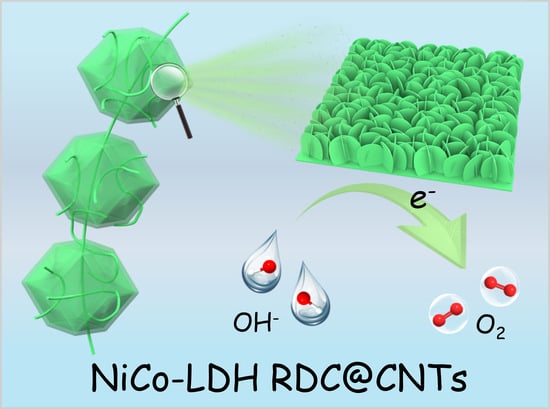

Carbon Nanotubes Interconnected NiCo Layered Double Hydroxide Rhombic Dodecahedral Nanocages for Efficient Oxygen Evolution Reaction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Chemicals

2.2. Methods

2.3. Characterization

2.4. Electrochemical Measurements

2.5. Zn–Air Battery Test

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, D.; Zhuang, Z.; Cao, X.; Zhang, C.; Peng, Q.; Chen, C.; Li, Y. Atomic site electrocatalysts for water splitting, oxygen reduction and selective oxidation. Chem. Soc. Rev. 2020, 49, 2215–2264. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.P.; Lu, X.F.; Zang, S.Q.; Lou, X.W. Non-Noble-Metal-Based Electrocatalysts toward the Oxygen Evolution Reaction. Adv. Funct. Mater. 2020, 30, 1910274. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, L.; Gong, J. Recent progress made in the mechanism comprehension and design of electrocatalysts for alkaline water splitting. Energy Environ. Sci. 2019, 12, 2620–2645. [Google Scholar] [CrossRef]

- Klingenhof, M.; Hauke, P.; Brückner, S.; Dresp, S.; Wolf, E.; Nong, H.N.; Spöri, C.; Merzdorf, T.; Bernsmeier, D.; Teschner, D.; et al. Modular Design of Highly Active Unitized Reversible Fuel Cell Electrocatalysts. ACS Energy Lett. 2021, 6, 177–183. [Google Scholar] [CrossRef]

- Zhang, J.; Xia, Z.; Dai, L. Carbon-based electrocatalysts for advanced energy conversion and storage. Sci. Adv. 2015, 1, 1500564. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Antolini, E. Iridium as Catalyst and Cocatalyst for Oxygen Evolution/Reduction in Acidic Polymer Electrolyte Membrane Electrolyzers and Fuel Cells. ACS Catal. 2014, 4, 1426–1440. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, X.; Wang, X.; Hu, J.; Liu, Y.; Fu, G.; Tang, Y. Concave PtCo nanocrosses for methanol oxidation reaction. Appl. Catal. B Environ. 2020, 277, 119135. [Google Scholar] [CrossRef]

- Li, M.; Li, Z.; Fu, G.; Tang, Y. Recent Advances in Amino-Based Molecules Assisted Control of Noble-Metal Electrocatalysts. Small 2021, 17, 2007179. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Pan, X.; Jiang, M.; Zhang, Y.; Tang, Y.; Fu, G. Interface engineering of oxygen-vacancy-rich CoP/CeO2 heterostructure boosts oxygen evolution reaction. Chem. Eng. J. 2020, 395, 125160. [Google Scholar] [CrossRef]

- Li, M.; Wang, Y.; Zheng, Y.; Fu, G.; Sun, D.; Li, Y.; Tang, Y.; Ma, T. Gadolinium-Induced Valence Structure Engineering for Enhanced Oxygen Electrocatalysis. Adv. Energy Mater. 2020, 10, 1903833. [Google Scholar] [CrossRef]

- Tan, Y.; Zhu, W.; Zhang, Z.; Wu, W.; Chen, R.; Mu, S.; Lv, H.; Cheng, N. Electronic tuning of confined sub-nanometer cobalt oxide clusters boosting oxygen catalysis and rechargeable Zn–air batteries. Nano Energy 2021, 83, 105813. [Google Scholar] [CrossRef]

- Wu, D.; Hao, J.; Song, Z.; Fu, X.-Z.; Luo, J.-L. All roads lead to Rome: An energy-saving integrated electrocatalytic CO2 reduction system for concurrent value-added formate production. Chem. Eng. J. 2021, 412, 127893. [Google Scholar] [CrossRef]

- Chen, Y.; Vise, A.; Klein, W.E.; Cetinbas, F.C.; Myers, D.J.; Smith, W.A.; Deutsch, T.G.; Neyerlin, K.C. A Robust, Scalable Platform for the Electrochemical Conversion of CO2 to Formate: Identifying Pathways to Higher Energy Efficiencies. ACS Energy Lett. 2020, 5, 1825–1833. [Google Scholar] [CrossRef]

- Lin, M.; Han, L.; Singh, M.R.; Xiang, C. An Experimental- and Simulation-Based Evaluation of the CO2 Utilization Efficiency of Aqueous-Based Electrochemical CO2 Reduction Reactors with Ion-Selective Membranes. ACS Appl. Energy Mater. 2019, 2, 5843–5850. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Li, H.; Fan, C.; Meng, Q.; Tang, Y.; Qiu, X.; Fu, G.; Ma, T. Dual Single-Atomic Ni-N4 and Fe-N4 Sites Constructing Janus Hollow Graphene for Selective Oxygen Electrocatalysis. Adv. Mater. 2020, 32, 2003134. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Li, S.; Liu, Q.; Tian, Y.; Zhang, Y.; Fu, G.; Tang, Y. Hollow Co3O4/CeO2 Heterostructures in Situ Embedded in N-Doped Carbon Nanofibers Enable Outstanding Oxygen Evolution. ACS Sustain. Chem. Eng. 2019, 7, 17950–17957. [Google Scholar] [CrossRef]

- Yin, J.; Jin, J.; Liu, H.; Huang, B.; Lu, M.; Li, J.; Liu, H.; Zhang, H.; Peng, Y.; Xi, P.; et al. NiCo2O4-Based Nanosheets with Uniform 4 nm Mesopores for Excellent Zn-Air Battery Performance. Adv. Mater. 2020, 32, 2001651. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Chang, L.; Guo, H.; Sun, J.; Xu, J.; Xiang, F.; Zhang, Y.; Wang, Z.; Wang, L.; Hao, F.; et al. Electronic structure modulation of bifunctional oxygen catalysts for rechargeable Zn–air batteries. J. Mater. Chem. A 2020, 8, 1229–1237. [Google Scholar] [CrossRef]

- Zhou, G.; Li, M.; Li, Y.; Dong, H.; Sun, D.; Liu, X.; Xu, L.; Tian, Z.; Tang, Y. Regulating the Electronic Structure of CoP Nanosheets by O Incorporation for High-Efficiency Electrochemical Overall Water Splitting. Adv. Funct. Mater. 2019, 30, 1905252. [Google Scholar] [CrossRef]

- Li, Z.; Wu, X.; Jiang, X.; Shen, B.; Teng, Z.; Sun, D.; Fu, G.; Tang, Y. Surface carbon layer controllable Ni3Fe particles confined in hierarchical N-doped carbon framework boosting oxygen evolution reaction. Adv. Powder Mater. 2021; in press. [Google Scholar] [CrossRef]

- Dionigi, F.; Zeng, Z.; Sinev, I.; Merzdorf, T.; Deshpande, S.; Lopez, M.B.; Kunze, S.; Zegkinoglou, I.; Sarodnik, H.; Fan, D.; et al. In-situ structure and catalytic mechanism of NiFe and CoFe layered double hydroxides during oxygen evolution. Nat. Commun. 2020, 11, 2522. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Bai, L.; Hu, X. Deciphering Iron-Dependent Activity in Oxygen Evolution Catalyzed by Nickel-Iron Layered Double Hydroxide. Angew. Chem. Int. Ed. 2020, 59, 8072–8077. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yin, S.; Shen, P.K. Asymmetric 3d Electronic Structure for Enhanced Oxygen Evolution Catalysis. ACS Appl. Mater. Inter. 2018, 10, 23131–23139. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Hu, Y.; Pan, X.; Yin, J.; Li, Y.; Wang, Y.; Zhang, Y.; Sun, H.; Tang, Y. N-carbon supported hierarchical Ni/Ni0.2Mo0.8N nanosheets as high-efficiency oxygen evolution electrocatalysts. Chem. Eng. J. 2020, 392, 124845. [Google Scholar] [CrossRef]

- Li, M.; Wu, X.; Liu, K.; Zhang, Y.; Jiang, X.; Sun, D.; Tang, Y.; Huang, K.; Fu, G. Nitrogen vacancies enriched Ce-doped Ni3N hierarchical nanosheets triggering highly-efficient urea oxidation reaction in urea-assisted energy-saving electrolysis. J. Energy Chem. 2022; in press. [Google Scholar] [CrossRef]

- Gong, M.; Li, Y.; Wang, H.; Liang, Y.; Wu, J.Z.; Zhou, J.; Wang, J.; Regier, T.; Wei, F.; Dai, H. An advanced Ni-Fe layered double hydroxide electrocatalyst for water oxidation. J. Am. Chem. Soc. 2013, 135, 8452–8455. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Liu, S.; Lai, C.; Zeng, G.; Li, M.; Liu, X.; Li, B.; Huo, X.; Qin, L.; Li, L.; et al. Recent Advance of Transition-Metal-Based Layered Double Hydroxide Nanosheets: Synthesis, Properties, Modification, and Electrocatalytic Applications. Adv. Energy Mater. 2021, 11, 2002863. [Google Scholar] [CrossRef]

- Fan, G.; Li, F.; Evans, D.G.; Duan, X. Catalytic applications of layered double hydroxides: Recent advances and perspectives. Chem. Soc. Rev. 2014, 43, 7040–7066. [Google Scholar] [CrossRef]

- Li, M.; Li, H.; Jiang, X.; Jiang, M.; Zhan, X.; Fu, G.; Lee, J.-M.; Tang, Y. Gd-induced electronic structure engineering of a NiFe-layered double hydroxide for efficient oxygen evolution. J. Mater. Chem. A 2021, 9, 2999–3006. [Google Scholar] [CrossRef]

- Zhou, G.; Wu, X.; Zhao, M.; Pang, H.; Xu, L.; Yang, J.; Tang, Y. Interfacial Engineering-Triggered Bifunctionality of CoS2/MoS2 Nanocubes/Nanosheet Arrays for High-Efficiency Overall Water Splitting. ChemSusChem 2021, 14, 699–708. [Google Scholar] [CrossRef]

- Fan, C.; Wu, X.; Li, M.; Wang, X.; Zhu, Y.; Fu, G.; Ma, T.; Tang, Y. Surface chemical reconstruction of hierarchical hollow inverse-spinel manganese cobalt oxide boosting oxygen evolution reaction. Chem. Eng. J. 2022, 431, 133829. [Google Scholar] [CrossRef]

- Ji, D.; Fan, L.; Tao, L.; Sun, Y.; Li, M.; Yang, G.; Tran, T.Q.; Ramakrishna, S.; Guo, S. The Kirkendall Effect for Engineering Oxygen Vacancy of Hollow Co3O4 Nanoparticles toward High-Performance Portable Zinc–Air Batteries. Angew. Chem. Int. Ed. 2019, 58, 13840–13844. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.; Honorato, A.M.B.; Ticianelli, E.A.; Varela, H. Uniformly self-decorated Co3O4 nanoparticles on N, S co-doped carbon layers derived from a camphor sulfonic acid and metal–organic framework hybrid as an oxygen evolution electrocatalyst. J. Mater. Chem. A 2018, 6, 12106–12114. [Google Scholar] [CrossRef]

- Wang, Q.; O’Hare, D. Recent Advances in the Synthesis and Application of Layered Double Hydroxide (LDH) Nanosheets. Chem. Rev. 2012, 112, 4124–4155. [Google Scholar] [CrossRef] [PubMed]

- Fu, G.T.; Yan, X.X.; Chen, Y.F.; Xu, L.; Sun, D.M.; Lee, J.M.; Tang, Y.W. Boosting Bifunctional Oxygen Electrocatalysis with 3D Graphene Aerogel-Supported Ni/MnO Particles. Adv. Mater. 2018, 30, 1704609. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Yang, J.F.; Guan, B.Y.; Lu, Y.; Lou, X.W. Hierarchical Hollow Nanoprisms Based on Ultrathin Ni-Fe Layered Double Hydroxide Nanosheets with Enhanced Electrocatalytic Activity towards Oxygen Evolution. Angew. Chem. Int. Ed. 2018, 57, 172–176. [Google Scholar] [CrossRef] [PubMed]

- Xiao, W.; Zhou, J.; Yu, L.; Wang, D.; Lou, X.W. Electrolytic Formation of Crystalline Silicon/Germanium Alloy Nanotubes and Hollow Particles with Enhanced Lithium-Storage Properties. Angew. Chem. Int. Ed. 2016, 55, 7427–7431. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Fan, C.; Hu, X.; Wang, C.; Huang, Z.; Fu, G.; Lee, J.-M.; Tang, Y. Hierarchically Porous Co/CoxMy (M = P, N) as an Efficient Mott–Schottky Electrocatalyst for Oxygen Evolution in Rechargeable Zn–Air Batteries. Small 2019, 15, 1901518. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Qiu, X.; Liang, F.; Zhang, Q.; Koo, A.; Dai, Y.; Lei, Y.; Sun, X. A metal-organic framework-derived bifunctional catalyst for hybrid sodium-air batteries. Appl. Catal. B Environ. 2019, 241, 407–414. [Google Scholar] [CrossRef]

- Suen, N.-T.; Hung, S.-F.; Quan, Q.; Zhang, N.; Xu, Y.-J.; Chen, H.M. Electrocatalysis for the oxygen evolution reaction: Recent development and future perspectives. Chem. Soc. Rev. 2017, 46, 337–365. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Tang, Y.; Lee, J.-M.; Fu, G. Recent advances in rare-earth-based materials for electrocatalysis. Chem Catal. 2022; in press. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Huang, Y.; Lin, J.; Li, M.; Jiang, M.; Ding, L.; Sun, D.; Huang, K.; Tang, Y. Carbon Nanotubes Interconnected NiCo Layered Double Hydroxide Rhombic Dodecahedral Nanocages for Efficient Oxygen Evolution Reaction. Nanomaterials 2022, 12, 1015. https://doi.org/10.3390/nano12061015

Li M, Huang Y, Lin J, Li M, Jiang M, Ding L, Sun D, Huang K, Tang Y. Carbon Nanotubes Interconnected NiCo Layered Double Hydroxide Rhombic Dodecahedral Nanocages for Efficient Oxygen Evolution Reaction. Nanomaterials. 2022; 12(6):1015. https://doi.org/10.3390/nano12061015

Chicago/Turabian StyleLi, Meng, Yujie Huang, Jiaqi Lin, Meize Li, Mengqi Jiang, Linfei Ding, Dongmei Sun, Kai Huang, and Yawen Tang. 2022. "Carbon Nanotubes Interconnected NiCo Layered Double Hydroxide Rhombic Dodecahedral Nanocages for Efficient Oxygen Evolution Reaction" Nanomaterials 12, no. 6: 1015. https://doi.org/10.3390/nano12061015