Atomistic Simulation of the Ion-Assisted Deposition of Silicon Dioxide Thin Films

Abstract

:1. Introduction

2. Model Description

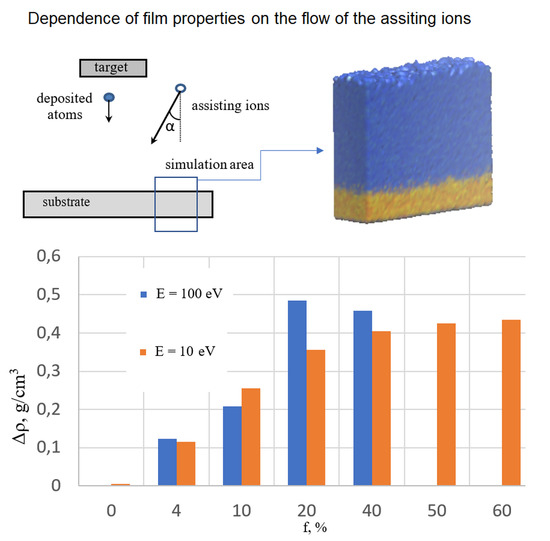

- Insertion of silicon and oxygen atoms with stoichiometric proportion of 1:2 at the top of the simulation box. Each of the oxygen atoms is considered either as thermal or as an assisting ion. Initial coordinates of the atoms are specified randomly. The initial values of kinetic energy are equal to 0.1 eV for Si atoms, 0.1 eV for thermal oxygen atoms, representing the gas in the vacuum chamber, and 100 eV for the assisting ions, having charge +e and mass equivalent to the molar weight of the oxygen molecule, 32 g/mol. The non-electrostatic part of the potential energy of the interaction between assisting ions and other atoms is calculated in the frame of the DESIL force field [14]. The initial velocity of Si atoms and thermal oxygen atoms is directed normally to the substrate. The initial velocity of assisting ions is directed under α = 0 or α = 60° (Figure 1).

- Start of the MD simulation using the initial conditions described in step 2. Due to the high energy of assisting ions, the time step of MD simulation is equal to 0.05 fs. This step is ten times smaller than that used earlier in the simulation of deposition with an energy of silicon ions of 10 eV. Since velocity increases as the square root of kinetic energy, a tenfold decrease in time step for a tenfold increase in energy seems more than enough. The length of the simulation trajectory is chosen equal to 2 ps. This duration is enough for the assisting atoms to lose their kinetic energy due to collisions with the atoms of the substrate and the previously deposited film layers [14].

- Continuation of MD simulation with the usual time step of 1 fs. At this stage, the charge of the assisting ions becomes equal to −0.65e, which corresponds to the charge of the oxygen atoms in the frame of the DESIL force field (see below for details), and the mass is equivalent to a molar weight of 16 g/mol. This change in the parameters takes into account that the assisting oxygen ions can be involved in the formation of film layers. The initial state for the simulation in step 4 is the final state of the simulation in step 3. The length of the simulation trajectory is chosen equal to 6 ps, as in our previous simulations [14,15,16,17].

- The vertical dimension of the simulation box is increased by d = 0.0085 ÷ 0.010 nm to compensate for the growth of film thickness.

- The injection steps 3–5 are repeated until the film thickness reaches the specified value.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zoeller, A.; Beisswenger, S.; Goetzelmann, R.; Matl, K. Plasma ion-assisted deposition: A novel technique for the production of optical coatings. In Proceedings of the Optical Interference Coatings, Grenoble, France, 5 June 1994; SPIE: Bellingham, WA, USA, 1994; Volume 2253. [Google Scholar] [CrossRef]

- McNeil, J.R.; Barron, A.C.; Wilson, S.R.; Herrmann, W.C. Ion-assisted deposition of optical thin films: Low energy vs high energy bombardment. Appl. Opt. 1984, 23, 552–559. [Google Scholar] [CrossRef]

- Ehlers, H.; Becker, K.-J.; Beckmann, R.; Beermann, N.; Brauneck, U.; Fuhrberg, P.; Gaebler, D.; Jakobs, S.; Kaiser, N.; Kennedy, M.; et al. Ion-assisted deposition processes: Industrial network IntIon. In Proceedings of the Advances in Optical Thin Films, St. Etienne, France, 30 September 2003; SPIE: Bellingham, WA, USA, 2004; Volume 5250. [Google Scholar] [CrossRef]

- Guo, C.; Kong, M. Fabrication of Ultralow Stress TiO2/SiO2 Optical Coatings by Plasma Ion-Assisted Deposition. Coatings 2020, 10, 720. [Google Scholar] [CrossRef]

- Bellum, J.; Field, E.; Kletecka, D.; Long, F. Reactive ion-assisted deposition of e-beam evaporated titanium for high refractive index TiO2 layers and laser damage resistant, broad bandwidth, high-reflection coatings. Appl. Opt. 2014, 53, A205–A211. [Google Scholar] [CrossRef] [PubMed]

- Ehlers, H.; Gross, T.; Lappschies, M.; Ristau, D. Ion-assisted deposition processes for precision and laser optics. In Proceedings of the Advances in Optical Thin Films, St. Etienne, France, 30 September 2003; SPIE: Bellingham, WA, USA, 2004; Volume 5250. [Google Scholar] [CrossRef]

- Komarov, F.F.; Komarov, A.F.; Mironov, A.M. Simulation of ion beam assisted deposition of layers on metals. Nucl. Instrum. Methods Phys. Res. Sect. B 1996, 115, 505–507. [Google Scholar] [CrossRef]

- Byeli, A.V.; Fedotov, S.A. Molecular Dynamics simulation od ion assisted deposition. Surf. Eng. 1994, 10, 136–139. [Google Scholar] [CrossRef]

- Dong, L.; Srolovitz, D.J. Texture development mechanisms in ion beam assisted deposition. J. Appl. Phys. 1998, 84, 5261–5269. [Google Scholar] [CrossRef]

- Strickland, B.; Roland, C. Low-temperature growth and ion-assisted deposition. Phys. Rev. B 1995, 51, 5061–5064. [Google Scholar] [CrossRef] [PubMed]

- Su, M.-H.; Lu, J.-M. Investigation of Ar incident energy and Ar incident angle effects on surface roughness of Cu metallic thin film in ion assisted deposition. Comput. Mater. Sci. 2006, 38, 386–394. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Zhao, Y.-Q. Molecular dynamics study of the effect of substrate temperature and Ar ion assisted deposition on the deposition of amorphous TiO2 films. Appl. Surf. Sci. 2017, 404, 409–417. [Google Scholar] [CrossRef]

- Matsui, M.; Akaogi, M. Molecular dynamics simulation of the structural and physical properties of the four polymorphs of TiO2. Mol. Simul. 1991, 6, 239–244. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, A.V.; Kochikov, I.V.; Kondakova, O.A.; Sulimov, V.B.; Tikhonravov, A.V. Supercomputer modeling of the ion beam sputtering process: Full-atomistic level. In Proceedings of the Optical Systems Design 2015: Advances in Optical Thin Films V, Jena, Germany, 7–10 September 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9627, p. 962708. [Google Scholar] [CrossRef]

- Grigoriev, F.; Sulimov, A.; Katkova, E.; Kochikov, I.; Kondakova, O.; Sulimov, V.; Tikhonravov, A. Full-atomistic nanoscale modeling of the ion beam sputtering deposition of SiO2 thin films. J. Non-Cryst. Solids 2016, 448, 1–5. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, A.V.; Kochikov, I.V.; Kondakova, O.A.; Sulimov, V.B.; Tikhonravov, A.V. Computational Experiments on Atomistic Modeling of Thin Film Deposition. Appl. Opt. 2017, 56, C87–C90. [Google Scholar] [CrossRef] [PubMed]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Atomistic simulation of the glancing angle deposition of SiO2 thin films. J. Non-Cryst. Solids 2019, 512, 98–102. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Postma, J.P.M.; van Gunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular-Dynamics with Coupling to an External Bath. J. Chem. Phys. 1984, 81, 3684–3690. [Google Scholar] [CrossRef]

- Takada, A.; Richet, P.; Catlow, C.; Price, G. Molecular dynamics simulations of vitreous silica structures. J. Non-Cryst. Solids 2004, 345–346, 224–229. [Google Scholar] [CrossRef]

- Van Beest, B.W.H.; Kramer, G.J.; van Santen, R.A. Force fields for silicas and aluminophosphates based on ab initio calculations. Phys. Rev. Lett. 1990, 64, 1955–1958. [Google Scholar] [CrossRef] [Green Version]

- Nayir, N.; van Duin, A.C.T.; Erkoc, S. Development of the ReaxFF Reactive Force Field for Inherent Point Defects in the Si/Silica System. J. Phys. Chem. A 2019, 123, 4303–4313. [Google Scholar] [CrossRef]

- Sulimov, V.B.; Kutov, D.C.; Sulimov, A.V.; Grigoriev, F.V.; Tikhonravov, A.V. Density functional modeling of structural and electronic properties of amorphous high temperature oxides. J. Non-Cryst. Solids 2022, 578, 121170. [Google Scholar] [CrossRef]

- Sulimov, A.V.; Kutov, D.C.; Grigoriev, F.V.; Tikhonravov, A.V.; Sulimov, V.B. Generation of Amorphous Silicon Dioxide Structures via Melting-Quenching Density Functional Modeling. Lobachevskii J. Math. 2020, 41, 1581–1590. [Google Scholar] [CrossRef]

- Abraham, M.J.; Murtola, T.; Schulz, R.; Páll, S.; Smith, J.C.; Hess, B.; Lindahl, E. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 2015, 1–2, 19–25. [Google Scholar] [CrossRef]

- Voevodin, V.V.; Antonov, A.S.; Nikitenko, D.A.; Shvets, P.A.; Sobolev, S.I.; Sidorov, I.Y.; Stefanov, K.S.; Voevodin, V.V.; Zhumatiy, S.A. Supercomputer Lomonosov-2: Large Scale, Deep Monitoring and Fine Analytics for the User Community. Supercomput. Front. Innov. 2019, 6, 4–11. [Google Scholar] [CrossRef]

- Yuan, X.; Cormack, A. Efficient Algorithm for Primitive Ring Statistics in Topological Networks. Comput. Mater. Sci. 2002, 24, 343–360. [Google Scholar] [CrossRef]

- King, S.V. Ring Configurations in a Random Network Model of Vitreous Silica. Nature 1967, 213, 1112–1113. [Google Scholar] [CrossRef]

- Vedam, K.; Limsuwan, P. Piezo- and elasto-optic properties of liquids under high pressure. II. Refractive index vs. density. J. Chem. Phys. 1978, 69, 4772–4778. [Google Scholar] [CrossRef]

- Pham, T.H.; Dang, C.X. Ion assisted deposition of SiO2 film from silicon. In Proceedings of the Advances in Optical Thin Films II, 59631U, Jena, Germany, 7–10 September 2015; SPIE: Bellingham, WA, USA, 2005; Volume 5963. [Google Scholar] [CrossRef]

- Hawkeye, M.M.; Brett, M.J. Glancing angle deposition: Fabrication, properties, and applications of micro- and nanostructured thin films. J. Vac. Sci. Technol. A 2007, 25, 1317. [Google Scholar] [CrossRef]

- Trottier-Lapointe, W.; Zabeida, O.; Schmitt, T.; Martinu, L. Ultralow refractive index optical films with enhanced mechanical performance obtained by hybrid glancing angle deposition. Appl. Opt. 2016, 55, 8796–8805. [Google Scholar] [CrossRef]

- Polder, D.; van Santen, J.H. The effective permeability of mixtures of solids. Physica 1946, 12, 257. [Google Scholar] [CrossRef]

- Schmidt, D.; Schubert, M. Anisotropic Bruggeman effective medium approaches for slanted columnar thin films. J. Appl. Phys. 2013, 114, 083510. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Combined modeling of the optical anisotropy of porous thin films. Coatings 2020, 10, 517. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Atomistic Simulation of the Ion-Assisted Deposition of Silicon Dioxide Thin Films. Nanomaterials 2022, 12, 3242. https://doi.org/10.3390/nano12183242

Grigoriev FV, Sulimov VB, Tikhonravov AV. Atomistic Simulation of the Ion-Assisted Deposition of Silicon Dioxide Thin Films. Nanomaterials. 2022; 12(18):3242. https://doi.org/10.3390/nano12183242

Chicago/Turabian StyleGrigoriev, F. V., V. B. Sulimov, and A. V. Tikhonravov. 2022. "Atomistic Simulation of the Ion-Assisted Deposition of Silicon Dioxide Thin Films" Nanomaterials 12, no. 18: 3242. https://doi.org/10.3390/nano12183242