Influences of Laser Spot Welding on Magnetic Property of a Sintered NdFeB Magnet

Abstract

:1. Introduction

2. Materials and Methods

3. Results

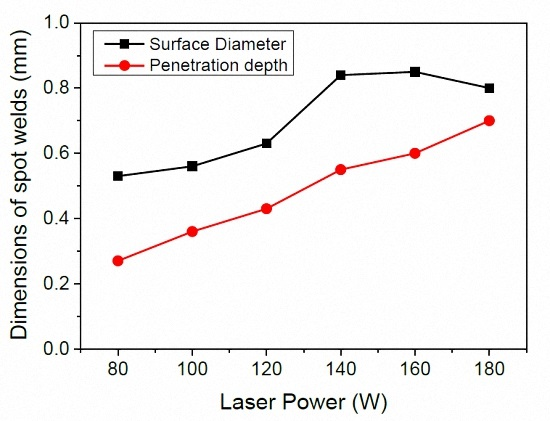

3.1. Effects of Laser Power on Weld Dimensions

3.2. Effects of Laser Power on Magnetic Property

4. Discussion

4.1. Characteristics of Microstructures of a Laser Spot Weld

4.2. Characteristics of Thermal Demagnetization of NdFeB

4.3. Divisions of Regions in a Laser Spot Weld of NdFeB

5. Conclusions

- (1)

- The magnetic property (in terms of Br) of NdFeB decreases with the increase of laser power. For the same welding parameters, the magnetic property of magnets that were magnetized before laser welding is much lower than that of magnets that were magnetized after laser welding.

- (2)

- The decrease in the magnetic property of magnets after laser welding results from the changes in microstructures and, in turn, the deterioration of magnetic properties in the nugget and the heat affected zone (HAZ) in a laser weld.

- (3)

- In order to obtain better magnetic performance, it is recommended that the NdFeB permanent magnets should be welded before being magnetized in practical engineering applications, while the dimensions of nuggets and HAZ should be as small as possible.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Croat, J.J.; Herbst, J.F.; Lee, R.W.; Pinkerton, F.E. Pr-Fe and Nd-Fe-based materials: A new class of high-performance permanent magnets. J. Appl. Phys. 1984, 55, 2078–2082. [Google Scholar] [CrossRef]

- Shield, J.E.; Zhou, J.; Aich, S.; Ravindran, V.K.; Skomski, R.; Sellmyer, D.J. Magnetic reversal in three-dimensional exchange-spring permanent magnets. J. Appl. Phys. 2006, 99, 08B508. [Google Scholar] [CrossRef]

- Zhou, S.Z.; Dong, Q.F. Super Permanent Magnet: Rare Earth Iron Series Permanent Magnet, 2nd ed.; Metallurgical Industry Press: Beijing, China, 2004. [Google Scholar]

- Je, S.S.; Rivas, F.; Diaz, R.E.; Kwon, J.; Kim, J.; Bakkaloglu, B.; Kiaei, S.; Chae, J. A compact and low-cost MEMS loudspeaker for digital hearing aids. IEEE Trans. Biomed. Circuits Syst. 2009, 3, 348–358. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Kim, D.H.; Koh, C.S.; Shin, P.S. Application of polar anisotropic NdFeB ring-type permanent magnet to brushless DC motor. IEEE Trans. Magn. 2007, 43, 2522–2524. [Google Scholar] [CrossRef]

- Mosca, E.; Marchetti, A.; Lampugnani, U. Laser welding of PM Materials. Powder Metall. Int. 1983, 15, 115–118. [Google Scholar]

- Chang, B.H.; Allen, C.; Blackburn, J.; Hilton, P.; Du, D. Fluid Flow Characteristics and Porosity Behavior in Full Penetration Laser Welding of a Titanium Alloy. Metall. Mater. Trans. B 2015, 46, 906–918. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Technol. 2013, 68, 209–216. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Gilmutdinov, A.K. The effect of laser beam wobbling mode in welding process for structural steels. Int. J. Adv. Manuf. Technol. 2015, 81, 1683–1691. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Leo, P.; Benyounis, K.Y.; Olabi, A.G. Study on arc and laser powers in the hybrid welding of AA5754 Al-alloy. Mater. Des. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Gilmutdinov, A.K. Heat treatment of welded joints of steel 0.3C-1Cr-1Si produced by high-power fiber lasers. Opt. Laser Technol. 2015, 74, 125–131. [Google Scholar] [CrossRef]

- Wu, S.J.; Gao, H.M.; Zhang, Z.Y. A preliminary test of a novel molten metal filler welding process. Int. J. Adv. Manuf. Technol. 2015, 80, 647–655. [Google Scholar] [CrossRef]

- Hilton, P.A.; Lloyd, D.; Tyrer, J.R. Use of a diffractive optic for high power laser cutting. J. Laser Appl. 2016, 28, 012014. [Google Scholar] [CrossRef]

- Kaakkunen, J.J.J.; Laakso, P.; Kujanpaa, V. Adaptive multibeam laser cutting of thin steel sheets with fiber laser using spatial light modulator. J. Laser Appl. 2014, 26, 032008. [Google Scholar] [CrossRef]

- Hilton, P.; Khan, A.; Walters, C. The laser alternative. Nucl. Eng. Int. 2010, 55, 18–20. [Google Scholar]

- Xing, B.; Chang, B.H.; Yang, S.; Du, D. A study on the cracking behaviour in laser metal deposition of IC10 directionally solidified nickel-based superalloy. Mater. Res. Innov. 2015, 19, 281–285. [Google Scholar] [CrossRef]

- Sexton, L.; Lavin, S.; Byrne, G.; Kennedy, A. Laser cladding of aerospace materials. J. Mater. Proc. Technol. 2002, 122, 63–68. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Angelastro, A.; Signorile, C.G.; Casalino, G. Investigation on direct laser powder deposition of 18 Ni (300) marage steel using mathematical model and experimental characterization. Int. J. Adv. Manuf. Technol. 2016. [Google Scholar] [CrossRef]

- Chang, B.H.; Yi, C.H.; Du, D.; Zhang, H.; Li, Y.H. Characteristics of microstructures in laser spot welds of a sintered NdFeB permanent magnet for different welding modes. J. Tsinghua Univ. Sci. Technol. 2014, 54, 1138–1142. [Google Scholar]

- Chang, B.H.; Bai, S.J.; Du, D.; Zhang, H.; Zhou, Y. Studies on the micro-laser spot welding of an NdFeB permanent magnet with a low carbon steel. J. Mater. Proc. Technol. 2010, 210, 885–891. [Google Scholar] [CrossRef]

- Chang, B.H.; Blackburn, J.; Allen, C.; Hilton, P. Studies on the spatter behaviour when welding AA5083 with a Yb-fibre laser. Int. J. Adv. Manuf. Technol. 2016, 84, 1769–1776. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, N.; Su, X.J. Thermal analysis and domain observation of Nd-Fe-B magnet. Acta Metall. Sin. 1987, 23, 136–140. [Google Scholar]

- Zhang, N.; Luo, Y. Thermal analysis of Nd-Fe-B magnet. J. Iron Steel Res. 1986, 6, 91–98. [Google Scholar]

| Elements | Nd | Fe | B | Pr | Dy | Co | Cu | Nb |

|---|---|---|---|---|---|---|---|---|

| Contents | 20.63 | 66.75 | 1.00 | 6.88 | 2.99 | 1.50 | 0.15 | 0.10 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, B.; Du, D.; Yi, C.; Xing, B.; Li, Y. Influences of Laser Spot Welding on Magnetic Property of a Sintered NdFeB Magnet. Metals 2016, 6, 202. https://doi.org/10.3390/met6090202

Chang B, Du D, Yi C, Xing B, Li Y. Influences of Laser Spot Welding on Magnetic Property of a Sintered NdFeB Magnet. Metals. 2016; 6(9):202. https://doi.org/10.3390/met6090202

Chicago/Turabian StyleChang, Baohua, Dong Du, Chenhui Yi, Bin Xing, and Yihong Li. 2016. "Influences of Laser Spot Welding on Magnetic Property of a Sintered NdFeB Magnet" Metals 6, no. 9: 202. https://doi.org/10.3390/met6090202