Effect of Metallic or Non-Metallic Element Addition on Surface Topography and Mechanical Properties of CrN Coatings

Abstract

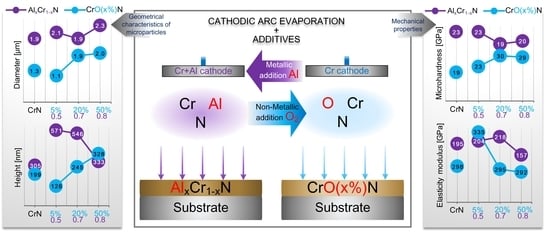

:1. Introduction

2. Materials and Methods

2.1. Coating Deposition

2.2. Coating Characterization

3. Results and Discussion

4. Conclusions

- (1)

- Strong correlations with a correlation coefficient of 0.82–1.00 between the friction coefficient obtained under conditions of sliding friction without a lubricant and the geometric characteristics of the microparticles on the coating surface (content, roughness, diameter, height, area and volume) for AlCrN coatings with 50%, 70%, and 80% aluminum and CrON coatings containing 5%, 20% and 50% oxygen have been established.

- (2)

- It was found that the friction coefficient does not change significantly with the increase in aluminum content but significantly decreases with the increase in the oxygen content.

- (3)

- The roughness parameters decrease with the increase of the Al concentration in AlCrN. For the CrON coatings, the opposite effect is observed. Similar relationships are observed for the size of the microparticles and their height for both types of coating.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Jäger, N.; Meindlhumer, M.; Spor, S.; Hruby, H.; Julin, J.; Stark, A.; Nahif, F.; Keckes, J.; Mitterer, C.; Daniel, R. Microstructural evolution and thermal stability of AlCr(Si)N hard coatings revealed by in-situ high-temperature high-energy grazing incidence transmission X-ray diffraction. Acta Mater. 2020, 186, 545–554. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Lechthaler, M.; Rudigier, H.; Polcik, P.; Mitterer, C. Microstructure and mechanical properties of nanocrystalline Al-Cr-B-N thin films. Surf. Coat. Technol. 2012, 213, 1–7. [Google Scholar] [CrossRef]

- Tillmann, W.; Grisales, D.; Stangier, D.; Butzke, T. Tribomechanical behaviour of TiAlN and CrAlN coatings deposited onto AISI H11 with different pre-treatments. Coatings 2019, 9, 519. [Google Scholar] [CrossRef] [Green Version]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Carlet, M. Wear behavior and thermal stability of HPPMS (Al,Ti,Cr,Si)ON, (Al,Ti,Cr,Si)N and (Ti,Al,Cr,Si)N coatings for cutting tools. Surf. Coat. Technol. 2020, 385, 125370. [Google Scholar] [CrossRef]

- Franz, R.; Mitterer, C. Vanadium containing self-adaptive low-friction hard coatings for high-temperature applications: A review. Surf. Coat. Technol. 2013, 228, 1–13. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Muratore, C.; Aouadi, S.M. Hard coatings with high temperature adaptive lubrication and contact thermal management: Review. Surf. Coat. Technol. 2014, 257, 247–265. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Carlet, M. Nanocomposite (Ti,Al,Cr,Si)N HPPMS coatings for high performance cutting tools. Surf. Coat. Technol. 2019, 378, 124857. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Gilewicz, A.; Jedrzejewski, R.; Myslinski, P.; Warcholinski, B. Influence of substrate bias voltage on structure, morphology and mechanical properties of AlCrN coatings synthesized using cathodic Arc evaporation. Tribol. Ind. 2019, 41, 484–497. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Multilayer coatings on tools for woodworking. Wear 2011, 271, 2812–2820. [Google Scholar] [CrossRef]

- Brögelmann, T.; Bobzin, K.; Kruppe, N.C.; Arghavani, M. Understanding the deformation and cracking behavior of Cr-based coatings deposited by hybrid direct current and high power pulse magnetron sputtering: From nitrides to oxynitrides. Thin Solid Films 2019, 688, 137354. [Google Scholar] [CrossRef]

- Volkhonsky, A.O.; Blinkov, I.V.; Belov, D.S. The effect of the metal phase on the compressive and tensile stresses reduction in the superhard nitride coatings. Coatings 2020, 10, 798. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, L.; Zheng, J.; Sidra, I.; Zhang, S. Characterization of AlCrN and AlCrON coatings deposited on plasma nitrided AISI H13 steels using ion-source-enhanced arc ion plating. Coatings 2020, 10, 306. [Google Scholar] [CrossRef] [Green Version]

- Kuznetsova, T.A.; Andreev, M.A.; Markova, L.V.; Chekan, V.A. Wear Resistance of Composite Chrome Coatings With Additives of Utlradispersed Diamonds. J. Frict. Wear 2001, 22, 423–428. [Google Scholar]

- Andreyev, M.; Anishchik, V.; Markova, L.; Kuznetsova, T. Ion-beam coatings based on Ni and Cr with ultradispersed diamonds—Structure and properties. Vacuum 2005, 78, 451–454. [Google Scholar] [CrossRef]

- Vityaz’, P.A.; Komarov, A.I.; Komarova, V.I.; Kuznetsova, T.A. Peculiarities of triboformation of wear-resistant layers on the surface of a MAO-coating1 modified by fullerenes. J. Frict. Wear 2011, 32, 231–241. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, T.-G.; Lin, W.; Zhu, Q.; Yan, B.; Hou, X. Microstructure and properties of the AlCrSi(O)N tool coatings by arc ion plating. Coatings 2020, 10, 841. [Google Scholar] [CrossRef]

- Hogmark, S.; Jacobson, S.; Larsson, M. Design and evaluation of tribological coatings. Wear 2000, 246, 20–33. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A.; Ronkainen, H. Coatings tribology—Contact mechanisms and surface design. Tribol. Int. 1998, 31, 107–120. [Google Scholar] [CrossRef]

- Kuznetsova, T.A.; Lapitskaya, V.A.; Chizhik, S.A.; Warcholinski, B.; Gilewicz, A.; Kuprin, A.S. Influence of the third element additives on the surface morphology of the wear-resistant ZrN coatings. IOP Conf. Ser. Mater. Sci. Eng. 2018, 443, 8–13. [Google Scholar] [CrossRef]

- Kumar, S.; Maity, S.R.; Patnaik, L. Friction and tribological behavior of bare nitrided, TiAlN and AlCrN coated MDC-K hot work tool steel. Ceram. Int. 2020, 46, 17280–17294. [Google Scholar] [CrossRef]

- Macías, H.A.; Yate, L.; Coy, L.E.; Aperador, W.; Olaya, J.J. Influence of Si-addition on wear and oxidation resistance of TiWSixN thin films. Ceram. Int. 2019, 45, 17363–17375. [Google Scholar] [CrossRef]

- Long, Y.; Zeng, J.; Yu, D.; Wu, S. Microstructure of TiAlN and CrAlN coatings and cutting performance of coated silicon nitride inserts in cast iron turning. Ceram. Int. 2014, 40, 9889–9894. [Google Scholar] [CrossRef]

- Wan, X.S.; Zhao, S.S.; Yang, Y.; Gong, J.; Sun, C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr-N coatings deposited by arc ion plating. Surf. Coat. Technol. 2010, 204, 1800–1810. [Google Scholar] [CrossRef]

- Reiter, A.E.; Derflinger, V.H.; Hanselmann, B.; Bachmann, T.; Sartory, B. Investigation of the properties of Al1-xCrxN coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2005, 200, 2114–2122. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Investigations into friction and wear behavior of AlTiN and AlCrN coatings deposited on laser textured WC/Co using novel open tribometer tests. Surf. Coat. Technol. 2020, 387, 125513. [Google Scholar] [CrossRef]

- Chen, W.; Hu, T.; Hong, Y.; Zhang, D.; Meng, X. Comparison of microstructures, mechanical and tribological properties of arc-deposited AlCrN, AlCrBN and CrBN coatings on Ti-6Al-4V alloy. Surf. Coat. Technol. 2020, 404. [Google Scholar] [CrossRef]

- Gilewicz, A.; Dobruchowska, E.; Murzynski, D.; Kuznetsova, T.A.; Lapitskaya, V.A. Influence of the Chemical Composition of AlCrN Coatings on Their Mechanical, Tribological, and Corrosion Characteristics. J. Frict. Wear 2020, 41, 383–392. [Google Scholar] [CrossRef]

- Brögelmann, T.; Bobzin, K.; Kruppe, N.C.; Carlet, M. Incorporation of oxygen at column boundaries in (Cr,Al)ON hard coatings. Thin Solid Films 2019, 685, 275–281. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Lupicka, O.; Kuprin, A.S.; Tolmachova, G.N.; Ovcharenko, V.D.; Kolodiy, I.V.; Sawczak, M.; Kochmanska, A.E.; Kochmanski, P.; et al. Structure of CrON coatings formed in vacuum arc plasma fluxes. Surf. Coat. Technol. 2017, 309, 920–930. [Google Scholar] [CrossRef]

- Lee, S.H.; Son, B.S.; Park, G.T.; Ryu, J.S.; Lee, H. Investigation of short-term, high-temperature oxidation of AlCrN coating on WC substrate. Appl. Surf. Sci. 2020, 505, 144587. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Investigation of oxidation behaviour of AlCrN and AlTiN coatings deposited by arc enhanced HIPIMS technique. Appl. Surf. Sci. 2020, 508, 144812. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Wang, Y.; Zhou, S.; Wang, Y.; Zeng, Z.; Li, J. A new method to improve the tribological performance of metal nitride coating: A case study for CrN coating. Vacuum 2020, 173, 109158. [Google Scholar] [CrossRef]

- Romero, J.; Gómez, M.A.; Esteve, J.; Montalà, F.; Carreras, L.; Grifol, M.; Lousa, A. CrAlN coatings deposited by cathodic arc evaporation at different substrate bias. Thin Solid Films 2006, 515, 113–117. [Google Scholar] [CrossRef]

- Reiter, A.E.; Mitterer, C.; De Figueiredo, M.R.; Franz, R. Abrasive and adhesive wear behavior of Arc-evaporated Al 1-x Cr x N hard coatings. Tribol. Lett. 2010, 37, 605–611. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. Microstructure, mechanical and tribological properties of Cr1-xAlxN films deposited by pulsed-closed field unbalanced magnetron sputtering (P-CFUBMS). Surf. Coat. Technol. 2006, 201, 4329–4334. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Chen, Z.; Li, J.; Li, M. Influence of deposition parameters on hard Cr-Al-N coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Tang, J.F.; Lin, C.Y.; Yang, F.C.; Tsai, Y.J.; Chang, C.L. Effects of nitrogen-argon flow ratio on the microstructural and mechanical properties of AlCrN coatings prepared using high power impulse magnetron sputtering. Surf. Coat. Technol. 2020, 386, 125484. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, H.; Gui, B.; Luo, Q.; Li, H.; Wang, Q. Influence of power pulse parameters on the microstructure and properties of the AlCrN Coatings by a modulated pulsed power magnetron sputtering. Coatings 2017, 7, 216. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Li, M.; Zhou, Y. Phase segregation and its effect on the adhesion of Cr-Al-N coatings on K38G alloy prepared by magnetron sputtering method. Surf. Coat. Technol. 2007, 201, 7692–7698. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Khabarava, A.; Chizhik, S.; Warcholinski, B.; Gilewicz, A. The influence of nitrogen on the morphology of ZrN coatings deposited by magnetron sputtering. Appl. Surf. Sci. 2020, 522, 146508. [Google Scholar] [CrossRef]

- Panjan, P.; Kek-Merl, D.; Zupanič, F.; Čekada, M.; Panjan, M. SEM study of defects in PVD hard coatings using focused ion beam milling. Surf. Coat. Technol. 2008, 202, 2302–2305. [Google Scholar] [CrossRef]

- Panjan, P.; Čekada, M.; Panjan, M.; Kek-Merl, D. Growth defects in PVD hard coatings. Vacuum 2009, 84, 209–214. [Google Scholar] [CrossRef]

- Panjan, P.; Gselman, P.; Kek-Merl, D.; Čekada, M.; Panjan, M.; Dražić, G.; Bončina, T.; Zupanič, F. Growth defect density in PVD hard coatings prepared by different deposition techniques. Surf. Coat. Technol. 2013, 237, 349–356. [Google Scholar] [CrossRef]

- Creasey, S.; Lewis, D.B.; Smith, I.J.; Münz, W.D. SEM image analysis of droplet formation during metal ion etching by a steered arc discharge. Surf. Coat. Technol. 1997, 97, 163–175. [Google Scholar] [CrossRef]

- Münz, W.D.; Smith, I.J.; Lewis, D.B.; Creasey, S. Droplet formation on steel substrates during cathodic steered arc metal ion etching. Vacuum 1997, 48, 473–481. [Google Scholar] [CrossRef]

- Kuznetsova, T.A.; Lapitskaya, V.A.; Chizhik, S.A.; Warcholinski, B.; Gilewicz, A.; Aizikovich, S.M. Uniformity Evaluation for the Mechanical Properties of an AlCrN Coating for Tribological Application Using Probe Methods. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 2020, 14, 1032–1039. [Google Scholar] [CrossRef]

- Chizhik, S.A.; Rymuza, Z.; Chikunov, V.V.; Kuznetsova, T.A.; Jarzabek, D. Micro-and nanoscale testing of tribomechanical properties of surfaces. In Recent Advances in Mechatronics; Springer: Berlin/Heidelberg, Germany, 2007; pp. 541–545. [Google Scholar] [CrossRef]

- Zhdanok, S.A.; Sviridenok, A.I.; Ignatovskii, M.I.; Krauklis, A.V.; Kuznetsova, T.A.; Chizhik, S.A.; Borisevich, K.O. On the properties of a steel modified with carbon nanomaterials. J. Eng. Phys. Thermophys. 2010, 83, 1–5. [Google Scholar] [CrossRef]

- Anishchik, V.M.; Uglov, V.V.; Kuleshov, A.K.; Filipp, A.R.; Rusalsky, D.P.; Astashynskaya, M.V.; Samtsov, M.P.; Kuznetsova, T.A.; Thiery, F.; Pauleau, Y. Electron field emission and surface morphology of a-C and a-C:H thin films. Thin Solid Films 2005, 482, 248–252. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuprin, A.S.; Tolmachova, G.N.; Ovcharenko, V.D.; Kuznetsova, T.A.; Zubar, T.I.; Khudoley, A.L.; Chizhik, S.A. Mechanical properties of Cr-O-N coatings deposited by cathodic arc evaporation. Vacuum 2018, 156, 97–107. [Google Scholar] [CrossRef]

- Hirai, M.; Ueno, Y.; Suzuki, T.; Jiang, W.; Grigoriu, C.; Yatsui, K. Characteristics of (Cr1-x, Alx)N films prepared by pulsed laser deposition. Jpn. J. Appl. Phys. Part. 1 Regul. Pap. Short Notes Rev. Pap. 2001, 40, 1056–1060. [Google Scholar] [CrossRef]

- Tang, J.F.; Lin, C.Y.; Yang, F.C.; Chang, C.L. Influence of nitrogen content and bias voltage on residual stress and the tribological and mechanical properties of CrAlN films. Coatings 2020, 10, 546. [Google Scholar] [CrossRef]

- Tlili, B.; Mustapha, N.; Nouveau, C.; Benlatreche, Y.; Guillemot, G.; Lambertin, M. Correlation between thermal properties and aluminum fractions in CrAlN layers deposited by PVD technique. Vacuum 2010, 84, 1067–1074. [Google Scholar] [CrossRef] [Green Version]

- Ghrib, T.; Tlili, B.; Nouveau, C.; Benlatreche, Y.; Lambertin, M.; Yacoubi, N.; Ennasri, M. Experimental investigation of the mechanical micro structural and thermal properties of thin CrAIN layers deposited by PVD technique for various aluminum percentages. Phys. Procedia 2009, 2, 1327–1336. [Google Scholar] [CrossRef] [Green Version]

- Yun, J.S.; Hong, Y.S.; Kim, K.H.; Kwon, S.H.; Wang, Q.M. Characteristics of ternary Cr-O-N coatings synthesized by using an arc ion plating technique. J. Korean Phys. Soc. 2010, 57, 103–110. [Google Scholar] [CrossRef]

- Castaldi, L.; Kurapov, D.; Reiter, A.; Shklover, V.; Schwaller, P.; Patscheider, J. Effect of the oxygen content on the structure, morphology and oxidation resistance of Cr–O–N coatings. Surf. Coat. Technol. 2008, 203, 545–549. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D. Structure and Properties of AlCrN Coatings Deposited Using Cathodic Arc Evaporation. Coatings 2020, 10, 793. [Google Scholar] [CrossRef]

- Gilewicz, A.; Jedrzejewski, R.; Myslinski, P.; Warcholinski, B. Structure, Morphology, and Mechanical Properties of AlCrN Coatings Deposited by Cathodic Arc Evaporation. J. Mater. Eng. Perform. 2019, 28, 1522–1531. [Google Scholar] [CrossRef] [Green Version]

- Warcholinski, B.; Gilewicz, A.; Kuprin, A.S.; Tolmachova, G.N.; Ovcharenko, V.D.; Kuznetsova, T.A.; Lapitskaya, V.A.; Chizhik, S.A. Comparison of Mechanical and Tribological Properties of Nitride and Oxynitride Coatings Based on Chrome and Zirconium Obtained by Cathodic Arc Evaporation. J. Frict. Wear 2019, 40, 163–170. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Chizhik, S.; Kuprin, A.S.; Tolmachova, G.N.; Ovcharenko, V.D.; Gilewicz, A.; Lupicka, O.; Warcholinski, B. Friction and Wear of Cr-O-N Coatings Characterized by Atomic Force Microscopy. Tribol. Ind. 2019, 41, 274–285. [Google Scholar] [CrossRef]

- Kuprin, A.S.; Kuznetsova, T.A.; Gilewicz, A.; Tolmachova, G.N.; Ovcharenko, V.D.; Abetkovskaia, S.O.; Zubar, T.I.; Khudoley, A.L.; Chizhik, S.A.; Lupicka, O.; et al. Tribological properties of vacuum arc Cr-O-N coatings in macro- and microscale. Probl. At. Sci. Technol. 2016, 106, 211–214. [Google Scholar]

- Lapitskaya, V.A.; Kuznetsova, T.A.; Melnikova, G.B.; Chizhik, S.A.; Kotov, D.A. The Changes in Particle Distribution over the Polymer Surface under the Dielectric Barrier Discharge Plasma. Int. J. Nanosci. 2019, 18, 1–4. [Google Scholar] [CrossRef]

- Khort, A.; Romanovski, V.; Lapitskaya, V.; Kuznetsova, T.; Yusupov, K.; Moskovskikh, D.; Haiduk, Y.; Podbolotov, K. Graphene@Metal Nanocomposites by Solution Combustion Synthesis. Inorg. Chem. 2020, 59, 6550–6565. [Google Scholar] [CrossRef] [PubMed]

- Coy, E.; Yate, L.; Kabacińska, Z.; Jancelewicz, M.; Jurga, S.; Iatsunskyi, I. Topographic reconstruction and mechanical analysis of atomic layer deposited Al2O3/TiO2 nanolaminates by nanoindentation. Mater. Des. 2016, 111, 584–591. [Google Scholar] [CrossRef]

- Sanchette, F.; Ducros, C.; Schmitt, T.; Steyer, P.; Billard, A. Nanostructured hard coatings deposited by cathodic arc deposition: From concepts to applications. Surf. Coat. Technol. 2011, 205, 5444–5453. [Google Scholar] [CrossRef]

- Kudish, I.I.; Pashkovski, E.; Volkov, S.S.; Vasiliev, A.S.; Aizikovich, S.M. Heavily loaded line EHL contacts with thin adsorbed soft layers. Math. Mech. Solids 2020, 25, 1011–1037. [Google Scholar] [CrossRef]

| Parameter\Coating | AlCrN | CrON |

|---|---|---|

| Deposition system | TINA 900M [10] (Vakuumtechnik Dresden GmbH, Dresden, Germany) | BULAT 3T [30] (Kharkov Institute of Physics and Technology, Kharkiv, Ukraine) |

| Cathode | Cr, AlCr (50:50), (70:30) and (80:20) | Cr |

| Cathode diameter [mm] | 100 | 60 |

| Base pressure [Pa] | 1 × 10−3 | 2 × 10−3 |

| Cathode-substrate distance [mm] | 180 | 300 |

| Rotation [rev/min] | 2 | 30 |

| Ion etching | ||

| Bias [V] | −600 | −1300 |

| Argon pressure [Pa] | 0.5 | 0.5 |

| Cr arc current [A] | 80 | 90 |

| Etching time [min] | 10 | 3 |

| Adhesion layer | ||

| Type of the layer | Cr | Cr |

| Cathode current [A] | 80 | 90 |

| Argon pressure [Pa] | 0.5 | 0.5 |

| Deposition temperature [°C] | 350 | 400 |

| Bias [V] | −100 | −100 |

| Thickness [µm] | 0.1 | 0.1 |

| Proper layer | ||

| Cathode current [A] | 80 | 90 |

| Total pressure [Pa] | 3 | 1.8 |

| Nitrogen pressure [Pa] | 3 | - |

| Relative oxygen concentration O2(x) = O2/(N2 + O2) | - | 0, 5, 20, 50% |

| Deposition temperature [°C] | 350 | 400 |

| Bias [V] | −100 | −150 |

| Thickness [µm] | 3 | 3 |

| Investigated coatings | ||

| Amount | 4 | 4 |

| Composition | CrN, Al50Cr50N, Al70Cr30N, Al80Cr20N, | CrN, CrO(5)N, CrO(20)N, CrO(50)N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuznetsova, T.; Lapitskaya, V.; Khabarava, A.; Chizhik, S.; Warcholinski, B.; Gilewicz, A.; Kuprin, A.; Aizikovich, S.; Mitrin, B. Effect of Metallic or Non-Metallic Element Addition on Surface Topography and Mechanical Properties of CrN Coatings. Nanomaterials 2020, 10, 2361. https://doi.org/10.3390/nano10122361

Kuznetsova T, Lapitskaya V, Khabarava A, Chizhik S, Warcholinski B, Gilewicz A, Kuprin A, Aizikovich S, Mitrin B. Effect of Metallic or Non-Metallic Element Addition on Surface Topography and Mechanical Properties of CrN Coatings. Nanomaterials. 2020; 10(12):2361. https://doi.org/10.3390/nano10122361

Chicago/Turabian StyleKuznetsova, Tatyana, Vasilina Lapitskaya, Anastasiya Khabarava, Sergei Chizhik, Bogdan Warcholinski, Adam Gilewicz, Aleksander Kuprin, Sergei Aizikovich, and Boris Mitrin. 2020. "Effect of Metallic or Non-Metallic Element Addition on Surface Topography and Mechanical Properties of CrN Coatings" Nanomaterials 10, no. 12: 2361. https://doi.org/10.3390/nano10122361