Exploiting the Potential of Biosilica from Rice Husk as Porous Support for Catalytically Active Iron Oxide Nanoparticles

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

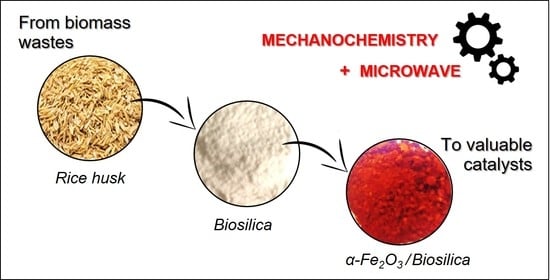

3.1. Obtaining Biosilica from Rice Husk Waste

3.2. Mechanochemical Synthesis of α-Fe2O3/RH-Silica

3.3. Material Characterization

3.4. Catalytic Activity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Polshettiwar, V.; Varma, R.S. Green chemistry by nano-catalysis. Green Chem. 2010, 12, 743–754. [Google Scholar] [CrossRef]

- Zhang, Q.; Uchaker, E.; Candelaria, S.L.; Cao, G. Nanomaterials for energy conversion and storage. Chem. Soc. Rev. 2013, 42, 3127–3171. [Google Scholar] [CrossRef]

- Khin, M.M.; Nair, A.S.; Babu, V.J.; Murugan, R.; Ramakrishna, S. A review on nanomaterials for environmental remediation. Energy Environ. Sci. 2012, 5, 8075–8109. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Luque, R. Heterogeneous photocatalytic nanomaterials: Prospects and challenges in selective transformations of biomass-derived compounds. Chem. Soc. Rev. 2014, 43, 765–778. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, C.; Grätzel, M.; Kostecki, R.; Mao, S.S. Nanomaterials for renewable energy production and storage. Chem. Soc. Rev. 2012, 41, 7909–7937. [Google Scholar] [CrossRef]

- White, R.J.; Luque, R.; Budarin, V.L.; Clark, J.H.; Macquarrie, D.J. Supported metal nanoparticles on porous materials. Chem. Soc. Rev. 2009, 38, 481–494. [Google Scholar] [CrossRef] [PubMed]

- Astruc, D. Introduction: Nanoparticles in catalysis. Chem. Rev. 2020, 120, 461–463. [Google Scholar] [CrossRef] [Green Version]

- Prieto, G.; Zečević, J.; Friedrich, H.; De Jong, K.P.; De Jongh, P.E. Towards stable catalysis by controlling collective properties of supported metal nanoparticles. Nat. Mater. 2013, 12, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Batista, A.T.; Baaziz, W.; Taleb, A.L.; Chaniot, J.; Moreaud, M.; Legens, C.; Aguilar-Tapia, A.; Proux, O.; Hazemann, J.-L.; Diehl, F. Atomic scale insight into the formation, size, and location of platinum nanoparticles supported on γ-alumina. ACS Catal. 2020, 10, 4193–4204. [Google Scholar] [CrossRef]

- Zou, X.; Rui, Z.; Ji, H. Core-shell NiO@PdO nanoparticles supported on alumina as an advanced catalyst for methane oxidation. ACS Catal. 2017, 7, 1615–1625. [Google Scholar] [CrossRef]

- Chen, F.; Kreyenschulte, C.; Radnik, J.; Lund, H.; Surkus, A.E.; Junge, K.; Beller, M. Selective semihydrogenation of alkynes with N-graphitic-modified cobalt nanoparticles supported on silica. ACS Catal. 2017, 7, 1526–1532. [Google Scholar] [CrossRef]

- Hong, Y.; Yan, X.; Liao, X.; Li, R.; Xu, S.; Xiao, L.; Fan, J. Platinum nanoparticles supported on Ca (Mg)-zeolites for efficient room-temperature alcohol oxidation under aqueous conditions. Chem. Commun. 2014, 50, 9679–9682. [Google Scholar] [CrossRef]

- Du, L.; Yuan, M.; Wei, H.; Xing, X.; Feng, D.; Liao, Y.; Chen, H.; Yang, D. Interconnected Pd nanoparticles supported on Zeolite-AFI for hydrogen detection under ultralow temperature. ACS Appl. Mater. Interfaces 2019, 11, 36847–36853. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.; Guo, X.; Yang, Y.; Zha, Z.; Wang, Z. Gold nanoparticles supported on titanium dioxide: An efficient catalyst for highly selective synthesis of benzoxazoles and benzimidazoles. Chem. Commun. 2014, 50, 6145–6148. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y. Rice husk silica derived nanomaterials for sustainable applications. Renew. Sustain. Energy Rev. 2017, 80, 453–466. [Google Scholar] [CrossRef]

- Szczęśniak, B.; Phuriragpitikhon, J.; Choma, J.; Jaroneic, M. Recent advances in the development and applications of biomass-derived cartons with uniform porosity. J. Mater. Chem. A 2020, 8, 18464–18491. [Google Scholar] [CrossRef]

- Varma, R.S. Biomass-derived renewable carbonaceous materials for sustainable chemical and environmental applications. ACS Sustain. Chem. Eng. 2019, 7, 6458–6470. [Google Scholar] [CrossRef]

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of lignocellulosic biomass with ionic liquids. Green. Chem. 2013, 15, 550–583. [Google Scholar] [CrossRef] [Green Version]

- Galkin, M.V.; Samec, J.S. Lignin valorization through catalytic lignocellulosic fractionation: A fundamental platform for the future biorefinery. ChemSusChem 2016, 9, 1544–1558. [Google Scholar] [CrossRef]

- Liu, X.; Duran, X.; Wei, W.; Wang, S.; Ni, B.J. Photocatalytic conversion of lignocellulosic biomass to valuable products. Green Chem. 2019, 21, 4266–4289. [Google Scholar] [CrossRef]

- Cecilia, J.A.; García-Sancho, C.; Maireles-Torres, P.J.; Luque, R. Industrial food waste valorization: A general overview. In Biorefinery; Springer: Berlin/Heidelberg, Germany, 2019; pp. 253–277. [Google Scholar]

- Beidaghy Dizaji, H.; Zeng, T.; Hartmann, I.; Enke, D.; Schliermann, T.; Lenz, V.; Bidabadi, M. Generation of high quality biogenic silica by combustion of rice husk and rice straw combined with pre- and post-treatment strategies—A review. Appl. Sci. 2019, 9, 1083. [Google Scholar] [CrossRef] [Green Version]

- Franco, A.; De, S.; Balu, A.M.; Romero, A.A.; Luque, R. Integrated mechanochemical/microwave-assisted approach for the synthesis of biogenic silica-based catalysts from rice husk waste. ACS Sustain. Chem. Eng. 2018, 6, 11555–11562. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Wang, Y.; Liu, H.; Qiu, J.; Wang, J.; Han, W.; Yeung, K.L. Perform of TS-1-coated structure packing materials for styrene oxidation reaction. ACS Catal. 2011, 1, 437–445. [Google Scholar] [CrossRef]

- Shi, Z.Q.; Dong, Z.P.; Sun, J.; Zhang, F.W.; Yang, H.L.; Zhou, J.H.; Zhu, X.H.; Li, R. Filled cobalt nanoparticles into carbon nanotubes as a rapid and high-efficiency catalyst for selective epoxidation of styrene with molecular oxygen. Chem. Eng. J. 2014, 237, 81–87. [Google Scholar] [CrossRef]

- Maleki, A. Green oxidation protocol: Selective conversions of alcohols and alkenes to aldehydes, ketones and epoxides by using a new multiwall carbon nanotube-based hybrid nanocatalyst via ultrasound irradiation. Ultrason. Sonochem. 2018, 40, 460–464. [Google Scholar] [CrossRef] [PubMed]

- Zammataro, A.; Gangemi, C.M.A.; Pappalardo, A.; Toscano, R.M.; Puglisi, R.; Nicotra, G.; Fragalà, M.E.; Tuccitto, N.; Strazzetto, G.T. Covalently functionalized carbon nanoparticles with a chiral Mn-Salen: A new nanocatalyst for enantioselective epoxidation of alkenes. Chem. Commun. 2019, 55, 5255–5258. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Peng, H.; Liu, J.; Wang, Y.; Hao, X.; Feng, X.; Khan, S.U.; Tan, H.; Li, Y. Polyoxometalate-based metal-organic frameworks for selective oxidation of aryl alkenes to aldehydes. Inorg. Chem. 2018, 57, 4109–4116. [Google Scholar] [CrossRef] [PubMed]

- Hajian, R.; Ehsanikhah, A. Manganese porphyrin immobilized on magnetic MCM-41 nanoparticles as an efficient and reusable catalyst for alkene oxidations with sodium periodate. Chem. Phys. Lett. 2018, 691, 146–154. [Google Scholar] [CrossRef]

- Liu, G.; Hou, M.; Song, J.; Zhang, Z.; Wu, T.; Han, B. Ni2+ containing ionic liquid immobilized on silica: Effective catalyst for styrene oxidation with H2O2 at solvent-free conditions. J. Mol. Catal. A Chem. 2010, 316, 90–94. [Google Scholar] [CrossRef]

- Brühne, F.; Wright, E. Benzaldehyde. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2011; Volume 6, pp. 1–13. [Google Scholar]

- Duarte, T.A.; Estrada, A.C.; Simões, M.M.; Santos, I.C.; Cavaleiro, A.M.; Neves, M.G.P.; Cavaleiro, J.A. Homogeneous catalytic oxidation of styrene and styrene derivatives with hydrogen peroxide in the presence of transition metal-substituted polyoxotungstates. Catal. Sci. Technol. 2015, 5, 351–363. [Google Scholar] [CrossRef]

- Frang, R.; Tian, P.; Yang, X.; Luque, R.; Li, Y. Encapsulation of ultrafine metal-oxide nanoparticles within mesopores for biomass-derived catalytic applications. Chem. Sci. 2018, 9, 1854–1859. [Google Scholar] [CrossRef] [Green Version]

- Marquez-Medina, M.D.; Prinsen, P.; Li, H.; Shih, K.; Romero, A.A.; Luque, R. Continuous flow synthesis of supported magnetic iron oxide nanoparticles for efficient isoeugenol conversion into vanillin. ChemSusChem 2018, 11, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Filiciotto, L.; Balu, A.M.; Romero, A.A.; Rodriguez-Castellón, E.; van der Waal, J.C.; Luque, R. Benign-by-design preparation of humin-based iron oxide catalytic nanocomposites. Green Chem. 2017, 19, 4423–4434. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Pan, X.; Bao, X. Tuning of redox properties of iron and iron oxides via encapsulation within carbon nanotubes. J. Am. Chem. Soc. 2007, 129, 7421–7426. [Google Scholar] [CrossRef]

- Sharma, R.K.; Dutta, S.; Sharma, S.; Zboril, R.; Varma, R.S.; Gawande, M.B. Fe3O4 (iron oxide)-supported nanocatalysts: Synthesis, characterization and applications in couplings reactions. Green Chem. 2016, 18, 3184–3209. [Google Scholar] [CrossRef]

- Kharisov, B.L.; Kharissova, O.V.; Rasika Dias, H.; Ortiz Méndez, U.; Gómez De La Fuente, I.; Peña, Y.; Vázquez Dimas, A. Iron-based nanomaterials in the catalysis. In Advanced Catalytic Materials-Photocatalysis and Other Current Trends; Norena, L.E., Wang, J.-A., Eds.; InTech: Rijeka, Croatia, 2016; pp. 35–68. [Google Scholar]

- Luque, R.; Balu, A.M.; Franco, A.; Romero, A.A. Method for obtaining biosilica from rice husk. International Patent WO/2018/178459, 4 October 2018. [Google Scholar]

- Xu, S.; Habid, A.; Gee, S.; Hong, Y.; McHenry, M. Spin orientation, structure, morphology, and magnetic properties of hematite nanoparticles. J. Appl. Phys. 2015, 117, 17A315. [Google Scholar] [CrossRef]

- El Mendili, Y.; Bardeau, J.F.; Randrianantoandro, N.; Grasset, F.; Greneche, J.M. Insights into the mechanism related to the phase transition from γ-Fe2O3 to α-Fe2O3 nanoparticles induce by thermal treatment and laser irradiation. J. Phys. Chem. C 2012, 116, 23785–23792. [Google Scholar] [CrossRef]

- Zboril, R.; Mashlan, M.; Petridis, D. Iron (III) oxides from thermal processes synthesis, structural and magnetic properties, Mössbauer spectroscopy characterization, and applications. Chem. Matter. 2002, 14, 969–982. [Google Scholar] [CrossRef]

- Li, X.; Chiba, A.; Takahashi, S.; Mato, M. Oxidation characteristics and magnetic properties of iron ultrafine particles. J. Appl. Phys. 1998, 83, 3871–3875. [Google Scholar] [CrossRef]

- Pineda, A.; Balu, A.M.; Campelo, J.M.; Romero, A.A.; Carmona, D.; Balas, F.; Santamaria, J.; Luque, R. A dry milling approach for the synthesis of highly active nanoparticles supported on porous materials. ChemSusChem 2011, 4, 1561–1565. [Google Scholar] [CrossRef]

| Material | SBET a (m2·g−1) | DBJH b (nm) | VBJH c (cm3·g−1) |

|---|---|---|---|

| RH-Silica | 352 | 8.0 | 0.56 |

| α-Fe2O3/RH-Silica | 272 | 7.1 | 0.39 |

| Entry | Material | Conversion | Selectivity to Benzaldehyde | Selectivity to Others |

|---|---|---|---|---|

| (mol%) | (mol%) | (mol%) | ||

| 1 | - | - | - | - |

| 2 | RH-Silica | - | - | - |

| 3 | α-Fe2O3/RH-Silica | 45 | >99 | - |

| 4 | Reuse 1 | 43 | >99 | - |

| 5 | Reuse 2 | 44 | >99 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franco, A.; Luque, R.; Carrillo-Carrión, C. Exploiting the Potential of Biosilica from Rice Husk as Porous Support for Catalytically Active Iron Oxide Nanoparticles. Nanomaterials 2021, 11, 1259. https://doi.org/10.3390/nano11051259

Franco A, Luque R, Carrillo-Carrión C. Exploiting the Potential of Biosilica from Rice Husk as Porous Support for Catalytically Active Iron Oxide Nanoparticles. Nanomaterials. 2021; 11(5):1259. https://doi.org/10.3390/nano11051259

Chicago/Turabian StyleFranco, Ana, Rafael Luque, and Carolina Carrillo-Carrión. 2021. "Exploiting the Potential of Biosilica from Rice Husk as Porous Support for Catalytically Active Iron Oxide Nanoparticles" Nanomaterials 11, no. 5: 1259. https://doi.org/10.3390/nano11051259