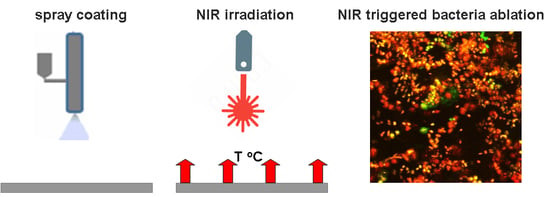

Nanocomposite Sprayed Films with Photo-Thermal Properties for Remote Bacteria Eradication

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Gold Nanostars (GNS) and Prussian Blue (PB) Nanoparticles Synthesis

2.3. General Method of Spray Solutions Containing Nanoparticles Preparation

2.4. Spray Coating of Glass Disks

2.5. Ultraviolet/Visible/Near-Infrared (UV/VIS/NIR) Spectroscopy

2.6. Contact Angle Measurement

2.7. Optical Confocal Microscopy

2.8. Photo-Thermal Effect of Sprayed Films upon NIR Irradiation

2.9. Antibacterial Effect Triggered by NIR Irradiation

3. Results and Discussion

3.1. Preparation and Characterization of Sprayed Films Containing GNS and PB Nanoparticles

3.2. Photo-Thermal Properties of Sprayed Films Containing PB and GNS Nanoparticles under NIR Light Irradiation

3.3. Photo-Thermally Induced Bacteria Eradication of Sprayed Films Containing PB and GNS Nanoparticles Triggered by NIR Light

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wang, L.; Hu, C.; Shao, L. The antimicrobial activity of nanoparticles: Present situation and prospects for the future. Int. J. Nanomed. 2017, 12, 1227–1249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Díez-Pascual, A.M. Antibacterial Activity of Nanomaterials. Nanomaterials 2018, 8, 359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gold, K.; Slay, B.; Knackstedt, M.; Gaharwar, A.K. Antimicrobial activity of metal and metal- oxide based nanoparticles. Adv. Therap. 2018, 1, 1700033. [Google Scholar] [CrossRef]

- Salvin, Y.N.; Asnis, J.; Häfeli, U.O.; Bach, H. Metal nanoparticles: Understanding the mechanisms behind antibacterial activity. J. Nanobiotechol. 2017, 15, 65. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, H.; Menson, S.; Kumar, S.V.; Rajeshkumar, S. Mechanistic study on antibacterial action of zinc oxide nanoparticles synthesized using green route. Chem.-Biol. Interact. 2018, 286, 60–70. [Google Scholar] [CrossRef] [PubMed]

- Dorati, R.; DeTrizio, A.; Spalla, M.; Migliavacca, R.; Pagani, L.; Pisani, S.; Chiesa, E.; Conti, B.; Modena, T.; Genta, I. Gentamicin Sulfate PEG-PLGA/PLGA-H Nanoparticles: Screening Design and Antimicrobial Effect Evaluation toward Clinic Bacterial Isolates. Nanomaterials 2018, 8, 37. [Google Scholar] [CrossRef] [Green Version]

- Borzenkov, M.; Pallavicini, P.; Chirico, G. Photothermally active inorganic nanoparticles: From colloidal solutions to photothermally active printed surfaces and polymeric nanocomposite materials. Eur. J. Inorg. Chem. 2019, 41, 4397–4404. [Google Scholar] [CrossRef]

- Mocan, L.; Tabaran, A.F.; Mocan, T.; Pop, T.; Mosteanu, O.; Agoston-Coldea, L.; Matea, C.D.; Gonciar, D.; Zdrehus, C.; Iancu, C. Laser thermal ablation of multi-drug resistant bacteria using functionalized gold nanoparticles. Int. J. Nanomed. 2017, 12, 2255–2263. [Google Scholar] [CrossRef] [Green Version]

- Levi-Polyachenko, N.; Young, C.; MacNeill, C.; Braden, A.; Argenta, L.; Reid, S. Eradicating group A streptococcus bacteria and biofilms using functionalized multi-wall carbon nanotubes. Int. J. Hyperth. 2014, 30, 490–501. [Google Scholar] [CrossRef]

- Gargioni, C.; Borzenkov, M.; D’Alfonso, L.; Sperandeo, P.; Polissi, A.; Cucca, L.; Dacarro, G.; Grisoli, P.; Pallavicini, P.; D’Agostino, A.; et al. Self-Assembled Monolayers of Copper Sulfide Nanoparticles on Glass as Antibacterial Coatings. Nanomaterials 2020, 10, 352. [Google Scholar] [CrossRef] [Green Version]

- American National Standard Institute. American National Standard for Safe Use of Lasers; Laser Institute of America: Orlando, FL, USA, 2000. [Google Scholar]

- Santos, G.M.; de Santi Ferrara, F.I.; Zhao, F.; Rodrigues, D.F.; Shih, W.S. Photothermal inactivation of heat-resistant bacteria on nanoporous gold disk arrays. Opt. Mater. Express 2016, 6, 1217–1229. [Google Scholar] [CrossRef]

- Teng, C.P.; Zhou, T.; Ye, E.; Liu, S.; Koh, L.D.; Low, M.; Loh, X.J.; Win, Y.K.; Zhang, L.; Han, M.Y. Effective targeted photothermal ablation of multidrug resistant bacteria and their biofilms with NIR-absorbing gold nanocrosses. Adv. Healthc. Mater. 2016, 5, 2122–2130. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Zhao, Y.; Yu, Y.; Chen, X.; Wei, X.; Zhang, X.; Li, C. Single continuous near-infrared laser-triggered photodynamic and photothermal ablation of antibiotic-resistant bacteria using effective targeted copper sulfide nanoclusters. ACS Appl. Mater. Interfaces 2017, 9, 30470–30479. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.K.; Kang, E.B.; Kim, S.M.; Park, P.C.; In, I.; Park, S.Y. Performance of NIR-mediated antibacterial continuous flow microreactor prepared by mussel-inspired immobilization of Cs0.33WO3 photothermal agents. ACS Appl. Mater. Interfaces 2017, 9, 3192–3200. [Google Scholar] [CrossRef]

- Robby, A.I.; Park, S.Y. Recyclable metal nanoparticles-immobilized polymer dot on montmorillonite for alkaline phosphate-based colorimetric sensor with photo-thermal ablation of Bacteria. Anal. Chim. Acta 2019, 1082, 152–164. [Google Scholar] [CrossRef]

- Oruc, B.; Unal, H. Fluorophore-decorated carbon nanotubes with enhanced photothermal activity as antimicrobial nanomaterials. ACS Omega 2019, 4, 5556–5564. [Google Scholar] [CrossRef]

- Luo, J.; Deng, W.; Yang, F.; Wu, Z.; Huang, M.; Gu, M. Gold nanoparticles decorated graphene oxide/nanocellulose paper for NIR-laser induced photothermal ablation of pathogenic bacteria. Carbohydr. Polym. 2018, 198, 206–214. [Google Scholar] [CrossRef]

- De Aberasturi, D.J.; Serrano-Montes, A.B.; Liz-Marzán, L.M. Modern application of plasmonic nanoparticles: From energy to health. Adv. Opt. Mater. 2015, 3, 602–617. [Google Scholar] [CrossRef]

- Bermúdez-Jimènez, C.; Romney, M.G.; Roa-Flores, S.A.; Martinez-Costanon, G.; Bach, H. Hydrogel-embedded gold nanorods activated by plasmonic photothermy with potent antimicrobial activity. Nanomed. Nanotechnol. Biol. Med. 2019, 22, 102093. [Google Scholar] [CrossRef]

- Borzenkov, M.; Moros, M.; Tortiglione, C.; Bertoldi, S.; Contessi, N.; Farè, S.; Taglietti, A.; D’Agostino, A.; Pallavicini, P.; Collini, M.; et al. Fabrication of photothermaly active poly(vinyl alcohol) films with gold nanostars for antibacterial applications. Beilstein J. Nantechnol. 2018, 9, 2040–2048. [Google Scholar] [CrossRef] [Green Version]

- Borzenkov, M.; D’Alfonso, L.; Polissi, A.; Sperandeo, P.; Collini, M.; Dacarro, G.; Taglietti, A.; Chirico, G.; Pallavicini, P. Novel photo-thermally active polyvininyl alcohol- Prussian blue nanoparticles hydrogel films capable of eradicating bacteria and mitigating biofilms. IOP Nanotechnol. 2019, 30, 295702. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, H.A.; Chakrabarti, L.; Dumont, M.F.; Sandler, A.D.; Fernandes, R. Prussian blue nanoparticles for laser-induced photothermal therapy of tumors. RCS Adv. 2014, 4, 29729–29734. [Google Scholar] [CrossRef]

- Dacarro, G.; Taglietti, A.; Pallavicini, P. Prussian Blue Nanoparticles as a Versatile Photothermal Tool. Molecules 2018, 23, 1414. [Google Scholar] [CrossRef] [Green Version]

- Sritharadol, R.; Nakpheng, T.; Wan Sia Heng, P.; Srichana, T. Development of a topical mupirocin spray for antibacterial and wound healing applications. Drug. Dev. Ind. Pharm. 2017, 43, 1715–1728. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Choi, S.; Moon, H.C.; Seo, H.; Kim, J.Y.; Hong, S.P.; Lee, B.S.; Kang, E.; Lee, J.; Ruy, D.H.; et al. Antimicrobial spray nanocoating of supramolecular Fe(III)-tannic acid metal-organic coordination complex: Applications to shoe insoles and fruits. Sci. Rep. 2017, 7, 6980. [Google Scholar] [CrossRef] [PubMed]

- Gunell, M.; Haapanen, J.; Brobbey, K.J.; Saarinen, J.J.; Toivakka, M.; Mäkelä, J.M.; Huovinen, P.; Eerola, E. Antimicrobial characterization of silver nanoparticle-coated surfaces by “touch test” method. Nanotechnol. Sci. Appl. 2017, 10, 137–145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iždinskŷ, J.; Reinprecht, L.; Nosál, E. Antibacterial efficiency of silver and zinc-oxide nanoparticles in acrylate coating for surface treatment of wooden composites. Wood Res. 2018, 63, 365–372. [Google Scholar]

- Pallavivini, P.; Doná, A.; Casu, A.; Chirico, G.; Collini, M.; Dacarro, G.; Falqui, A.; Milanese, C.; Sironi, L.; Taglietti, A. Triton X-100 for three –plasmon gold nanostars with two phototermally active NIR (near IR) and SWIR (short-wavelengths IR) channels. Chem. Commun. 2013, 49, 6265–6267. [Google Scholar] [CrossRef] [Green Version]

- Musetti, A.; Pademi, K.; Fabbri, P.; Pulvirenti, A.; Al-Moghazy, M.; Fava, P. Poly(vinyl alcohol) based film potentially suitable for antimicrobial packaging applications. J. Food Sci. 2014, 79, E577–E582. [Google Scholar] [CrossRef]

- Birck, C.; Degoutin, S.; Tabary, N.; Miri, V.; Bacquet, M. New crosslinked cast films based on poly(vinyl alcohol): Preparation and physico-chemical properties. Express Polym. Lett. 2014, 8, 941–952. [Google Scholar] [CrossRef] [Green Version]

- Dacarro, G.; Grisoli, P.; Borzenkov, M.; Milanese, C.; Fratini, E.; Ferraro, G.; Taglietti, A.; Pallavicini, P. Self-assembled monolayers of Prussian blue nanoparticles with photothermal effect. Supramol. Chem. 2017, 29, 823–833. [Google Scholar] [CrossRef]

- Chirico, G.; Dacarro, G.; O’Regan, C.; Peltonen, J.; Sarfraz, J.; Taglietti, A.; Borzenkov, M.; Pallavicini, P. Photothermally responsive inks for inkjet-printing secure information. Part. Part. Syst. Charact. 2018, 35, 1800095. [Google Scholar] [CrossRef]

- Liao, S.; Zhang, Y.; Pan, X.; Zhu, F.; Jiang, C.; Liu, Q.; Cheng, Z.; Dai, G.; Wu, G.; Wang, L.; et al. Antibacterial activity and mechanism of silver nanoparticles against multidrug-resistant Pseudomonas aeruginosa. Int. J. Nanomedicine 2019, 14, 1469–1487. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pang, Z.; Raudonis, R.; Click, B.R.; Lin, T.J.; Cheng, Z. Antibiotic resistance of Pseudomonas aeruginosa: Mechanisms and alternative therapeutic strategies. Biotechnol. Adv. 2019, 37, 177–192. [Google Scholar] [CrossRef]

- Wu, M.C.; Deokar, A.R.; Liao, J.H.; Shih, P.Y.; Ling, Y.C. Graphene-based photothermal agent for rapid and effective killing of bacteria. ACS Nano 2013, 7, 1281–1290. [Google Scholar] [CrossRef]

- Tong, S.; Devis, J.S.; Eichenberger, E.; Holland, T.L.; Flower, V.J. Staphylococcus aureus infections: Epidemiology, pathophysiology, clinical manisfestattions, amd management. Clin. Microbiol. Rev. 2015, 28, 603–661. [Google Scholar] [CrossRef] [Green Version]

- Montanari, C.; Serrazanetti, D.I.; Felis, G.; Torriani, S.; Tabanelli, G.; Lanciotti, R.; Gardini, F. New insights in thermal resistance of staphylococcal strains belonging to the species Staphylococcus epidermidis, Staphylococcus lugdunensis and Staphylococcus aureus. Food Control 2015, 50, 605–615. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borzenkov, M.; Chirico, G.; Pallavicini, P.; Sperandeo, P.; Polissi, A.; Dacarro, G.; Doveri, L.; Collini, M.; Sironi, L.; Bouzin, M.; et al. Nanocomposite Sprayed Films with Photo-Thermal Properties for Remote Bacteria Eradication. Nanomaterials 2020, 10, 786. https://doi.org/10.3390/nano10040786

Borzenkov M, Chirico G, Pallavicini P, Sperandeo P, Polissi A, Dacarro G, Doveri L, Collini M, Sironi L, Bouzin M, et al. Nanocomposite Sprayed Films with Photo-Thermal Properties for Remote Bacteria Eradication. Nanomaterials. 2020; 10(4):786. https://doi.org/10.3390/nano10040786

Chicago/Turabian StyleBorzenkov, Mykola, Giuseppe Chirico, Piersandro Pallavicini, Paola Sperandeo, Alessandra Polissi, Giacomo Dacarro, Lavinia Doveri, Maddalena Collini, Laura Sironi, Margaux Bouzin, and et al. 2020. "Nanocomposite Sprayed Films with Photo-Thermal Properties for Remote Bacteria Eradication" Nanomaterials 10, no. 4: 786. https://doi.org/10.3390/nano10040786