Magnetite Geochemistry of the Jinchuan Ni-Cu-PGE Deposit, NW China: Implication for Its Ore-Forming Processes

Abstract

:1. Introduction

2. Geological Background

3. Analytical Method

3.1. Back-Scattered Electron (BSE)

3.2. LA-ICP-MS

4. Results

4.1. Petrography

4.2. Magnetite Geochemistry

5. Discussion

5.1. Genesis of Magnetite

5.2. Factors Controlling Magnetite Compositions

5.2.1. Factor I: Magma Compositions

5.2.2. Factor II: Temperature and fO2

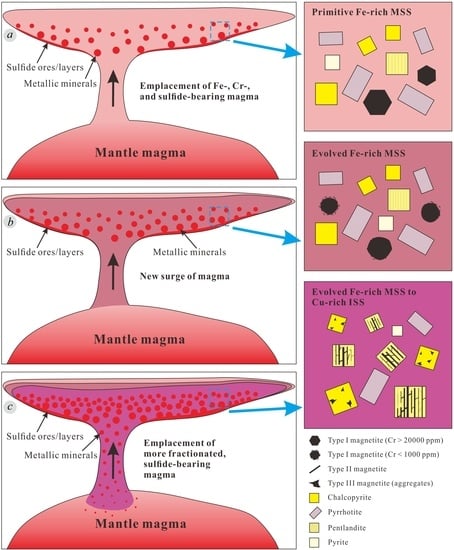

5.3. Implications for Ore-Forming Processes

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, W.T.; Zhou, M.F.; Li, X.C.; Gao, J.F.; Hou, K.J. In-situ LA-ICP-MS trace elemental analyses of magnetite: Cu-(Au, Fe) deposits in the Khetri copper belt in Rajasthan Province, NW India. Ore Geol. Rev. 2015, 65, 929–939. [Google Scholar] [CrossRef]

- Dare, S.A.; Barnes, S.J.; Beaudoin, G.; Méric, J.; Boutroy, E.; Potvin-Doucet, C. Trace elements in magnetite as petrogenetic indicators. Miner. Depos. 2014, 49, 785–796. [Google Scholar] [CrossRef]

- Dupuis, C.; Beaudoin, G. Discriminant diagrams for iron oxide trace element fingerprinting of mineral deposit types. Miner. Depos. 2011, 46, 319–335. [Google Scholar] [CrossRef]

- Huberty, J.M.; Konishi, H.; Heck, P.R.; Fournelle, J.H.; Valley, J.W.; Xu, H. Silician magnetite from the Dales Gorge member of the Brockman iron formation, Hamersley Group, Western Australia. Am. Mineral. 2012, 97, 26–37. [Google Scholar] [CrossRef]

- Nadoll, P.; Mauk, J.L.; Hayes, T.S.; Koenig, A.E.; Box, S.E. Geochemistry of magnetite from hydrothermal ore deposits and host rocks of the Mesoproterozoic Belt Supergroup, United States. Econ. Geol. 2012, 107, 1275–1292. [Google Scholar] [CrossRef]

- Dare, S.A.; Barnes, S.J.; Beaudoin, G. Variation in trace element content of magnetite crystallized from a fractionating sulfide liquid, Sudbury, Canada: Implications for provenance discrimination. Geochim. Cosmochim. Acta 2012, 88, 27–50. [Google Scholar] [CrossRef]

- Buddington, A.F.; Lindsley, D.H. Iron-titanium oxide minerals and synthetic equivalents. J. Petrol. 1964, 5, 310–357. [Google Scholar] [CrossRef]

- Frost, B.; Lindsley, D.H. Occurrence of iron-titanium oxides in igneous rocks. Rev. Mineral. Geochem. 1991, 25, 433–468. [Google Scholar]

- Nadoll, P.; Angerer, T.; Mauk, J.L.; French, D.; Walshe, J. The chemistry of hydrothermal magnetite: A review. Ore Geol. Rev. 2014, 61, 1–32. [Google Scholar] [CrossRef]

- Toplis, M.J.; Carroll, M.R. An experimental study of the influence of oxygen fugacity on Fe–Ti oxide stability, phase relations, and mineral—Melt equilibria in ferro-basaltic systems. J. Petrol. 1995, 36, 1137–1170. [Google Scholar] [CrossRef]

- Broughm, S.G.; Hanchar, J.M.; Tornos, F.; Westhues, A.; Attersley, S. Mineral chemistry of magnetite from magnetite-apatite mineralization and their host rocks: Examples from Kiruna, Sweden, and El Laco, Chile. Miner. Depos. 2017, 52, 1223–1244. [Google Scholar] [CrossRef]

- Boutroy, E.; Dare, S.A.S.; Beaudoin, G.; Barnes, S.J.; Lightfoot, P.C. Magnetite composition in Ni-Cu-PGE deposits worldwide: Application to mineral exploration. J. Geochem. Explor. 2014, 145, 64–81. [Google Scholar] [CrossRef]

- Chen, W.T.; Zhou, M.F.; Gao, J.F.; Hu, R.Z. Geochemistry of magnetite from Proterozoic Fe-Cu deposits in the Kangdian metallogenic province, SW China. Miner. Depos. 2015, 50, 795–809. [Google Scholar] [CrossRef]

- Ding, T.; Ma, D.S.; Lu, J.J.; Zhang, R.Q. Magnetite as an indicator of mixed sources for W–Mo–Pb–Zn mineralization in the Huangshaping polymetallic deposit, southern Hunan Province, China. Ore Geol. Rev. 2018, 95, 65–78. [Google Scholar] [CrossRef]

- Hu, X.; Chen, H.Y.; Zhao, L.D.; Han, J.S.; Xia, X.P. Magnetite geochemistry of the Longqiao and Tieshan Fe–(Cu) deposits in the Middle-Lower Yangtze River Belt: Implications for deposit type and ore genesis. Ore Geol. Rev. 2017, 89, 822–835. [Google Scholar] [CrossRef]

- Huang, X.W.; Boutroy, É.; Makvandi, S.; Beaudoin, G.; Corriveau, L.; de Toni, A.F. Trace element composition of iron oxides from IOCG and IOA deposits: Relationship to hydrothermal alteration and deposit subtypes. Miner. Depos. 2019, 54, 525–552. [Google Scholar] [CrossRef]

- Neumann, E.R.; Svensen, H.H.; Polozov, A.G.; Hammer, Ø. Formation of Si-Al-Mg-Ca-rich zoned magnetite in an end-Permian phreatomagmatic pipe in the Tunguska Basin, East Siberia. Miner. Depos. 2017, 52, 1205–1222. [Google Scholar] [CrossRef]

- Velasco, F.; Tornos, F.; Hanchar, J.M. Immiscible iron- and silica-rich melts and magnetite geochemistry at the El Laco volcano (northern Chile): Evidence for a magmatic origin for the magnetite deposits. Ore Geol. Rev. 2016, 79, 346–366. [Google Scholar] [CrossRef]

- Ward, L.A.; Holwell, D.A.; Barry, T.L.; Blanks, D.E.; Graham, S.D. The use of magnetite as a geochemical indicator in the exploration for magmatic Ni-Cu-PGE sulfide deposits: A case study from Munali, Zambia. J. Geochem. Explor. 2018, 188, 172–184. [Google Scholar] [CrossRef] [Green Version]

- Wen, G.; Li, J.W.; Hofstra, A.H.; Koenig, A.E.; Lowers, H.A.; Adams, D. Hydrothermal reequilibration of igneous magnetite in altered granitic plutons and its implications for magnetite classification schemes: Insights from the Handan-Xingtai iron district, North China Craton. Geochim. Cosmochim. Acta 2017, 213, 255–270. [Google Scholar] [CrossRef]

- Zhao, L.D.; Chen, H.Y.; Zhang, L.; Li, D.F.; Zhang, W.F.; Wang, C.M.; Yang, J.T.; Yan, X.L. Magnetite geochemistry of the Heijianshan Fe–Cu (–Au) deposit in Eastern Tianshan: Metallogenic implications for submarine volcanic-hosted Fe–Cu deposits in NW China. Ore Geol. Rev. 2018, 100, 422–440. [Google Scholar] [CrossRef]

- Dare, S.A.S.; Barnes, S.J.; Beaudoin, G. Did the massive magnetite ‘lava flows’ of El Laco (Chile) form by magmatic or hydrothermal processes? New constraints from magnetite composition by LA-ICP-MS. Miner. Depos. 2015, 50, 607–617. [Google Scholar] [CrossRef]

- Pisiak, L.K.; Canil, D.; Lacourse, T.; Plouffe, A.; Ferbey, T. Magnetite as an indicator mineral in the exploration of porphyry deposits: A case study in Till near the Mount Polley Cu-Au deposit, British Columbia, Canada. Econ. Geol. 2017, 112, 919–940. [Google Scholar] [CrossRef]

- Tang, Z.L.; Song, X.Y.; Su, S. Ni-Cu deposits related to high Mg basaltic magma, Jinchuan, western China. In New Developments in Magmatic Ni-Cu and PGE Deposits; Li, C.S., Ripley, E.M., Eds.; Geological Publishing House: Beijing, China, 2009; pp. 121–140. [Google Scholar]

- Duan, J.; Li, C.S.; Qian, Z.Z.; Jiao, J.G.; Ripley, E.M.; Feng, Y.Q. Multiple S isotopes, zircon Hf isotopes, whole-rock Sr-Nd isotopes, and spatial variations of PGE tenors in the Jinchuan Ni-Cu-PGE deposit, NW China. Miner. Depos. 2016, 51, 557–574. [Google Scholar] [CrossRef]

- Li, C.S.; Xu, Z.H.; de Waal, S.A.; Ripley, E.M.; Maier, W.D. Compositional variations of olivine from the Jinchuan Ni–Cu sulfide deposit, western China: Implications for ore genesis. Miner. Depos. 2004, 39, 159–172. [Google Scholar] [CrossRef]

- Naldrett, A.J. Fundamentals of magmatic sulfide deposits. Rev. Econ. Geol. 2011, 17, 1–50. [Google Scholar]

- Chai, G.; Naldrett, A.J. Characteristics of Ni–Cu–PGE mineralization and genesis of the Jinchuan deposit, northwest China. Econ. Geol. 1992, 87, 1475–1495. [Google Scholar] [CrossRef]

- Chen, L.M.; Song, X.Y.; Keays, R.R.; Tian, Y.L.; Wang, Y.S.; Deng, Y.F.; Xiao, J.F. Segregation and fractionation of magmatic Ni–Cu–PGE sulfides in the western Jinchuan intrusion, northwestern China: Insights from platinum group element geochemistry. Econ. Geol. 2013, 108, 1793–1811. [Google Scholar] [CrossRef]

- de Waal, S.A.; Xu, Z.H.; Li, C.; Mouri, H. Emplacement of viscous mushes in the Jinchuan ultramafic intrusion, western China. Can. Mineral. 2004, 42, 371–392. [Google Scholar] [CrossRef]

- Lehmann, J.; Arndt, N.; Windley, B.; Zhou, M.F.; Wang, C.Y.; Harris, C. Field relationships and geochemical constraints on the emplacement of the Jinchuan intrusion and its Ni–Cu–PGE sulfide deposit, Gansu, China. Econ. Geol. 2007, 102, 75–94. [Google Scholar] [CrossRef]

- Jiao, J.G.; Rui, H.C.; Duan, J. Genesis of the main types of sulphide ore in the Jinchuan N–Cu–PGE deposit, NW China: Constraints from texture and mineral chemistry of pyrrhotite. Geol. J. 2018, 53, 147–158. [Google Scholar] [CrossRef]

- Song, X.Y.; Zhou, M.F.; Wang, C.Y.; Qi, L.; Zhang, C.J. Role of crustal contamination in the formation of the Jinchuan Ni–Cu–(PGE) sulfide deposit, NW China. Int. Geol. Rev. 2006, 48, 1113–1132. [Google Scholar] [CrossRef]

- Song, X.Y.; Keays, R.R.; Zhou, M.F.; Qi, L.; Ihlenfeld, C.; Xiao, J.F. Siderophile and chalcophile elemental constraints on the origin of the Jinchuan Ni–Cu–(PGE) sulfide deposit, NW China. Geochim. Cosmochim. Acta 2009, 73, 404–424. [Google Scholar] [CrossRef]

- Song, X.Y.; Danyushevsky, L.V.; Keays, R.R.; Chen, L.M.; Wang, Y.S.; Tian, Y.L.; Xiao, J.F. Structural, lithological, and geochemical constraints on the dynamic magma plumbing system of the Jinchuan Ni–Cu sulfide deposit, NW China. Miner. Depos. 2012, 47, 277–297. [Google Scholar] [CrossRef]

- Su, S.G.; Li, C.; Zhou, M.F.; Ripley, E.M.; Qi, L. Controls on variations of platinum-group element concentrations in the sulfide ores of the Jinchuan Ni–Cu deposit, western China. Miner. Depos. 2008, 43, 609–626. [Google Scholar] [CrossRef]

- Tang, Z.L. Genetic models of the Jinchuan nickel–copper deposit. In Mineral Deposit Modeling; Kirkham, R.V., Sinclair, W.D., Thorpe, R.I., Duke, J.M., Eds.; Geological Association of Canada: St. John’s, NL, Canada, 1993; Volume 40, pp. 389–401. [Google Scholar]

- Tonnelier, N.J. Geology and Genesis of the Jinchuan Ni–Cu–(PGE) Deposit, China. Unpublished Ph.D. Thesis, Laurentian University, Sudbury, ON, Canada, 2010. [Google Scholar]

- Naldrett, A.J. A portion of the Fe–O–S system between 900 and 1080 °C and its application to sulfide ore magma. J. Petrol. 1969, 10, 171–201. [Google Scholar] [CrossRef]

- Craig, J.R.; Kullerud, G. Phase relations in the Cu–Fe–Ni–S system and their application to magmatic ore deposits. Econ. Geol. Monogr. 1969, 4, 344–358. [Google Scholar]

- Fleet, M.E.; Pan, Y. Fractional crystallization of anhydrous sulfide liquid in the system Fe–Ni–Cu–S, with application to magmatic sulfide deposits. Geochim. Cosmochim. Acta 1994, 58, 3369–3377. [Google Scholar] [CrossRef]

- Gao, J.F.; Zhou, M.F.; Lightfoot, P.C.; Wang, C.Y.; Qi, L.; Sun, M. Sulfde saturation and magma emplacement in the formation of the Permian Huangshandong Ni-Cu sulfde deposit, Xinjiang, northwestern China. Econ. Geol. 2013, 108, 1833–1848. [Google Scholar] [CrossRef]

- Li, C.S.; Ripley, E.M. The giant Jinchuan Ni–Cu–(PGE) deposit: Tectonic setting, magma evolution, ore genesis and exploration implications. Rev. Econ. Geol. 2011, 17, 163–180. [Google Scholar]

- Tang, Z.L.; Li, W.Y. The Metallogenetic Model and Geological Characteristics of the Jinchuan Pt-Bearing Ni–Cu Sulfide Deposit; Geological Publishing House: Beijing, China, 1995; pp. 1–209. (In Chinese) [Google Scholar]

- Li, X.H.; Su, L.; Chung, S.L.; Li, Z.X.; Liu, Y.; Song, B.; Liu, D.Y. Formation of the Jinchuan ultramafic intrusion and the world’s third largest Ni-Cu sulfide deposit: Associated with the ~825 Ma south Chinese mantle plume? Geochem. Geophys. Geosyst. 2005, 6, 1029–1044. [Google Scholar] [CrossRef]

- Zhang, M.J.; Kamob, S.L.; Li, C.S.; Hu, P.Q.; Ripley, E.M. Precise U–Pb zircon-baddeleyite age of the Jinchuan sulphide ore-bearing ultramafic intrusion, western China. Miner. Depos. 2010, 45, 3–9. [Google Scholar] [CrossRef]

- Liu, Y.S.; Hu, Z.C.; Gao, S.; Gunther, D.; Xu, J.; Gao, C.G.; Chen, H.H. In situ analysis of major and trace elements of anhydrous minerals by LA–ICP–MS without applying an internal standard. Chem. Geol. 2008, 257, 34–43. [Google Scholar] [CrossRef]

- Rudnick, R.; Gao, S. Composition of the continental crust. Treatise Geochem. 2003, 3, 1–64. [Google Scholar]

- Wu, C.; Chen, H.Y.; Hong, W.; Li, D.; Liang, P.; Fang, J.; Zhang, L.J.; Lai, C. Magnetite chemistry and implications for the magmatic-hydrothermal ore-forming process: An example from the Devonian Yuleken porphyry Cu system, NW China. Chem. Geol. 2019, 522, 1–15. [Google Scholar] [CrossRef]

- Ray, G.; Webster, I. Geology and chemistry of the low Ti magnetite-bearing Heff Cu–Au skarn and its associated plutonic rocks, Heffley Lake, south-central British Columbia. Explor. Min. Geol. 2007, 16, 159–186. [Google Scholar] [CrossRef]

- Zhao, W.W.; Zhou, M.F. In-situ LA–ICP-MS trace elemental analyses of magnetite: The Mesozoic Tengtie skarn Fe deposit in the Nanling Range, South China. Ore Geol. Rev. 2015, 65, 872–883. [Google Scholar] [CrossRef]

- Hu, H.; Lentz, D.; Li, J.W.; McCarron, T.; Zhao, X.F.; Hall, D. Reequilibration processes in magnetite from iron skarn deposits. Econ. Geol. 2015, 110, 1–8. [Google Scholar] [CrossRef]

- Ilton, E.S.; Eugster, H.P. Base metal exchange between magnetite and a chloride-rich hydrothermal fluid. Geochim. Cosmochim. Acta 1989, 53, 291–301. [Google Scholar] [CrossRef]

- Toplis, M.J.; Corgne, A. An experimental study of element partitioning between magnetite, clinopyroxene and iron-bearing silicate liquids with particular emphasis on vanadium. Contrib. Mineral. Petrol. 2002, 144, 22–37. [Google Scholar] [CrossRef]

- Bordage, A.; Balan, E.; de Villiers, J.P.; Cromarty, R.; Juhin, A.; Carvallo, C.; Calas, G.; Raju, P.V.; Glatzel, P. V oxidation state in Fe–Ti oxides by high-energy resolution fluorescence-detected X-ray absorption spectroscopy. Phys. Chem. Miner. 2011, 38, 449–458. [Google Scholar] [CrossRef]

- Barnes, S.J.; Godel, B.; Gürer, D.; Brenan, J.M.; Robertson, J.; Paterson, D. Sulfide-olivine Fe-Ni exchange and the origin of anomalously Ni rich magmatic sulfides. Econ. Geol. 2013, 108, 1971–1982. [Google Scholar] [CrossRef]

| Sample Number | Location | Magnetite Types | Hosted Ores | Comments |

|---|---|---|---|---|

| Ni2 | Drill core ZK4503, 1294 m in depth, No. 2 orebody, Segment II | Type I-A | Massive Ni-rich sulfide ore | Magnetite is commonly subhedral to anhedral granular with different sizes, and is intergrown with pyrrhotite, chalcopyrite, and minor pyrite and pentlandite. |

| Cu3 | No. 15 exploration line, No. 24 orebody, Segment I | Type I-A | Massive Ni-rich sulfide ore | |

| Cu1 | No. 10 exploration line, No. 1 orebody, Segment II | Type I-B | Massive Cu-rich sulfide ore | Magnetite is commonly subhedral to anhedral granular with different sizes, and is intergrown with chalcopyrite, pyrrhotite, and minor pentlandite. |

| Cu9 | No. 6 exploration line, No. 24 orebody, Segment I | Type II | Disseminated Cu-rich sulfide ore | Magnetite is euhedral to subhedral as dendritic or laminar crystals, with the former being majority, coexisting with pentlandite and minor chalcopyrite. This type of magnetite has different sizes that commonly infilled pentlandite along its cleavages, indicating this type of magnetite silightly postdated pentlandite. |

| Cu4 | No. 16 exploration line, No. 24 orebody, Segment I | Type III | Disseminated Cu-rich sulfide ore | Magnetite is fine-grained and euhedral to anhedral with disseminated structures, akin to metasomatic textures replacing chalcopyrite, probably showing magnetite having a relatively later crystallization phase than chalcopyrite. |

| Cu14 | No. 7 exploration line, No. 24 orebody, Segment I | Type III | Disseminated Cu-rich sulfide ore |

| Elements | Detection Limit | Magnetite from Massive Ni-rich Sulfide Ores (Type I-A, n = 28) | Magnetite from Massive Cu-Rich Sulfide Ores (Type I-B, n = 24) | ||||||||

| Min | Max | Mean | Stdev | n | Min | Max | Mean | Stdev | n | ||

| 24Mg | 2.35 | 61.4 | 388 | 239 | 94 | 27 | 854 | 1158 | 1014 | 68.0 | 24 |

| 27Al | 2.45 | 6.16 | 940 | 114 | 221 | 28 | 79.9 | 438 | 333 | 69.6 | 24 |

| 47Ti | 1.79 | 6.87 | 120 | 60.1 | 34.4 | 27 | 2249 | 4855 | 3441 | 518 | 24 |

| 51V | 0.17 | 116 | 3859 | 653 | 698 | 28 | 360 | 658 | 493 | 58.1 | 24 |

| 52Cr | 5.78 | 19.2 | 66,596 | 20,778 | 25,171 | 28 | 7.01 | 86.8 | 22.0 | 19.1 | 22 |

| 55Mn | 1.20 | 1115 | 4560 | 2157 | 1188 | 28 | 9127 | 11239 | 10529 | 610 | 24 |

| 59Co | 0.18 | 42.1 | 72.6 | 52.6 | 7.63 | 28 | 20.3 | 96.4 | 53.9 | 22.9 | 24 |

| 60Ni | 0.70 | 1247 | 2137 | 1687 | 166 | 28 | 854 | 1432 | 1255 | 111 | 24 |

| 63Cu | 1.10 | 2.78 | 2.78 | 2.78 | 0.00 | 1 | 1.13 | 9.48 | 3.52 | 2.64 | 8 |

| 66Zn | 1.44 | 13.0 | 85.6 | 39.0 | 19.7 | 28 | 165 | 2417 | 1101 | 480 | 24 |

| 71Ga | 0.09 | 3.48 | 24.8 | 9.78 | 4.30 | 28 | 10.1 | 13.0 | 11.5 | 0.68 | 24 |

| 72Ge | 2.92 | 3.11 | 8.24 | 5.92 | 1.28 | 28 | 2.98 | 8.70 | 6.51 | 1.32 | 24 |

| 90Zr | 0.01 | 0.01 | 7.17 | 0.71 | 1.47 | 24 | 1.31 | 28.4 | 11.5 | 7.06 | 24 |

| 93Nb | 0.01 | 0.01 | 5.88 | 1.10 | 1.90 | 17 | 2.01 | 12.7 | 6.96 | 2.62 | 24 |

| 95Mo | 0.06 | 0.07 | 0.13 | 0.09 | 0.02 | 12 | 0.29 | 1.37 | 0.86 | 0.29 | 24 |

| 118Sn | 1.93 | 2.23 | 9.39 | 5.06 | 1.62 | 24 | 23.5 | 62.6 | 49.9 | 7.48 | 24 |

| 178Hf | 0.02 | 0.03 | 0.15 | 0.06 | 0.05 | 4 | 0.04 | 0.33 | 0.14 | 0.07 | 23 |

| 181Ta | 0.00 | 0.00 | 0.06 | 0.02 | 0.02 | 10 | 0.07 | 0.23 | 0.17 | 0.04 | 24 |

| Elements | Detection Limit | Magnetite from Disseminated Cu-rich Sulfide Ores (Type II, n = 13) | Magnetite from Disseminated Cu-rich Sulfide Ores (Type III, n = 23) | ||||||||

| Min | Max | Mean | Stdev | n | Min | Max | Mean | Stdev | n | ||

| 24Mg | 2.35 | 25.8 | 1428 | 351 | 435 | 8 | 2.42 | 3326 | 1105 | 880 | 21 |

| 27Al | 2.45 | 2.95 | 50.6 | 22.5 | 15.4 | 6 | 2.49 | 23.9 | 7.71 | 5.93 | 10 |

| 47Ti | 1.79 | 2.37 | 19.7 | 9.40 | 7.29 | 4 | 1.52 | 9.32 | 3.76 | 2.58 | 6 |

| 51V | 0.17 | 0.21 | 0.34 | 0.30 | 0.06 | 3 | 0.22 | 5.79 | 2.98 | 2.54 | 4 |

| 52Cr | 5.78 | 8.63 | 154 | 63.3 | 46.9 | 12 | 7.84 | 354 | 93.3 | 88.6 | 21 |

| 55Mn | 1.20 | 1623 | 3333 | 2333 | 473 | 13 | 913 | 6344 | 3454 | 1785 | 23 |

| 59Co | 0.18 | 0.38 | 11.5 | 2.59 | 2.89 | 12 | 0.39 | 12.1 | 4.97 | 2.72 | 21 |

| 60Ni | 0.70 | 13.8 | 309 | 67.2 | 88.7 | 9 | 13.4 | 423 | 137 | 109 | 17 |

| 63Cu | 1.10 | 1.33 | 24.7 | 10.9 | 9.42 | 4 | 3.50 | 184 | 68.5 | 60.6 | 11 |

| 66Zn | 1.44 | 1.83 | 32.3 | 8.00 | 8.71 | 12 | 1.70 | 247 | 30.2 | 61.9 | 18 |

| 71Ga | 0.09 | 0.09 | 0.17 | 0.12 | 0.03 | 7 | 0.12 | 0.39 | 0.23 | 0.10 | 6 |

| 72Ge | 2.92 | 3.84 | 7.15 | 5.47 | 1.01 | 12 | 3.35 | 7.98 | 6.29 | 1.09 | 22 |

| 90Zr | 0.01 | 0.01 | 0.03 | 0.02 | 0.01 | 6 | 0.02 | 0.57 | 0.12 | 0.17 | 8 |

| 93Nb | 0.01 | 0.01 | 0.04 | 0.02 | 0.01 | 7 | 0.01 | 0.14 | 0.04 | 0.04 | 14 |

| 95Mo | 0.06 | 0.09 | 0.26 | 0.15 | 0.08 | 3 | 0.07 | 1.12 | 0.27 | 0.35 | 7 |

| 118Sn | 1.93 | 2.02 | 3.43 | 2.65 | 0.49 | 6 | 2.16 | 9.25 | 4.42 | 1.65 | 22 |

| 178Hf | 0.02 | 0.03 | 0.03 | 0.03 | 0.00 | 1 | 0.03 | 0.06 | 0.05 | 0.01 | 3 |

| 181Ta | 0.00 | 0.01 | 0.01 | 0.01 | 0.00 | 3 | 0.01 | 0.21 | 0.11 | 0.10 | 2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, J.; Han, F.; Zhao, L.; Duan, J.; Wang, M. Magnetite Geochemistry of the Jinchuan Ni-Cu-PGE Deposit, NW China: Implication for Its Ore-Forming Processes. Minerals 2019, 9, 593. https://doi.org/10.3390/min9100593

Jiao J, Han F, Zhao L, Duan J, Wang M. Magnetite Geochemistry of the Jinchuan Ni-Cu-PGE Deposit, NW China: Implication for Its Ore-Forming Processes. Minerals. 2019; 9(10):593. https://doi.org/10.3390/min9100593

Chicago/Turabian StyleJiao, Jiangang, Feng Han, Liandang Zhao, Jun Duan, and Mengxi Wang. 2019. "Magnetite Geochemistry of the Jinchuan Ni-Cu-PGE Deposit, NW China: Implication for Its Ore-Forming Processes" Minerals 9, no. 10: 593. https://doi.org/10.3390/min9100593