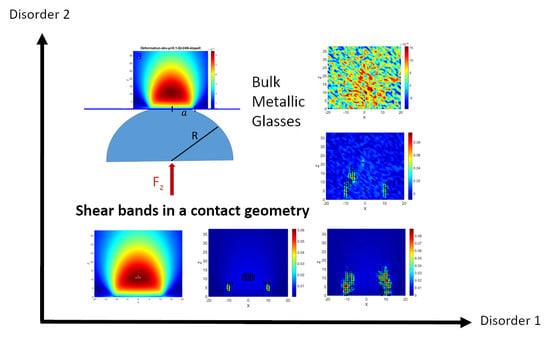

Shear Banding in a Contact Problem between Metallic Glasses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Local Plastic Criteria and Plastic Transformations

2.2. A Semi-Analytical Method for Long-Range Elasticity

2.3. Contact Problem

3. Results

3.1. Homogeneous vs. Heterogeneous Nucleation

3.2. Role of Disorder in the Residual Plastic Eigenstrain

3.3. Role of Disorder in the Local Plastic Thresholds

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashby, M.; Greer, A. Metallic glasses as structural materials. Scr. Mater. 2006, 54, 321–326. [Google Scholar] [CrossRef]

- Ma, M.Z.; Liu, R.P.; Xiao, Y.; Lou, D.C.; Liu, L.; Wang, Q.; Wang, W.K. Wear resistance of Zr-based bulk metallic glass applied in bearing rollers. Mater. Sci. Eng. A 2004, 386, 326–330. [Google Scholar] [CrossRef]

- Wang, L.; Bian, X.; Hu, L.; Wu, Y.; Guo, J.; Zhang, J. Glass transition temperature of bulk metallic glasses: A linear connection with the mixing enthalpy. J. Appl. Phys. 2007, 101, 103540. [Google Scholar] [CrossRef]

- Liu, Y.H.; Wang, G.; Wang, R.J.; Zhao, D.; Pan, M.X.; Wang, W.H. Super Plastic Bulk Metallic Glasses at Room Temperature. Science 2007, 315, 1385–1388. [Google Scholar] [CrossRef]

- Li, X.; Wei, D.; Zhang, J.; Liu, X.; Li, Z.; Wang, T.; He, Q.; Wang, Y.-J.; Ma, J.; Wang, W.; et al. Ultrasonic plasticity of metallic glass near room temperature. Appl. Mater. Today 2020, 21, 100866. [Google Scholar] [CrossRef]

- Gross, T.; Tomozawa, M.; Koike, A. A glass with high crack initiation load: Role of fictive temperature-independent mechanical properties. J. Non-Cryst. Solids 2009, 355, 563–568. [Google Scholar] [CrossRef]

- Luo, J.; Lezzi, P.J.; Vargheese, K.D.; Tandia, A.; Harris, J.T.; Gross, T.M.; Mauro, J.C. Competing Indentation Deformation Mechanisms in Glass Using Different Strengthening Methods. Front. Mater. 2016, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Met. 1977, 25, 407–415. [Google Scholar] [CrossRef]

- Cohen, M.H.; Turnbull, D. Molecular Transport in Liquids and Glasses. J. Chem. Phys. 1959, 31, 1164–1169. [Google Scholar] [CrossRef] [Green Version]

- Argon, A. Plastic deformation in metallic glasses. Acta Met. 1979, 27, 47–58. [Google Scholar] [CrossRef]

- Albaret, T.; Tanguy, A.; Boioli, F.; Rodney, D. Mapping between atomistic simulations and Eshelby inclusions in the shear de-formation of an amorphous silicon model. Phys. Rev. E 2016, 93, 053002. [Google Scholar] [CrossRef]

- Maloney, C.; Lemaître, A. Universal Breakdown of Elasticity at the Onset of Material Failure. Phys. Rev. Lett. 2004, 93, 195501. [Google Scholar] [CrossRef] [Green Version]

- Gartner, L.; Lerner, E. Nonlinear modes disentangle glassy and Goldstone modes in structural glasses. Sci. Post Phys. 2016, 1, 16. [Google Scholar] [CrossRef] [Green Version]

- Boioli, F.; Albaret, T.; Rodney, D. Shear transformation distribution and activation in glasses at the atomic scale. Phys. Rev. E 2017, 95, 033005. [Google Scholar] [CrossRef]

- Rottler, J.; Robbins, M.O. Yield conditions for deformation of amorphous polymer glasses. Phys. Rev. E 2001, 64, 051801. [Google Scholar] [CrossRef] [Green Version]

- Tanguy, A.; Leonforte, F.; Barrat, J.L. Plastic response of a 2d lennard-jones amorphous solid: Detailed analyses of the local rearrangements at very slow strain rate. Eur. Phys. J. E 2006, 20, 355–364. [Google Scholar] [CrossRef] [Green Version]

- Tanguy, A.; Mantisi, B.; Tsamados, M. Vibrational modes as a predictor for plasticity in a model glass. EPL Eur. Phys. Lett. 2010, 90, 16004. [Google Scholar] [CrossRef]

- Rodney, D.; Tanguy, A.; Vandembroucq, D. Modeling the mechanics of amorphous solids at different length scale and time scale. Model. Simul. Mater. Sci. Eng. 2011, 19, 083001. [Google Scholar] [CrossRef] [Green Version]

- Albe, K.; Ritter, Y.; Şopu, D. Enhancing the plasticity of metallic glasses: Shear band formation, nanocomposites and nanoglasses investigated by molecular dynamics simulations. Mech. Mater. 2013, 67, 94–103. [Google Scholar] [CrossRef]

- Albano, F.; Falk, M.L. Shear softening and structure in a simulated three-dimensional binary glass. J. Chem. Phys. 2005, 122, 154508. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.; Homer, E.R.; Schuh, C.A. Shear transformation zone dynamics model for metallic glasses incorporating free volume as a state variable. Acta Mater. 2013, 61, 3347–3359. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, A.; Budrikis, Z.; Chikkadi, V.; Sellerio, A.L.; Zapperi, S.; Schall, P. Direct Observation of Percolation in the Yielding Transition of Colloidal Glasses. Phys. Rev. Lett. 2017, 118, 148001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shrivastav, G.P.; Chaudhuri, P.; Horbach, J. Yielding of glass under shear: A directed percolation transition precedes shear-band formation. Phys. Rev. E 2016, 94, 042605. [Google Scholar] [CrossRef] [Green Version]

- Varnik, F.; Bocquet, L.; Barrat, J.-L.; Berthier, L. Shear Localization in a Model Glass. Phys. Rev. Lett. 2003, 90, 095702. [Google Scholar] [CrossRef] [Green Version]

- Qu, R.; Zhao, J.; Stoica, M.; Eckert, J.; Zhang, Z. Macroscopic tensile plasticity of bulk metallic glass through designed artificial defects. Mater. Sci. Eng. A 2012, 534, 365–373. [Google Scholar] [CrossRef]

- Su, C.; Anand, L. Plane strain indentation of a Zr-based metallic glass: Experiments and numerical simulation. Acta Mater. 2006, 54, 179–189. [Google Scholar] [CrossRef]

- Budrikis, Z.; Castellanos, D.F.; Sandfeld, S.; Zaiser, M.; Zapperi, S. Universal features of amorphous plasticity. Nat. Commun. 2017, 8, 15928. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Falk, M.L. Stress-induced structural transformation and shear banding during simulated nanoindentation of a metallic glass. Acta Mater. 2007, 55, 4317–4324. [Google Scholar] [CrossRef]

- Le Bouil, A.; Amon, A.; McNamara, S.; Crassous, J. Emergence of Cooperativity in Plasticity of Soft Glassy Materials. Phys. Rev. Lett. 2014, 112, 246001. [Google Scholar] [CrossRef]

- Nicolas, A.; Ferrero, E.E.; Martens, K.; Barrat, J.-L. Deformation and flow of amorphous solids: A review of mesoscale elas-toplastic models. Rev. Mod. Phys. 2018, 90, 045006. [Google Scholar] [CrossRef] [Green Version]

- Baret, J.-C.; Vandembroucq, D.; Roux, S. Extremal Model for Amorphous Media Plasticity. Phys. Rev. Lett. 2002, 89, 195506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Patinet, S.; Vandembroucq, D.; Falk, M.L. Connecting Local Yield Stresses with Plastic Activity in Amorphous Solids. Phys. Rev. Lett. 2016, 117, 045501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castellanos, D.F.; Roux, S.; Patinet, S. Insights from the quantitative calibration of an elasto-plastic model from a Lennard-Jones atomic glass. Comptes Rendus Phys. l’Académie Sci. 2021. to appear. [Google Scholar]

- Gottschalk, H.P.; Eisner, E.; Hosalkar, H.S. Medial epicondyle fractures in the pediatric population. J. Am. Acad. Orthop. Surg. 2012, 20, 223–232. [Google Scholar] [CrossRef]

- Martens, K.; Bocquet, L.; Barrat, J.L. Spontaneous formation of permanent shear bands in a mesoscopic model of flowing disor-dered matter. Soft Matter 2012, 8, 4197–4205. [Google Scholar] [CrossRef] [Green Version]

- Dahmen, K.A.; Ben-Zion, Y.; Uhl, J.T. Micromechanical Model for Deformation in Solids with Universal Predictions for Stress-Strain Curves and Slip Avalanches. Phys. Rev. Lett. 2009, 102, 175501. [Google Scholar] [CrossRef] [Green Version]

- Tsamados, M.; Tanguy, A.; Goldenberg, C.; Barrat, J.-L. Local elasticity map and plasticity in a model Lennard-Jones glass. Phys. Rev. E 2009, 80, 026112. [Google Scholar] [CrossRef] [Green Version]

- Johnson, K.L.; Keer, L.M. Contact Mechanics. J. Tribol. 1986, 108, 659. [Google Scholar] [CrossRef]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity, 4th ed.; Unabridged and Unaltered Republ. of the 4. (1927) ed; Dover Publ: New York, NY, USA, 1990. [Google Scholar]

- Eshelby, J.D. The Determination of the Elastic Field of an Ellipsoidal Inclusion, and Related Problems. Math. Phys. Eng. Sci. 1957, 241, 376–396. [Google Scholar]

- Eshelby, J.D. The Elastic Field Outside an Ellipsoidal Inclusion. Math. Phys. Eng. Sci. 1959, 252, 561–569. [Google Scholar]

- Koumi, K.E.; Zhao, L.; Leroux, J.; Chaise, T.; Nélias, D. Contact analysis in the presence of an ellipsoidal inhomogeneity within a half space. Int. J. Solids Struct. 2014, 51, 1390–1402. [Google Scholar] [CrossRef] [Green Version]

- Jacq, C.; Nélias, D.; Lormand, G.; Girodin, D. Development of a Three-Dimensional Semi-Analytical Elastic-Plastic Contact Code. J. Tribol. 2002, 124, 653–667. [Google Scholar] [CrossRef]

- Chaise, T.; Nélias, D. Contact Pressure and Residual Strain in 3D Elasto-Plastic Rolling Contact for a Circular or Elliptical Point Contact. J. Tribol. 2011, 133, 041402. [Google Scholar] [CrossRef]

- Boucly, V.; Nelias, D.; Liu, S.; Wang, Q.; Keer, L. Contact analyses for bodies with frictional heating and plastic behaviour. ASME J. Tribol. 2005, 127, 355–364. [Google Scholar] [CrossRef]

- Medina, S.; Dini, D. A numerical model for the deterministic analysis of adhesive rough contacts down to the nano-scale. Int. J. Solids Struct. 2014, 51, 2620–2632. [Google Scholar] [CrossRef] [Green Version]

- Ghaednia, H.; Wang, X.; Saha, S.; Xu, Y.; Sharma, A.; Jackson, R.L. A Review of Elastic–Plastic Contact Mechanics. Appl. Mech. Rev. 2017, 69, 060804. [Google Scholar] [CrossRef] [Green Version]

- Seleznev, M.; Vinogradov, A. Shear Bands Topology in the Deformed Bulk Metallic Glasses. Metal 2020, 10, 374. [Google Scholar] [CrossRef] [Green Version]

- Keryvin, V.; Crosnier, R.; Laniel, R.; Hoang, V.H.; Sanglebœuf, J.-C. Indentation and scratching mechanisms of a ZrCuAlNi bulk metallic glass. J. Phys. D: Appl. Phys. 2008, 41, 1–7. [Google Scholar] [CrossRef]

- Tyukodi, B.; Vandembroucq, D.; Maloney, C.E. Avalanches, thresholds, and diffusion in mesoscale amorphous plasticity. Phys. Rev. E 2019, 100, 043003. [Google Scholar] [CrossRef] [Green Version]

- Richard, D.; Ozawa, M.; Patinet, S.; Stanifer, E.; Shang, B.; Ridout, S.A.; Xu, B.; Zhang, G.; Morse, P.K.; Barrat, J.-L.; et al. Predicting plasticity in disordered solids from structural indicators. Phys. Rev. Mater. 2020, 4, 113609. [Google Scholar] [CrossRef]

- Li, W.; Bei, H.; Tong, Y.; Dmowski, W.; Gao, Y.F. Structural heterogeneities induced plasticity in bulk metallic glasses: From well-relaxed fragile glass to metal-llike behavior. App. Phys. Lett. 2013, 103, 171910. [Google Scholar] [CrossRef]

- Makarov, A.; Afonin, G.V.; Mitrofanov, Y.; Kobelev, N.; Khonik, V. Heat Effects Occurring in the Supercooled Liquid State and Upon Crystallization of Metallic Glasses as a Result of Thermally Activated Evolution of Their Defect Systems. Metal 2020, 10, 417. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Liu, Z.; Huan, Y.; Wu, X.; Lou, Y.; Huang, X.; He, L.; Li, P.; Zhang, L.-C. Effect of structural heterogeneity on serrated flow behavior of Zr-based metallic glass. J. Alloy. Compd. 2018, 766, 908–917. [Google Scholar] [CrossRef] [Green Version]

- Brechtl, J.; Wang, H.; Kumar, N.; Yang, T.; Lin, Y.-R.; Bei, H.; Neuefeind, J.; Dmowski, W.; Zinkle, S. Investigation of the thermal and neutron irradiation response of BAM-11 bulk metallic glass. J. Nucl. Mater. 2019, 526, 151771. [Google Scholar] [CrossRef]

- Yu, P.; Bai, H. Poisson’s ratio and plasticity in CuZrAl bulk metallic glasses. Mater. Sci. Eng. A 2008, 485, 1–4. [Google Scholar] [CrossRef]

- Salerno, K.M.; Robbins, M.O. Effect of inertia on sheared disordered solids: Critical scaling of avalanches in two and three dimensions. Phys. Rev. E 2013, 88, 062206. [Google Scholar] [CrossRef] [Green Version]

- Gamcova, J.; Mohanty, G.; Michalik, S.; Wehrs, J.; Bednarcik, J.; Krywka, C.; Breguet, J.M.; Michler, J.; Franz, H. Mapping strain fields induced in Zr-based bulk metallic glasses during in-situ nanoindentation by X-ray nanodiffraction. Appl. Phys. Lett. 2016, 108, 031907. [Google Scholar] [CrossRef] [Green Version]

- Perepezko, J.H.; Imhoff, S.D.; Chen, M.-W.; Wang, J.-Q.; Gonzalez, S. Nucleation of shear bands in amorphous alloys. Proc. Nat. Acad. Sci. USA 2014, 111, 3938–3942. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghidelli, M.; Idrissi, H.; Gravier, S.; Blandin, J.-J.; Raskin, J.-P.; Schryvers, D.; Pardoen, T. Homogeneous flow and size dependent mechanical behavior in highly ductile Zr65Ni35 metallic glass films. Acta Mater. 2017, 131, 246–259. [Google Scholar] [CrossRef]

- Jang, D.; Greer, J.R. Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses. Nat. Mater. 2010, 9, 215–219. [Google Scholar] [CrossRef] [PubMed]

- Fusco, C.; Albaret, T.; Tanguy, A. Rheological properties vs Local Dynamics in model disordered materials at Low Temperature. Eur. Phys. J. E 2014, 37, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Idrissi, H.; Ghidelli, M.; Béché, A.; Turner, S.; Gravier, S.; Blandin, J.-J.; Raskin, J.-P.; Schryvers, D.; Pardoen, T. Atomic-scale viscoplasticity mechanisms revealed in high ductility metallic glass films. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mantisi, B.; Kermouche, G.; Barthel, E.; Tanguy, A. Impact of pressure on plastic yield in amorphous solids with open structure. Phys. Rev. E 2016, 93, 033001. [Google Scholar] [CrossRef] [Green Version]

- Molnár, G.; Ganster, P.; Tanguy, A. Effect of composition and pressure on the shear strength of sodium silicate glasses: An atomic scale simulation study. Phys. Rev. E 2017, 95, 043001. [Google Scholar] [CrossRef] [Green Version]

- Keryvin, V.; Charleux, L.; Hin, R.; Guin, J.-P.; Sangleboeuf, J.-C. Mechanical behaviour of fully densified silica glass under Vickers indentation. Acta Mater. 2017, 129, 492–499. [Google Scholar] [CrossRef] [Green Version]

| nsites | S = 0.01 | S = 0.10 | S = 1.00 |

|---|---|---|---|

| 5 | ~0.015 εd0 | ~0.99 εd0 | ~1.5 εd0 |

| 10 | ~0.015 εd0 | ~0.99 εd0 | ~1.5 εd0 |

| 100 | ~0.015 εd0 | ~0.98 εd0 | ~1.5 εd0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanguy, A.; Chen, P.; Chaise, T.; Nélias, D. Shear Banding in a Contact Problem between Metallic Glasses. Metals 2021, 11, 257. https://doi.org/10.3390/met11020257

Tanguy A, Chen P, Chaise T, Nélias D. Shear Banding in a Contact Problem between Metallic Glasses. Metals. 2021; 11(2):257. https://doi.org/10.3390/met11020257

Chicago/Turabian StyleTanguy, Anne, Peifang Chen, Thibaut Chaise, and Daniel Nélias. 2021. "Shear Banding in a Contact Problem between Metallic Glasses" Metals 11, no. 2: 257. https://doi.org/10.3390/met11020257