Temperature-Dependent Gas Transport Behavior in Cross-Linked Liquid Crystalline Polyacrylate Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Methods

2.3. Monomer Synthesis

2.4. Membrane Fabrication

3. Results

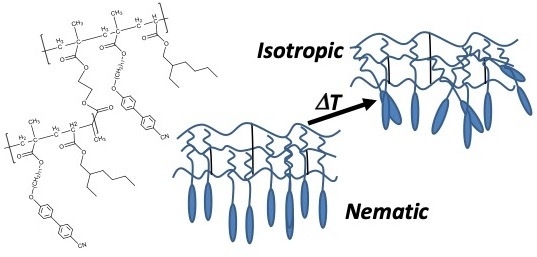

3.1. The Dependence of LC Ordering on Crosslinker and Temperature

3.2. Permeability and Diffusivity through LC Crosslinked Membranes

3.3. Permeability Selectivity Dependence on Temperature and Crosslink Density

3.4. Diffusion Selectivity Dependence on Temperature and Crosslinker Density

3.5. The Effect of LC Phase and Crosslinker Density on Solubility of Gases

3.6. Activation Energies of Gas Transport in the Nematic and Isotropic LC Phase

3.7. Mixed Gas Permeation of Propylene and Propane

4. Discussion

Author Contributions

Funding

Conflicts of Interest

Appendix A

Monomer Characterization Data

References

- Stern, A.S. Polymers for gas separations: The next decade. J. Membr. Sci. 1994, 94, 1–65. [Google Scholar] [CrossRef]

- Charcosset, C. A review of membrane processes and renewable energies for desalination. Desalination 2009, 245, 214–231. [Google Scholar] [CrossRef]

- Lin, H.; Van Wagner, E.; Raharjo, R.; Freeman, B.D.; Roman, I. High-Performance Polymer Membranes for Natural-Gas Sweetening. Adv. Mater. 2006, 18, 39–44. [Google Scholar] [CrossRef]

- Bernardo, P.; Drioli, E.; Golemme, G. Membrane Gas Separation: A Review/State of the Art. Ind. Eng. Chem. Res. 2009, 48, 4638–4663. [Google Scholar] [CrossRef]

- Kanehashi, S.; Kusakabe, A.; Sato, S.; Nagai, K. Analysis of permeability; solubility and diffusivity of carbon dioxide; oxygen; and nitrogen in crystalline and liquid crystalline polymers. J. Membr. Sci. 2010, 365, 40–51. [Google Scholar] [CrossRef]

- Rowe, B.W.; Freeman, B.D.; Paul, D.R. Physical aging of ultrathin glassy polymer films tracked by gas permeability. Polymer 2009, 50, 5565–5575. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Martin-Gil, V.; Ahmad, M.Z.; Fíla, V. Matrimid® 5218 in preparation of membranes for gas separation: Current state-of-the-art. Chem. Eng. Commun. 2018, 205, 161–196. [Google Scholar] [CrossRef]

- Kawakami, H.; Mikawa, M.; Nagaoka, S. Gas transport properties in thermally cured aromatic polyimide membranes. J. Membr. Sci. 1996, 118, 223–230. [Google Scholar] [CrossRef]

- Brehmer, M.; Zentel, R. Ferroelectric liquid-crystalline elastomers with short switching times. Macromol. Rapid Commun. 1995, 16, 659–662. [Google Scholar] [CrossRef]

- Simonov, A.N.; Larichev, A.V.; Shibaev, V.P. Holographic recording in films of azo-containing LC polymers in the presence of orienting electric field. Quantum Electron. 2000, 30, 635. [Google Scholar] [CrossRef]

- Rodríguez, F.J.; Sánchez, C.; Villacampa, B.; Alcalá, R.; Cases, R.; Millaruelo, M.; Oriol, L. Optical anisotropy and non-linear optical properties of azobenzene methacrylic polymers. Polymer 2004, 45, 2341–2348. [Google Scholar] [CrossRef]

- Ilavsky, M.; Nedbal, J.; Polakova, L.; Sedlakova, Z. Thermal and Dielectric Behavior of Liquid-Crystalline Polybutadiene-Diols with Mesogenic Groups in Side Chains. AIP Conf. Proc. 2008, 982, 440–445. [Google Scholar]

- Inui, K.; Miyata, T.; Uragami, T. Effect of permeation temperature on permeation and separation of a benzene/cyclohexane mixture through liquid-crystalline polymer membranes. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 281–288. [Google Scholar] [CrossRef]

- Han, S.; Martin, S.M. Diffusivity and Solubility of Organic Solutes in Supported Liquid Crystal Membranes. J. Phys. Chem. B 2009, 113, 12696–12703. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Martin, S.M. Enantioselective cholesteric liquid crystalline membranes characterized using nonchiral HPLC with circular dichroism detection. J. Membr. Sci. 2011, 367, 1–6. [Google Scholar] [CrossRef]

- Han, S.; Rabie, F.; Marand, E.; Martin, S.M. Enantioselective Separations Using Chiral Supported Liquid Crystalline Membranes. Chirality 2012, 24, 519–525. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.-S.; Hsiue, G.-H. Gas transport properties of linear and crosslinked side-chain liquid crystalline polymers with variable spacer lengths. Die Makromol. Chem. 1993, 194, 2025–2033. [Google Scholar] [CrossRef]

- Chen, D.-S.; Hsiue, G.-H.; Hsu, C.-S. Gas permeation through a side-chain liquid-crystalline polysiloxane-based membrane. Die Makromol. Chem. 1991, 192, 2021–2029. [Google Scholar] [CrossRef]

- Chen, D.-S.; Hsiue, G.-H.; Hsu, C.-S. Gas permeation through two side-chain liquid-crystalline polyacrylate-based membranes containing 4-methoxyphenyl 4-hexyloxybenzoate or 4-cyanophenyl 4-hexyloxybenzoate mesogenic side groups. Die Makromol. Chem. 1992, 193, 1469–1479. [Google Scholar] [CrossRef]

- Głowacki, E.; Horovitz, K.; Tang, C.W.; Marshall, K.L. Photoswitchable Gas Permeation Membranes Based on Liquid Crystals. Adv. Funct. Mater. 2010, 20, 2778–2785. [Google Scholar] [CrossRef]

- Kawakami, H. Gas transport properties of liquid crystalline polysiloxane with laterally attached side chain. J. Membr. Sci. 1997, 133, 245–253. [Google Scholar] [CrossRef]

- Loth, H.; Euschen, A. Diffusion flux control by liquid-crystalline side-chain polysiloxane elastomer foils. Die Makromol. Chem. Rapid Commun. 1988, 9, 35–38. [Google Scholar] [CrossRef]

- Chen, D.-S. Gas sorption in side-chain liquid crystalline polymers. Polymer 1993, 35, 2808–2814. [Google Scholar] [CrossRef]

- Barrer, R.M. Diffusivities in glassy polymers for the dual mode sorption model. J. Membr. Sci. 1984, 18, 25–35. [Google Scholar] [CrossRef]

- Rabie, F.; Sedlakova, Z.; Sheth, S.; Marand, E.; Martin, S.M.; Poláková, L. (Meth) acrylate liquid crystalline polymers for membrane applications. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Wan, X.-H.; Tu, H.-L.; Liu, Y.-X.; Zhang, D. A New Strategy for the Design of Liquid Crystalline Polymers with Flexible and Apolar Building Blocks. Chin. J. Polym. Sci. 2003, 21, 21–27. [Google Scholar]

- Pragliola, S.; Ober, C.K.; Mather, P.T.; Jeon, H.G. Mesogen-jacketed liquid crystalline polymers via stable free radical polymerization. Macromol. Chem. Phys. 1999, 200, 2338–2344. [Google Scholar] [CrossRef]

- Serrette, A.; Carroll, P.J.; Swager, T.M. Tuning the intermolecular dative interactions in vanadium-oxo linear chain compounds: Formation of a new type of liquid crystalline polymer. [Erratum to document cited in CA116(12):117814y]. J. Am. Chem. Soc. 1993, 115, 11656. [Google Scholar] [CrossRef]

- Koros, W.J.; Fleming, G.K. Membrane-based gas separation. J. Membr. Sci. 1993, 83, 1–80. [Google Scholar] [CrossRef]

- Ghosal, K.; Freeman, B.D. Gas separation using polymer membranes: An overview. Polym. Adv. Technol. 1994, 5, 673–697. [Google Scholar] [CrossRef]

- Baraa, J.E.; Gabriel, C.J.; Hatakeyama, E.S.; Carlisle, T.K.; Lessmann, S.; Noble, R.D.; Gin, D.L. Improving CO2 selectivity in polymerized room-temperature ionic liquid gas separation membranes through incorporation of polar substituents. J. Membr. Sci. 2008, 321, 3–7. [Google Scholar] [CrossRef]

- Li, Y.; Kröger, M.; Liu, W.K. Primitive chain network study on uncrosslinked and crosslinked cis-polyisoprene polymers. Polymer 2011, 52, 5867–5878. [Google Scholar] [CrossRef]

- Minelli, M.; Campagnoli, S.; De Angelis, M.G.; Doghieri, F.; Sarti, G.C. Predictive Model for the Solubility of Fluid Mixtures in Glassy Polymers. Macromolecules 2011, 44, 4852–4862. [Google Scholar] [CrossRef]

| Tg (°C) | Tm (°C) | ΔH (J/g) | |

|---|---|---|---|

| CNBPh75_2.5 (2.5% Crosslinker) | 12.2 | 73.5 | 4.1 |

| CNBPh75_5.0 (5.0% Crosslinker) | 17.0 | 63.4 | 2.3 |

| Sample | Phase | CO2 (KJ/mol K) | Propylene (KJ/mol K) | CH4 (KJ/mol K) | Propane (KJ/mol K) |

|---|---|---|---|---|---|

| CNBPh75_2.5 | Isotropic | 16.5 (2.9 a) | 16.0 (4.6 a) | 20.9 (1.40 a) | 30.8(1.0 a) |

| Nematic | 53.3 (2.6 a) | 72.3 (3.6 a) | 71.8 (1.4 a) | 91.2 (9.5 a) | |

| CNBPh75_5.0 | Isotropic | 37.4 (2.7 a) | 43.2 (5.0 a) | 42.4 (2.8 a) | 52.6 (7.6 a) |

| Nematic | 52.6 (4.1 a) | 76.4 (2.2 a) | 61.0 (3.2 a) | 88.1 (4.8 a) |

| Propane (KJ/mol K) | Propylene (KJ/mol K) | |

|---|---|---|

| Isotropic EA | 47.6 (0 a) | 43.4 (0 a) |

| Nematic EA | 71.9 (4.9 a) | 65.8 (3.3 a) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rabie, F.; Poláková, L.; Fallas, S.; Sedlakova, Z.; Marand, E.; Martin, S.M. Temperature-Dependent Gas Transport Behavior in Cross-Linked Liquid Crystalline Polyacrylate Membranes. Membranes 2019, 9, 104. https://doi.org/10.3390/membranes9080104

Rabie F, Poláková L, Fallas S, Sedlakova Z, Marand E, Martin SM. Temperature-Dependent Gas Transport Behavior in Cross-Linked Liquid Crystalline Polyacrylate Membranes. Membranes. 2019; 9(8):104. https://doi.org/10.3390/membranes9080104

Chicago/Turabian StyleRabie, Feras, Lenka Poláková, Sebastian Fallas, Zdenka Sedlakova, Eva Marand, and Stephen M. Martin. 2019. "Temperature-Dependent Gas Transport Behavior in Cross-Linked Liquid Crystalline Polyacrylate Membranes" Membranes 9, no. 8: 104. https://doi.org/10.3390/membranes9080104