Analysis of Changes in Soot Content in Engine Oils under Operating Conditions

Abstract

:1. Introduction

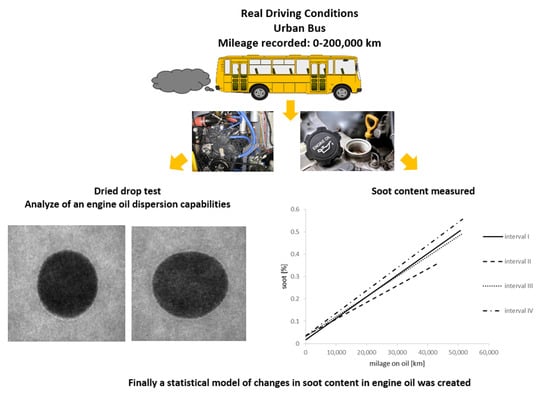

2. Materials and Methods

2.1. Materials

2.2. Test Apparatus

2.3. Statistical Analysis

3. Results and Discussion

3.1. Changes in Soot Content in Oils

Statistical Analysis and Modeling Changes in Soot Content in Oils

3.2. Changes in the Level of Oil Dispersion

Statistical Analysis and Modeling Changes in the Level of Oil Dispersion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ge, J.C.; Wu, G.; Yoo, B.-O.; Choi, N.J. Effect of Injection Timing on Combustion, Emission and Particle Morphology of an Old Diesel Engine Fueled with Ternary Blends at Low Idling Operations. Energy 2022, 253, 124150. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.Y.; Yoon, S.K.; Choi, N.J. Optimization of Palm Oil Biodiesel Blends and Engine Operating Parameters to Improve Performance and PM Morphology in a Common Rail Direct Injection Diesel Engine. Fuel 2020, 260, 116326. [Google Scholar] [CrossRef]

- Dzieniszewski, G.; Kuboń, M.; Pristavka, M.; Findura, P. Operating Parameters and Environmental Indicators of Diesel Engines Fed with Crop-Based Fuels. Agric. Eng. 2021, 25, 13–28. [Google Scholar] [CrossRef]

- Caban, J.; Vrábel, J.; Šarkan, B.; Ignaciuk, P. About Eco-Driving, Genesis, Challenges and Benefits, Application Possibilities. Transp. Res. Procedia 2019, 40, 1281–1288. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.Y.; Yoon, S.K.; Choi, N.J. Reducing Volatile Organic Compound Emissions from Diesel Engines Using Canola Oil Biodiesel Fuel and Blends. Fuel 2018, 218, 266–274. [Google Scholar] [CrossRef]

- Ge, J.C.; Wu, G.; Choi, N.J. Comparative Study of Pilot–Main Injection Timings and Diesel/Ethanol Binary Blends on Combustion, Emission and Microstructure of Particles Emitted from Diesel Engines. Fuel 2022, 313, 122658. [Google Scholar] [CrossRef]

- Vyavhare, K.; Bagi, S.; Patel, M.; Aswath, P.B. Impact of Diesel Engine Oil Additives–Soot Interactions on Physiochemical, Oxidation, and Wear Characteristics of Soot. Energy Fuels 2019, 33, 4515–4530. [Google Scholar] [CrossRef]

- George, S.; Balla, S.; Gautam, M. Effect of Diesel Soot Contaminated Oil on Engine Wear. Wear 2007, 262, 1113–1122. [Google Scholar] [CrossRef]

- Wolak, A.; Krzyzaniak, M. Performance Evaluation of Engine Oils with the Use of Paper Chromatography. NAFTA-GAZ-Sci. Technol. OIL GAS Ind. 2017, 73, 54–60. [Google Scholar] [CrossRef]

- Gołębiowski, W.; Zając, G.; Sarkan, B. Evaluation of the Impact of Tractor Field Works on Changes in Selected Elements of Engine Oils. Agric. Eng. 2022, 26, 1–12. [Google Scholar] [CrossRef]

- La Rocca, A.; Bonatesta, F.; Fay, M.; Campanella, F. Characterisation of Soot in Oil from a Gasoline Direct Injection Engine Using Transmission Electron Microscopy. Tribol. Int. 2015, 86, 77–84. [Google Scholar] [CrossRef]

- Salehi, F.M.; Morina, A.; Neville, A. The Effect of Soot and Diesel Contamination on Wear and Friction of Engine Oil Pump. Tribol. Int. 2017, 115, 285–296. [Google Scholar] [CrossRef] [Green Version]

- Gołębiowski, W.; Wolak, A.; Zając, G. Definition of Oil Change Intervals Based on the Analysis of Selected Physicochemical Properties of Used Engine Oils. Combust. Engines 2018, 172, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Kontou, A.; Southby, M.; Morgan, N.; Spikes, H. Influence of Dispersant and ZDDP on Soot Wear. Tribol. Lett. 2018, 66, 157. [Google Scholar] [CrossRef] [Green Version]

- Bagi, S.; Kamp, C.J.; Sharma, V.; Aswath, P.B. Multiscale Characterization of Exhaust and Crankcase Soot Extracted from Heavy-Duty Diesel Engine and Implications for DPF Ash. Fuel 2020, 282, 118878. [Google Scholar] [CrossRef]

- Omar, A.A.S.; Salehi, F.M.; Farooq, U.; Morina, A.; Neville, A. Chemical and Physical Assessment of Engine Oils Degradation and Additive Depletion by Soot. Tribol. Int. 2021, 160, 107054. [Google Scholar] [CrossRef]

- Furch, J.; Jelinek, J. Design of a Tribotechnical Diagnostics Model for Determining the Technical Condition of an Internal Combustion Engine during Its Life Cycle. Eksploat. Niezawodn.-Maint. Reliab. 2022, 24, 437–445. [Google Scholar] [CrossRef]

- Famfulik, J.; Richtar, M.; Smiraus, J.; Muckova, P.; Sarkan, B.; Dresler, P. Internal Combustion Engine Diagnostics Using Statistically Processed Wiebe Function. Eksploat. Niezawodn. 2021, 23, 505–511. [Google Scholar] [CrossRef]

- Hurtová, I. Hodnocení Karbonového Znečištění Motorových Olejů. Perner’ Contacts 2020, 15, 1–6. [Google Scholar] [CrossRef]

- Shi, J.; Yi, X.; Wang, J.; Jin, G.; Lu, Y.; Wu, H.; Fan, X. Carbonaceous Soot Dispersion Characteristic and Mechanism in Lubricant with Effect of Dispersants by Molecular Dynamics Simulation and Experimental Studies. Carbon 2022, 200, 253–263. [Google Scholar] [CrossRef]

- Kontou, A.; Taylor, R.; Spikes, H. Effects of Dispersant and ZDDP Additives on Fretting Wear. Tribol. Lett. 2021, 69, 1–13. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, Z.; Huang, Z.; Zhang, F.; Zhao, Y. Simulation and Experimental Study on the Effect of Dispersants on Soot Aggregation. China Pet. Process. Petrochem. Technol. 2020, 22, 101–107. [Google Scholar]

- Nassar, A.M.; Ahmed, N.S.; Abdel-Hameed, H.S.; El-Kafrawy, A.F. Synthesis and Utilization of Non-Metallic Detergent/Dispersant and Antioxidant Additives for Lubricating Engine Oil. Tribol. Int. 2016, 93, 297–305. [Google Scholar] [CrossRef]

- Sejkorová, M.; Hurtová, I.; Jilek, P.; Novák, M.; Voltr, O. Study of the Effect of Physicochemical Degradation and Contamination of Motor Oils on Their Lubricity. Coatings 2021, 11, 60. [Google Scholar] [CrossRef]

- Abdulqadir, L.B. Investigation of the Effects of Soot on the Wear of Automotive Engine Components. Ph.D. Thesis, The University of Sheffield, Sheffield, UK, 2017. [Google Scholar]

- Bredin, A.; Larcher, A.V.; Mullins, B.J. Thermogravimetric Analysis of Carbon Black and Engine Soot—Towards a More Robust Oil Analysis Method. Tribol. Int. 2011, 44, 1642–1650. [Google Scholar] [CrossRef] [Green Version]

- Van De Voort, F.; Sedman, J.; Cocciardi, R.; Pinchuk, D. FTIR Condition Monitoring of In-Service Lubricants: Ongoing Developments and Future Perspectives. Tribol. Trans. 2006, 49, 410–418. [Google Scholar] [CrossRef]

- Macián, V.; Tormos, B.; Ruiz, S.; García-Barberá, A. An Alternative Procedure to Quantify Soot in Engine Oil by Ultraviolet-Visible Spectroscopy. Tribol. Trans. 2019, 62, 1063–1071. [Google Scholar] [CrossRef]

- Abdulqadir, L.; Mohd Nor, N.; Lewis, R.; Slatter, T. Contemporary Challenges of Soot Build-up in IC Engine and Their Tribological Implications. Tribol.-Mater. Surf. Interfaces 2018, 12, 115–129. [Google Scholar] [CrossRef]

- Chourasia, S.; Patel, P.D.; Lakdawala, A.; Patel, R.N. Study on Tribological Behavior of Biodiesel—Diethyl Ether (B20A4) Blend for Long Run Test on Compression Ignition Engine. Fuel 2018, 230, 64–77. [Google Scholar] [CrossRef]

- Wolak, A.; Krasodomski, W.; Zając, G. FTIR Analysis and Monitoring of Used Synthetic Oils Operated under Similar Driving Conditions. Friction 2020, 8, 995–1006. [Google Scholar] [CrossRef]

- Sejkorová, M.; Hurtová, I.; Glos, J.; Pokorný, J. Definition of a Motor Oil Change Interval for High-Volume Diesel Engines Based on Its Current Characteristics Assessment. Acta Univ. Agric. Silvic. Mendel. Brun. 2017, 65, 481–490. [Google Scholar] [CrossRef] [Green Version]

- Al Sheikh Omar, A.; Salehi, F.M.; Farooq, U.; Neville, A.; Morina, A. Effect of Zinc Dialkyl Dithiophosphate Replenishment on Tribological Performance of Heavy-Duty Diesel Engine Oil. Tribol. Lett. 2022, 70, 24. [Google Scholar] [CrossRef] [PubMed]

- Kozak, M.; Siejka, P. Soot Contamination of Engine Oil-the Case of a Small Turbocharged Spark-Ignition Engine. Combust. Engines 2020, 182, 28–32. [Google Scholar] [CrossRef]

- Kozak, M. A Comparison of Thermogravimetric Characteristics of Fresh and Used Engine Oils. Combust. Engines 2019, 178, 289–292. [Google Scholar] [CrossRef]

- Jamshidian, M.; Liu, W.; Zhang, Y.; Jamishidian, F. SimReg: A Software Including Some New Developments in Multiple Comparison and Simultaneous Confidence Bands for Linear Regression Models. J. Stat. Softw. 2005, 12, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Neter, J.; Kutner, M.H.; Nachtsheim, C.J.; Wasserman, W. Applied Linear Statistical Models; McGraw-Hill/Irwin: New York, NY, USA, 1996. [Google Scholar]

- Dörr, N.; Agocs, A.; Besser, C.; Ristić, A.; Frauscher, M. Engine Oils in the Field: A Comprehensive Chemical Assessment of Engine Oil Degradation in a Passenger Car. Tribol. Lett. 2019, 67, 68. [Google Scholar] [CrossRef]

| Oil Drain Intervals | Total Vehicle Mileage (km) | Oil Mileage (km) |

|---|---|---|

| Interval I | 20,289 | 20,289 |

| 29,872 | 29,872 | |

| 39,459 | 39,459 | |

| 50,780 | 50,780 (oil change) | |

| Interval II | 65,345 | 14,565 |

| 74,992 | 24,212 | |

| 85,097 | 34,317 | |

| 95,195 | 44,415 (oil change) | |

| Interval III | 114,691 | 20,110 |

| 125,179 | 30,598 | |

| 135,380 | 40,799 | |

| 146,496 | 51,915 (oil change) | |

| Interval IV | 167,800 | 21,849 |

| 175,061 | 29,179 | |

| 185,546 | 39,595 | |

| 197,961 | 52,079 (oil change) |

| Samples | Overall Vehicle Mileage (km) | Soot (%) | Merit of Dispersancy (0–100) | ||

|---|---|---|---|---|---|

| ± SD | ± SD | ||||

| Interval I | 1st cycle | 20,289 | 20,289 | 0.21 ± 0.00 | 98.00 ± 2.00 |

| 2nd cycle | 29,872 | 29,872 | 0.30 ± 0.00 | 92.67 ± 1.52 | |

| 3rd cycle | 39,459 | 39,459 | 0.40 ± 0.01 | 82.00 ± 7.21 | |

| 4th cycle | 50,780 | 50,780 | 0.51 ± 0.00 | 82.33 ± 0.58 | |

| Interval II | 1st cycle | 13,951 | 65,345 | 0.16 ± 0.00 | 97.67 ± 0.58 |

| 2nd cycle | 23,598 | 74,992 | 0.22 ± 0.00 | 93.00 ± 1.00 | |

| 3rd cycle | 33,703 | 85,097 | 0.30 ± 0.01 | 99.67 ± 0.58 | |

| 4th cycle | 43,801 | 95,195 | 0.34 ± 0.00 | 97.00 ± 1.00 | |

| Interval III | 1st cycle | 19,496 | 114,691 | 0.23 ± 0.00 | 96.00 ± 4.00 |

| 2nd cycle | 29,984 | 125,179 | 0.31 ± 0.00 | 96.00 ± 3.00 | |

| 3rd cycle | 40,185 | 135,380 | 0.37 ± 0.01 | 97.00 ± 2.00 | |

| 4th cycle | 51,301 | 146,496 | 0.49 ± 0.00 | 84.67 ± 3.21 | |

| Interval IV | 1st cycle | 21,235 | 167,800 | 0.27 ± 0.00 | 99.00 ± 1.00 |

| 2nd cycle | 28,565 | 175,061 | 0.36 ± 0.00 | 97.67 ± 0.58 | |

| 3rd cycle | 38,981 | 185,546 | 0.40 ± 0.00 | 97.00 ± 1.00 | |

| 4th cycle | 51,465 | 197,961 | 0.55 ± 0.00 | 84.33 ± 2.08 | |

| Parameter | Average from All Four Intervals | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1st Cycle | 2nd Cycle | p | 2nd Cycle | 3rd Cycle | p | 3rd Cycle | 4th Cycle | p | |

| N = 12 | N = 12 | N = 12 | N = 12 | N = 12 | N = 12 | ||||

| ± SD | ± SD | ± SD | |||||||

| Soot (%) | 0.22 ± 0.04 | 0.3 ± 0.05 | <0.001 | 0.3 ± 0.05 | 0.4 ± 0.04 | <0.001 | 0.4 ± 0.04 | 0.5 ± 0.08 | <0.001 |

| Oil Drain Intervals | Equations | Correlation Coefficient |

|---|---|---|

| Interval I | S = 9.6 × 10−6 M + 0.0173 | 0.9997 |

| Interval II | S = 7.4 × 10−6 M + 0.0358 | 0.9896 |

| Interval III | S = 9.0 × 10−6 M + 0.0314 | 0.9959 |

| Interval IV | S = 1.0 × 10−5 M + 0.0354 | 0.9920 |

| Parameter | Average from All Four Intervals | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1st Cycle | 2nd Cycle | p | 2nd Cycle | 3rd Cycle | p | 3rd Cycle | 4th Cycle | p | |

| N = 12 | N = 12 | N = 12 | N = 12 | N = 12 | N = 12 | ||||

| ± SD | ± SD | ± SD | |||||||

| Merit of Disperancy (0–100) | 97.7 ± 2.3 | 94.8 ± 2.7 | <0.001 | 94.8 ± 2.6 | 93.9 ± 7.9 | <0.001 | 93.9 ± 7.9 | 87.1 ± 6.3 | <0.001 |

| Oil Drain Intervals | Equations | Correlation Coefficient |

|---|---|---|

| Interval I | MD = −3.7 × 10−4 M + 101.0855 | −0.8510 |

| Interval III | MD = −2.1 × 10−4 M + 100.3022 | −0.6963 |

| Interval IV | MD = −2.4 × 10−4 M + 101.7997 | −0.7363 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zając, G.; Gołębiowski, W.; Szczepanik, M.; Wolak, A.; Sejkorová, M. Analysis of Changes in Soot Content in Engine Oils under Operating Conditions. Lubricants 2023, 11, 89. https://doi.org/10.3390/lubricants11020089

Zając G, Gołębiowski W, Szczepanik M, Wolak A, Sejkorová M. Analysis of Changes in Soot Content in Engine Oils under Operating Conditions. Lubricants. 2023; 11(2):89. https://doi.org/10.3390/lubricants11020089

Chicago/Turabian StyleZając, Grzegorz, Wojciech Gołębiowski, Małgorzata Szczepanik, Artur Wolak, and Marie Sejkorová. 2023. "Analysis of Changes in Soot Content in Engine Oils under Operating Conditions" Lubricants 11, no. 2: 89. https://doi.org/10.3390/lubricants11020089