2.1. Material

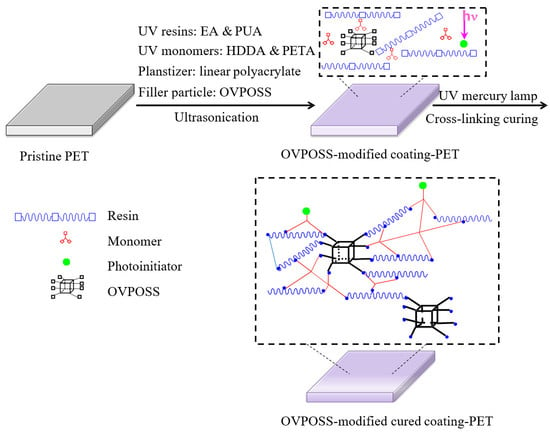

Epoxy acrylate (EA, Zhuhai Changxing Chemical Materials, Zhuhai, China) and 6-functional aliphatic urethane acrylate (PUA, Wanhua Chemical, Beijing, China) were used as the main resins, pentaerythritol triacrylate (PETA) and 1,6-hexanediol diacrylate (HDDA, Jiangmen Sanmu Chemical, Jiangmen, China) were used as reactive diluents, linear thermoplastic polyacrylate (Garbo Chemical, Via Prati Nuovi, Italy) was used as a plasticizer, acetone (Yihua Chemical, Shanghai, China) and tetrahydrofuran (THF, Yihua Chemical, Shanghai, China) were used as solvents, and 125 μm PET film (Buddha DuPont Hongji Film Chemical, Foshan, China) was used as the substrate.

The inorganic component consisted of a transparent glass powder named JH-10, belonging to a quartz sand filler, whose model is TS010, and particle size is 2.5 μm, purchased from Jia Baoli Chemical (Shanghai, China). SiO2 NPs, whose model is HL-150 and particle size is 20 nm, was prepared using the vapor deposition method. Al2O3 NPs, whose model is Aluna-100, and particle size is 13 nm, was prepared by AEROSIL similarly to the vapor deposition method. The two materials were both purchased from Guangzhou Top Billion Trade Chemical (Guangzhou, China). ZrO NPs (JC-R50, average particle sizes = 50 nm) and TiO2 NPs (JC-T25, average particle sizes = 60 nm) were purchased from Shenzhen Jingdi Chemical (Shenzhen, China). Octavinyl polyhedral oligomeric silsesquioxane (OVPOSS, 98%) was prepared by Balingway Technology. 1-Hydroxycyclohexyl-phenyl-ketone (Irgacure184, Ciba Specialty Chemicals, Basel, Switzerland), and 2-Hydroxy-2-methyl-1-phenyl-1-prop-anone (Darocure1173, Shanghai Titan Technology, Shanghai, China) were used as photoinitiators.

2.3. Characterization

Pencil hardness was characterized using a PPH-1 type tester according to the standardized pencil hardness test (GB/T 6739-86) [

19]. Impact resistance was tested using a heavy impact tester based on the GB/T 1732-93 standardized test [

20]. The standardized Crosshatch adhesion test (GB/T 9286-1998) [

21] was used to test paint film adhesion. Flexibility was tested according to the GB/T 6742-86 standardized test [

22]. The water resistance of the paint was carried out using the GB/T 1733-1993 method [

23]. The chemical resistance properties, including acid, alkali, alcohol and salt, were detected by the GB/T 1763-1979 standardized test [

24].

Ultraviolet visible light spectra (UV-Vis spectra) of the coating transmittance were recorded by the U-3010 spectrophotometer (Hitachi, Tokyo, Japan). The detected wavelength was 200–800 nm.

The change in the functional structure of OVPOSS before and after curing the UV coating was studied using a Fourier transform infrared spectrometer (FT-IR, Nicolet 5700, Nicolet company, New York, NY, USA). Infrared spectra were recorded using the KBr tableting method with a resolution of 4 cm−1 and scan times of 32.

Thermal gravity analysis (TG) was performed under nitrogen and air atmosphere on a TG 209 F3 Tarsus apparatus (Netzsch, Selb, Germany), from 25 to 600 °C, with a heating rate of 10 °C/min. The samples (about 5 mg) were placed in open alumina pans and fluxed with nitrogen or air (gas flow: 20 mL/min). Differential thermal gravity (DTG) was a differential curve of TG, used to measure the relationship between the rate of change in weight loss and the temperature of the sample under constant temperature rising conditions.

Dynamic–mechanical (DMA) analyses were performed using a DMA Q800 (TA Instruments, New Castle, DE, USA) in tensile configuration. The following experimental conditions were adopted: temperature range from 25 to 250 °C; heating rate of 5 °C/min; 1 Hz frequency; 0.05% of oscillation amplitude in strain-controlled mode; and sample with length × width × height: (30–50) mm × 8 mm × 2 mm. The storage modulus (E′), loss modulus (E″), and tan δ curve were recorded. Tg values were calculated from the peak value of tan δ curve.

A field emission scanning electron microscope (Hitachi uhr FE-SEM SU8200, Tokyo, Japan) was used to observe the dispersion morphology of different fillers in films. Three square millimeters of the cured film was adhered to the conductive adhesive. As the samples were not conductive, a gold film was plated on the surface of the film and placed in a vacuum chamber for electronic scanning.

An atomic force microscope (AFM, Nanoscope IIIa, Veeco Company, Plainview, NY, USA) was used to test the surface of hybrid films. The test mode was tapping mode and the resonance frequency was 1 Hz. The cantilever adjusted sum value used was greater than 2.5 and the vertical level signal was ±0.1. The cured film was stuck on the mica plate under the probe, and the instrument was adjusted to a proper position to carry out a scanning test of the sample surface topography.