Rheological and Tribological Properties of Lithium Grease and Polyurea Grease with Different Consistencies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microstructure Characterization

2.3. Rheological Test

2.4. Tribological Test

3. Results and Discussion

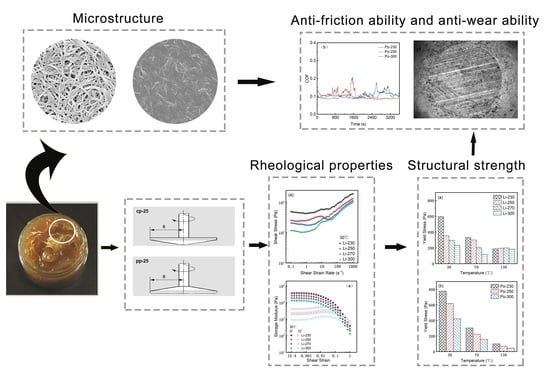

3.1. Microstructure and Plateau Modulus of Greases and Their Correlation

3.2. Apparent Viscosity of Grease

3.3. Rheological Properties of Grease

3.4. Yield Stress and Structural Strength of Grease

3.5. Tribological Properties of Grease

4. Conclusions

- Through the plateau modulus GN and yield stress τy in the rheological experiment, the structural strength of grease can be obtained, the degree of entanglement of the same type of grease can be assessed, and then the tribological and wear properties of the grease can be predicted.

- The increase in temperature will decrease the degree of fiber entanglement, apparent viscosity, storage modulus and structural strength of the greases. The rheological properties of PAO oil-polyurea grease are greatly affected by temperature, but its structural strength is better than that of mineral oil-lithium grease, and its fluidity is lower than that of mineral oil-lithium grease.

- The higher the consistency (the smaller the cone penetration), the higher the apparent viscosity, yield stress (structural strength), and cross-stress (the worse the fluidity) due to the enhancement in inner compositions interactions of greases. The consistency exerts little influence on the shear-thinning rate.

- In boundary lubrication state: The consistency of mineral oil-lithium grease is expected to affect the friction coefficient through its influence on the grease’s structural strength and the film-forming ability. Higher consistency promotes better separation of the surfaces of friction pair to result in a reducing wear rate. For PAO-polyurea grease, the consistency, within a certain range, has little effect on the coefficient of friction and wear. The wear for PAO-polyurea grease is larger than that for lithium grease because the higher storage modulus and yield stress of PAO-polyurea grease lead to worse contact replenishment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; He, Q.; Du, S.M.; Zhang, Y.Z. Effect of few layer graphene additive on the tribolog-ical properties of lithium grease. Lubr. Sci. 2020, 32, 333–343. [Google Scholar] [CrossRef]

- Lugt, P.M. A Review on Grease Lubrication in Rolling Bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Fan, X.Q.; Li, W.; Li, H.; Zhu, M.H.; Xia, Y.Q.; Wang, J.J. Probing the effect of thickener on tribolo-gical properties of lubricating greases. Tribol. Int. 2018, 118, 128–139. [Google Scholar] [CrossRef]

- Shah, R.; Gashi, B.; Poggini, S.G.; Lagrille, M.C.; Rosenkranz, A. Recent trends in batteries and lubricants for electric vehicles. Adv. Mech. Eng. 2021, 13, 1–10. [Google Scholar] [CrossRef]

- Shah, R.; Mittal, V.; Matsil, E.; Rosenkranz, A. Magnesium-ion batteries for electric vehicles: Current trends and future perspectives. Adv. Mech. Eng. 2021, 13, 1–9. [Google Scholar] [CrossRef]

- Gow, G. Lubricating grease. In Book Chemistry and Technology of Lubricants, 3rd ed.; Mortier, R.M., Orszulik, S.T., Eds.; Springer: Dordrecht, The Netherlands, 2010; Volume 3, pp. 411–432. [Google Scholar] [CrossRef]

- Mas, R.; Magnin, A. Rheology of colloidal suspensions: Case of lubricating greases. J. Rheol. 1994, 38, 889–908. [Google Scholar] [CrossRef]

- Maciej, P. Assessment of the effect of temperature, shear rate and thickener cont-ent on the thixotropy of lithium lubricating greases. Proc. Inst. Mech. Eng. Part J. 2013, 227, 209–219. [Google Scholar] [CrossRef]

- Yeong, S.K.; Luckham, P.F.; Tadros, T.F. Steady flow and viscoelastic properties of lu-bricating grease containing various thickener concentrations. J. Colloid Interface Sci. 2004, 274, 285–293. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Moreno, G.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Influence of soap/polymer concentration ratio on the rheological properties of lithium lubricating greases modified with virgin LDPE. J. Ind. Eng. Chem. 2009, 15, 687–693. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Valencia, C.; Sánchez, M.C.; Franco, J.M. Evaluation of Thermal and Rheological Properties of Lubricating Greases Modified with Recycled LDPE. Tribol. Trans. 2012, 55, 518–528. [Google Scholar] [CrossRef]

- Delgado, M.A.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Influence of Soap Concentration and Oil Viscosity on the Rheology and Microstructure of Lubricating Greases. Ind. Eng. Chem. Res. 2006, 45, 1902–1910. [Google Scholar] [CrossRef]

- Mao, J.; Cheng, X.; Zhang, S. Study on Relationship between Rheological Properties and Microstructure for Lithium Complex Grease. Lubr. Eng. 2013, 38, 79–83. [Google Scholar]

- Couronne, I.; Blettner, G.; Vergne, P. Rheological Behavior of Greases: Part I-Effects of Composition and Structure. Tribol. Trans. 2000, 43, 619–626. [Google Scholar] [CrossRef]

- Sánchez, M.C.; Franco, J.M.; Valencia, C.; Gallegos, C.; Urquiola, F.; Urchegui, R. Atomic Force Microscopy and Thermo-Rheological Characterisation of Lubricating Greases. Tribol. Lett. 2011, 41, 463–470. [Google Scholar] [CrossRef]

- Xu, Z.; Ren, J.; Zhao, G.; Wang, Z.; Cai, H.; Wang, X.B. Effect of Amine Molecular Stru-cture on Rheological Properties of Polyurea Grease. Mocaxue Xuebao 2020, 40, 378–384. [Google Scholar] [CrossRef]

- Maciej, P. Effect of grease thickener and surface material on rheological properties of boundary layer. Colloids Surf. A 2015, 480, 462–467. [Google Scholar] [CrossRef]

- Cousseau, T.; Graca, B.M.; Campos, A.V.; Seabra, J.H.O. Influence of grease rheology on thrust ball bearings friction torque. Tribol. Int. 2012, 46, 106–113. [Google Scholar] [CrossRef] [Green Version]

- Gonçalves, D.; Pinho, S.; Graça, B.; Campos, A.V. Friction torque in thrust ball bearin-gs lubricated with polymer greases of different thickener content. Tribol. Int. 2016, 96, 87–96. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Evaluation of different polyolefins as rheology modifier additives in lubricating grease formulations. Mater. Chem. Phys. 2011, 128, 530–538. [Google Scholar] [CrossRef]

- Wu, C.; Xiong, R.; Ni, J.; Yao, L.; Chen, L.; Li, X. Effects of CuO nanoparticles on fricti-on and vibration behaviors of grease on rolling bearing. Tribol. Int. 2020, 152, 106552. [Google Scholar] [CrossRef]

- Gonçalves, D.; Graça, B.; Campos, A.V.; Seabra, J.H.O.; Leckner, J.; Westbroek, R. Form-ulation, rheology and thermal ageing of polymer greases—Part I: Influence of the thickener content. Tribol. Int. 2015, 87, 160–170. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, Z. Fatigue Failure Analysis of a Grease-Lubricated Roller Bearing from an Electric Motor. J. Fail. Anal. Prev. 2011, 11, 158–166. [Google Scholar] [CrossRef]

- Pan, J.; Cheng, Y.; Yang, J. Effect of heat treatment on the lubricating properties of lithium lubricating grease. RSC Adv. 2015, 5, 58686–58693. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydroynamic Lubrication of Point contacts: Part VI- Starvation Results. J. Lubr. Technol. 1977, 99, 15–23. [Google Scholar] [CrossRef]

| Grease | Base Oil | Thickener Type | Viscosity of Base Oil (mm2/s) | Unworked Penetration (0.1 mm) |

|---|---|---|---|---|

| Li-230 | Paraffin based mineral oil | Lithium 12 Hydroxystearate | 48 ± 0.1 | 230 ± 6.7 |

| Li-250 | 250 ± 7.0 | |||

| Li-270 | 270 ± 6.5 | |||

| Li-300 | 300 ± 7.1 | |||

| Po-230 | PAO | Cyclohexylamine, 18 amine and isocyanate | 48 ± 0.1 | 230 ± 6.8 |

| Po-250 | 250 ± 7.2 | |||

| Po-300 | 300 ± 7.0 |

| Base Oil | Dynamic Viscosity η (mPa·s) | Viscosity-Pressure Coefficient α (10−8 Pa−1) |

|---|---|---|

| Paraffin based mineral oil | 42.24 ± 0.08 | 1.94 |

| PAO | 39.36 ± 0.09 | 1.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, P.; Lin, J.; Gao, X. Rheological and Tribological Properties of Lithium Grease and Polyurea Grease with Different Consistencies. Coatings 2022, 12, 527. https://doi.org/10.3390/coatings12040527

Wang Y, Zhang P, Lin J, Gao X. Rheological and Tribological Properties of Lithium Grease and Polyurea Grease with Different Consistencies. Coatings. 2022; 12(4):527. https://doi.org/10.3390/coatings12040527

Chicago/Turabian StyleWang, Yanshuang, Pu Zhang, Jianghai Lin, and Xudong Gao. 2022. "Rheological and Tribological Properties of Lithium Grease and Polyurea Grease with Different Consistencies" Coatings 12, no. 4: 527. https://doi.org/10.3390/coatings12040527