In Situ Characterization of the Effect of Twin-Microstructure Interactions on {1 0 1 2} Tension and {1 0 1 1} Contraction Twin Nucleation, Growth and Damage in Magnesium

Abstract

:1. Introduction

2. Methods and Materials

2.1. Experimental Procedure

2.2. Fractography

2.3. In Situ and Interrupted Electron Backscatter Diffraction (EBSD)

3. Results and Discussion

3.1. Fractographic Analysis of Twin-Interactions Induced Cracks

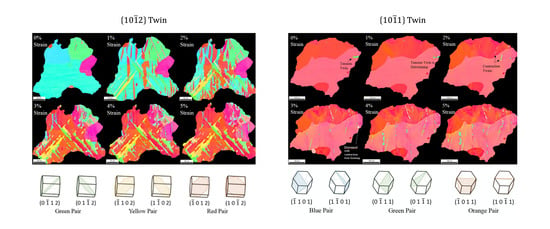

3.2. Interrupted EBSD Characterization in AOI 1

3.3. Characterization of Contraction Twinning in AOI 2

4. Conclusions

- a

- In situ electron backscatter diffraction (EBSD) and scanning electron microscopy (SEM) micrographs revealed the importance of the twin–slip, twin–GBs, and twin–twin interactions in the formation of large cracks inside the material. Twins nucleating under a very low macroscopic Schmid factor show a greater sensitivity to crack nucleation through these interactions.

- b

- During {1 0 1 2} profuse twinning inside a favorably oriented grain, two variants of which were able to nucleate more substantially on grain boundaries grew much faster than all the other variants. This could be due to an enhanced nucleation of glissile disconnections at the intersection between grain boundary and twin boundary than between two twin boundaries.

- c

- {1 0 1 1} twins nucleate under 〈c〉-axis contraction at much lower CRSS values than those previously reported in the literature under 〈c〉-axis compression. This behavior was attributed to the greater hydrostatic pressure in the case of contraction compared to the case of uniaxial 〈c〉 compression, which may assist the complex shuffles required for this twinning mode.

Author Contributions

Funding

Conflicts of Interest

References

- Pollock, T.M. Weight loss with magnesium alloys. Science 2010, 328, 986–987. [Google Scholar] [CrossRef] [PubMed]

- Mordike, B.L.; Ebert, T. Magnesium: Properties–applications–potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Al-Samman, T.; Gottstein, G. Room temperature formability of a magnesium AZ31 alloy: Examining the role of texture on the deformation mechanisms. Mater. Sci. Eng. A 2008, 488, 406–414. [Google Scholar] [CrossRef]

- Zhang, Y.; Millett, P.C.; Tonks, M.; Biner, B. Deformation-twin-induced grain boundary failure. Scr. Mater. 2012, 66, 117–120. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the ductility of magnesium alloys: Part II.“Contraction” twins. Mater. Sci. Eng. A 2007, 464, 8–16. [Google Scholar] [CrossRef]

- Pratt, P.L.; Pugh, S.F. Twin accommodation in zinc. J. Inst. Met. 1952, 80, 653–658. [Google Scholar]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Kumar, M.A.; Beyerlein, I.J. Local microstructure and micromechanical stress evolution during deformation twinning in hexagonal polycrystals. J. Mater. Res. 2020, 35, 217–241. [Google Scholar] [CrossRef]

- Baird, J.C.; Li, B.; Parast, S.Y.; Horstemeyer, S.J.; Hector, L.G., Jr.; Wang, P.T.; Horstemeyer, M.F. Localized twin bands in sheet bending of a magnesium alloy. Scr. Mater. 2012, 67, 471–474. [Google Scholar] [CrossRef]

- Paudel, Y.; Barrett, C.D.; Tschopp, M.A.; Inal, K.; El Kadiri, H. Beyond initial twin nucleation in hcp metals: Micromechanical formulation for determining twin spacing during deformation. Acta Mater. 2017, 133, 134–146. [Google Scholar] [CrossRef]

- Paudel, Y.; Indeck, J.; Hazeli, K.; Priddy, M.W.; Inal, K.; Rhee, H.; Barrett, C.D.; Whittington, W.R.; Limmer, K.R.; El Kadiri, H. Characterization and modeling of {1 0 1 2} twin banding in magnesium. Acta Mater. 2020, 183, 438–451. [Google Scholar] [CrossRef]

- Gilman, J.J. Mechanism of ortho kink-band formation in compressed zinc monocrystals. JOM 1954, 6, 621–629. [Google Scholar] [CrossRef]

- Rosenbaum, H.S. Non-basal slip and twin accommodation in zinc crystals. Acta Metall. 1961, 9, 742–748. [Google Scholar] [CrossRef]

- Rosenbaum, H.S. Nonbasal Slip in h.c.p. Metals and its Relation to Mechanical Twinning. In Deformation Twinning; Reed-Hill, R.E., Hirth, J.P., Rogers, H.C., Eds.; Grodon and Breach Science Publishers: New York, NY, USA, 1964; pp. 43–76. [Google Scholar]

- Rose, G. Über die im kalkspath vorkommenden hohlen canäle. Aus Den Abh. Königlichen Akad. Wissenschalten 1868, 23, 57–79. [Google Scholar]

- Priestner, R. The Relationship Between Brittle Cleavage and Deformation Twinning in BCC Metals. In Deformation Twinning; Reed-Hill, R.E., Hirth, J.P., Rogers, H.C., Eds.; Grodon and Breach Science Publishers: New York, NY, USA, 1964; pp. 321–355. [Google Scholar]

- Sleeswyk, A.W. Emissary dislocations: Theory and experiments on the propagation of deformation twins in α-iron. Acta Metall. 1962, 10, 705–725. [Google Scholar] [CrossRef]

- Sleeswyk, A.W. Twinning and the origin of cleavage nuclei in α-iron. Acta Metall. 1962, 10, 803–812. [Google Scholar] [CrossRef]

- Sleeswyk, A.W. 1/2〈1 1 1〉 screw dislocations and the nucleation of {112}〈1 1 1〉 twins in the bcc lattice. Philos. Mag. 1963, 8, 1467–1486. [Google Scholar]

- Barnett, M.R.; Stanford, N.; Cizek, P.; Beer, A.; Xuebin, Z.; Keshavarz, Z. Deformation mechanisms in Mg alloys and the challenge of extending room-temperature plasticity. JOM 2009, 61, 19–24. [Google Scholar] [CrossRef]

- Holden, J. Plastic deformation features on cleavage surfaces of metal crystals. Philos. Mag. 1952, 43, 976–984. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Constitutive relations for the plastic deformation of metals. AIP conference proceedings. Am. Inst. Phys. 1994, 309, 989–992. [Google Scholar]

- Zerilli, F.J.; Armstrong, R.W. Dislocation mechanics based analysis of material dynamics behavior: Enhanced ductility, deformation twinning, shock deformation, shear instability, dynamic recovery. J. Phys. IV 1997, 7, 637–642. [Google Scholar] [CrossRef]

- Remy, L. Twin-slip interaction in fcc crystals. Acta Metall. 1977, 25, 711–714. [Google Scholar] [CrossRef]

- Remy, L. The interaction between slip and twinning systems and the influence of twinning on the mechanical behavior of fcc metals and alloys. Metall. Trans. A 1981, 12, 387–408. [Google Scholar] [CrossRef]

- Ma, Q.; El Kadiri, H.; Oppedal, A.L.; Baird, J.C.; Horstemeyer, M.F.; Cherkaoui, M. Twinning and double twinning upon compression of prismatic textures in an AM30 magnesium alloy. Scr. Mater. 2011, 64, 813–816. [Google Scholar] [CrossRef]

- Ma, Q.; El Kadiri, H.; Oppedal, A.L.; Baird, J.C.; Li, B.; Horstemeyer, M.F.; Vogel, S.C. Twinning effects in a rod-textured AM30 magnesium alloy. Int. J. Plast. 2012, 29, 60–76. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the ductility of magnesium alloys: Part I: “Tension” twins. Mater. Sci. Eng. A 2007, 464, 1–7. [Google Scholar] [CrossRef]

- Oppedal, A.L.; El Kadiri, H.; Tomé, C.N.; Kaschner, G.C.; Vogel, S.C.; Baird, J.C.; Horstemeyer, M.F. Effect of dislocation transmutation on modeling hardening mechanisms by twinning in magnesium. Int. J. Plast. 2012, 30, 41–61. [Google Scholar] [CrossRef]

- Martin, É.; Capolungo, L.; Jiang, L.; Jonas, J.J. Variant selection during secondary twinning in Mg–3% Al. Acta Mater. 2010, 58, 3970–3983. [Google Scholar] [CrossRef]

- Jonas, J.J.; Mu, S.; Al-Samman, T.; Gottstein, G.; Jiang, L.; Martin, Ė. The role of strain accommodation during the variant selection of primary twins in magnesium. Acta Mater. 2011, 59, 2046–2056. [Google Scholar] [CrossRef]

- Mu, S.; Jonas, J.J.; Gottstein, G. Variant selection of primary, secondary and tertiary twins in a deformed Mg alloy. Acta Mater. 2012, 60, 2043–2053. [Google Scholar] [CrossRef]

- Paudel, Y. Micromechanics-Crystal Plasticity Links for Deformation Twinning. Ph.D. Thesis, Mississippi State University, Mississippi State, MS, USA, 2018. [Google Scholar]

- Paudel, Y.; Barrett, C.D.; El Kadiri, H. Full-Field Crystal Plasticity Modeling of {1 0 1 2} Twin Nucleation. In Magnesium Technology 2020; Jordon, J., Miller, V., Joshi, V., Neelameggham, N., Eds.; Springer: Cham, Switzerland, 2020; pp. 141–146. [Google Scholar]

- Cheng, J.; Ghosh, S. Crystal plasticity finite element modeling of discrete twin evolution in polycrystalline magnesium. J. Mech. Phys. Solids 2017, 99, 512–538. [Google Scholar] [CrossRef] [Green Version]

- El Kadiri, H.; Baird, J.C.; Kapil, J.; Oppedal, A.L.; Cherkaoui, M.; Vogel, S.C. Flow asymmetry and nucleation stresses of {1 0 1 2} twinning and non-basal slip in magnesium. Int. J. Plast. 2013, 44, 111–120. [Google Scholar] [CrossRef]

- Wenk, H.R.; Lutterotti, L.; Vogel, S. Texture analysis with the new HIPPO TOF diffractometer. Nucl. Instrum. Meth. A 2003, 515, 575–588. [Google Scholar] [CrossRef]

- Takajo, S.; Vogel, S.C. Determination of pole figure coverage for texture measurements with neutron time-of-flight diffractometers. J. Appl. Crystallogr. 2018, 51, 895–900. [Google Scholar] [CrossRef]

- Losko, A.S.; Vogel, S.C.; Reiche, H.M.; Nakotte, H. A six-axis robotic sample changer for high-throughput neutron powder diffraction and texture measurements. J. Appl. Crystallogr. 2014, 47, 2109–2112. [Google Scholar] [CrossRef]

- Wenk, H.R.; Lutterotti, L.; Vogel, S.C. Rietveld texture analysis from TOF neutron diffraction data. Powder Diffr. 2010, 25, 283–296. [Google Scholar] [CrossRef] [Green Version]

- Hielscher, R.; Schaeben, H. A novel pole figure inversion method: Specification of the MTEX algorithm. J. Appl. Crystallogr. 2008, 41, 1024–1037. [Google Scholar] [CrossRef]

- Barrett, C.D.; El Kadiri, H.; Tschopp, M.A. Breakdown of the Schmid law in homogeneous and heterogeneous nucleation events of slip and twinning in magnesium. J. Mech. Phys. Solids 2012, 60, 2084–2099. [Google Scholar] [CrossRef]

- Barrett, C.D.; El Kadiri, H. The roles of grain boundary dislocations and disclinations in the nucleation of {1 0 1 2} twinning. Acta Mater. 2014, 63, 1–15. [Google Scholar] [CrossRef]

- El Kadiri, H.; Barrett, C.D.; Wang, J.; Tomé, C.N. Why are {1 0 1 2} twins profuse in magnesium? Acta Mater. 2015, 85, 354–361. [Google Scholar] [CrossRef] [Green Version]

- Barrett, C.D.; El Kadiri, H. Impact of deformation faceting on {1 0 1 2}, {1 0 1 1} and {1 0 1 3} embryonic twin nucleation in hexagonal close-packed metals. Acta Mater. 2014, 70, 137–161. [Google Scholar] [CrossRef]

- Barrett, C.D.; Tschopp, M.A.; El Kadiri, H. Automated analysis of twins in hexagonal close-packed metals using molecular dynamics. Scr. Mater. 2012, 66, 666–669. [Google Scholar] [CrossRef]

- El Kadiri, H.; Oppedal, A.L. A crystal plasticity theory for latent hardening by glide twinning through dislocation transmutation and twin accommodation effects. J. Mech. Phys. Solids 2010, 58, 613–624. [Google Scholar] [CrossRef]

- Partridge, P.G. Effect of cyclic stresses on the microstructures of hexagonal close packed metals. Czech. J. Phys. Sect. B 1969, 19, 323–332. [Google Scholar] [CrossRef]

- Molodov, K.D.; Al-Samman, T.; Molodov, D.A. Profuse slip transmission across twin boundaries in magnesium. Acta Mater. 2017, 124, 397–409. [Google Scholar] [CrossRef]

- Wang, F.; Barrett, C.D.; McCabe, R.J.; El Kadiri, H.; Capolungo, L.; Agnew, S.R. Dislocation induced twin growth and formation of basal stacking faults in {1 0 1 2} twins in pure Mg. Acta Mater. 2019, 165, 471–485. [Google Scholar] [CrossRef]

- Mahajan, S. Twin-slip and twin-twin interactions in Mo-35 at.% Re alloy. Philos. Mag. 1971, 23, 781–794. [Google Scholar] [CrossRef]

- Mahajan, S.; Chin, G.Y. Twin-slip, twin-twin and slip-twin interactions in Co-8 wt.% Fe alloy single crystals. Acta Metall. 1973, 21, 173–179. [Google Scholar] [CrossRef]

- Mahajan, S.; Chin, G.Y. Formation of deformation twins in fcc crystals. Acta Metall. 1973, 21, 1353–1363. [Google Scholar] [CrossRef]

- Sleeswyk, A.W.; Verbraak, C.A. Incorporation of slip dislocations in mechanical twins–I. Acta Metall. 1961, 9, 917–927. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Tomé, C.N. A dislocation-based constitutive law for pure Zr including temperature effects. Int. J. Plast. 2008, 24, 867–895. [Google Scholar] [CrossRef]

- Reed-Hill, R.E. Twin intersections & Cahns continuity conditions. Trans. Met. Soc. AIME 1964, 230, 809. [Google Scholar]

- Reed-Hill, R.E.; Robertson, W.D. The crystallographic characteristics of fracture in magnesium single crystals. Acta Metall. 1957, 5, 728–737. [Google Scholar] [CrossRef]

- Chin, G.Y. The role of preferred orientation in plastic deformation. In The Inhomogeneity of Plastic Deformation; Reed-Hill, R.E., Ed.; American Society for Metals: Russell, OH, USA, 1973; Chapter 4; pp. 83–112. [Google Scholar]

- Yu, Q.; Wang, J.; Jiang, Y.; McCabe, R.J.; Li, N.; Tomé, C.N. Twin–twin interactions in magnesium. Acta Mater. 2014, 77, 28–42. [Google Scholar] [CrossRef]

- Crocker, A.G. Double twinning. Philos. Mag. 1962, 7, 1901–1924. [Google Scholar] [CrossRef]

- Hartt, W.H.; Reed-Hill, R.E. Internal deformation and fracture of second-order {1 0 1 1}-{1 0 1 2}-twins in magnesium. Trans. Met. Soc. AIME 1968, 242, 1127–1133. [Google Scholar]

- Wonsiewicz, B.C. Plasticity of Magnesium Crystals. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1966. [Google Scholar]

- Cizek, P.; Barnett, M.R. Characteristics of the contraction twins formed close to the fracture surface in Mg–3Al–1Zn alloy deformed in tension. Scr. Mater. 2008, 59, 959–962. [Google Scholar] [CrossRef]

- Koike, J. Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature. Metall. Mater. Trans. A 2005, 36, 1689–1696. [Google Scholar] [CrossRef]

- Koike, J.; Fujiyama, N.; Ando, D.; Sutou, Y. Roles of deformation twinning and dislocation slip in the fatigue failure mechanism of AZ31 Mg alloys. Scr. Mater. 2010, 63, 747–750. [Google Scholar] [CrossRef]

- Ando, D.; Koike, J.; Sutou, Y. The role of deformation twinning in the fracture behavior and mechanism of basal textured magnesium alloys. Mater. Sci. Eng. A 2014, 600, 145–152. [Google Scholar] [CrossRef]

- Ando, D.; Koike, J. Relationship between Deformation-Induced Surface Relief and Double Twinning in AZ31 Magnesium Alloy. J. Jpn. Inst. Met. 2007, 71, 684–687. [Google Scholar] [CrossRef]

- Hazeli, K.; Cuadra, J.; Streller, F.; Barr, C.; Taheri, M.; Carpick, R.; Kontsos, A. Three-dimensional effects of twinning in magnesium alloys. Scr. Mater. 2015, 100, 9–12. [Google Scholar] [CrossRef] [Green Version]

- Kelley, E.W.; Hosford, W.F., Jr. Plane-strain compression of magnesium and magnesium alloy crystals. Trans. Met. Soc. AIME 1968, 242, 5–13. [Google Scholar]

- El Kadiri, H.; Barrett, C.D.; Tschopp, M.A. The candidacy of shuffle and shear during compound twinning in hexagonal close-packed structures. Acta Mater. 2013, 61, 7646–7659. [Google Scholar] [CrossRef] [Green Version]

- Keshavarz, Z.; Barnett, M.R. EBSD analysis of deformation modes in Mg–3Al–1Zn. Scr. Mater. 2006, 55, 915–918. [Google Scholar] [CrossRef]

- Xu, S.W.; Kamado, S.; Matsumoto, N.; Honma, T.; Kojima, Y. Recrystallization mechanism of as-cast AZ91 magnesium alloy during hot compressive deformation. Mater. Sci. Eng. A 2009, 527, 52–60. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Ma, X. Non-Schmid behaviour during secondary twinning in a polycrystalline magnesium alloy. Acta Mater. 2008, 56, 5–15. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Wang, J.; Barnett, M.R.; Tomé, C.N. Double twinning mechanisms in magnesium alloys via dissociation of lattice dislocations. Proc. R. Soc. A Math. Phys. Eng. Sci. 2012, 468, 1496–1520. [Google Scholar] [CrossRef] [Green Version]

- Xu, D.S.; Chang, J.P.; Li, J.; Yang, R.; Li, D.; Yip, S. Dislocation slip or deformation twinning: Confining pressure makes a difference. Mater. Sci. Eng. A 2004, 387-389, 840–844. [Google Scholar] [CrossRef]

| Slip or Twin Plane | Schmid Factor | Resolved Shear Stress | |

|---|---|---|---|

| (h k i l) [u v t w] | SF | RSS (MPa) | |

| Tension Twin Variants | (1 0 1 2) [1 0 1 1] | 0.499 | 19.96 |

| (1 0 1 2) [1 0 1 1] | 0.499 | 19.96 | |

| (0 1 1 2) [0 1 1 1] | 0.499 | 19.96 | |

| (0 1 1 2) [0 1 1 1] | 0.499 | 19.96 | |

| (1 1 0 2) [1 1 0 1] | 0.499 | 19.96 | |

| (1 1 0 2) [1 1 0 1] | 0.499 | 19.96 | |

| Slip Systems | Basal 〈a〉 | 0 | - |

| Pyramidal 〈a〉 | 0 | - | |

| Pyramidal 〈c + a〉 | 0.401 | 16.04 |

| Tensile Twin Pairs | (0 1 1 2) | (1 1 0 2) | (1 0 1 2) |

| Schmid Factor (m) | 0.219 | 0.479 | 0.245 |

| Slip or Twin Plane | Schmid Factor | Resolved Shear Stress | |

|---|---|---|---|

| (h k i l) [u v t w] | SF | RSS (MPa) | |

| Comp. Twin Variants | (1 0 1 1) [1 0 1 2] | −0.311 | 21.77 |

| (1 0 1 1) [1 0 1 2] | −0.311 | 21.77 | |

| (0 1 1 1) [0 1 1 2] | 0 | - | |

| (0 1 1 1) [0 1 1 2] | 0 | - | |

| (1 1 0 1) [1 1 0 2] | −0.311 | 21.77 | |

| (1 1 0 1) [1 1 0 2] | −0.311 | 21.77 | |

| Slip Systems | Basal 〈a〉 | 0 | - |

| Prismatic 〈a〉 | 0.433 | 30.31 | |

| Pyramidal 〈a〉 | 0.382 | 26.74 | |

| Pyramidal 〈c + a〉 | 0.446 | 31.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russell, W.D.; Bratton, N.R.; Paudel, Y.; Moser, R.D.; McClelland, Z.B.; Barrett, C.D.; Oppedal, A.L.; Whittington, W.R.; Rhee, H.; Mujahid, S.; et al. In Situ Characterization of the Effect of Twin-Microstructure Interactions on {1 0 1 2} Tension and {1 0 1 1} Contraction Twin Nucleation, Growth and Damage in Magnesium. Metals 2020, 10, 1403. https://doi.org/10.3390/met10111403

Russell WD, Bratton NR, Paudel Y, Moser RD, McClelland ZB, Barrett CD, Oppedal AL, Whittington WR, Rhee H, Mujahid S, et al. In Situ Characterization of the Effect of Twin-Microstructure Interactions on {1 0 1 2} Tension and {1 0 1 1} Contraction Twin Nucleation, Growth and Damage in Magnesium. Metals. 2020; 10(11):1403. https://doi.org/10.3390/met10111403

Chicago/Turabian StyleRussell, William D., Nicholas R. Bratton, YubRaj Paudel, Robert D. Moser, Zackery B. McClelland, Christopher D. Barrett, Andrew L. Oppedal, Wilburn R. Whittington, Hongjoo Rhee, Shiraz Mujahid, and et al. 2020. "In Situ Characterization of the Effect of Twin-Microstructure Interactions on {1 0 1 2} Tension and {1 0 1 1} Contraction Twin Nucleation, Growth and Damage in Magnesium" Metals 10, no. 11: 1403. https://doi.org/10.3390/met10111403