LQR Trajectory Tracking Control of Unmanned Wheeled Tractor Based on Improved Quantum Genetic Algorithm

Abstract

:1. Introduction

2. Related Work

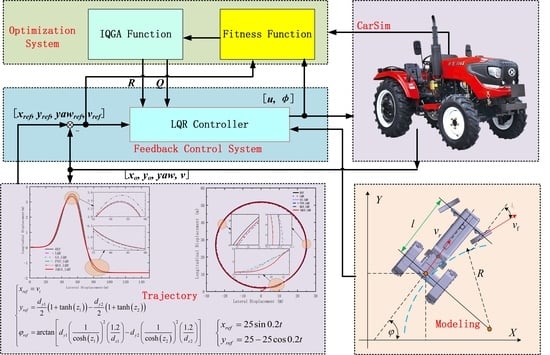

3. Kinematic Model for Wheeled Tractors

4. LQR-Based Trajectory Tracking Control Algorithm

4.1. Linear Quadratic Optimal Control Principle

4.2. Standard QGA

4.3. Improvement Strategies

4.3.1. Quantum Gate Rotation Angle Dynamic Adjustment Strategy

4.3.2. Diversification Strategies for Populations

4.4. Construction of the Fitness Function

4.5. Algorithms in This Paper

4.6. Optimization Algorithm Process

- Population initialization

- 2.

- Fitness measurement

- 3.

- Judgment of the number of iterations

- 4.

- Dynamic updates using the Quantum Revolving Gate

- 5.

- Fitness measurement

- 6.

- Three different operations are performed according to the standard deviation coefficient

- 7.

- End the program

5. Experimental Results and Analysis

5.1. Experimental Environment

5.2. Experimental Data and Parameter Selection

5.3. Tracking a Circular Trajectory

5.4. Tracking Double Shift Trajectory

6. Summary and Prospect

- (1)

- The coefficient matrix selected by IQGA had better tracking accuracy. The lateral position deviation, longitudinal position deviation, and heading angle deviation all tended to be zero, the control effect was better, and the system tended to be stable. Adding constraints to the LQR increases ride comfort. The RMSE of lateral displacement, longitudinal displacement, and the heading angle after tractor stabilization were 0.2714 m, 0.1253 m, and 0.0099 rad, respectively, when the tracking circular trajectory was at 5 m/s. The error of lateral displacement, longitudinal displacement, and the heading angle after tractor stabilization was 0.1134 m, 0.0043 m, and 0.0004 rad, respectively, when tracking a double-shift trajectory at 5 m/s.

- (2)

- The tracking method designed based on kinematics is suitable for low-speed work scenarios. If the wheeled tractor is tracked at high speed, the situation is more complex when the wheeled tractor’s kinematics cannot meet the actual demand. At the same time, the kinematic modeling of the wheel tractor is simplified, such as linearizing the nonlinear system, ignoring the disturbance term, etc., so some errors in the tracking process are difficult to eliminate. In the subsequent research, we can design the nonlinear trajectory tracking controller based on the wheel tractor dynamics and consider the influence of the wheel tractor’s lateral tilt characteristics, the tire’s slip characteristics, the disturbance term, and other factors.

- (3)

- The reference trajectory also greatly influences the tracking effect. For example, when the connection point of the trajectory is not derivable, there is an oscillation in the control data when controlling the wheel tractor. Therefore, in the subsequent study, the original reference trajectory can be sampled, and the original reference trajectory can be reprogrammed according to the kinematic constraints of the wheel tractor or wheel tractor dynamics constraints. A trajectory that meets the constraints can be reprogrammed for tracking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yadav, A.; Gaur, A.; Jain, S.; Chaturvedi, D.; Sharma, R. Development Navigation, Guidance & Control Program for GPS based Autonomous Ground Vehicle (AGV) using Soft Computing Techniques. Mater. Today Proc. 2020, 29, 530–535. [Google Scholar]

- Zhang, Z.; Wu, L.; Zhang, W.; Peng, T.; Zheng, J. Energy-efficient path planning for a single-load automated guided vehicle in a manufacturing workshop. Comput. Ind. Eng. 2021, 158, 107397. [Google Scholar] [CrossRef]

- Feilong, W.; Shiyong, G. Intelligent Vehicle Path Tracking Algorithm Based on Nonlinear Model Predictive Control. Automob. Technol. 2020, 1–7. [Google Scholar]

- Nie, Z.G.; Wang, W.Q.; Zhao, W.Q.; Huang, Z.; Zong, C.F. Dynamic trajectory planning and tracking control for lane change of intelligent vehicle based on trajectory preview. J. Traffic Transp. Eng. 2020, 20, 147–160. [Google Scholar]

- Wongsathan, C.; Sirima, C. Application of GA to design LQR controller for an Inverted Pendulum System. In Proceedings of the IEEE International Conference on Robotics & Biomimetics, Bangkok, Thailand, 22–25 February 2009. [Google Scholar]

- Rahimi, A.; Ghazi, R. GA-Based Optimal LQR Controller to Improve LVRT Capability of DFIG Wind Turbines. Iran. J. Electr. Electron. Eng. 2013, 9, 167–176. [Google Scholar]

- Kafafy, M.; Rabeih, A.; Eldemerdash, S.; Elbutch, A. Active Suspension Design for Passenger Cars Using LQR and GA with PID Controller. SAE Technical Papers, St. Charles, IL, USA, 15–17 May 2007. [Google Scholar] [CrossRef]

- Amini, F.; Hazaveh, N.; Rad, A. Wavelet PSO-Based LQR Algorithm for Optimal Structural Control Using Active Tuned Mass Dampers. Comput.-Aided Civ. Infrastruct. Eng. 2013, 28, 542–557. [Google Scholar] [CrossRef]

- Mf, A.; Sn, A.; Ak, B. On the ability of sliding mode and LQR controllers optimized with PSO in attitude control of a flexible 4-DOF satellite with time-varying payload. Adv. Space Res. 2021, 67, 334–349. [Google Scholar]

- Reddipogu, J.; Elumalai, V. Hardware in the Loop Testing of Adaptive Inertia Weight PSO-Tuned LQR Applied to Vehicle Suspension Control. J. Control. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Li, L.; Qiu, T.; Jia, T.; Chen, C. Stepping quantum genetic algorithm-based LQR control strategy for lateral vibration of high-speed elevator. at-Automatisierungstechnik 2022, 70, 623–634. [Google Scholar] [CrossRef]

- Sajid, U.; Wahid, M. Topology Control of wireless sensor network using Quantum Inspired Genetic algorithm. Int. J. Swarm Intell. Evol. Comput. 2015, 4, 121. [Google Scholar] [CrossRef]

- Marji, M.; Sumarli, E. Design and Investigation of Fuzzy Control For Independent Full Car Suspension Model in Random Road And Braking Excitation. Int. J. Adv. Sci. Technol. 2020, 29, 20–23. [Google Scholar]

- Meng, Y.; Gan, X.; Wang, Y.; Qing, G. LQR-GA Controller for Articulated Dump Truck Path Tracking System. J. Shanghai Jiaotong Univ. (Sci.) 2019, 24, 78–85. [Google Scholar] [CrossRef]

- Zhang, W. A robust lateral tracking control strategy for autonomous driving vehicles. Mech. Syst. Signal Process. 2021, 150, 107238. [Google Scholar] [CrossRef]

- Yuan, S.; Zhao, P.; Zhang, Q.; Hu, X. Research on Model Predictive Control-based Trajectory Tracking for Unmanned Vehicles. In Proceedings of the 2019 4th International Conference on Control and Robotics Engineering (ICCRE), Nanjing, China, 20–23 April 2019; pp. 79–86. [Google Scholar]

- Kanieski, J.; Carati, E.; Cardoso, R. An energy based LQR tuning approach applied for Uninterruptible Power Supplies. In Proceedings of the 2010 First IEEE Latin American Symposium on Circuits and Systems (LASCAS), Foz do Iguacu, Brazil, 24–26 February 2010; pp. 41–44. [Google Scholar]

- Ufnalski, B.; Kaszewski, A.; Grzesiak, L. Particle Swarm Optimization of the Multioscillatory LQR for a Three-Phase Four-Wire Voltage-Source Inverter With an $LC$ Output Filter. IEEE Trans. Ind. Electron. 2015, 62, 484–493. [Google Scholar] [CrossRef]

- Almeida, P.; Ribeiro, A.; Souza, I.; Fernandes, M.; Fogli, G.; Ćuk, V.; Barbosa, P.; Ribeiro, P. Systematic Design of a DLQR Applied to Grid-Forming Converters. IEEE J. Emerg. Sel. Top. Ind. Electron. 2020, 1, 200–210. [Google Scholar] [CrossRef]

- Liu, S.; Wu, W.; Jin, Q.; Zhu, Y. Design Method for Helicopter Flight Control Law Based on Particle Swarm Optimization. J. Nanjing Univ. Aeronaut. Astronaut. 2021, 53, 267–274. [Google Scholar]

- Tian, J.; Guo, Q.; Shi, G. Laminated piezoelectric beam element for dynamic analysis of piezolaminated smart beams and GA-based LQR active vibration control. Compos. Struct. 2020, 252, 112480. [Google Scholar] [CrossRef]

- Kumar, E.V.; Raaja, G.; Jerome, J. Adaptive PSO for optimal LQR tracking control of 2 DoF laboratory helicopter. Appl. Soft Comput. 2016, 41, 77–90. [Google Scholar] [CrossRef]

- Gokul Prassad, S.; Malar Mohan, K. A contemporary adaptive air suspension using LQR control for passenger vehicles. ISA Trans. 2019, 93, 244–254. [Google Scholar] [CrossRef]

- Belyaev, A.; Sumenkov, O. Hybrid control algorithm based on LQR and genetic algorithm for active support weight compensation system. IFAC-Pap. 2021, 54, 431–436. [Google Scholar] [CrossRef]

- Jianwei, G.; Yan, J.; Wei, X. Model Predictive Control for self-driving Vehicles, 2nd ed.; Beijing Institute of Technology Press: Beijing, China, 2014. [Google Scholar]

- Han, K.; Park, K.; Lee, C.; Kim, J. Parallel quantum-inspired genetic algorithm for combinatorial optimization problem. In Proceedings of the Proceedings of the 2001 Congress on Evolutionary Computation (IEEE Cat. No.01TH8546), Seoul, Korea, 27–30 May 2001. [Google Scholar]

- Gexiang, Z.; Na, L.; Weidong, J.; Laizhao, H. A Novel Quantum Genetic Algorithm and Its Applicat. Acta Electron. Sin. 2004, 32, 476–479. [Google Scholar]

- Zhang, X.F.; Sui, G.F.; Zheng, R.; Li, Z.N.; Yang, G.W. An Improved Quantum Genetic Algorithm of Quantum Revolving Gate. Comput. Eng. 2013, 39, 234–238. [Google Scholar]

- He, X.; Liang, J. Genetic Algorithms Using Gradients of Object Functions. J. Softw. 2001, 12, 981–986. [Google Scholar]

- Xu, E.; Gai, J.; Zhou, J.; Yang, F.; Liu, C. Quantum Genetic Algorithm for Hadamard Gate Mutation. Control Eng. China 2018, 25, 143–148. [Google Scholar]

- Haiyan, G. Quantum genetic algorithm based on chaotic optimization. Electron. Meas. Technol. 2006, 29, 14–15+18. [Google Scholar]

- Katzourakis, D.; de Winter, J.; de Groot, S.; Happee, R. Driving simulator parameterization using double-lane change steering metrics as recorded on five modern cars. Simul. Model. Pract. Theory 2012, 26, 96–112. [Google Scholar] [CrossRef]

- Qu, X.; Feng, H.; Li, G. Cooperative Control of Vehicle Active Steering and Electronic Stability Program. Sci. Technol. Eng. 2021, 21, 13155–13162. [Google Scholar]

- Wang, N.; Shi, J.; Zhao, C. Experimental Analysis on Handing Stability of Two Rear Drive Wheel Pure Electric Vehicle. In Proceedings of the SAECCE2020-EV025, Shanghai, China, 27 October 2020; pp. 408–413. [Google Scholar]

- Falcone, P.; Tseng, H.E.; Borrelli, F.; Asgari, J.; Hrovat, D. MPC-based yaw and lateral stabilisation via active front steering and braking. Veh. Syst. Dyn. 2008, 46, 611–628. [Google Scholar] [CrossRef]

| Algorithms | Parameters |

|---|---|

| Trad_LQR | Q = [10,0,0;0,10,0;0,0,100], R = [5,0;0,10] |

| GA | Population size , Number of elites = 10, Maximum iterations , Constraint termination error = 1 × 10−100, Crossover probability , Mutation probability |

| PSO | Population size = 20, Maximum iterations = 40, Acceleration parameters = 2, Initial weights = 0.9, End weights = 0.4, Algorithm termination threshold = 1 × 10−25, Iteration termination threshold = 10, PSO Algorithm Type = 0, Specify random seeds = 1 |

| QGA | Population size , Maximum iterations , Binary length of the variable |

| IQGA | Population size , Maximum iterations , Speed Maximum , Speed Minimum , Particle Dimension , Learning Factor , , Inertia weight maximum , Inertia weight minimum |

| TRAD_LQR | GA | PSO | QGA | IQGA | ||

|---|---|---|---|---|---|---|

| Lateral Deviation (m) | Maximum value | 1.4238 | 0.5843 | 1.4471 | 0.5844 | 0.2878 |

| Minimum value | −2.3882 | −2.4397 | −2.3773 | −2.4398 | −2.56378 | |

| RMSE | 0.435 | 0.2724 | 0.4493 | 0.2724 | 0.2714 | |

| Longitudinal Deviation (m) | Maximum value | 3.0731 | 1.4622 | 3.1136 | 1.4622 | 0.4668 |

| Minimum value | −2 | −2 | −2 | −2 | −2 | |

| RMSE | 1.2018 | 0.2972 | 1.2605 | 0.2972 | 0.1253 | |

| Heading Angle Deviation (rad) | Maximum value | 0.2364 | 0.2526 | 0.2305 | 0.2526 | 0.2439 |

| Minimum value | −0.1426 | −0.223 | −0.1398 | −0.223 | −0.1004 | |

| RMSE | 0.0093 | 0.0104 | 0.009 | 0.0104 | 0.0099 | |

| Speed Deviation (m/s2) | Maximum value | 2.3865 | 2.2329 | 2.4391 | 2.2329 | 1.555 |

| Minimum value | −3.6443 | −3.6444 | −3.6443 | −3.6444 | −3.6698 | |

| RMSE | 0.6736 | 0.4326 | 0.6791 | 0.4326 | 0.2853 | |

| Parameters | Values |

|---|---|

| Q | |

| R | |

| Q0 | |

| 1106 |

| TRAD | GA | PSO | QGA | IQGA | ||

|---|---|---|---|---|---|---|

| Lateral Deviation (m) | Maximum value | 0.7250 | 0.7016 | 0.7234 | 0.6413 | 0.7250 |

| Minimum value | −1.6156 | −1.6225 | −1.6140 | −1.6217 | −1.6156 | |

| RMSE | 0.1134 | 0.1430 | 0.1542 | 0.2592 | 0.1134 | |

| Longitudinal Deviation (m) | Maximum value | 0.1518 | 0.1836 | 0.1518 | 0.2161 | 0.1331 |

| Minimum value | −0.2240 | −0.2448 | −0.2240 | −0.2269 | −0.1796 | |

| RMSE | 0.0061 | 0.0082 | 0.0061 | 0.0074 | 0.0043 | |

| Heading Angle Deviation (rad) | Maximum value | 0.0574 | 0.0569 | 0.0574 | 0.0615 | 0.0571 |

| Minimum value | −0.0361 | −0.0332 | −0.0361 | −0.0326 | −0.0338 | |

| RMSE | 0.0004 | 0.0004 | 0.0004 | 0.0004 | 0.0004 | |

| Speed Deviation (m/s2) | Maximum value | 1.49623 | 1.5013 | 1.4962 | 1.4825 | 0.9810 |

| Minimum value | −3.6112 | −3.6112 | −3.6112 | −3.6112 | −3.6112 | |

| RMSE | 0.2474 | 0.2619 | 0.2474 | 0.3078 | 0.1670 | |

| Parameters | Values |

|---|---|

| Q | |

| R | |

| Q0 | |

| 1106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Wang, J.; Wang, H.; Yang, L.; Xia, C. LQR Trajectory Tracking Control of Unmanned Wheeled Tractor Based on Improved Quantum Genetic Algorithm. Machines 2023, 11, 62. https://doi.org/10.3390/machines11010062

Fan X, Wang J, Wang H, Yang L, Xia C. LQR Trajectory Tracking Control of Unmanned Wheeled Tractor Based on Improved Quantum Genetic Algorithm. Machines. 2023; 11(1):62. https://doi.org/10.3390/machines11010062

Chicago/Turabian StyleFan, Xin, Junyan Wang, Haifeng Wang, Lin Yang, and Changgao Xia. 2023. "LQR Trajectory Tracking Control of Unmanned Wheeled Tractor Based on Improved Quantum Genetic Algorithm" Machines 11, no. 1: 62. https://doi.org/10.3390/machines11010062