Synthesis of High Quality Transparent Nanocrystalline Diamond Films on Glass Substrates Using a Distributed Antenna Array Microwave System

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Srikanth, V.V.S.S. Review of advances in diamond thin film synthesis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 303–318. [Google Scholar] [CrossRef]

- Kawano, Y.; Chiba, S.; Inoue, A. Application of diamond window for infrared laser diagnostics in a tokamak device. Rev. Sci. Instrum. 2004, 75, 279–280. [Google Scholar] [CrossRef]

- Mildren, R.P.; Butler, J.E.; Rabeau, J.R. CVD-diamond external cavity Raman laser at 573 nm. Opt. Express 2008, 16, 18950. [Google Scholar] [CrossRef] [PubMed]

- Martineau, P.M.; Lawson, S.C.; Taylor, A.J.; Quinn, S.J.; Evans, D.J.F.; Crowder, M.J. Identification of Synthetic Diamond Grown Using Chemical Vapor Deposition (CVD). Gems Gemol. 2004, 40, 2–25. [Google Scholar] [CrossRef]

- Ficeka, M.; Bogdanowicza, R.; Rylb, J. Nanocrystalline CVD Diamond Coatings on Fused Silica Optical Fibres: Optical Properties Study. Acta Phys. Pol. A 2015, 127, 868–873. [Google Scholar] [CrossRef]

- Simões, R.; Neto, V.F. Nanodiamond Coated Glass as a Protective Layer in Solar Cells. Mater. Today Proc. 2015, 2, 230–235. [Google Scholar] [CrossRef]

- Veerasamy, V.S.; Luten, H.A.; Petrmichl, R.H.; Thomsen, S.V. Diamond-like amorphous carbon coatings for large areas of glass. Thin Solid Film. 2003, 442, 1–10. [Google Scholar] [CrossRef]

- Ko, H.-W.; Chen, C.K.; Liu, C.-H.J. Optical scattering of diamond films. Diam. Relat. Mater. 1996, 5, 861–865. [Google Scholar] [CrossRef]

- Williams, O.A.; Daenen, M.; D’Haen, J.; Haenen, K.; Maes, J.; Moshchalkov, V.V.; Nesládek, M.; Gruen, D.M. Comparison of the growth and properties of ultrananocrystalline diamond and nanocrystalline diamond. Diam. Relat. Mater. 2006, 15, 654–658. [Google Scholar] [CrossRef]

- Yang, T.S.; Lai, J.Y.; Cheng, C.L.; Wong, M.S. Growth of faceted, ballas-like and nanocrystalline diamond films deposited in CH4/H2/Ar MPCVD. Diam. Relat. Mater. 2001, 10, 2161–2166. [Google Scholar] [CrossRef]

- Gruen, D.M. Nanocrystalline diamond films. Annu. Rev. Mater. Sci. 1999, 29, 211–259. [Google Scholar] [CrossRef]

- Liou, Y.; Inspektor, A.; Knight, D.; Weimer, R.; Pickrell, D.; Badzian, A.R.; Messier, R. Low Temperature Diamond Deposition on Glass. In Diamond Optics II; SPIE: Bellingham, WA, USA, 1989; Volume 1146. [Google Scholar]

- Achatz, P.; Garrido, J.A.; Stutzmann, M.; Williams, O.A.; Gruen, D.M.; Kromka, A.; Steinmüller, D. Optical properties of nanocrystalline diamond thin films. Appl. Phys. Lett. 2006, 88, 101908. [Google Scholar] [CrossRef]

- Shen, B.; Lin, Q.; Chen, S.; Ji, Z.; Huang, Z.; Zhang, Z. High-rate synthesis of ultra-nanocrystalline diamond in an argon-free hot filament chemical vapor deposition atmosphere for tribological films. Surf. Coat. Technol. 2019, 378, 124999. [Google Scholar] [CrossRef]

- Hamzah, E.; Yong, T.M.; Yajid, M.A.M. Surface morphology and bond characterization of nanocrystalline diamonds grown on tungsten carbide via hot filament chemical vapor deposition. J. Cryst. Growth 2013, 372, 109–115. [Google Scholar] [CrossRef]

- Liu, H.; Dandy, D.S. Diamond Chemical Vapor Deposition: Nucleation and Early Growth Stages; Noyes Publications: Park Ridge, NJ, USA, 1996. [Google Scholar]

- Zhou, D.; McCauley, T.G.; Qin, L.C.; Krauss, A.R.; Gruen, D.M. Synthesis of nanocrystalline diamond thin films from an Ar–CH4 microwave plasma. J. Appl. Phys. 1998, 83, 540–543. [Google Scholar] [CrossRef]

- Grotjohn, T.; Liske, R.; Hassouni, K.; Asmussen, J. Scaling behavior of microwave reactors and discharge size for diamond deposition. Diam. Relat. Mater. 2005, 14, 288–291. [Google Scholar] [CrossRef]

- Gracio, J.J.; Fan, Q.H.; Madaleno, J.C. Diamond growth by chemical vapour deposition. J. Phys. D Appl. Phys. 2010, 43, 374017. [Google Scholar] [CrossRef]

- Mehedi, H.A.; Achard, J.; Rats, D.; Brinza, O.; Tallaire, A.; Mille, V.; Silva, F.; Provent, C.; Gicquel, A. Low temperature and large area deposition of nanocrystalline diamond films with distributed antenna array microwave-plasma reactor. Diam. Relat. Mater. 2014, 47, 58–65. [Google Scholar] [CrossRef]

- Baudrillart, B.; Bénédic, F.; Melouani, A.S.; Oliveira, F.J.; Silva, R.F.; Achard, J. Low-temperature deposition of nanocrystalline diamond films on silicon nitride substrates using distributed antenna array PECVD system. Phys. Status Solidi (A) 2016, 213, 2575–2581. [Google Scholar] [CrossRef]

- Kim, J.; Tsugawa, K.; Ishihara, M.; Koga, Y.; Hasegawa, M. Large-area surface wave plasmas using microwave multi-slot antennas for nanocrystalline diamond film deposition. Plasma Sources Sci. Technol. 2009, 19, 015003. [Google Scholar] [CrossRef]

- Taylor, A.; Fendrych, F.; Fekete, L.; Vlček, J.; Řezáčová, V.; Petrák, V.; Krucký, J.; Nesládek, M.; Liehr, M. Novel high frequency pulsed MW-linear antenna plasma-chemistry: Routes towards large area, low pressure nanodiamond growth. Diam. Relat. Mater. 2011, 20, 613–615. [Google Scholar] [CrossRef]

- Drijkoningen, S.; Pobedinskas, P.; Korneychuk, S.; Momot, A.; Balasubramaniam, Y.; van Bael, M.K.; Turner, S.; Verbeeck, J.; Nesládek, M.; Haenen, K. On the Origin of Diamond Plates Deposited at Low Temperature. Cryst. Growth Des. 2017, 17, 4306–4314. [Google Scholar] [CrossRef]

- Liehr, M.; Wieder, S.; Dieguez-Campo, M. Large area microwave coating technology. Thin Solid Film. 2006, 502, 9–14. [Google Scholar] [CrossRef]

- Kromka, A.; Babchenko, O.; Izak, T.; Hruska, K.; Rezek, B. Linear antenna microwave plasma CVD deposition of diamond films over large areas. Vacuum 2012, 86, 776–779. [Google Scholar] [CrossRef]

- Zalieckas, J.; Pobedinskas, P.; Greve, M.M.; Eikehaug, K.; Haenen, K.; Holst, B. Large area microwave plasma CVD of diamond using composite right/left-handed materials. Diam. Relat. Mater. 2021, 116, 108394. [Google Scholar] [CrossRef]

- Latrasse, L.; Lacoste, A.; Sirou, J.; Pelletier, J. High density distributed microwave plasma sources in a matrix configuration: Concept, design and performance. Plasma Sources Sci. Technol. 2006, 16, 7–12. [Google Scholar] [CrossRef]

- Dekkar, D.; Bénédic, F.; Falentin-Daudré, C.; Brinza, O.; Issaoui, R.; Achard, J. Investigation of a distributed antenna array microwave system for the three-dimensional low-temperature growth of nanocrystalline diamond films. Diam. Relat. Mater. 2019, 94, 28–36. [Google Scholar] [CrossRef]

- Baudrillart, B.; Bénédic, F.; Brinza, O.; Bieber, T.; Chauveau, T.; Achard, J.; Gicquel, A. Microstructure and growth kinetics of nanocrystalline diamond films deposited in large area/low temperature distributed antenna array microwave-plasma reactor. Phys. Status Solidi A 2015, 212, 2611. [Google Scholar] [CrossRef]

- Baudrillart, B.; Bénédic, F.; Chauveau, T.; Bartholomot, A.; Achard, J. Nanocrystalline diamond films grown at very low substrate temperature using a distributed antenna array microwave process: Towards polymeric substrate coating. Diam. Relat. Mater. 2017, 75, 44–51. [Google Scholar] [CrossRef]

- Klauser, F.; Steinmüller-Nethl, D.; Kaindl, R.; Bertel, E.; Memmel, N. Raman Studies of Nano- and Ultra-nanocrystalline Diamond Films Grown by Hot-Filament CVD. Chem. Vap. Depos. 2010, 16, 127–135. [Google Scholar] [CrossRef]

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World J. Nano Sci. Eng. 2012, 2, 154. [Google Scholar] [CrossRef]

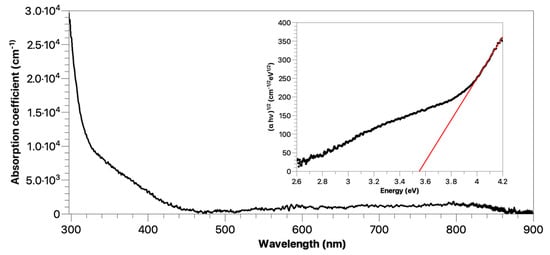

- Hassanien, A.S.; Akl, A.A.; El Radaf, I.M. Comparative studies for determining the optical band-gap energy of the novel polycrystalline thin ZnGa2S4 films sprayed at different film thickness. Research Sq. 2021. [Google Scholar] [CrossRef]

- Look, D.C.; Leach, J.H. On the accurate determination of absorption coefficient from reflectance and transmittance measurements: Application to Fe-doped GaN. J. Vac. Sci. Technol. B 2016, 34, 4–105. [Google Scholar] [CrossRef]

- Tauc, J. (Ed.) Amorphous and Liquid Semiconductors; Plenum Press: London, UK, 1974; p. 159. [Google Scholar]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical Properties and Electronic Structure of Amorphous Germanium. Phys. Status Solidi (B) 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Suram, S.K.; Newhouse, P.F.; Gregoire, J.M. High throughput light absorber discovery, Part 1: An algorithm for automated Tauc analysis. ACS Comb. Sci. 2016, 18, 673–681. [Google Scholar] [CrossRef]

- Baudrillart, B.; Nave, A.S.C.; Hamann, S.; Bénédic, F.; Lombardi, G.; van Helden, J.H.; Röpcke, J.; Achard, J. Growth processes of nanocrystalline diamond films in microwave cavity and distributed antenna array systems: A comparative study. Diam. Relat. Mater. 2017, 71, 53–62. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond. Philos. Transact. A Math. Phys. Eng. Sci. 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Origin of the 1150 cm−1 Raman mode in nanocrystalline diamond. Phys. Rev. B 2001, 63, 121405(R). [Google Scholar] [CrossRef]

- Pfeiffer, R.; Kuzmany, H.; Knoll, P.; Bokova, S.; Salk, N.; Günther, B. Evidence for trans- polyacetylene in nano-crystalline diamond films. Diam. Relat. Mater. 2003, 12, 268–271. [Google Scholar] [CrossRef]

- Hu, L.; Guo, Y.; Du, S.; Tian, S.; Li, J.; Gu, C. Probing trans-polyacetylene segments in a diamond film by tip-enhanced Raman spectroscopy. Diam. Relat. Mater. 2021, 116, 108415. [Google Scholar] [CrossRef]

- Barbosa, D.C.; Barreto, P.R.P.; Ribas, V.W.; Trava-Airoldi, V.J.; Corat, E.J. Diamond nanostructures growth. Encycl. Nanosci. Nanotechnol. 2009, 10, 3–10. [Google Scholar]

- Irshidat, M.R.; Al-Saleh, M.H.; Sanad, S. Effect of Nanoclay on Expansive Potential of Cement Mortar due to Alkali-Silica Reaction. ACI Mater. J. 2015, 112, 801. [Google Scholar] [CrossRef]

- Dekkar, D.; Bénédic, F.; Floer, C.; Hage-Ali, S.; Brinza, O.; Achard, J.; Elmazria, O. Study of Low Temperature Deposition of Nanocrystalline Diamond Films on ZnO/LiNbO3Layered Structures Suitable for Waveguiding Layer Acoustic Wave Devices. Phys. Status Solidi (A) 2018, 215, 1800251. [Google Scholar] [CrossRef]

- Haubner, R.; Lux, B. Deposition of ballas diamond and nano-crystalline diamond. Int. J. Refract. Met. Hard Mater. 2002, 20, 93–100. [Google Scholar] [CrossRef]

- Tsugawa, K.; Ishihara, M.; Kim, J.; Hasegawa, M.; Koga, Y. Large-Area and Low-Temperature Nanodiamond Coating by Microwave Plasma Chemical Vapor Deposition. New Diam. Front. Carbon Technol. 2006, 16, 14. [Google Scholar]

- Potocky, S.; Kromka, A.; Potmesil, J.; Remes, Z.; Polackova, Z.; Vanecek, M. Growth of nanocrystalline diamond films deposited by microwave plasma CVD system at low substrate temperatures. Phys. Status Solidi (A) 2006, 203, 3011–3015. [Google Scholar] [CrossRef]

- Potocky, S.; Kromka, A.; Potmesil, J.; Remes, Z.; Vorlicek, V.; Vanecek, M.; Michalka, M. Investigation of nanocrystalline diamond films grown on silicon and glass at substrate temperature below 400 °C. Diam. Relat. Mater. 2007, 16, 744–747. [Google Scholar] [CrossRef]

- Hu, Z.G.; Hess, P. Optical constants and thermo-optic coefficients of nanocrystalline diamond films at 30–500 °C. Appl. Phys. Lett. 2006, 89, 081906. [Google Scholar] [CrossRef]

- Williams, O.A. Nanocrystalline diamond. Diam. Relat. Mater. 2011, 20, 621–640. [Google Scholar] [CrossRef]

- Ralchenko, V.; Pimenov, S.; Konov, V.; Khomich, A.; Saveliev, A.; Popovich, A.; Vlasov, I.; Zavedeev, E.; Bozhko, A.; Loubnin, E.; et al. Nitrogenated nanocrystalline diamond films: Thermal and optical properties. Diam. Relat. Mater. 2007, 16, 2067–2073. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Ren, L.; Su, Q.; Shi, W.; Xia, Y. Effect of carbon concentration on the optical properties of nanocrystalline diamond films deposited by hot-filament chemical vapor deposition method. J. Nanosci. Nanotechnol. 2008, 8, 2534–2539. [Google Scholar] [CrossRef] [PubMed]

- Mertens, M.; Mohr, M.; Brühne, K.; Fecht, H.J.; Łojkowski, M.; Święszkowski, W.; Łojkowski, W. Patterned hydrophobic and hydrophilic surfaces of ultra-smooth nanocrystalline diamond layers. Appl. Surf. Sci. 2016, 30, 526–530. [Google Scholar] [CrossRef] [Green Version]

- Ostrovskaya, L.; Perevertailo, V.; Ralchenko, V.; Dementjev, A.; Loginova, O. Wettability and surface energy of oxidized and hydrogen plasma-treated diamond films. Diam. Relat. Mater. 2002, 11, 845–850. [Google Scholar] [CrossRef]

| Sample | Deposition Time (h) | Substrate Temperature (°C) | Thickness (nm) | Growth Rate (nm·h−1) | Rms Roughness (nm) | FWHM (cm−1) | sp3 (%) | Contact Angle (°) |

|---|---|---|---|---|---|---|---|---|

| B-0 | Uncoated substrate | 2.0 + 0.4 | 54.3 ± 2.7 | |||||

| B-1 | 2 | 300 | 95 ± 9 | 48 ± 5 | 6.6 ± 1.3 | 17.5 ± 0.9 | 79 ± 8 | 76.0 ± 3.8 |

| B-2 | 4 | 153 ± 15 | 38.3 ± 4 | 7.4 + 1.5 | 17.8 ± 0.9 | 82 ± 8 | ||

| S-0 | Uncoated substrate | 2.0 ± 0.4 | 40.5 ± 2.0 | |||||

| S-1 | 2 | 265 | 79 ± 8 | 39.5 ± 4 | 4.9 ± 1.0 | 16.8 ± 0.8 | 84 ± 8 | |

| S-2 | 300 | 104 ± 10 | 52 ± 5 | 5.1 ± 1.0 | 17.2 ± 0.9 | 73 ± 7 | 76.5 ± 3.8 | |

| S-3 | 400 | 110 ± 11 | 55 ± 6 | 10.5 ± 2.1 | 17.4 ± 0.9 | 59 ± 6 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahi, C.; Brinza, O.; Issaoui, R.; Achard, J.; Bénédic, F. Synthesis of High Quality Transparent Nanocrystalline Diamond Films on Glass Substrates Using a Distributed Antenna Array Microwave System. Coatings 2022, 12, 1375. https://doi.org/10.3390/coatings12101375

Mahi C, Brinza O, Issaoui R, Achard J, Bénédic F. Synthesis of High Quality Transparent Nanocrystalline Diamond Films on Glass Substrates Using a Distributed Antenna Array Microwave System. Coatings. 2022; 12(10):1375. https://doi.org/10.3390/coatings12101375

Chicago/Turabian StyleMahi, Chaimaa, Ovidiu Brinza, Riadh Issaoui, Jocelyn Achard, and Fabien Bénédic. 2022. "Synthesis of High Quality Transparent Nanocrystalline Diamond Films on Glass Substrates Using a Distributed Antenna Array Microwave System" Coatings 12, no. 10: 1375. https://doi.org/10.3390/coatings12101375