Integrated Path Tracking and Lateral Stability Control with Four-Wheel Independent Steering for Autonomous Electric Vehicles on Low Friction Roads

Abstract

:1. Introduction

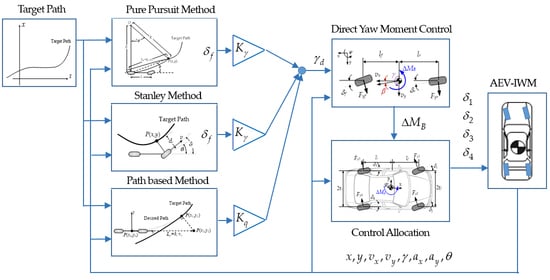

- In this paper, we converted the path tracking control to the yaw rate tracking one in order to fully utilize 4WIS for path tracking. It was difficult to determine the steering angles of 4WIS by virtue of the methods used for path tracking control on FWS vehicles. In this paper, with the aid of control allocation in the yaw rate tracking control, the path tracking controller was designed for an autonomous electric vehicle with 4WIS.

- For path tracking on low friction roads, we designed a yaw tracking controller guaranteeing lateral stability with 4WIS. With this manner, the path tracking control was integrated with lateral stability control.

- This paper shows that a coordination or switching scheme between path tracking and lateral stability on low friction roads was not needed under a particular controller structure and parameter setting.

2. Derivation of Reference Yaw Rate

2.1. Driver Models

2.2. Calculation of the Reference Yaw Rate from the Steering Angle

2.3. Path-Based Method for Reference Yaw Rate Generation

3. Design of Yaw Rate Tracking Controller

3.1. Design of Direct Yaw Moment Controller in the Upper Layer

3.2. Control Allocation in the Lower Layer

4. Validation with Simulation

4.1. Simulation without Any Controllers

4.2. Simulation for the Proposed Controller with Various Values of Tuning Parameters

4.3. Simulation for the Proposed Controller with Various Values of Yaw Rate Gains

4.4. Simulation for the Proposed Controller with Selected Values of Yaw Rate Gains

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 4WD | 4-wheel drive |

| 4WIB | 4-wheel independent braking |

| 4WID | 4-wheel independent driving |

| 4WIS | 4-wheel independent steering |

| 4WS | 4-wheel steering |

| AEV-IWM | autonomous electric vehicle with in-wheel motor |

| AFS | active front steering |

| EMB | electro-mechanical brake |

| ESC | electronic stability control |

| EV-IWM | electric vehicle equipped with in-wheel motor |

| FWS | front wheel steering |

| ICC | integrated chassis control |

| IWM | in-wheel motor |

| LQR | linear quadratic regulator |

| MALOE | maximum absolute value of lateral offset error |

| MALD | maximum absolute value of lateral deviation |

| MAYRE | maximum absolute value of yaw rate error |

| MASSA | maximum absolute value of side-slip angle |

| MPC | model predictive control |

| PATH-RYR | reference yaw rate from path-based method |

| PPM | pure pursuit method |

| PPM-RYR | reference yaw rate from pure pursuit method |

| RWS | rear-wheel steering |

| SMC | sliding mode control |

| STL-RYR | reference yaw rate from Stanley method |

| TVD | torque vectoring device |

| UCC | unified chassis control |

| VSC | vehicle stability control |

| WPCA | weighted pseudo-inverse-based control allocation |

References

- Montanaro, U.; Dixit, S.; Fallaha, S.; Dianatib, M.; Stevensc, A.; Oxtobyd, D.; Mouzakitisd, A. Towards connected autonomous driving: Review of use-cases. Veh. Syst. Dyn. 2019, 57, 779–814. [Google Scholar] [CrossRef]

- Yurtsever, E.; Lambert, J.; Carballo, A.; Takeda, K. A survey of autonomous driving: Common practices and emerging technologies. IEEE Access 2020, 8, 58443–58469. [Google Scholar] [CrossRef]

- Omeiza, D.; Webb, H.; Jirotka, M.; Kunze, M. Explanations in autonomous driving: A survey. IEEE Trans. Intell. Transp. Syst. 2021; early access. [Google Scholar] [CrossRef]

- Thomas, P.; Morris, A.; Talbot, R.; Fagerlind, H. Identifying the causes of road crashes in Europe. Ann. Adv. Automot. Med. 2013, 57, 13–22. [Google Scholar]

- NHTSA. Critical reasons for crashes investigated in the national motor vehicle crash causation survey. In Traffic Safety Facts; Report No. DOT HS 812 115; National Highway Traffic Safety Administration: Washington, DC, USA, 2015; pp. 1–2. [Google Scholar]

- Shladover, S.E. Cooperative (rather than autonomous) vehicle-highway automation systems. IEEE Intell. Transp. Syst. Mag. 2009, 1, 10–19. [Google Scholar] [CrossRef]

- Nowakowski, C.; O’Connell, J.; Shladover, S.E.; Cody, D. Cooperative adaptive cruise control: Driver acceptance of following gap settings less than one second. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting; Sage: Los Angeles, CA, USA, 2010; pp. 2033–2037. [Google Scholar]

- Paden, B.; Cap, M.; Yong, S.Z.; Yershov, D.; Frazzoli, E. A survey of motion planning and control techniques for self-driving urban vehicles. IEEE Trans. Intell. Veh. 2016, 1, 33–55. [Google Scholar] [CrossRef] [Green Version]

- Sorniotti, A.; Barber, P.; De Pinto, S. Path tracking for automated driving: A tutorial on control system formulations and ongoing research. In Automated Driving; Watzenig, D., Horn, M., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Amer, N.H.; Hudha, H.Z.K.; Kadir, Z.A. Modelling and control strategies in path tracking control for autonomous ground vehicles: A review of state of the art and challenges. J. Intell. Robot. Syst. 2017, 86, 225–254. [Google Scholar] [CrossRef]

- Bai, G.; Meng, Y.; Liu, L.; Luo, W.; Gu, Q.; Liu, L. Review and comparison of path tracking based on model predictive control. Electronics 2019, 8, 10. [Google Scholar] [CrossRef] [Green Version]

- Yao, Q.; Tian, Y.; Wang, Q.; Wang, S. Control strategies on path tracking for autonomous vehicle: State of the art and future challenges. IEEE Access 2020, 8, 161211–161222. [Google Scholar] [CrossRef]

- Rokonuzzaman, M.; Mohajer, N.; Nahavandi, S.; Mohamed, S. Review and performance evaluation of path tracking controllers of autonomous vehicles. IET Intell. Transp. Syst. 2021, 15, 646–670. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, X.; Zhang, Y.; Luo, Y.; Peng, X. Trajectory planning and tracking strategy applied to an unmanned ground vehicle in the presence of obstacles. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1575–1589. [Google Scholar] [CrossRef]

- van Zanten, A.T.; Erhardt, R.; Pfaff, G. VDC, the vehicle dynamics control system of Bosch. SAE Trans. 1995, 950759, 1419–1436. [Google Scholar]

- Mousavinejad, I.E.; Zhu, Y.; Vlacic, L. Control strategies for improving ground vehicle stability: State-of-the-art review. In Proceedings of the 2015 10th Asian Control Conference (ASCC), Kota Kinabalu, Malaysia, 31 May–3 June 2015. [Google Scholar]

- Yim, S. Coordinated control with electronic stability control and active steering devices. J. Mech. Sci. Technol. 2015, 29, 5409–5416. [Google Scholar] [CrossRef]

- Nah, J.; Yim, S. Optimization of control allocation with ESC, AFS, ARS and TVD in integrated chassis control. J. Mech. Sci. Technol. 2019, 33, 2941–2948. [Google Scholar] [CrossRef]

- Wong, H.Y. Theory of Ground Vehicles, 3rd ed.; John Wiley and Sons, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Yim, S. Comparison among active front, front independent, 4-wheel and 4-wheel independent steering systems for vehicle stability control. Electronics 2020, 9, 798. [Google Scholar] [CrossRef]

- Croft-White, M.; Harrison, M. Study of torque vectoring for all-wheel drive vehicles. Veh. Syst. Dyn. 2006, 44, 313–320. [Google Scholar] [CrossRef]

- Murata, S. Innovation by in-wheel-motor drive unit. Veh. Syst. Dyn. 2012, 50, 807–830. [Google Scholar] [CrossRef]

- Nah, J.; Yim, S. Vehicle stability control with four-wheel independent braking, drive and steering on in-wheel motor-driven electric vehicles. Electronics 2020, 9, 1934. [Google Scholar] [CrossRef]

- Raksincharoensak, P.; Nagai, M.; Mouri, H. Investigation of automatic path tracking control using four-wheel steering vehicle. In Proceedings of the IEEE International Vehicle Electronics Conference 2001, Tottori, Japan, 25–28 September 2001; pp. 73–77. [Google Scholar]

- Potluri, R.; Singh, A.K. Path-tracking control of an autonomous 4WS4WD electric vehicle using its natural feedback loops. IEEE Trans. Control Syst. Technol. 2015, 23, 2053–2062. [Google Scholar] [CrossRef]

- Wang, R.; Yin, G.; Jin, X. Robust adaptive sliding mode control for nonlinear four-wheel steering autonomous Vehicles path tracking systems. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference, Hefei, China, 22–26 May 2016; pp. 2999–3006. [Google Scholar]

- Wang, R.; Yin, G.; Zhuang, J.; Zhang, N.; Chen, J. The path tracking of four-wheel steering autonomous vehicles via sliding mode control. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016. [Google Scholar]

- Deremetz, M.; Lenain, R.; Couvent, A.; Cariou, C.; Thuilot, B. Path tracking of a four-wheel steering mobile robot: A robust off-road parallel steering strategy. In Proceedings of the 2017 European Conference on Mobile Robots (ECMR), Paris, France, 6–8 September 2017. [Google Scholar]

- Hang, P.; Luo, F.; Fang, S.; Chen, X. Path tracking control of a four-wheel-independent-steering electric vehicle based on model predictive control. In Proceedings of the 2017 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017. [Google Scholar]

- Jin, L.; Gao, L.; Jiang, Y.; Chen, M.; Zheng, Y.; Li, K. Research on the control and coordination of four-wheel independent driving/steering electric vehicle. Adv. Mech. Eng. 2017, 9, 1687814017698877. [Google Scholar] [CrossRef]

- Hang, P.; Chen, X.; Luo, F. Path-Tracking Controller Design for a 4WIS and 4WID Electric Vehicle with Steer-by-Wire System; SAE Technical Paper 2017-01-1954; SAE: Warrendale, PN, USA, 2017. [Google Scholar]

- Tan, Q.; Dai, P.; Zhang, Z.; Katupitiya, J. MPC and PSO based control methodology for path tracking of 4WS4WD vehicles. Appl. Sci. 2018, 8, 1000. [Google Scholar] [CrossRef] [Green Version]

- Hang, P.; Chen, X.; Luo, F. LPV/H∞ controller design for path tracking of autonomous ground vehicles through four-wheel steering and direct yaw-moment control. Int. J. Automot. Technol. 2019, 20, 679–691. [Google Scholar] [CrossRef]

- Hang, P.; Chen, X. Integrated chassis control algorithm design for path tracking based on four-wheel steering and direct yaw-moment control. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2019, 233, 625–641. [Google Scholar] [CrossRef]

- Chen, X.; Peng, Y.; Hang, P.; Tang, T. Path tracking control of four-wheel independent steering electric vehicles based on optimal control. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–30 July 2020; pp. 5436–5442. [Google Scholar]

- Liang, Y.; Li, Y.; Zheng, L.; Yu, Y.; Ren, Y. Yaw rate tracking-based path-following control for four-wheel independent driving and four-wheel independent steering autonomous vehicles considering the coordination with dynamics stability. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 260–272. [Google Scholar] [CrossRef]

- Jeong, Y.; Yim, S. Model predictive control-based integrated path tracking and velocity control for autonomous vehicle with four-wheel independent steering and driving. Electronics 2021, 10, 22. [Google Scholar] [CrossRef]

- Du, Q.; Zhu, C.; Li, Q.; Tian, B.; Li, L. Optimal path tracking control for intelligent four-wheel steering vehicles based on MPC and state estimation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 1964–1976. [Google Scholar] [CrossRef]

- Hang, P.; Chen, X. Towards autonomous driving: Review and perspectives on configuration and control of four-wheel independent drive/steering electric vehicles. Actuators 2021, 10, 184. [Google Scholar] [CrossRef]

- Jeong, Y.; Yim, S. Path tracking control with four-wheel independent steering, driving and braking systems for autonomous electric vehicles. IEEE Access 2022, 10, 74733–74746. [Google Scholar] [CrossRef]

- Tan, X.; Liu, D.; Xiong, H. Optimal control method of path tracking for four-wheel steering vehicles. Actuators 2022, 11, 61. [Google Scholar] [CrossRef]

- Yakub, F.; Mori, Y. Comparative study of autonomous path-following vehicle control via model predictive control and linear quadratic control. J. Automob. Eng. 2015, 229, 1695–1714. [Google Scholar] [CrossRef]

- Hu, C.; Wang, R.; Yan, F.; Chen, N. Output constraint control on path following of four-wheel independently actuated autonomous ground vehicles. IEEE Trans. Veh. Technol. 2016, 65, 4033–4043. [Google Scholar] [CrossRef]

- Guo, J.; Luo, Y.; Li, K. An adaptive hierarchical trajectory following control approach of autonomous four-wheel independent drive electric vehicles. IEEE Trans. Intell. Transp. Syst. 2018, 19, 2482–2492. [Google Scholar] [CrossRef]

- Guo, J.; Luo, Y.; Li, K.; Dai, Y. Coordinated path-following and direct yaw-moment control of autonomous electric vehicles with sideslip angle estimation. Mech. Syst. Signal Process. 2018, 105, 183–199. [Google Scholar] [CrossRef]

- Ren, Y.; Zheng, L.; Khajepour, A. Integrated model predictive and torque vectoring control for path tracking of 4-wheeldriven autonomous vehicles. IET Intell. Transp. Syst. 2019, 13, 98–107. [Google Scholar] [CrossRef]

- Peng, H.; Wang, W.; An, Q.; Xiang, C.; Li, L. Path tracking and direct yaw moment coordinated control based on robust MPC with the finite time horizon for autonomous independent-drive vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6053–6066. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Q.; Zhou, J.; Zheng, H.; Chen, H. Longitudinal and lateral control of autonomous vehicles in multi-vehicle driving environments. IET Intell. Transp. Syst. 2020, 14, 924–935. [Google Scholar] [CrossRef]

- Xiang, C.; Peng, H.; Wang, W.; Li, L.; An, Q.; Cheng, S. Path tracking coordinated control strategy for autonomous four in-wheel-motor independent-drive vehicles with consideration of lateral stability. J. Automob. Eng. 2021, 235, 1023–1036. [Google Scholar] [CrossRef]

- Yim, S.; Kim, S.; Yun, H. Coordinated control with electronic stability control and active front steering using the optimum yaw moment distribution under a lateral force constraint on the active front steering. J. Automob. Eng. 2016, 230, 581–592. [Google Scholar] [CrossRef]

- Mechanical Simulation Corporation. VS Browser: Reference Manual, The Graphical User Interfaces of BikeSim, CarSim, and TruckSim; Mechanical Simulation Corporation: Ann Arbor, MI, USA, 2009. [Google Scholar]

- Chen, X.; Wu, S.; Shi, C.; Huang, Y.; Yang, Y.; Ke, R.; Zhao, J. Sensing data supported traffic flow prediction via denoising schemes and ANN: A comparison. IEEE Sens. J. 2020, 20, 14317–14328. [Google Scholar] [CrossRef]

- Thrun, S.; Montemerlo, M.; Dahlkamp, H.; Stavens, D.; Aron, A.; Diebel, J.; Fong, P.; Gale, J.; Halpenny, M.; Hoffmann, G.; et al. The robot that won the DARPA grand challenge. J. Field Robot. 2006, 23, 661–692. [Google Scholar] [CrossRef]

- Rajamani, R. Vehicle Dynamics and Control; Springer: New York, NY, USA, 2006. [Google Scholar]

- Baffet, G.; Charara, A.; Lechner, D. Estimation of vehicle side-slip, tire force and wheel cornering stiffness. Control Eng. Pract. 2009, 17, 1255–1264. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.H.; Ryu, J. Sideslip angle estimation considering short-duration longitudinal velocity variation. Int. J. Automot. Technol. 2011, 12, 545–553. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X.; Zhou, Q.; Tian, Y. A model predictive controller with switched tracking error for autonomous vehicle path tracking. IEEE Access 2019, 7, 53103–53114. [Google Scholar] [CrossRef]

- Xie, J.; Xu, X.; Wang, F.; Tang, Z.; Chen, L. Coordinated control based path following of distributed drive autonomous electric vehicles with yaw-moment control. Control Eng. Pract. 2021, 106, 104659. [Google Scholar] [CrossRef]

- Ahn, T.; Lee, Y.; Park, K. Design of integrated autonomous driving control system that incorporates chassis controllers for improving path tracking performance and vehicle stability. Electronics 2021, 10, 144. [Google Scholar] [CrossRef]

- Yim, S.; Choi, J.; Yi, K. Coordinated control of hybrid 4WD vehicles for enhanced maneuverability and lateral stability. IEEE Trans. Veh. Technol. 2012, 61, 1946–1950. [Google Scholar] [CrossRef]

- Durali., M.; Javid, G.A.; Kasaiezadeh, A. Collision avoidance maneuver for an autonomous vehicle. In Proceedings of the 9th IEEE International Workshop on Advanced Motion Control, Istanbul, Turkey, 27–29 March 2006. [Google Scholar]

- He, X.; Liu, Y.; Lv, C.; Ji, X.; Liu, Y. Emergency steering control of autonomous vehicle for collision avoidance and stabilization. Veh. Syst. Dyn. 2019, 57, 1163–1187. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ms | 1823 kg | lf | 1.27 m |

| Iz | 6286 kg·m2 | lr | 1.90 m |

| Cf | 62,000 N/rad | tf | 0.80 m |

| Cr | 55,000 N/rad | tr | 0.80 m |

| MALOE (m) | MALD (m) | MAYRE (deg/s) | MASSA (deg) | ||

|---|---|---|---|---|---|

| First Simulation | PPM | 1.62 | 2.72 | 4.8 | 0.5 |

| Stanley | 1.56 | 2.59 | 7.9 | 0.5 | |

| Fourth Simulation | PPM-RYR | 1.38 | 2.92 | 3.6 | 2.0 |

| STL-RYR | 1.43 | 2.93 | 3.3 | 1.9 | |

| PATH-RYR | 1.53 | 2.98 | 3.8 | 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, Y.; Yim, S. Integrated Path Tracking and Lateral Stability Control with Four-Wheel Independent Steering for Autonomous Electric Vehicles on Low Friction Roads. Machines 2022, 10, 650. https://doi.org/10.3390/machines10080650

Jeong Y, Yim S. Integrated Path Tracking and Lateral Stability Control with Four-Wheel Independent Steering for Autonomous Electric Vehicles on Low Friction Roads. Machines. 2022; 10(8):650. https://doi.org/10.3390/machines10080650

Chicago/Turabian StyleJeong, Yonghwan, and Seongjin Yim. 2022. "Integrated Path Tracking and Lateral Stability Control with Four-Wheel Independent Steering for Autonomous Electric Vehicles on Low Friction Roads" Machines 10, no. 8: 650. https://doi.org/10.3390/machines10080650