- Tucher-Schwartz, J.M.; Breavers, K.R.; Sit, W.W.; Shah, A.T.; Duvall, C.L.; Skala, M.C. In vivo imaging of nanoparticle delivery and tumor microvasculature with multimodal optical coherence tomography. Biomed. Opt. Express 2014, 5, 1731–1743. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Latour, G.; Robinet, L.; Dazzi, A.; Portier, F.; Deniset-Besseau, A.; Schanne-Klein, M.C. Correlative nonlinear optical microscopy and infrared nanoscopy reveals collagen degradation in altered parchments. Sci. Rep. 2016, 6, 26344. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vogler, N.; Heuke, S.; Bocklitz, T.W.; Schmitt, M.; Popp, J. Multimodal imaging spectroscopy of tissue. Annu. Rev. Anal. Chem. 2015, 8, 359–387. [Google Scholar] [CrossRef] [PubMed]

- Su, W.X.; Wu, C.Y.; Lee, Y.C. Anti-reflection nano-structures fabricated on curved surface of glass lens based on metal contact printing lithography. Microelectron. Eng. 2019, 214, 15–20. [Google Scholar] [CrossRef]

- Lee, Y.; Bae, S.I.; Eom, J.; Suh, H.C.; Jeong, K.H. Antireflective glass nanoholes on optical lenses. Opt. Express 2018, 26, 14786–14791. [Google Scholar] [CrossRef] [PubMed]

- Park, S.C.; Kim, N.; Ji, S.; Lim, H. Fabrication and characterization of moth-eye mimicking nanostructured convex lens. Microelectron. Eng. 2016, 158, 35–40. [Google Scholar] [CrossRef]

- Mano, I.; Uchida, T.; Taniguchi, J. Fabrication of the antireflection structure on aspheric lens surface and lens holder. Microelectron. Eng. 2018, 191, 97–103. [Google Scholar] [CrossRef]

- Xie, R.; Su, J.; Rentchler, E.C.; Zhang, Z.; Johnson, C.K.; Shi, H.; Hui, R. Multi-modal label-free imaging based on a femtosecond fiber laser. Biomed. Opt. Express 2014, 5, 2390–2396. [Google Scholar] [CrossRef] [Green Version]

- Perera, M.N.M.N.; Schmidt, D.; Gibbs, W.E.K.; Juodkazis, S.; Stoddart, P.R. Effective optical constants of anisotropic silver nanoparticle films with plasmonic properties. Opt. Lett. 2016, 41, 5495–5498. [Google Scholar] [CrossRef]

- Lin, C.; Huang, N.; Povinelli, M.L. Effect of aperiodicity on the broadband reflection of silicon nanorod structures for photovoltaics. Opt. Express 2012, 20, A125–A132. [Google Scholar] [CrossRef]

- Song, Y.M.; Choi, H.J.; Yu, J.S.; Lee, Y.T. Design of highly transparent glasses with broadband antireflective subwavelength structures. Opt. Express 2010, 18, 13063–13071. [Google Scholar] [CrossRef] [PubMed]

- Park, G.C.; Song, Y.M.; Ha, J.H.; Lee, Y.T. Broadband antireflective glasses with subwavelength structures using randomly distributed Ag nanoparticles. J. Nanosci. Nanotechnol. 2011, 11, 6152–6156. [Google Scholar] [CrossRef] [PubMed]

- Nam, W.I.; Yoo, Y.J.; Song, Y.M. Geometrical shape design of nanophotonic surfaces for thin film solar cells. Opt. Express 2016, 24, A1033–A1044. [Google Scholar] [CrossRef] [PubMed]

- Yoo, Y.J.; Chang, K.S.; Song, Y.M. Design of ZnO hollow nanosphere arrays for UV absorbing transparent glasses. Opt. Quantum Electron. 2016, 48, 88. [Google Scholar] [CrossRef]

- Hopkins, H.H. On the diffraction theory of optical images. Proc. R. Soc. London Ser. A 1953, 217, 408–432. [Google Scholar]

- Park, G.C.; Song, Y.M.; Kang, E.K.; Lee, Y.T. Size-dependent optical behavior of disordered nanostructures on glass substrates. Appl. Opt. 2012, 51, 5890–5896. [Google Scholar] [CrossRef]

- McDonald, A.; McConnell, G.; Cox, D.C.; Riis, E.; Griffin, P.F. 3D mapping of intensity field about the focus of a micrometer–scale parabolic mirror. Opt. Express 2015, 23, 2375–2382. [Google Scholar] [CrossRef]

- Novotny, L.; Pohl, D.W.; Hecht, B. Scanning near-field optical probe with ultrasmall spot size. Opt. Lett. 1995, 20, 970–972. [Google Scholar] [CrossRef]

| Material | ROC | Refractive Index at 587.6 nm | Diameter (nm) | EFL (mm) at 587.6 nm | Center Thickness (mm) | Edge Thickness (mm) | NA | f/# |

|---|---|---|---|---|---|---|---|---|

| SF11 | 45.61 | 1.78 | 30 | 30 | 6.50 | 1.43 | 0.50 | 1.0 |

| BK7 | 123.17 | 1.51 | 30 | 120 | 5.00 | 3.17 | 0.13 | 4.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, H.J.; Kim, Y.J.; Yoo, Y.J.; Lee, G.J.; Kim, M.S.; Chang, K.S.; Song, Y.M. Double-Sided Anti-Reflection Nanostructures on Optical Convex Lenses for Imaging Applications. Coatings 2019, 9, 404. https://doi.org/10.3390/coatings9060404

Jang HJ, Kim YJ, Yoo YJ, Lee GJ, Kim MS, Chang KS, Song YM. Double-Sided Anti-Reflection Nanostructures on Optical Convex Lenses for Imaging Applications. Coatings. 2019; 9(6):404. https://doi.org/10.3390/coatings9060404

Chicago/Turabian StyleJang, Hyuk Jae, Yeong Jae Kim, Young Jin Yoo, Gil Ju Lee, Min Seok Kim, Ki Soo Chang, and Young Min Song. 2019. "Double-Sided Anti-Reflection Nanostructures on Optical Convex Lenses for Imaging Applications" Coatings 9, no. 6: 404. https://doi.org/10.3390/coatings9060404