Green Synthesis and Antimicrobial Study on Functionalized Chestnut-Shell-Extract Ag Nanoparticles

Abstract

:1. Introduction

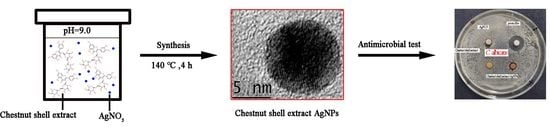

2. Materials and Methods

2.1. Materials

2.2. Preparation of Chestnut Shell Extract

2.3. Characterization

2.3.1. Ultraviolet-Visible Absorption Spectra

2.3.2. Transmission Electron Microscope

2.3.3. Dynamic Light Scattering (DLS) and Zeta Potential Analysis

2.3.4. Fourier Transform Infrared Spectroscopy

2.3.5. X-ray Diffractometer

2.3.6. X-ray Photoelectron Spectroscopy

2.3.7. LC-MS/MS Analysis

2.3.8. Antimicrobial Test

3. Results and Discussion

3.1. Characterization of Functionalized Chestnut-Shell-Extract Ag Nanomaterials

3.2. Antibacterial Activity of Functionalized Chestnut-Shell-Extract Ag Nanoparticles

3.3. Formation Mechanism of Ag Nanoparticles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- AlMasoud, N.; Alhaik, H.; Almutairi, M.; Houjak, A.; Hazazi, K.; Alhayek, F.; Aljanoubi, S.; Alkhaibari, A.; Alghamdi, A.; Soliman, D.A.; et al. Green nanotechnology synthesized silver nanoparticles: Characterization and testing its antibacterial activity. Green Process. Synth. 2021, 10, 518–528. [Google Scholar] [CrossRef]

- Saqr, A.A.; Khafagy, E.S.; Alalaiwe, A.; Aldawsari, M.F.; Hegazy, W. Synthesis of Gold Nanoparticles by Using Green Machinery: Characterization and In Vitro Toxicity. Nanomaterials 2021, 11, 808. [Google Scholar] [CrossRef] [PubMed]

- Prema, P.; Veeramanikandan, V.; Rameshkumar, K.; Gatasheh, M.K.; Hatamleh, A.A.; Balasubramani, R.; Balaji, P. Statistical optimization of silver nanoparticle synthesis by green tea extract and its efficacy on colorimetric detection of mercury from industrial waste water. Environ. Res. 2021, 204, 111915. [Google Scholar] [CrossRef]

- Srikhao, N.; Kasemsiri, P.; Lorwanishpaisarn, N.; Okhawilai, M. Green synthesis of silver nanoparticles using sugarcane leaves extract for colorimetric detection of ammonia and hydrogen peroxide. Res. Chem. Intermed. 2021, 47, 1269–1283. [Google Scholar] [CrossRef]

- Yun, H.; Kim, J.; Choi, W.; Han, M.H.; Yun, J. Understanding morphological degradation of Ag nanoparticle during electrochemical CO2 reduction reaction by identical location observation. Electrochim. Acta 2021, 371, 137795. [Google Scholar] [CrossRef]

- Pirtarighat, S.; Ghannadnia, M.; Baghshahi, S. Green synthesis of silver nanoparticles using the plant extract of Salvia spinosa grown in vitro and their antibacterial activity assessment. J. Nanostructure Chem. 2019, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Tashi, T.; Gupta, N.V.; Mbuya, V.B. Silver nanoparticles: Synthesis, mechanism of antimicrobial action, characterization, medical applications, and toxicity effects. J. Chem. Pharm. Res. 2016, 8, 526–537. [Google Scholar]

- Nayem, S.M.A.; Sultana, N.; Haque, M.A.; Miah, B.; Hasan, M.M.; Islam, T.; Hasan, M.M.; Awal, A.; Uddin, J.; Aziz, M.A.; et al. Green Synthesis of Gold and Silver Nanoparticles by Using Amorphophallus paeoniifolius Tuber Extract and Evaluation of Their Antibacterial Activity. Molecules 2020, 25, 4773. [Google Scholar] [CrossRef]

- Shkryl, Y.; Rusapetova, T.; Yugay, Y.; Egorova, A.; Bulgakov, V. Biosynthesis and Cytotoxic Properties of Ag, Au and Bimetallic Nanoparticles Synthesized Using Lithospermum erythrorhizon Callus Culture Extract. Int. J. Mol. Sci. 2021, 22, 9305. [Google Scholar] [CrossRef]

- Ma, Y.; Tao, L.; Bai, S.; Hu, A. Green Synthesis of Ag Nanoparticles for Plasmon-Assisted Photocatalytic Degradation of Methylene Blue. Catalysts 2021, 11, 21499. [Google Scholar] [CrossRef]

- Vella, F.M.; De Masi, L.; Calandrelli, R.; Morana, A.; Laratta, B. Valorization of the agro-forestry wastes from Italian chestnut cultivars for the recovery of bioactive compounds. Eur. Food Res. Technol. 2019, 245, 2679–2686. [Google Scholar] [CrossRef]

- Sun, Q.; Cai, X.; Li, J.; Zheng, M.; Chen, Z.; Yu, C.P. Green synthesis of silver nanoparticles using tea leaf extract and evaluation of their stability and antibacterial activity. Colloids Surf. A Physicochem. Eng. Asp. 2014, 444, 226–231. [Google Scholar] [CrossRef]

- Vázquez, G.; González-Alvarez, J.; Santos, J.; Freire, M.S.; Antorrena, G. Evaluation of potential applications for chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind. Crops Prod. 2009, 29, 364–370. [Google Scholar] [CrossRef]

- Biao, L.; Tan, S.; Zhang, X.; Gao, J.; Liu, Z.; Fu, Y. Synthesis and characterization of proanthocyanidins-functionalized Ag nanoparticles. Colloids Surf. B Biointerfaces 2018, 169, 438–443. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Xu, R. New materials in hydrothermal synthesis. Acc. Chem. Res. 2001, 34, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, L.; Xiong, H.; Hu, L.; Yang, B.; Li, W. Hydrothermal Synthesis for High-Quality CDTe Nanocrystals. Adv. Mater. 2010, 15, 1712–1715. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, H.; Tan, S.; Gao, J.; Fu, Y.; Liu, Z. Hydrothermal synthesis of Ag nanoparticles on the nanocellulose and their antibacterial study. Inorg. Chem. Commun. 2019, 100, 44–50. [Google Scholar] [CrossRef]

- Shi, Y.; Xing, Y.; Deng, S.; Zhao, B.; Fu, Y.; Liu, Z. Synthesis of proanthocyanidins-functionalized Fe3O4 magnetic nanoparticles with high solubility for removal of heavy-metal ions. Chem. Phys. Lett. 2020, 753, 137600. [Google Scholar] [CrossRef]

- Mulfinger, L. Synthesis and Study of Silver Nanoparticles. J. Chem. Educ. 2007, 84, 322–325. [Google Scholar] [CrossRef]

- Li, S.; Jiang, Z.; Thamm, L.; Zhou, G. 10-Hydroxy-2-decenoic Acid as an Antimicrobial Agent in Draft Keg-conditioned Wheat Beer. J. Am. Soc. Brew. Chem. 2010, 68, 114–118. [Google Scholar] [CrossRef]

- Vázquez, G.; Fontenla, E.; Santos, J.; Freire, M.S.; González-Álvarez, J.; Antorrena, G. Antioxidant activity and phenolic content of chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind. Crops Prod. 2008, 28, 279–285. [Google Scholar] [CrossRef]

- Liu, Z.; Xing, Z.; Zu, Y.; Tan, S.; Zhao, L.; Zhou, Z.; Sun, T. Synthesis and characterization of L-histidine capped silver nanoparticles. Mater. Sci. Eng. C 2012, 32, 811–816. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wang, Y.L.; Zu, Y.G.; Fu, Y.J.; Li, N.; Guo, N.; Liu, R.S.; Zhang, Y.M. Synthesis of polyethylenimine (PEI) functionalized silver nanoparticles by a hydrothermal method and their antibacterial activity study. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 42, 31–37. [Google Scholar] [CrossRef] [PubMed]

- Biao, L.; Tan, S.; Wang, Y.; Guo, X.; Fu, Y.; Xu, F.; Zu, Y.; Liu, Z. Synthesis, characterization and antibacterial study on the chitosan-functionalized Ag nanoparticles. Mater. Sci. Eng. C 2017, 76, 73–80. [Google Scholar] [CrossRef]

- Aygün, A.; Özdemir, S.; Gülcan, M.; Cellat, K.; Şen, F. Synthesis and characterization of Reishi mushroom-mediated green synthesis of silver nanoparticles for the biochemical applications. J. Pharm. Biomed. Anal. 2019, 178, 112970. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Qi, J.; Wang, L. Isolation, fractionation and characterization of melanin-like pigments from chestnut (Castanea mollissima) shells. J. Food Sci. 2012, 77, 671–676. [Google Scholar] [CrossRef]

- Khan, M.J.; Kumari, S.; Shameli, K.; Selamat, J.; Sazili, A.Q. Green Synthesis and Characterization of Pullulan Mediated Silver Nanoparticles through Ultraviolet Irradiation. Materials 2019, 12, 2382. [Google Scholar] [CrossRef] [Green Version]

- Ji, X.; Song, X.; Li, J.; Bai, Y.; Yang, W.; Peng, X. Size Control of Gold Nanocrystals in Citrate Reduction: The Third Role of Citrate. J. Am. Chem. Soc. 2007, 129, 13939–13948. [Google Scholar] [CrossRef]

- Philip, D. Biosynthesis of Au, Ag and Au-Ag nanoparticles using edible mushroom extract. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2009, 73, 374–381. [Google Scholar] [CrossRef]

- Liu, S.; Ma, J.; Wang, S.; Chen, S.; Wang, B.; Li, J. Silver nanoparticles incorporated chitosan/calcium pyrophosphate hybrid microflowers for antibacterial applications. Mater. Lett. 2019, 255, 126570. [Google Scholar] [CrossRef]

- Wypij, M.; Czarnecka, J.; Swiecimska, M.; Dahm, H.; Rai, M.; Golinska, P. Synthesis, characterization and evaluation of antimicrobial and cytotoxic activities of biogenic silver nanoparticles synthesized from Streptomyces xinghaiensis OF1 strain. World J. Microbiol. Biotechnol. 2018, 34, 23. [Google Scholar] [CrossRef] [PubMed]

- Boonpavanitchakul, K.; Pimpha, N.; Kangwansupamonkon, W.; Magaraphan, R. Processing and antibacterial application of biodegradable sponge nano-composite materials of silver nanoparticles and silk sericin. Eur. Polym. J. 2020, 130, 109649. [Google Scholar] [CrossRef]

- Barabadi, H.; Mojab, F.; Vahidi, H.; Marashi, B.; Talank, N.; Hosseini, O.; Saravanan, M. Green synthesis, characterization, antibacterial and biofilm inhibitory activity of silver nanoparticles compared to commercial silver nanoparticles. Inorg. Chem. Commun. 2021, 129, 108647. [Google Scholar] [CrossRef]

- Barabadi, H.; Mohammadzadeh, A.; Vahidi, H.; Rashedi, M.; Saravanan, M.; Talank, N.; Alizadeh, A. Penicillium chrysogenum-derived silver nanoparticles: Exploration of their antibacterial and biofilm inhibitory activity against the standard and pathogenic Acinetobacter baumannii compared to tetracycline. J. Clust. Sci. 2022, 33, 1929–1942. [Google Scholar] [CrossRef]

- Talank, N.; Morad, H.; Barabadi, H.; Mojab, F.; Amidi, S.; Kobarfard, F.; Mahjoub, M.A.; Jounaki, K.; Mohammadi, N.; Salehi, G. Bioengineering of green-synthesized silver nanoparticles: In vitro physicochemical, antibacterial, biofilm inhibitory, anticoagulant, and antioxidant performance. Talanta 2022, 243, 123374. [Google Scholar] [CrossRef]

- Truong, L.B.; Medina-Cruz, D.; Martínez-Sanmiguel, J.J.; Soto-Mendoza, A.; Esquivel-López, I.G.; Pérez, Y.; Saravanan, M.; Barabadi, H.; Cholula-Díaz, J.L.; Mostafavi, E. Biogenic metal nanomaterials to combat antimicrobial resistance. In Emerging Nanomaterials and Nano-Based Drug Delivery Approaches to Combat Antimicrobial Resistance; Elsevier: Amsterdam, The Netherlands, 2022; pp. 261–304. [Google Scholar]

- Liu, J.; Sonshine, D.A.; Shervani, S.; Hurt, R.H. Controlled Release of Biologically Active Silver from Nanosilver Surfaces. ACS Nano 2010, 4, 6903–6913. [Google Scholar] [CrossRef] [Green Version]

- Squillaci, G.; Apone, F.; Sena, L.M.; Carola, A.; Tito, A.; Bimonte, M.; De Lucia, A.; Colucci, G.; La Cara, F.; Morana, A. Annalisa, Chestnut (Castanea sativa Mill.) industrial wastes as a valued bioresource for the production of active ingredients. Process Biochem. 2018, 64, 228–236. [Google Scholar] [CrossRef]

- Aisida, S.O.; Ugwu, K.; Akpa, P.A.; Nwanya, A.C.; Ezema, F.I. Biogenic synthesis and antibacterial activity of controlled silver nanoparticles using an extract of Gongronema Latifolium. Mater. Chem. Phys. 2019, 237, 121859. [Google Scholar] [CrossRef]

- Vijaya, J.J.; Jayaprakash, N.; Kombaiah, K.; Kaviyarasu, K.; Maaza, M. Bioreduction potentials of dried root of Zingiber officinale for a simple green synthesis of silver nanoparticles: Antibacterial studies. J. Photochem. Photobiol. B Biol. 2017, 177, 62–68. [Google Scholar] [CrossRef]

- Mayedwa, N.; Mongwaketsi, N.; Khamlich, S.; Kaviyarasu, K.; Matinise, N. Green synthesis of nickel oxide, palladium and palladium oxide synthesized via Aspalathus linearis natural extracts: Physical properties & mechanism of formation. Appl. Surf. Sci. 2018, 446, 266–272. [Google Scholar]

- Aisida, S.O.; Ugwu, K.; Akpa, P.A.; Nwanya, A.C.; Nwankwo, U.; Botha, S.S.; Ejikeme, P.M.; Ahmad, I.; Maaza, M.; Ezema, F.I. Biosynthesis of silver nanoparticles using bitter leave (Veronica amygdalina) for antibacterial activities—ScienceDirect. Surf. Interfaces 2019, 17, 100359. [Google Scholar] [CrossRef]

- Ali, H.; Abd, K.; Kajani, A.A.; Bordbar, A.-K. Green synthesis of silver nanoparticles using Mentha pulegium and investigation of their antibacterial, antifungal and anticancer activity. IET Nanobiotechnol. 2017, 11, 370–376. [Google Scholar]

- Ajitha, B.; Ashok, K.R.Y.; Reddy, P.S. Green synthesis and characterization of silver nanoparticles using Lantana camara leaf extract. Mater. Sci. Eng. C 2015, 49, 373–381. [Google Scholar] [CrossRef]

- Xing, Y.; Shi, Y.; Deng, S.; Zhao, B.; Liu, Z. Preparation and Application of Catechin—Silver Nanocomposites. Chin. J. Appl. Chem. 2020, 37, 1062–1068. [Google Scholar]

- Ditlopo, N.; Sintwa, N.; Khamlich, S.; Manikandan, E.; Gnanasekaran, K.; Henini, M.; Gibaud, A.; Krief, A.; Maaza, M. From Khoi—San indigenous knowledge to bioengineered CeO2 nanocrystals to exceptional UV—Blocking green nanocosmetics. Sci. Rep. 2022, 12, 3468. [Google Scholar] [CrossRef]

- Havenga, D.; Akoba, R.; Menzi, L.; Azizi, S.; Sackey, J.; Swanepoel, N.; Gibaud, A.; Maaza, M. From Himba indigenous knowledge to engineered Fe2O3 UV—Blocking green nanocosmetics. Sci. Rep. 2022, 12, 2259. [Google Scholar] [CrossRef] [PubMed]

- Kedi, P.B.E.; Meva, F.E.A.; Kotsedi, L.; Nguemfo, E.L.; Zangueu, C.B.; Ntoumba, A.A.; Mohamed, H.E.A.; Dongmo, A.B.; Maaza, M. Eco-friendly synthesis, characterization, in vitro and in vivo anti-inflammatory activity of silver nanoparticle-mediated Selaginella myosurus aqueous extract. Int. J. Nanomed. 2018, 13, 8537. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rathnakumar, S.S.; Noluthando, K.; Kulandaiswamy, A.J.; Rayappan, J.B.B.; Kasinathan, K.; Kennedy, J.; Maaza, M. Stalling behaviour of chloride ions: A non-enzymatic electrochemical detection of α-Endosulfan using CuO interface. Sens. Actuators B Chem. 2019, 293, 100–106. [Google Scholar] [CrossRef]

- Nwanya, A.C.; Razanamahandry, L.C.; Bashir, A.; Ikpo, C.O.; Nwanya, S.C.; Botha, S.; Ntwampe, S.K.O.; Ezema, F.I.; Iwuoha, E.I.; Maaza, M. Industrial textile effluent treatment and antibacterial effectiveness of Zea mays L. Dry husk mediated bio-synthesized copper oxide nanoparticles. J. Hazard. Mater. 2019, 375, 281–289. [Google Scholar] [CrossRef]

- Maaza, M.; Hamidi, D.; Simo, A.; Kerdja, T.; Chaudhary, A.; Kana, J.K. Optical limiting in pulsed laser deposited VO2 nanostructures. Opt. Commun. 2012, 285, 1190–1193. [Google Scholar] [CrossRef]

- Sone, B.; Fuku, X.; Maaza, M. Physical & electrochemical properties of green synthesized bunsenite NiO nanoparticles via Callistemon viminalis’ extracts. Int. J. Electrochem. Sci. 2016, 11, 8204–8220. [Google Scholar]

| μg/mL | E. coli | S. aureus | C. albicans | |||

|---|---|---|---|---|---|---|

| MIC | MBC | MIC | MBC | MIC | MBC | |

| Chestnut-shell-extract AgNPs | 0.13 | 0.25 | 0.25 | 0.50 | 0.13 | 0.25 |

| AgNPs from NaBH4 reduction | 21.25 | 42.50 | 21.25 | 42.50 | 21.25 | 42.50 |

| Penicillin | 1.60 | 3.30 | 6.00 | 12.00 | 6.00 | 12.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, K.; Sun, J.; Lin, Y.; Zhi, H.; Wang, X.; Fu, Y.; Xu, J.; Liu, Z. Green Synthesis and Antimicrobial Study on Functionalized Chestnut-Shell-Extract Ag Nanoparticles. Antibiotics 2023, 12, 201. https://doi.org/10.3390/antibiotics12020201

Shao K, Sun J, Lin Y, Zhi H, Wang X, Fu Y, Xu J, Liu Z. Green Synthesis and Antimicrobial Study on Functionalized Chestnut-Shell-Extract Ag Nanoparticles. Antibiotics. 2023; 12(2):201. https://doi.org/10.3390/antibiotics12020201

Chicago/Turabian StyleShao, Kai, Jixiang Sun, Yamei Lin, Hongxin Zhi, Xitong Wang, Yujie Fu, Jiating Xu, and Zhiguo Liu. 2023. "Green Synthesis and Antimicrobial Study on Functionalized Chestnut-Shell-Extract Ag Nanoparticles" Antibiotics 12, no. 2: 201. https://doi.org/10.3390/antibiotics12020201