Single-Mode Polymer Ridge Waveguide Integration of Organic Thin-Film Laser

Abstract

:1. Introduction

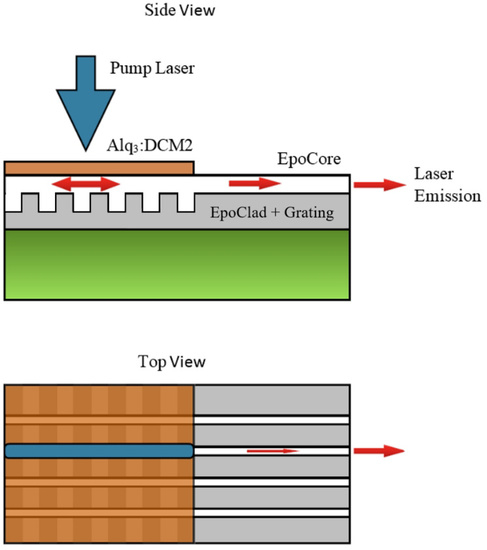

2. The Polymeric Single-Mode Waveguide

3. The Organic Thin-Film Laser

4. Device Fabrication

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Estevez, M.; Alvarez, M.; Lechuga, L. Integrated optical devices for lab-on-a-chip biosensing applications. Laser Photonics Rev. 2012, 6, 463–487. [Google Scholar] [CrossRef] [Green Version]

- Kuehne, A.J.C.; Gather, M.C. Organic Lasers: Recent Developments on Materials, Device Geometries, and Fabrication Techniques. Chem. Rev. 2016, 116, 12823–12864. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balslev, S.; Jorgensen, A.M.; Bilenberg, B.; Mogensen, K.B.; Snakenborg, D.; Geschke, O.; Kutter, J.P.; Kristensen, A. Lab-on-a-chip with integrated optical transducers. Lab Chip 2006, 6, 213–217. [Google Scholar] [CrossRef] [PubMed]

- Christiansen, M.B.; Schøler, M.; Kristensen, A. Integration of active and passive polymer optics. Opt. Express 2007, 15, 3931–3939. [Google Scholar] [CrossRef] [PubMed]

- Mappes, T.; Vannahme, C.; Klinkhammer, S.; Woggon, T.; Schelb, M.; Lenhert, S.; Mohr, J.; Lemmer, U. Polymer biophotonic lab-on-chip devices with integrated organic semiconductor laser. In Organic Semiconductors in Sensors and Bioelectronics II; Shinar, R., Malliaras, G.G., Eds.; International Society for Optics and Photonics, SPIE: New York, NY, USA, 2009; Volume 7418, pp. 48–55. [Google Scholar] [CrossRef]

- Vannahme, C.; Klinkhammer, S.; Kolew, A.; Jakobs, P.J.; Guttmann, M.; Dehm, S.; Lemmer, U.; Mappes, T. Integration of organic semiconductor lasers and single-mode passive waveguides into a PMMA substrate. Microelectron. Eng. 2010, 87, 693–695. [Google Scholar] [CrossRef]

- Becker, J.; Čehovski, M.; Caspary, R.; Kowalsky, W.; Müller, C. Distributed feedback ridge waveguide lasers fabricated by CNP process. Microelectron. Eng. 2017, 181, 29–33. [Google Scholar] [CrossRef]

- Madigan, C.F.; Bulović, V. Solid State Solvation in Amorphous Organic Thin Films. Phys. Rev. Lett. 2003, 91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kozlov, V.G.; Bulovic, V.; Burrows, P.E.; Baldo, M.; Khalfin, V.B.; Parthasarathy, G.; Forrest, S.R.; You, Y.; Thompson, M.E. Study of lasing action based on Foerster energy transfer in optically pumped organic semiconductor thin films. J. Appl. Phys. 1998, 84, 4096–4108. [Google Scholar] [CrossRef]

- Berggren, M.; Dodabalapur, A.; Slusher, R.E. Stimulated emission and lasing in dye-doped organic thin films with Foerster transfer. Appl. Phys. Lett. 1997, 71, 2230–2232. [Google Scholar] [CrossRef]

- Schneider, D.; Rabe, T.; Riedl, T.; Dobbertin, T.; Kröger, M.; Becker, E.; Johannes, H.H.; Kowalsky, W.; Weimann, T.; Wang, J.; et al. Ultrawide tuning range in doped organic solid-state lasers. Appl. Phys. Lett. 2004, 85, 1886–1888. [Google Scholar] [CrossRef]

- Čehovski, M.; Döring, S.; Rabe, T.; Caspary, R.; Kowalsky, W. Combined optical gain and degradation measurements in DCM2 doped Tris-(8-hydroxyquinoline)aluminum thin-films. In Organic Photonics VII; Cheyns, D., Beaujuge, P.M., van Elsbergen, V., Ribierre, J.C., Eds.; SPIE: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Rabe, T. Materialien und Bauelementstrukturen für Organische Laserdioden; Cuvillier: Goettingen, Germany, 2010. [Google Scholar]

- Zaharov, V.V.; Farahi, R.H.; Snyder, P.J.; Davison, B.H.; Passian, A. Karhunen–Loève treatment to remove noise and facilitate data analysis in sensing, spectroscopy and other applications. Analyst 2014, 139, 5927–5935. [Google Scholar] [CrossRef] [PubMed]

- Rabe, T.; Döring, S.; Hildebrandt, N.; Riedl, T.; Kowalsky, W.; Scherf, U. Optical Gain in Foerster Energy Transfer Based Organic Guest-Host-Systems. MRS Proc. 2009, 1197. [Google Scholar] [CrossRef]

- Chiasera, A.; Dumeige, Y.; Féron, P.; Ferrari, M.; Jestin, Y.; Conti, G.N.; Pelli, S.; Soria, S.; Righini, G. Spherical whispering-gallery-mode microresonators. Laser Photonics Rev. 2010, 4, 457–482. [Google Scholar] [CrossRef]

- Canazza, G.; Scotognella, F.; Lanzani, G.; Silvestri, S.D.; Zavelani-Rossi, M.; Comoretto, D. Lasing from all-polymer microcavities. Laser Phys. Lett. 2014, 11, 035804. [Google Scholar] [CrossRef]

- Tsiminis, G.; Wang, Y.; Kanibolotsky, A.L.; Inigo, A.R.; Skabara, P.J.; Samuel, I.D.W.; Turnbull, G.A. Nanoimprinted Organic Semiconductor Laser Pumped by a Light-Emitting Diode. Adv. Mater. 2013, 25, 2826–2830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samuel, I.D.W.; Turnbull, G.A. Organic Semiconductor Lasers. Chem. Rev. 2007, 107, 1272–1295. [Google Scholar] [CrossRef] [PubMed]

- Bülow, T.; Gargouri, H.; Siebert, M.; Rudolph, R.; Johannes, H.H.; Kowalsky, W. Moisture barrier properties of thin organic-inorganic multilayers prepared by plasma-enhanced ALD and CVD in one reactor. Nanoscale Res. Lett. 2014, 9, 223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ebeling, K.J. Integrierte Optoelektronik; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar] [CrossRef]

- Kogelnik, H.; Shank, C.V. Coupled-Wave Theory of Distributed Feedback Lasers. J. Appl. Phys. 1972, 43, 2327–2335. [Google Scholar] [CrossRef]

- Lowery, A.; Novak, D. Performance comparison of gain-coupled and index-coupled DFB semiconductor lasers. IEEE J. Quantum Electron. 1994, 30, 2051–2063. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Čehovski, M.; Becker, J.; Charfi, O.; Johannes, H.-H.; Müller, C.; Kowalsky, W. Single-Mode Polymer Ridge Waveguide Integration of Organic Thin-Film Laser. Appl. Sci. 2020, 10, 2805. https://doi.org/10.3390/app10082805

Čehovski M, Becker J, Charfi O, Johannes H-H, Müller C, Kowalsky W. Single-Mode Polymer Ridge Waveguide Integration of Organic Thin-Film Laser. Applied Sciences. 2020; 10(8):2805. https://doi.org/10.3390/app10082805

Chicago/Turabian StyleČehovski, Marko, Jing Becker, Ouacef Charfi, Hans-Hermann Johannes, Claas Müller, and Wolfgang Kowalsky. 2020. "Single-Mode Polymer Ridge Waveguide Integration of Organic Thin-Film Laser" Applied Sciences 10, no. 8: 2805. https://doi.org/10.3390/app10082805