Retention of Ciprofloxacin and Carbamazepine from Aqueous Solutions Using Chitosan-Based Cryostructured Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

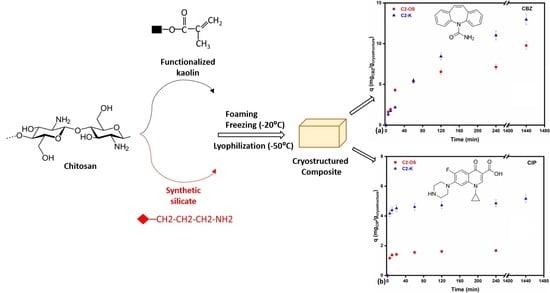

2.2. Synthesis of Cryostructured Composites

2.3. Characterization Techniques

- Fourier Transform Infrared Spectrometry (FTIR)

- Scanning electron microscopy (SEM)

- Mechanical tests

- Determination of Swelling Degrees (SDs)

- Retention capacity of cryostructured composites for CBZ and CIP

3. Results and Discussion

3.1. Synthesis of Cryostructured Composites

3.2. Structure and Morphology of Cryostructured Composites

3.3. Mechanical Stiffness of Cryostructured Composites

3.4. Evaluation of the Swelling Degrees (SDs) at Various pH Values

3.5. Evaluation of CBZ and CIP Retention via Batch Adsorption Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carvalho, I.T.; Santos, L. Antibiotics in the Aquatic Environments: A Review of the European Scenario. Environ. Int. 2016, 94, 736–757. [Google Scholar] [CrossRef] [PubMed]

- Martinez, J.L. Environmental Pollution by Antibiotics and by Antibiotic Resistance Determinants. Environ. Pollut. 2009, 157, 2893–2902. [Google Scholar] [CrossRef] [PubMed]

- Andrzejak, T.; Raje, H.; LaFleur, G.; Willis, J.; Boopathy, R. Water Quality and Antibiotic Resistance in the Recreational Waters. Bioresour. Technol. 2023, 370, 128546. [Google Scholar] [CrossRef]

- Igwegbe, C.A.; Oba, S.N.; Aniagor, C.O.; Adeniyi, A.G.; Ighalo, J.O. Adsorption of Ciprofloxacin from Water: A Comprehensive Review. J. Ind. Eng. Chem. 2021, 93, 57–77. [Google Scholar] [CrossRef]

- Al-Buriahi, A.K.; Al-shaibani, M.M.; Mohamed, R.M.S.R.; Al-Gheethi, A.A.; Sharma, A.; Ismail, N. Ciprofloxacin Removal from Non-Clinical Environment: A Critical Review of Current Methods and Future Trend Prospects. J. Water Process Eng. 2022, 47, 102725. [Google Scholar] [CrossRef]

- Khan, N.A.; Najam, T.; Shah, S.S.A.; Hussain, E.; Ali, H.; Hussain, S.; Shaheen, A.; Ahmad, K.; Ashfaq, M. Development of Mn-PBA on GO Sheets for Adsorptive Removal of Ciprofloxacin from Water: Kinetics, Isothermal, Thermodynamic and Mechanistic Studies. Mater. Chem. Phys. 2020, 245, 122737. [Google Scholar] [CrossRef]

- Ma, J.; Yang, M.; Yu, F.; Zheng, J. Water-Enhanced Removal of Ciprofloxacin from Water by Porous Graphene Hydrogel. Sci. Rep. 2015, 5, 13578. [Google Scholar] [CrossRef]

- El-Kemary, M.; El-Shamy, H.; El-Mehasseb, I. Photocatalytic Degradation of Ciprofloxacin Drug in Water Using ZnO Nanoparticles. J. Lumin. 2010, 130, 2327–2331. [Google Scholar] [CrossRef]

- Sharma, D.; Patel, R.P.; Zaidi, S.T.R.; Sarker, M.R.; Lean, Q.Y.; Ming, L.C. Interplay of the Quality of Ciprofloxacin and Antibiotic Resistance in Developing Countries. Front. Pharmacol. 2017, 8, 546. [Google Scholar] [CrossRef]

- Sayin, F.; Akar, S.T.; Akar, T. From Green Biowaste to Water Treatment Applications: Utilization of Modified New Biochar for the Efficient Removal of Ciprofloxacin. Sustain. Chem. Pharm. 2021, 24, 100522. [Google Scholar] [CrossRef]

- Girardi, C.; Greve, J.; Lamshöft, M.; Fetzer, I.; Miltner, A.; Schäffer, A.; Kästner, M. Biodegradation of Ciprofloxacin in Water and Soil and Its Effects on the Microbial Communities. J. Hazard. Mater. 2011, 198, 22–30. [Google Scholar] [CrossRef]

- Al-Badaii, F.; Shuhaimi-Othman, M. Water Pollution and Its Impact on the Prevalence of Antibiotic-Resistant E. Coli and Total Coliform Bacteria: A Study of the Semenyih River, Peninsular Malaysia. Water Qual. Expo. Health 2015, 7, 319–330. [Google Scholar] [CrossRef]

- Nemati Sani, O.; Navaei Fezabady, A.A.; Yazdani, M.; Taghavi, M. Catalytic Ozonation of Ciprofloxacin Using γ-Al2O3 Nanoparticles in Synthetic and Real Wastewaters. J. Water Process Eng. 2019, 32, 100894. [Google Scholar] [CrossRef]

- Xing, X.; Du, Z.; Zhuang, J.; Wang, D. Removal of Ciprofloxacin from Water by Nitrogen Doped TiO2 Immobilized on Glass Spheres: Rapid Screening of Degradation Products. J. Photochem. Photobiol. 2018, 359, 23–32. [Google Scholar] [CrossRef]

- Qalyoubi, L.; Al-Othman, A.; Al-Asheh, S. Removal of Ciprofloxacin Antibiotic Pollutants from Wastewater Using Nano-Composite Adsorptive Membranes. Environ. Res. 2022, 215, 114182. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Guo, Y.; Zhang, X.; Kamali, M.; Aminabhavi, T.M.; Appels, L.; Dewil, R. Efficient Adsorptive Removal of Ciprofloxacin and Carbamazepine Using Modified Pinewood Biochar—A Kinetic, Mechanistic Study. J. Chem. Eng. 2022, 450, 137896. [Google Scholar] [CrossRef]

- Bizi, M.; EL Bachra, F.-E. Transport of Carbamazepine, Ciprofloxacin and Sulfamethoxazole in Activated Carbon: Solubility and Relationships between Structure and Diffusional Parameters. Molecules 2021, 26, 7318. [Google Scholar] [CrossRef] [PubMed]

- Clara, M.; Strenn, B.; Kreuzinger, N. Carbamazepine as a Possible Anthropogenic Marker in the Aquatic Environment: Investigations on the Behaviour of Carbamazepine in Wastewater Treatment and during Groundwater Infiltration. Water Res. 2004, 38, 947–954. [Google Scholar] [CrossRef]

- Antiñolo Bermúdez, L.; Martín-Luis, A.; Leyva Díaz, J.C.; Muñío Martínez, M.D.M.; Poyatos Capilla, J.M. Kinetic Effects of Ciprofloxacin, Carbamazepine, and Bisphenol on Biomass in Membrane Bioreactor System at Low Temperatures to Treat Urban Wastewater. Membranes 2023, 13, 419. [Google Scholar] [CrossRef]

- Chèvre, N.; Coutu, S.; Margot, J.; Wynn, H.K.; Bader, H.-P.; Scheidegger, R.; Rossi, L. Substance Flow Analysis as a Tool for Mitigating the Impact of Pharmaceuticals on the Aquatic System. Water Res. 2013, 47, 2995–3005. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Ayati, A.; Davoodi, R.; Tanhaei, B.; Karimi, F.; Malekmohammadi, S.; Orooji, Y.; Fu, L.; Sillanpää, M. Recent Advances in Using of Chitosan-Based Adsorbents for Removal of Pharmaceutical Contaminants: A Review. J. Clean. Prod. 2021, 291, 125880. [Google Scholar] [CrossRef]

- Khan, A.H.; Khan, N.A.; Zubair, M.; Azfar Shaida, M.; Manzar, M.S.; Abutaleb, A.; Naushad, M.; Iqbal, J. Sustainable Green Nanoadsorbents for Remediation of Pharmaceuticals from Water and Wastewater: A Critical Review. Environ. Res. 2022, 204, 112243. [Google Scholar] [CrossRef]

- Zhu, S.; Zhao, W.; Wang, P.; Zhao, L.; Jin, C.; Qiu, R. Co-Transport and Retention of Zwitterionic Ciprofloxacin with Nano-Biochar in Saturated Porous Media: Impact of Oxidized Aging. Sci. Total Environ. 2021, 779, 146417. [Google Scholar] [CrossRef] [PubMed]

- Keerthanan, S.; Jayasinghe, C.; Biswas, J.K.; Vithanage, M. Pharmaceutical and Personal Care Products (PPCPs) in the Environment: Plant Uptake, Translocation, Bioaccumulation, and Human Health Risks. Crit. Rev. Environ. Sci. Technol. 2021, 51, 1221–1258. [Google Scholar] [CrossRef]

- Peings, V.; Pigot, T.; Baylere, P.; Sotiropoulos, J.-M.; Frayret, J. Removal of Pharmaceuticals by a Potassium Ferrate(VI) Material: From Practical Implementation to Reactivity Prediction. Environ. Sci. Water Res. Technol. 2017, 3, 699–709. [Google Scholar] [CrossRef]

- Punyapalakul, P.; Sitthisorn, T. Removal of Ciprofloxazin and Carbamazepine by Adsorption on Functionalized Mesoporous Silicates. Int. J. Environ. Eng. 2010, 4, 412–416. [Google Scholar]

- Álvarez-Torrellas, S.; Peres, J.A.; Gil-Álvarez, V.; Ovejero, G.; García, J. Effective Adsorption of Non-Biodegradable Pharmaceuticals from Hospital Wastewater with Different Carbon Materials. J. Chem. Eng. 2017, 320, 319–329. [Google Scholar] [CrossRef]

- Kümmerer, K. Antibiotics in the Aquatic Environment—A Review—Part I. Chemosphere 2009, 75, 417–434. [Google Scholar] [CrossRef] [PubMed]

- Brown, S.A. Fluoroquinolones in Animal Health. J. Vet. Pharmacol. Ther. 1996, 19, 1–14. [Google Scholar] [CrossRef]

- Scaria, J.; Gopinath, A.; Ranjith, N.; Ravindran, V.; Ummar, S.; Nidheesh, P.V.; Kumar, M.S. Carbonaceous Materials as Effective Adsorbents and Catalysts for the Removal of Emerging Contaminants from Water. J. Clean. Prod. 2022, 350, 131319. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Lv, Z.; Wang, B. Ultrahigh Ciprofloxacin Accumulation and Visible-Light Photocatalytic Degradation: Contribution of Metal Organic Frameworks Carrier in Magnetic Surface Molecularly Imprinted Polymers. J. Colloid Interface Sci. 2022, 616, 872–885. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Kamali, M.; Yu, X.; Costa, M.E.V.; Appels, L.; Cabooter, D.; Dewil, R. Kinetics and Mechanisms of the Carbamazepine Degradation in Aqueous Media Using Novel Iodate-Assisted Photochemical and Photocatalytic Systems. Sci. Total Environ. 2022, 825, 153871. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Liu, T.; Zhang, Y.; Ge, F.; Steel, R.M.; Sun, L. Advances in Technologies for Pharmaceuticals and Personal Care Products Removal. J. Mater. Chem. A 2017, 5, 12001–12014. [Google Scholar] [CrossRef]

- Patel, M.; Kumar, R.; Kishor, K.; Mlsna, T.; Pittman, C.U.; Mohan, D. Pharmaceuticals of Emerging Concern in Aquatic Systems: Chemistry, Occurrence, Effects, and Removal Methods. Chem. Rev. 2019, 119, 3510–3673. [Google Scholar] [CrossRef]

- Tunioli, F.; Khaliha, S.; Mantovani, S.; Bianchi, A.; Kovtun, A.; Xia, Z.; Bafqi, M.S.S.; Okan, B.S.; Marforio, T.D.; Calvaresi, M.; et al. Adsorption of Emerging Contaminants by Graphene Related Materials and Their Alginate Composite Hydrogels. J. Environ. Chem. Eng. 2023, 11, 109566. [Google Scholar] [CrossRef]

- Qin, Y.; Luo, J.; An, Q.; Xiao, Z.; Hao, J.; Tong, Y.; Zhai, S. Three-Dimensional Co–N/SBA-15/Alginate Hydrogels with Excellent Recovery and Recyclability for Activating Peroxymonosulfate to Degrade Ciprofloxacin. Microporous Mesoporous Mater. 2021, 323, 111259. [Google Scholar] [CrossRef]

- Nawaz, M.; Miran, W.; Jang, J.; Lee, D.S. One-Step Hydrothermal Synthesis of Porous 3D Reduced Graphene Oxide/TiO2 Aerogel for Carbamazepine Photodegradation in Aqueous Solution. Appl. Catal. B Environ. 2017, 203, 85–95. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, A.; Gao, W.; Fu, H.; Wang, Z. Al2O3 Nanoparticles Promote the Removal of Carbamazepine in Water by Chlorella vulgaris Immobilized in Sodium Alginate Gel Beads. J. Chem. 2020, 2020, e8758432. [Google Scholar] [CrossRef]

- Saya, L.; Rameshwor Singh, W.; Hooda, S. Adsorptive Removal of Ciprofloxacin from Aqueous Medium by Magnetic Guar Gum Grafted Graphene Oxide Nano Composite. J. Environ. Chem. Eng. 2023, 11, 110766. [Google Scholar] [CrossRef]

- Hu, C.; Li, J.; Ke, J.; Liang, J.; Liu, Q.; Wang, Q.; Huang, W. The Preparation and Removal Performance of Carbamazepine/Oxcarbazepine Double Template Magnetic Molecularly Imprinted Polymers. Sep. Purif. Technol. 2023, 306, 122556. [Google Scholar] [CrossRef]

- Nezhadali, A.; Koushali, S.E.; Divsar, F. Synthesis of Polypyrrole—Chitosan Magnetic Nanocomposite for the Removal of Carbamazepine from Wastewater: Adsorption Isotherm and Kinetic Study. J. Environ. Chem. Eng. 2021, 9, 105648. [Google Scholar] [CrossRef]

- Zhao, L.; You, Y.; Zhao, Y.; Chen, Y.; Du, Y.; Ji, S.; Guo, M.; Tang, D. Molecularly Imprinted Polymer Membranes Based on Single Template for Recognition and Extraction of Carbamazepine and Its Structurally Analogues. Microchem. J. 2023, 195, 109518. [Google Scholar] [CrossRef]

- Aghababaei, A.; Azargohar, R.; Dalai, A.K.; Soltan, J.; Niu, C.H. Effective Adsorption of Carbamazepine from Water by Adsorbents Developed from Flax Shives and Oat Hulls: Key Factors and Characterization. Ind. Crop. Prod. 2021, 170, 113721. [Google Scholar] [CrossRef]

- Al-Ghoul, N.E.; Albarghouti, G.A.; Qandeel, R.G. Activated Carbon-Based Pomegranate Peels as an Efficient Removal Method for Carbamazepine. Environ. Monit. Assess. 2023, 195, 821. [Google Scholar] [CrossRef] [PubMed]

- Ajduković, M.; Stevanović, G.; Marinović, S.; Mojović, Z.; Banković, P.; Radulović, K.; Jović-Jovičić, N. Ciprofloxacin Adsorption onto a Smectite–Chitosan-Derived Nanocomposite Obtained by Hydrothermal Synthesis. Water 2023, 15, 2608. [Google Scholar] [CrossRef]

- Ye, W.; Xi, J.; Sun, Y.; Meng, L.; Bian, H.; Xiao, H.; Wu, W. Superelastic Chitin Nanofibril/Chitosan Aerogel for Effective Circulating and Continuous Oil-Water Separation. Int. J. Biol. Macromol. 2023, 249, 125958. [Google Scholar] [CrossRef]

- Mangla, D.; Annu; Sharma, A.; Ikram, S. Critical Review on Adsorptive Removal of Antibiotics: Present Situation, Challenges and Future Perspective. J. Hazard. Mater. 2022, 425, 127946. [Google Scholar] [CrossRef]

- Chacko, R.T.; Ventura, J.; Zhuang, J.; Thayumanavan, S. Polymer Nanogels: A Versatile Nanoscopic Drug Delivery Platform. Adv. Drug Deliv. Rev. 2012, 64, 836–851. [Google Scholar] [CrossRef]

- Hajebi, S.; Rabiee, N.; Bagherzadeh, M.; Ahmadi, S.; Rabiee, M.; Roghani-Mamaqani, H.; Tahriri, M.; Tayebi, L.; Hamblin, M.R. Stimulus-Responsive Polymeric Nanogels as Smart Drug Delivery Systems. Acta Biomater. 2019, 92, 1–18. [Google Scholar] [CrossRef]

- Feraru, A.; Tóth, Z.-R.; Mureșan-Pop, M.; Baia, M.; Gyulavári, T.; Páll, E.; Turcu, R.V.F.; Magyari, K.; Baia, L. Anionic Polysaccharide Cryogels: Interaction and In Vitro Behavior of Alginate–Gum Arabic Composites. Polymers 2023, 15, 1844. [Google Scholar] [CrossRef]

- Ferreira, S.A.; Gama, F.M.; Vilanova, M. Polymeric Nanogels as Vaccine Delivery Systems. Nanomed. Nanotechnol. Biol. Med. 2013, 9, 159–173. [Google Scholar] [CrossRef]

- Duan, Q.-Y.; Zhu, Y.-X.; Jia, H.-R.; Wang, S.-H.; Wu, F.-G. Nanogels: Synthesis, Properties, and Recent Biomedical Applications. Prog. Mater. Sci. 2023, 139, 101167. [Google Scholar] [CrossRef]

- Radouane, N. Review on Thermoelectric Aerogels and Their Applications: Progress and Challenges. J. Sol-Gel Sci. Technol. 2023, 106, 639–653. [Google Scholar] [CrossRef]

- Haleem, A.; Pan, J.-M.; Shah, A.; Hussain, H.; He, W. A Systematic Review on New Advancement and Assessment of Emerging Polymeric Cryogels for Environmental Sustainability and Energy Production. Sep. Purif. Technol. 2023, 316, 123678. [Google Scholar] [CrossRef]

- Nita, L.E.; Crețu, B.-E.-B.; Șerban, A.-M.; Rusu, A.G.; Rosca, I.; Pamfil, D.; Chiriac, A.P. New Cryogels Based on Poly (Vinyl Alcohol) and a Copolymacrolactone System. II. Antibacterial Properties of the Network Embedded with Thymol Bioactive Agent. React. Funct. Polym. 2023, 182, 105461. [Google Scholar] [CrossRef]

- Di Muzio, L.; Sergi, C.; Carriero, V.C.; Tirillò, J.; Adrover, A.; Messina, E.; Gaetani, R.; Petralito, S.; Casadei, M.A.; Paolicelli, P. Gelatin-Based Spongy and Compressive Resistant Cryogels with Shape Recovery Ability as Ideal Scaffolds to Support Cell Adhesion for Tissue Regeneration. React. Funct. Polym. 2023, 189, 105607. [Google Scholar] [CrossRef]

- Dumitru, M.V.; Sandu, T.; Miron, A.; Zaharia, A.; Radu, I.C.; Gavrilă, A.-M.; Sârbu, A.; Iovu, H.; Chiriac, A.-L.; Iordache, T.V. Hybrid Cryogels with Superabsorbent Properties as Promising Materials for Penicillin G Retention. Gels 2023, 9, 443. [Google Scholar] [CrossRef]

- Neagu, A.-L.; Gavrilă, A.-M.; Stoica, B.-E.; Zaharia, C.; Iordache, T.-V. Molecularly imprinted microparticles based on quaternary ammonium salts for lipopolysaccharide recognition. U.P.B. Sci. Bull. Ser. B 2023, 85, 1–16. [Google Scholar]

- Moussout, H.; Ahlafi, H.; Aazza, M.; Maghat, H. Critical of Linear and Nonlinear Equations of Pseudo-First Order and Pseudo-Second Order Kinetic Models. Karbala Int. J. Mod. Sci. 2018, 4, 244–254. [Google Scholar] [CrossRef]

- Sahoo, S.; Uma; Banerjee, S.; Sharma, Y.C. Application of Natural Clay as a Potential Adsorbent for the Removal of a Toxic Dye from Aqueous Solutions. Desalin. Water Treat. 2014, 52, 6703–6711. [Google Scholar] [CrossRef]

- Wu, F.-C.; Tseng, R.-L.; Juang, R.-S. Initial Behavior of Intraparticle Diffusion Model Used in the Description of Adsorption Kinetics. Chem. Eng. J. 2009, 153, 1–8. [Google Scholar] [CrossRef]

- Kajjumba, G.W.; Emik, S.; Öngen, A.; Özcan, H.K.; Aydın, S. Modelling of Adsorption Kinetic Processes—Errors, Theory and Application. In Advanced Sorption Process Applications; IntechOpen: London, UK, 2018; ISBN 978-1-78984-819-9. [Google Scholar]

- Miron, A.; Sarbu, A.; Zaharia, A.; Sandu, T.; Iovu, H.; Fierascu, R.C.; Neagu, A.-L.; Chiriac, A.-L.; Iordache, T.-V. A Top-Down Procedure for Synthesizing Calcium Carbonate-Enriched Chitosan from Shrimp Shell Wastes. Gels 2022, 8, 742. [Google Scholar] [CrossRef] [PubMed]

- Dinu, M.V.; Humelnicu, I.; Ghiorghita, C.A.; Humelnicu, D. Aminopolycarboxylic Acids-Functionalized Chitosan-Based Composite Cryogels as Valuable Heavy Metal Ions Sorbents: Fixed-Bed Column Studies and Theoretical Analysis. Gels 2022, 8, 221. [Google Scholar] [CrossRef] [PubMed]

- Biswas, S.; Rashid, T.U.; Mallik, A.K.; Islam, M.M.; Khan, M.N.; Haque, P.; Khan, M.; Rahman, M.M. Facile Preparation of Biocomposite from Prawn Shell Derived Chitosan and Kaolinite-Rich Locally Available Clay. Int. J. Polym. Sci. 2017, 2017, e6472131. [Google Scholar] [CrossRef]

- Dey, S.C.; Al-Amin, M.; Rashid, T.U.; Ashaduzzaman, M.; Shamsuddin, S.M. pH Induced Fabrication of Kaolinite-Chitosan Biocomposite. Int. Lett. Chem. Phys. Astron. 2016, 68, 1–9. [Google Scholar] [CrossRef]

- Le, H.R.; Qu, S.; Mackay, R.E.; Rothwell, R. Fabrication and Mechanical Properties of Chitosan Composite MembraneContaining Hydroxyapatite Particles. J. Adv. Ceram. 2012, 1, 66–71. [Google Scholar] [CrossRef]

- Buchtová, N.; Pradille, C.; Bouvard, J.-L.; Budtova, T. Mechanical Properties of Cellulose Aerogels and Cryogels. Soft Matter 2019, 15, 7901–7908. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X. Rethinking of the Intraparticle Diffusion Adsorption Kinetics Model: Interpretation, Solving Methods and Applications. Chemosphere 2022, 309, 136732. [Google Scholar] [CrossRef]

- Agbovi, H.K.; Wilson, L.D. 1—Adsorption Processes in Biopolymer Systems: Fundamentals to Practical Applications. In Natural Polymers-Based Green Adsorbents for Water Treatment; Kalia, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–51. ISBN 978-0-12-820541-9. [Google Scholar]

- Zhang, C.-L.; Qiao, G.-L.; Zhao, F.; Wang, Y. Thermodynamic and Kinetic Parameters of Ciprofloxacin Adsorption onto Modified Coal Fly Ash from Aqueous Solution. J. Mol. Liq. 2011, 163, 53–56. [Google Scholar] [CrossRef]

- Adeyanju, C.A.; Ogunniyi, S.; Selvasembian, R.; Oniye, M.M.; Ajala, O.J.; Adeniyi, A.G.; Igwegbe, C.A.; Ighalo, J.O. Recent Advances on the Aqueous Phase Adsorption of Carbamazepine. ChemBioEng Rev. 2022, 9, 231–247. [Google Scholar] [CrossRef]

- Jemutai-Kimosop, S.; Orata, F.; Shikuku, V.O.; Okello, V.A.; Getenga, Z.M. Insights on Adsorption of Carbamazepine onto Iron Oxide Modified Diatomaceous Earth: Kinetics, Isotherms, Thermodynamics, and Mechanisms. Environ. Res. 2020, 180, 108898. [Google Scholar] [CrossRef] [PubMed]

| Pharmaceutical Code | CBZ | CIP | ||||

|---|---|---|---|---|---|---|

| Pseudo-first-order kinetic model (Equation (4)) | ||||||

| Sample Code | K (g mg−1 min−1) | qe (mg g−1) | R2 | K (min−1) | qe (mg g−1) | R2 |

| C2-K | 8.50 × 10−3 | 12.95 | 0.992 | 430.00 × 10−3 | 5.15 | 0.980 |

| C2-OS | 18.00 × 10−3 | 9.76 | 0.927 | 68.00 × 10−3 | 3.68 | 0.490 |

| Pseudo-second-order kinetic model (Equation (5)) | ||||||

| Sample Code | K2 (g mg−1 min−1) | qe (mg g−1) | R2 | K2 (g mg−1 min−1) | qe (mg g−1) | R2 |

| C2-K | 9.30 × 10−4 | 12.95 | 0.995 | 17.17 | 5.15 | 0.999 |

| C2-OS | 1.98 × 10−3 | 9.76 | 0.998 | 36.35 | 3.68 | 0.984 |

| Intraparticle diffusion kinetic model (Equation (6)) | ||||||

| Sample Code | Kp (mg g−1 min−1/2) | C (mg g−1) | R2 | Kp (mg g−1 min−1/2) | C (mg g−1) | R2 |

| C2-K | 0.33 | 2.16 | 0.752 | 0.02 | 4.34 | 0.833 |

| C2-OS | 0.21 | 2.73 | 0.789 | 0.07 | 0.96 | 0.959 |

| Elovich linear kinetic model (Equation (7)) | ||||||

| Sample Code | α (mg g−1 min−1) | β (mg g−1) | R2 | α (mg g−1 min−1) | β (mg g−1) | R2 |

| C2-K | 0.42 | −3.42 | 0.949 | 6.16 | 3.96 | 0.980 |

| C2-OS | 0.68 | −0.74 | 0.979 | 2.72 | 0.28 | 0.703 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dumitru, M.-V.; Neagu, A.-L.; Miron, A.; Roque, M.I.; Durães, L.; Gavrilă, A.-M.; Sarbu, A.; Iovu, H.; Chiriac, A.-L.; Iordache, T.V. Retention of Ciprofloxacin and Carbamazepine from Aqueous Solutions Using Chitosan-Based Cryostructured Composites. Polymers 2024, 16, 639. https://doi.org/10.3390/polym16050639

Dumitru M-V, Neagu A-L, Miron A, Roque MI, Durães L, Gavrilă A-M, Sarbu A, Iovu H, Chiriac A-L, Iordache TV. Retention of Ciprofloxacin and Carbamazepine from Aqueous Solutions Using Chitosan-Based Cryostructured Composites. Polymers. 2024; 16(5):639. https://doi.org/10.3390/polym16050639

Chicago/Turabian StyleDumitru, Marinela-Victoria, Ana-Lorena Neagu, Andreea Miron, Maria Inês Roque, Luisa Durães, Ana-Mihaela Gavrilă, Andrei Sarbu, Horia Iovu, Anita-Laura Chiriac, and Tanța Verona Iordache. 2024. "Retention of Ciprofloxacin and Carbamazepine from Aqueous Solutions Using Chitosan-Based Cryostructured Composites" Polymers 16, no. 5: 639. https://doi.org/10.3390/polym16050639