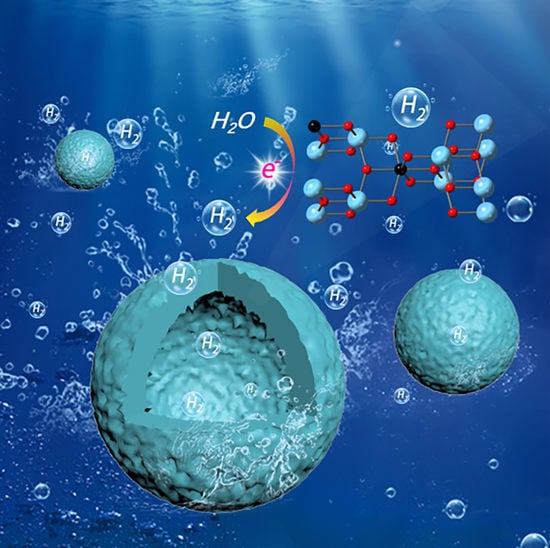

Surface Modification of Hollow Structure TiO2 Nanospheres for Enhanced Photocatalytic Hydrogen Evolution

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Characterization

2.3. Photoelectrochemical Measurements

2.4. Photocatalytic Activity

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schultz, D.M.; Yoon, T.P. Solar synthesis: Prospects in visible light photocatalysis. Science 2014, 343, 1239176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tian, L.; Yue, L.; Wang, F.; Min, S.; Zhang, Z. CdS/Metallic Mo hybrid photocatalysts with highly active interfacial Mo–O–S active sites for efficient photocatalytic hydrogen evolution under visible light. J. Phys. Chem. C 2020, 124, 18911–18919. [Google Scholar] [CrossRef]

- Ye, S.; Ding, C.; Liu, M.; Wang, A.; Huang, Q.; Li, C. Water oxidation catalysts for artificial photosynthesis. Adv. Mater. 2019, 31, 1902069. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, W.; Zhang, J.; Zhu, X.; Zhang, Q.; Zhang, Y.; Ren, Z.; Song, S.; Wang, J.; Ying, Z.; et al. Highly efficient photocatalytic hydrogen evolution by ReS2 via a two-electron catalytic reaction. Adv. Mater. 2018, 30, 1707123. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Huang, H.; Ma, T.; Zhang, Y. Photocatalytic oxygen evolution from water splitting. Adv. Sci. 2021, 8, 2002458. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.; Ding, C.; Chen, R.; Fan, F.; Fu, P.; Yin, H.; Wang, X.; Wang, Z.; Du, P.; Li, C. Mimicking the key functions of photosystem II in artificial photosynthesis for photoelectrocatalytic water splitting. J. Am. Chem. Soc. 2018, 140, 3250–3256. [Google Scholar] [CrossRef]

- Hoang, S.; Gao, P.-X. Nanowire array structures for photocatalytic energy conversion and utilization: A review of design concepts, assembly and integration, and function enabling. Adv. Energy Mater. 2016, 6, 1600683. [Google Scholar] [CrossRef]

- Yang, H.G.; Sun, C.H.; Qiao, S.Z.; Zou, J.; Liu, G.; Smith, S.C.; Cheng, H.M.; Lu, G.Q. Anatase TiO2 single crystals with a large percentage of reactive facets. Nature 2008, 453, 638–641. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Zhou, C.; Ma, Z.; Yang, X. Fundamentals of TiO2 photocatalysis: Concepts, mechanisms, and challenges. Adv. Mater. 2019, 31, 1901997. [Google Scholar] [CrossRef]

- Shi, C.; Ye, S.; Wang, X.; Meng, F.; Liu, J.; Yang, T.; Zhang, W.; Wei, J.; Ta, N.; Lu, G.Q.; et al. Modular construction of prussian blue analog and TiO2 dual-compartment janus nanoreactor for efficient photocatalytic water splitting. Adv. Sci. 2021, 8, 2001987. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, X.-L.; He, L.; Zhang, Y.-X.; Hu, Z.-Y.; Tian, G.; Cheng, X.; Wu, S.-M.; Li, Y.-Z.; Yang, X.-H.; et al. Spatial heterojunction in nanostructured TiO2 and its cascade effect for efficient photocatalysis. Nano Lett. 2020, 20, 3122–3129. [Google Scholar] [CrossRef] [PubMed]

- Rajaraman, T.S.; Parikh, S.P.; Gandhi, V.G. Black TiO2: A review of its properties and conflicting trends. Chem. Eng. J. 2020, 389, 123918. [Google Scholar] [CrossRef]

- Wang, K.; Peng, T.; Wang, Z.; Wang, H.; Chen, X.; Dai, W.; Fu, X. Correlation between the H2 response and its oxidation over TiO2 and N doped TiO2 under UV irradiation induced by Fermi level. Appl. Catal. B-Environ. 2019, 250, 89–98. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, N.; Yu, J.; Yu, J.C. A hollow porous CdS photocatalyst. Adv. Mater. 2018, 30, 1804368. [Google Scholar] [CrossRef]

- Tian, H.; Huang, F.; Zhu, Y.; Liu, S.; Han, Y.; Jaroniec, M.; Yang, Q.; Liu, H.; Lu, G.Q.M.; Liu, J. The development of yolk–shell-structured Pd&ZnO@carbon submicroreactors with high selectivity and stability. Adv. Funct. Mater. 2018, 28, 1801737. [Google Scholar]

- Fan, S.; Li, X.; Yin, Z.; Qin, M.; Wang, L.; Gan, G.; Wang, X.; Xu, F.; Tadé, M.O.; Liu, S. Rational design of cobaltate MCo2O4−δ hierarchical nanomicrostructures with bunch of oxygen vacancies toward highly efficient photocatalytic fixing of carbon dioxide. J. Phys. Chem. C 2021, 125, 9782–9794. [Google Scholar] [CrossRef]

- Sousa-Castillo, A.; Couceiro, J.R.; Tomás-Gamasa, M.; Mariño-López, A.; López, F.; Baaziz, W.; Ersen, O.; Comesaña-Hermo, M.; Mascareñas, J.L.; Correa-Duarte, M.A. Remote activation of hollow nanoreactors for heterogeneous photocatalysis in biorelevant media. Nano Lett. 2020, 20, 7068–7076. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, X.F.; Luan, D.; Lou, X.W. Fabrication of heterostructured Fe2TiO5–TiO2 nanocages with enhanced photoelectrochemical performance for solar energy conversion. Angew. Chem. Int. Ed. 2020, 59, 8128–8132. [Google Scholar] [CrossRef]

- Wu, H.; Wu, X.-L.; Wang, Z.-M.; Aoki, H.; Kutsuna, S.; Jimura, K.; Hayashi, S. Anchoring titanium dioxide on carbon spheres for high-performance visible light photocatalysis. Appl. Catal. B-Environ. 2017, 207, 255–266. [Google Scholar] [CrossRef]

- Hu, Z.; Li, X.; Zhang, S.; Li, Q.; Fan, J.; Qu, X.; Lv, K. Fe1/TiO2 hollow microspheres: Fe and Ti dual active sites boosting the photocatalytic oxidation of NO. Small 2020, 16, 2004583. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Zang, S.-Q.; Lou, X.W. Hierarchical hollow heterostructures for photocatalytic CO2 reduction and water splitting. Small Methods 2020, 4, 1900586. [Google Scholar] [CrossRef]

- Wang, X.; Maeda, K.; Thomas, A.; Takanabe, K.; Xin, G.; Carlsson, J.M.; Domen, K.; Antonietti, M. A metal-free polymeric photocatalyst for hydrogen production from water under visible light. Nat. Mater. 2009, 8, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Shi, R.; Ye, H.-F.; Liang, F.; Wang, Z.; Li, K.; Weng, Y.; Lin, Z.; Fu, W.-F.; Che, C.-M.; Chen, Y. Interstitial P-doped CdS with long-lived photogenerated electrons for photocatalytic water splitting without sacrificial agents. Adv. Mater. 2018, 30, 1705941. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Li, J.; Dong, C.-L.; Ren, J.; Huang, Y.-C.; Zhao, D.; Cai, R.; Wei, D.; Yang, X.; Lv, C.; et al. Red phosphorus decorated and doped TiO2 nanofibers for efficient photocatalytic hydrogen evolution from pure water. Appl. Catal. B Environ. 2019, 255, 117764. [Google Scholar] [CrossRef]

- Divyasri, Y.V.; Lakshmana Reddy, N.; Lee, K.; Sakar, M.; Navakoteswara Rao, V.; Venkatramu, V.; Shankar, M.V.; Gangi Reddy, N.C. Optimization of N doping in TiO2 nanotubes for the enhanced solar light mediated photocatalytic H2 production and dye degradation. Environ. Pollut. 2021, 269, 116170. [Google Scholar] [CrossRef]

- Jia, G.; Wang, Y.; Cui, X.; Zheng, W. Highly carbon-doped TiO2 derived from MXene boosting the photocatalytic hydrogen evolution. ACS Sustain. Chem. Eng. 2018, 6, 13480–13486. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, S.Z.; Liu, H.; Chen, J.; Orpe, A.; Zhao, D.; Lu, G.Q. Extension of the stober method to the preparation of monodisperse resorcinol-formaldehyde resin polymer and carbon spheres. Angew. Chem. Int. Ed. 2011, 50, 5947–5951. [Google Scholar] [CrossRef]

- Signoretto, M.; Ghedini, E.; Trevisan, V.; Bianchi, C.L.; Ongaro, M.; Cruciani, G. TiO2–MCM-41 for the photocatalytic abatement of NOx in gas phase. Appl. Catal. B-Environ. 2010, 95, 130–136. [Google Scholar] [CrossRef]

- Shao, J.; Sheng, W.; Wang, M.; Li, S.; Chen, J.; Zhang, Y.; Cao, S. In situ synthesis of carbon-doped TiO2 single-crystal nanorods with a remarkably photocatalytic efficienc. Appl. Catal. B Environ. 2017, 209, 311–319. [Google Scholar] [CrossRef]

- Wang, M.; Han, J.; Hu, Y.; Guo, R.; Yin, Y. Carbon-incorporated NiO/TiO2 mesoporous shells with p–n heterojunctions for efficient visible light photocatalysis. ACS Appl. Mater. Interfaces 2016, 8, 29511–29521. [Google Scholar] [CrossRef]

- Wei, Q.; Yang, X.; Zhang, G.; Wang, D.; Zuin, L.; Banham, D.; Yang, L.; Ye, S.; Wang, Y.; Mohamedi, M.; et al. An active and robust Si-Fe/N/C catalyst derived from waste reed for oxygen reduction. Appl. Catal. B Environ. 2018, 237, 85–93. [Google Scholar] [CrossRef]

- Huo, Q.; Li, J.; Liu, G.; Qi, X.; Zhang, X.; Ning, Y.; Zhang, B.; Fu, Y.; Liu, S. Adsorption desulfurization performances of Zn/Co porous carbons derived from bimetal-organic frameworks. Chem. Eng. J. 2019, 362, 287–297. [Google Scholar] [CrossRef]

- Iqbal, S.; Amjad, A.; Javed, M.; Alfakeer, M.; Mushtaq, M.; Rabea, S.; Elkaeed, E.B.; Pashameah, R.A.; Alzahrani, E.; Farouk, A.-E. Boosted spatial charge carrier separation of binary ZnFe2O4/S-g-C3N4 heterojunction for visible-light-driven photocatalytic activity and antimicrobial performance. Front. Chem. 2022, 10, 975355. [Google Scholar] [CrossRef]

- Zou, Y.; Shi, J.-W.; Ma, D.; Fan, Z.; Lu, L.; Niu, C. In situ synthesis of C-doped TiO2@g-C3N4 core-shell hollow nanospheres with enhanced visible-light photocatalytic activity for H2 evolution. Chem. Eng. J. 2017, 322, 435–444. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Liang, R.; Zhou, N.Y.; Pan, Z. Carbon black-doped anatase TiO2 nanorods for solar light-induced photocatalytic degradation of methylene blue. ACS Omega 2020, 5, 10042–10051. [Google Scholar] [CrossRef] [Green Version]

- Hoang, S.; Berglund, S.P.; Hahn, N.T.; Bard, A.J.; Mullins, C.B. Enhancing visible light photo-oxidation of water with TiO2 nanowire arrays via cotreatment with H2 and NH3: Synergistic effects between Ti3+ and N. J. Am. Chem. Soc. 2012, 134, 3659–3662. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Meng, F.; Cheng, Y.; Dewangan, N.; Ho, G.W.; Kawi, S. Z-scheme transition metal bridge of Co9S8/Cd/CdS tubular heterostructure for enhanced photocatalytic hydrogen evolution. Appl. Catal. B-Environ. 2021, 286, 119853. [Google Scholar] [CrossRef]

- Shen, Y.; Yuan, Z.; Cheng, F.; Cui, Z.; Ma, D.; Bai, Y.; Zhao, S.; Deng, J.; Li, E. Preparation and characterization of ZnO/graphene/graphene oxide/multi-walled carbon nanotube composite aerogels. Front. Chem. 2022, 10, 992482. [Google Scholar] [CrossRef]

- Yi, L.; Lan, F.; Li, J.; Zhao, C. Efficient noble-metal-free Co-NG/TiO2 photocatalyst for H2 evolution: Synergistic effect between single-atom Co and N-doped graphene for enhanced photocatalytic activity. ACS. Sustain. Chem. Eng. 2018, 10, 12766–12775. [Google Scholar] [CrossRef]

- Yu, J.; Hai, Y.; Cheng, B. Enhanced Photocatalytic H2-Production Activity of TiO2 by Ni(OH)2 Cluster Modification. J. Phys. Chem. C 2011, 11, 4953–4958. [Google Scholar] [CrossRef]

- Si, J.; Wang, Y.; Xia, X.; Peng, S.; Wang, Y.; Xiao, S.; Gao, Y. Novel quantum dot and nano-sheet TiO2 (B) composite for enhanced photocatalytic H2 – Production without Co-Catalyst. J. Power Sources 2017, 360, 353–359. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z.; Lu, N.; Hua, R.; Dong, B. Prolonging charge-separation states by doping lanthanide-ions into {001}/{101} facets-coexposed TiO2 nanosheets for enhancing photocatalytic H2 evolution. Chin. J. Cata. 2019, 3, 413–423. [Google Scholar] [CrossRef]

- Zahid Hussain, M.; Yang, Z.; Van der Linden, B.; Huang, Z.; Jia, Q.; Cerrato, E.; Xia, Y. Surface functionalized N-C–TiO2/C nanocomposites derived from metal-organic framework in water vapour for enhanced photocatalytic H2 generation. J. Energy. Chem. 2021, 57, 485–495. [Google Scholar]

- Bai, H.; Liu, Z.; Sun, D.D. Facile Fabrication of TiO2/SrTiO3 Composite Nanofibers by Electrospinning for High Efficient H2 Generation. J. Am. Ceram. Soc. 2012, 3, 942–949. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, G.; Zhang, Y.; Shi, C.; Zhao, C.; Liu, M.; Chang, F.; Gao, W.; Ye, S.; Liu, J.; Zhang, J. Surface Modification of Hollow Structure TiO2 Nanospheres for Enhanced Photocatalytic Hydrogen Evolution. Nanomaterials 2023, 13, 926. https://doi.org/10.3390/nano13050926

Ning G, Zhang Y, Shi C, Zhao C, Liu M, Chang F, Gao W, Ye S, Liu J, Zhang J. Surface Modification of Hollow Structure TiO2 Nanospheres for Enhanced Photocatalytic Hydrogen Evolution. Nanomaterials. 2023; 13(5):926. https://doi.org/10.3390/nano13050926

Chicago/Turabian StyleNing, Gaomin, Yan Zhang, Chunjing Shi, Chen Zhao, Mengmeng Liu, Fangfang Chang, Wenlong Gao, Sheng Ye, Jian Liu, and Jing Zhang. 2023. "Surface Modification of Hollow Structure TiO2 Nanospheres for Enhanced Photocatalytic Hydrogen Evolution" Nanomaterials 13, no. 5: 926. https://doi.org/10.3390/nano13050926