Pulsed Electric Fields (PEF) to Mitigate Emerging Mycotoxins in Juices and Smoothies

Abstract

:Featured Application

Abstract

1. Introduction

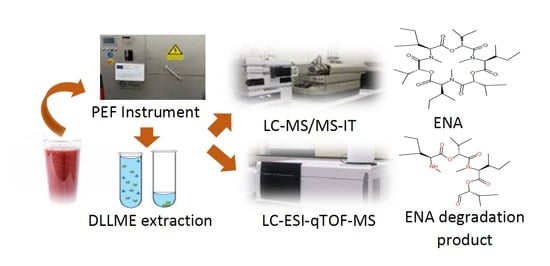

2. Materials and Methods

2.1. Reagents and Chemicals

2.2. Samples

2.3. Pulsed Electric Field Treatment

2.4. Dispersive Liquid-Liquid Microextraction Procedure (DLLME)

2.5. LC-MS/MS-IT Determination

2.6. LC-ESI-qTOF-MS Analysis

2.7. Method Validation

2.8. In Silico Prediction Methods

- Class I: fatal if swallowed (LD50 ≤ 5 mg/Kgbw)

- Class II: fatal if swallowed (5 mg/kg < LD50 ≤ 50 mg/Kgbw)

- Class III: toxic if swallowed (50 mg/kg < LD50 ≤ 300 mg/Kgbw)

- Class IV: harmful if swallowed (300 mg/kg < LD50 ≤ 2000 mg/Kgbw)

- Class V: may be harmful if swallowed (2000 mg/kg < LD50 ≤ 5000 mg/Kgbw)

3. Results and Discussion

3.1. Reduction of ENs and BEA Contents after PEF Treatment

3.2. Identification of Degradation Products

3.3. In Silico Prediction Methods

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pinela, J.; Ferreira, I.C. Nonthermal physical technologies to decontaminate and extend the shelf-life of fruits and vegetables: Trends aiming at quality and safety. Crit. Rev. Food Sci. Nutr. 2017, 57, 2095–2111. [Google Scholar] [CrossRef]

- Misra, N.N.; Koubaa, M.; Roohinejad, S.; Juliano, P.; Alpas, H.; Inácio, R.S.; Saraiva, J.A.; Barba, F.J. Landmarks in the historical development of twenty first century food processing technologies. Food Res. Int. 2017, 97, 318–339. [Google Scholar] [CrossRef]

- Picart-Palmade, L.; Cunault, C.; Chevalier-Lucia, D.; Belleville, M.P.; Marchesseau, S. Potentialities and limits of some non-thermal technologies to improve sustainability of food processing. Front. Nutr. 2019, 5, 130. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wang, L.H.; Zeng, X.A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Misra, N.N.; Martynenko, A.; Chemat, F.; Paniwnyk, L.; Barba, F.J.; Jambrak, A.R. Thermodynamics, transport phenomena, and electrochemistry of external field-assisted nonthermal food technologies. Crit. Rev. Food Sci. Nutr. 2018, 58, 1832–1836. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gabrić, D.; Barba, F.; Roohinejad, S.; Gharibzahedi, S.M.T.; Radojčin, M.; Putnik, P.; Bursać Kovačević, D. Pulsed electric fields as an alternative to thermal processing for preservation of nutritive and physicochemical properties of beverages: A review. J. Food Process. Eng. 2018, 41, e12638. [Google Scholar] [CrossRef]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Salehi, F. Physico-chemical properties of fruit and vegetable juices as affected by pulsed electric field: A review. Int. J. Food Proper. 2020, 23, 1036–1050. [Google Scholar] [CrossRef]

- Guo, M.; Jin, T.Z.; Geveke, D.J.; Fan, X.; Sites, J.E.; Wang, L. Evaluation of microbial stability, bioactive compounds, physicochemical properties, and consumer acceptance of pomegranate juice processed in a commercial scale pulsed electric field system. Food Bioprocess Technol. 2014, 7, 2112–2120. [Google Scholar] [CrossRef]

- Zhang, Y.; Hou, Y.; Zhang, Y.; Chen, J.; Chen, F.; Liao, X.; Hu, X. Reduction of diazinon and dimethoate in apple juice by pulsed electric field treatment. J. Sci. Food Agric. 2012, 92, 743–750. [Google Scholar] [CrossRef]

- Gavahian, M.; Pallares, N.; Al Khawli, F.; Ferrer, E.; Barba, F. Recent advances in the application of innovative food processing technologies for reducing pesticides and mycotoxins in foods. Trends Food Sci. Technol. 2020, in press. [Google Scholar]

- Carballo, D.; Pinheiro-Fernandes-Vieira, P.; Tolosa, J.; Font, G.; Berrada, H.; Ferrer, E. Dietary exposure to mycotoxins through fruits juice consumption. Rev. Toxicol. 2018, 35, 2–6. [Google Scholar]

- Mallebrera, B.; Prosperini, A.; Font, G.; Ruiz, M.J. In vitro mechanisms of Beauvericin toxicity: A review. Food Chem. Toxicol. 2018, 111, 537–545. [Google Scholar] [CrossRef] [PubMed]

- Prosperini, A.; Berrada, H.; Ruiz, M.J.; Caloni, F.; Coccini, T.; Spicer, L.J.; Perego, M.C.; Lafranconi, A. A review of the mycotoxin enniatin B. Front. Public Health 2017, 5, 304. [Google Scholar] [CrossRef]

- Karlovsky, P.; Suman, M.; Berthiller, F.; De Meester, J.; Eisenbrand, G.; Perrin, I.; Oswald, I.P.; Speijers, G.; Chiodini, A.; Recker, T.; et al. Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res. 2016, 32, 179–205. [Google Scholar] [CrossRef]

- Vijayalakshmi, S.; Nadanasabhapathi, S.; Kumar, R.; Kumar, S.; Reddy, R. Effect of combination processing on aflatoxin reduction: Process optimization by response surface methodology. J. Food Process. Preserv. 2017, 41, e13230. [Google Scholar] [CrossRef]

- Vijayalakshmi, S.; Nadanasabhapathi, S.; Kumar, R.; Kumar, S.S. Effect of pH and pulsed electric field process parameters on the aflatoxin reduction in model system using response surface methodology. J. Food Sci. Technol. 2018, 55, 868–878. [Google Scholar] [CrossRef]

- Cotterill, J.V.; Chaudhry, M.Q.; Matthews, W.; Watkins, R.W. In silico assessment of toxicity of heat-generated food contaminants. Food Chem. Toxicol. 2008, 46, 1905–1918. [Google Scholar] [CrossRef]

- Kar, S.; Leszczynski, J. Exploration of computational approaches to predict the toxicity of chemical mixtures. Toxics 2019, 7, 15. [Google Scholar] [CrossRef] [Green Version]

- Gozalbes, R.; de Julián-Ortiz, J.V.; Fito-López, C. Métodos computacionales en toxicología predictiva: Aplicación a la reducción de ensayos con animales en el contexto de la legislación comunitaria REACH. Rev. Toxicol. 2014, 31, 157–167. [Google Scholar]

- Pallarés, N.; Carballo, D.; Ferrer, E.; Fernández-Franzón, M.; Berrada, H. Mycotoxin Dietary Exposure Assessment through Fruit Juices Consumption in Children and Adult Population. Toxins 2019, 11, 684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Commission. Decision 2002/657/EC of 12 August 2002, implementing Council Directive 96/23/EC concerning the performance of analytical methods and the interpretation of results. OJEU L 2002, 221, 8–36. [Google Scholar]

- Drwal, M.N.; Banerjee, P.; Dunkel, M.; Wettig, M.R.; Preissner, R. ProTox: A web server for the in silico prediction of rodent oral toxicity. Nucleic Acids Res. 2014, 42, W53–W58. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Banerjee, P.; Eckert, A.O.; Schrey, A.K.; Preissner, R. ProTox-II: A webserver for the prediction of toxicity of chemicals. Nucleic Acids Res. 2018, 46, W257–W263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- United Nations. Globally Harmonized System of Classification and Labelling of Chemicals (GHS) 8th Revised Edition; United Nations: New York, NY, USA; Geneva, Switzerland, 2019; Available online: http://www.unece.org/fileadmin/DAM/trans/danger/publi/ghs/ghs_rev08/ST-SG-AC10-30-Rev8e.pdf (accessed on 30 October 2019).

- Serrano, A.B.; Font, G.; Mañes, J.; Ferrer, E. Development a mitigation strategy of enniatins in pasta under home-cooking conditions. LWT-Food Sci. Technol. 2016, 65, 1017–1024. [Google Scholar] [CrossRef]

- Tolosa, J.; Font, G.; Mañes, J.; Ferrer, E. Mitigation of enniatins in edible fish tissues by thermal processes and identification of degradation products. Food Chem. Toxicol. 2017, 101, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Avsaroglu, M.D.; Bozoglu, F.; Alpas, H.; Largeteau, A.; Demazeau, G. Use of pulsed-high hydrostatic pressure treatment to decrease patulin in apple juice. High Press. Res. 2015, 35, 214–222. [Google Scholar] [CrossRef]

- Hao, H.; Zhou, T.; Koutchma, T.; Wu, F.; Warriner, K. High hydrostatic pressure assisted degradation of patulin in fruit and vegetable juice blends. Food Control 2016, 62, 237–242. [Google Scholar] [CrossRef]

- Meca, G.; Ritieni, A.; Mañes, J. Influence of the heat treatment on the degradation of the minor Fusarium mycotoxin beauvericin. Food Control 2012, 28, 13–18. [Google Scholar] [CrossRef]

- Serrano, A.B.; Meca, G.; Font, G.; Ferrer, E. Degradation study of enniatins by liquid chromatography–triple quadrupole linear ion trap mass spectrometry. Food Chem. 2013, 141, 4215–4225. [Google Scholar] [CrossRef]

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Scientific Opinion on the risks for animal and public health related to the presence of T-2 and HT-2 toxin in food and feed. EFSA J. 2011, 9, 2481. [Google Scholar] [CrossRef]

| Mycotoxin | Degradation Product | [M+H]+ (m/z) | Lost Fragment | Molecular Structure |

|---|---|---|---|---|

| ENA degradation product | [ENA-HyLv-Ile+H2O]+ | 475.3261 | HyLV+Ile |  |

| ENA1 degradation product | [ENA1-HyLv-Val+H2O]+ | 475.3244 | HyLv+Val |  |

| ENB degradation product 1 | [ENB-HyLv-Val+Na]+ | 437.1936 | HyLv+Val |  |

| ENB degradation product 2 | [ENB-Val+H2O]+ | 527.2000 | Val |  |

| ENB1 degradation product | [ENB1-HyLv-Val]+ | 443.1674 | HyLv+Val |  |

| BEA degradation product | [BEA-Phe-HyLv+2H2O]+ | 517.3705 | Phe+HyLv |  |

| Mycotoxin | Oral Toxicity Prediction Results | |||

|---|---|---|---|---|

| Predicted LD50 (mg/Kgbw) | Predicted Toxicity Class | Average Similarity (%) | Prediction Accuracy (%) | |

| ENA degradation product | 1600 | IV | 76.28 | 69.26 |

| ENA1 degradation product | 1600 | IV | 76.28 | 69.26 |

| ENB degradation product | 3 | I | 100 | 100 |

| ENB degradation product (2) | 3 | I | 100 | 100 |

| ENB1 degradation product | 1600 | IV | 75.91 | 69.26 |

| BEA degradation product | 200 | III | 75.89 | 69.26 |

| Mycotoxin (Degradation Product) | Classification | ||||

|---|---|---|---|---|---|

| Organ Toxicity (% Probability) | Toxicity Endpoint (% Probability) | ||||

| Hepatotoxicity | Carcinogenicity | Immunotoxicity | Mutagenicity | Cytotoxicity | |

| ENA | Inactive (74) | Inactive (56) | Inactive (83) | Inactive (68) | Inactive (63) |

| ENA1 | Inactive (74) | Inactive (56) | Inactive (83) | Inactive (68) | Inactive (63) |

| ENB | Inactive (76) | Inactive (58) | Inactive (77) | Inactive (68) | Inactive (58) |

| *ENB | Inactive (76) | Inactive (58) | Inactive (89) | Inactive (77) | Inactive (64) |

| ENB1 | Inactive (75) | Inactive (56) | Active (51) | Inactive (76) | Inactive (66) |

| BEA | Inactive (85) | Inactive (53) | Inactive (91) | Inactive (76) | Inactive (70) |

| Mycotoxin (Degradation Product) | Tox21 Nuclear Receptor Signaling Pathways (% Probability) | ||||||

|---|---|---|---|---|---|---|---|

| Aryl Hydrocarbon Receptor (AhR) | Androgen Receptor (AR) | Androgen Receptor Ligand Binding Domain (AR-LBD) | Aromatase | Estrogen Receptor Alpha (ER) | Estrogen Receptor Ligand Binding Domain (ER-LBD) | Peroxisome Proliferator Activated Receptor Gamma (PPAR-Gamma) | |

| ENA | Inactive (97) | Inactive (95) | Inactive (97) | Inactive (98) | Inactive (87) | Inactive (97) | Inactive (98) |

| ENA1 | Inactive (97) | Inactive (95) | Inactive (97) | Inactive (98) | Inactive (87) | Inactive (97) | Inactive (98) |

| ENB | Inactive (98) | Inactive (97) | Inactive (99) | Inactive (98) | Inactive (83) | Inactive (96) | Inactive (98) |

| *ENB | Inactive (98) | Inactive (95) | Inactive (97) | Inactive (99) | Inactive (86) | Inactive (97) | Inactive (96) |

| ENB1 | Inactive (97) | Inactive (96) | Inactive (99) | Inactive (99) | Inactive (90) | Inactive (97) | Inactive (93) |

| BEA | Inactive (93) | Inactive (95) | Inactive (98) | Inactive (95) | Inactive (89) | Inactive (97) | Inactive (95) |

| Mycotoxin (Degradation Product) | Nuclear Factor (Erythroid-Derived 2-Like 2/Antioxidant Responsive Element) (nrf2/ARE) | Heat Shock Factor Response Element (HSE) | Mitochondrial Membrane Potential (MMP) | Phosphoprotein (Tumor Suppressor) p53 | ATPase Family AAA Domain Containing Protein 5 (ATAD5) |

|---|---|---|---|---|---|

| ENA | Inactive (98) | Inactive (98) | Inactive (98) | Inactive (98) | Inactive (98) |

| ENA1 | Inactive (98) | Inactive (98) | Inactive (98) | Inactive (98) | Inactive (98) |

| ENB | Inactive (99) | Inactive (99) | Inactive (98) | Inactive (99) | Inactive (97) |

| *ENB | Inactive (99) | Inactive (99) | Inactive (99) | Inactive (99) | Inactive (96) |

| ENB1 | Inactive (98) | Inactive (98) | Inactive (97) | Inactive (97) | Inactive (99) |

| BEA | Inactive (97) | Inactive (97) | Inactive (91) | Inactive (96) | Inactive (95) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pallarés, N.; Barba, F.J.; Berrada, H.; Tolosa, J.; Ferrer, E. Pulsed Electric Fields (PEF) to Mitigate Emerging Mycotoxins in Juices and Smoothies. Appl. Sci. 2020, 10, 6989. https://doi.org/10.3390/app10196989

Pallarés N, Barba FJ, Berrada H, Tolosa J, Ferrer E. Pulsed Electric Fields (PEF) to Mitigate Emerging Mycotoxins in Juices and Smoothies. Applied Sciences. 2020; 10(19):6989. https://doi.org/10.3390/app10196989

Chicago/Turabian StylePallarés, Noelia, Francisco J. Barba, Houda Berrada, Josefa Tolosa, and Emilia Ferrer. 2020. "Pulsed Electric Fields (PEF) to Mitigate Emerging Mycotoxins in Juices and Smoothies" Applied Sciences 10, no. 19: 6989. https://doi.org/10.3390/app10196989