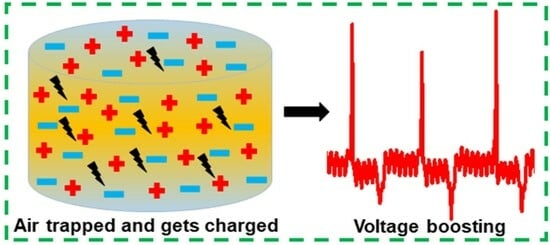

An Ultrasensitive Laser-Induced Graphene Electrode-Based Triboelectric Sensor Utilizing Trapped Air as Effective Dielectric Layer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of LIG Film Using PI Film

2.2. Preparation of Circular Padded Film of Silicone Rubber

2.3. Characterization and Electrical Output Measurements

2.4. Fabrication of Air-Trapped Padded Sensor (ATPS)

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Lin, L.; Wang, Z.L. Triboelectric nanogenerators as self-powered active sensors. Nano Energy 2015, 11, 436–462. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerator (TENG)—Sparking an Energy and Sensor Revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef]

- Tao, J.; Bao, R.; Wang, X.; Peng, Y.; Li, J.; Fu, S.; Pan, C.; Wang, Z.L. Self-Powered Tactile Sensor Array Systems Based on the Triboelectric Effect. Adv. Funct. Mater. 2019, 29, 1806379. [Google Scholar] [CrossRef]

- Jiang, J.; Sun, X.; Wen, Z. Perspectives of Triboelectric Sensors for Internet of Healthcare. Adv. Sens. Res. 2022, 1, 2200011. [Google Scholar] [CrossRef]

- Korotcenkov, G.; Cho, B.K. Ozone measuring: What can limit the application of SnO2-based gas sensors? Sens. Actuators B 2012, 161, 28–44. [Google Scholar] [CrossRef]

- Suriano, D. A Portable Air Quality Monitoring Unit and a Modular, Flexible Tool for on-Field Evaluation and Calibration of Low-Cost Gas Sensors. HardwareX 2021, 9, e00198. [Google Scholar] [CrossRef] [PubMed]

- Ren, K.; Huang, L.; Yue, S.; Lu, S.; Liu, K.; Azam, M.; Wang, Z.; Wei, Z.; Qu, S.; Wang, Z. Turning a disadvantage into an advantage: Synthesizing high-quality organometallic halide perovskite nanosheet arrays for humidity sensors. J. Mater. Chem. C 2017, 5, 2504–2508. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Kamilya, T.; Sarkar, P.K.; Acharya, S. Unveiling Peritoneum Membrane for a Robust Triboelectric Nanogenerator. ACS Omega 2019, 4, 17684–17690. [Google Scholar] [CrossRef]

- Sarkar, P.K.; Kamilya, T.; Acharya, S. Introduction of Triboelectric Positive Bioplastic for Powering Portable Electronics and Self-Powered Gait Sensor. ACS Appl. Energy Mater. 2019, 2, 5507–5514. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Wang, N.; Wang, X.X.; Yan, K.; Song, W.; Fan, Z.; Yu, M.; Long, Y.Z. Anisotropic Triboelectric Nanogenerator Based on Ordered Electrospinning. ACS Appl. Mater. Interfaces 2020, 12, 46205–46211. [Google Scholar] [CrossRef]

- Pan, R.; Xuan, W.; Chen, J.; Dong, S.; Jin, H.; Wang, X.; Li, H.; Luo, J. Fully biodegradable triboelectric nanogenerators based on electrospun polylactic acid and nanostructured gelatin films. Nano Energy 2018, 45, 193–202. [Google Scholar] [CrossRef]

- Stanford, M.G.; Li, J.T.; Chyan, Y.; Wang, Z.; Wang, W.; Tour, J.M. Laser-Induced Graphene Triboelectric Nanogenerators. ACS Nano 2019, 13, 7166–7174. [Google Scholar] [CrossRef]

- Lei, R.; Shi, Y.; Ding, Y.; Nie, J.; Li, S.; Wang, F.; Zhai, H.; Chen, X.; Wang, Z.L. Sustainable high-voltage source based on triboelectric nanogenerator with a charge accumulation strategy. Energy Environ. Sci. 2020, 13, 2178–2190. [Google Scholar] [CrossRef]

- Bai, Y.; Feng, H.; Li, Z. Theory and applications of high-voltage triboelectric nanogenerators. Cell Rep. Phys. Sci. 2022, 3, 101108. [Google Scholar] [CrossRef]

- Cao, X.; Jie, Y.; Wang, N.; Wang, Z.L. Triboelectric nanogenerators driven self-powered electrochemical processes for energy and environmental science. Adv. Energy Mater. 2016, 6, 1600665. [Google Scholar] [CrossRef]

- Zou, H.-X.; Zhao, L.-C.; Wang, Q.; Gao, Q.-H.; Yan, G.; Wei, K.-X.; Zhang, W.-M. A self-regulation strategy for triboelectric nanogenerator and self-powered wind-speed sensor. Nano Energy 2022, 95, 106990. [Google Scholar] [CrossRef]

- Nazar, A.M.; Narazaki, Y.; Rayegani, A.; Sardo, F.R. Recent progress of triboelectric nanogenerators as self-powered sensors in transportation engineering. Measurement 2022, 203, 112010. [Google Scholar] [CrossRef]

- Khandelwal, G.; Chandrasekhar, A.; Raj, N.P.M.J.; Kim, S.-J. Metal-Organic Framework: A Novel Material for Triboelectric Nanogenerator-Based Self-Powered Sensors and Systems. Adv. Energy Mater. 2019, 9, 1803581. [Google Scholar] [CrossRef]

- Liu, H.Y.; Wang, H.; Lyu, Y.; He, C.F.; Liu, Z.H. A novel triboelectric nanogenerator based on carbon fiber reinforced composite lamina and as a self-powered displacement sensor. Microelectron. Eng. 2020, 224, 9. [Google Scholar] [CrossRef]

- Han, Z.; Jiao, P.; Zhu, Z. Combination of Piezoelectric and Triboelectric Devices for Robotic Self-Powered Sensors. Micromachines 2021, 12, 813. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y.; Boyer, C.; Kalantar-Zadeh, K.; Peng, S.; Chu, D.; Wang, C.H. Recent Developments of Hybrid Piezo–Triboelectric Nanogenerators for Flexible Sensors and Energy Harvesters. Nanoscale Adv. 2021, 3, 5465–5486. [Google Scholar] [CrossRef]

- Lee, J.W.; Cho, H.J.; Chun, J.; Kim, K.N.; Kim, S.; Ahn, C.W.; Kim, I.W.; Kim, J.; Kim, S.; Yang, C.; et al. Robust nanogenerators based on graft copolymers via control of dielectrics for remarkable output power enhancement. Sci. Adv. 2017, 3, e1602902. [Google Scholar] [CrossRef]

- Shao, Y.; Feng, C.; Deng, B.; Yin, B.; Yang, M. Facile method to enhance output performance of bacterial cellulose nanofiber based triboelectric nanogenerator by controlling micro-nano structure and dielectric constant. Nano Energy 2019, 62, 620–627. [Google Scholar] [CrossRef]

- Zi, Y.; Wu, C.; Ding, W.; Wang, Z.L. Maximized Effective Energy Output of Contact-Separation-Triggered Triboelectric Nanogenerators as Limited by Air Breakdown. Adv. Funct. Mater. 2017, 27, 1700049. [Google Scholar] [CrossRef]

- Jiang, C.; Dai, K.; Yi, F.; Han, Y.; Wang, X.; You, Z. Optimization of triboelectric nanogenerator load characteristics considering the air breakdown effect. Nano Energy 2018, 53, 706–715. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, B.; Long, J.; Kuang, Y.; Chen, X.; Hou, M.; Gao, J.; Zhou, S.; Fan, B.; He, Y.; et al. Interfacial laser-induced graphene enabling high-performance liquid−solid triboelectric nanogenerator. Adv. Mater. 2021, 33, 2104290. [Google Scholar] [CrossRef]

- Zou, Y.; Zhong, M.; Li, S.; Qing, Z.; Xing, X.; Gong, G.; Yan, R.; Qin, W.; Shen, J.; Zhang, H.; et al. Flexible Wearable Strain Sensors Based on Laser-Induced Graphene for Monitoring Human Physiological Signals. Polymers 2023, 15, 3553. [Google Scholar] [CrossRef]

- Zhao, P.; Bhattacharya, G.; Fishlock, S.J.; Guy, J.G.M.; Kumar, A.; Tsonos, C.; Yu, Z.; Raj, S.; McLaughlin, J.A.; Luo, J.; et al. Replacing the metal electrodes in triboelectric nanogenerators: High-performance laser-induced graphene electrodes. Nano Energy 2020, 75, 104958. [Google Scholar] [CrossRef]

- Chu, H.; Jang, H.; Lee, Y.; Chae, Y.; Ahn, J.H. Conformal, graphene-based triboelectric nanogenerator for self-powered wearable electronics. Nano Energy 2016, 27, 298–305. [Google Scholar] [CrossRef]

- Inagaki, N.; Tasaka, S.; Masumoto, M. Improved adhesion between kapton film and copper metal by plasma graft polymerization of vinylimidazole. Macromolecules 1996, 29, 1642–1648. [Google Scholar] [CrossRef]

- Xiao, T.X.; Jiang, T.; Zhu, J.X.; Liang, X.; Xu, L.; Shao, J.J.; Zhang, C.L.; Wang, J.; Wang, Z.L. Silicone-based triboelectric nanogenerator for water wave energy harvesting. ACS Appl. Mater. Interfaces 2018, 10, 3616–3623. [Google Scholar] [CrossRef]

- Vu, D.L.; Le, C.D.; Ahn, K.K. Polyvinylidene Fluoride Surface Polarization Enhancement for Liquid-Solid Triboelectric Nanogenerator and Its Application. Polymers 2022, 14, 960. [Google Scholar] [CrossRef]

- Choi, Y.S.; Jing, Q.; Datta, A.; Boughey, C.; Kar-Narayan, S. A Triboelectric Generator Based on Self-Poled Nylon-11 Nanowires Fabricated by Gas-Flow Assisted Template Wetting. Energy Environ. Sci. 2017, 10, 2180–2189. [Google Scholar] [CrossRef]

- Mi, Y.; Zhao, Z.; Wu, H.; Lu, Y.; Wang, N. Porous Polymer Materials in Triboelectric Nanogenerators: A Review. Polymers 2023, 15, 4383. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material Aspects of Triboelectric Energy Generation and Sensors. NPG Asia Mater. 2020, 12, 6. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, T.; Jiang, X.; Li, C.; Yang, S.; Zhang, Y. Characterization of silicone rubber degradation under salt-fog environment with AC test voltage. IEEE Access 2019, 7, 66714. [Google Scholar]

- Song, W.X.; Gan, B.H.; Jiang, T.; Zhang, Y.; Yu, A.F.; Yuan, H.T.; Chen, N.; Sun, C.W.; Wang, Z.L. Nanopillar Arrayed Triboelectric Nanogenerator as a Self-Powered Sensitive Sensor for a Sleep Monitoring System. ACS Nano 2016, 10, 8097–8103. [Google Scholar] [CrossRef] [PubMed]

- Maharjan, P.; Toyabur, R.M.; Park, J.Y. A human locomotion inspired hybrid nanogenerator for wrist-wearable electronic device and sensor applications. Nano Energy 2018, 46, 383–395. [Google Scholar] [CrossRef]

- Chen, S.; Wu, N.; Lin, S.; Duan, J.; Xu, Z.; Pan, Y.; Zhang, H.; Xu, Z.; Huang, L.; Hu, B.; et al. Hierarchical Elastomer Tuned Self-Powered Pressure Sensor for Wearable Multifunctional Cardiovascular Electronics. Nano Energy 2020, 70, 104460. [Google Scholar] [CrossRef]

- Ouyang, H.; Tian, J.; Sun, G.; Zou, Y.; Liu, Z.; Li, H.; Zhao, L.; Shi, B.; Fan, Y.; Fan, Y. Self-Powered Pulse Sensor for Antidiastole of Cardiovascular Disease. Adv. Mater. 2017, 29, 1703456. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Zhang, Y.; Shi, N.; Liu, Z.; Zhang, X.; Wu, M.; Pan, C.; Liu, H.; Li, L.; Wang, Z.L. Transparent and Stretchable Triboelectric Nanogenerator for Self-Powered Tactile Sensing. Nano Energy 2019, 59, 302–310. [Google Scholar] [CrossRef]

- Ha, M.; Lim, S.; Cho, S.; Lee, Y.; Na, S.; Baig, C.; Ko, H. Skin-Inspired Hierarchical Polymer Architectures with Gradient Stiffness for Spacer-Free, Ultrathin, and Highly Sensitive Triboelectric Sensors. ACS Nano 2018, 12, 3964–3974. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zheng, Q.; Liu, Y.; Shi, B.; Xue, X.; Ji, W.; Liu, Z.; Jin, Y.; Zou, Y.; An, Z.; et al. Self-powered, one-step, and multifunctional implantable triboelectric active sensor for real-time biomedical monitoring. Nano Lett. 2016, 16, 6042–6051. [Google Scholar] [CrossRef]

- Cui, X.N.; Zhang, C.; Liu, W.H.; Zhang, Y.; Zhang, J.H.; Li, X.; Geng, L.; Wang, X.L. Pulse sensor based on single-electrode triboelectric nanogenerator. Sens. Actuators A 2018, 280, 326–331. [Google Scholar] [CrossRef]

- Barlett, D. Respiratory functions of the larynx. Physiol. Rev. 1982, 69, 33–57. [Google Scholar] [CrossRef]

| Ref. Work | Type | Materials Used | Size | Mode of Operation | Max. Current | Power Density |

|---|---|---|---|---|---|---|

| [39] | Sleep sensor | APLF–Cu | 1.8 cm2 | Contact–separation | 0.9 µA | 120 mW/m2 |

| [40] | Motion sensor | ABS–Cu | - | Contact–separation | 0.26 µA | 0.22 µW/cm3 |

| [41] | Cardiovascular sensor | FEP–PET | 1.5 × 3 cm2 | Contact–separation | - | 23 μW/m2 |

| [42] | Coronary heart disease sensor | Kapton–Cu | 20 × 10 mm2 | Contact–separation | 2.73 µA | - |

| [43] | Tactile sensor | Ionogel–PDMS | 2 × 1.5 cm2 | Contact–separation | 2.3 nA | - |

| [44] | Touch sensor | P(VDF-TrFE)–PDMS | - | Contact–separation | - | 46.7 µW/cm2 |

| [45] | Respiratory sensor | PTFE–Al | 3 × 2 × 0.1 cm3 | Contact–separation | 4 µA | - |

| [46] | Pulse sensor | PET | 40 × 20 mm2 | Single-electrode mode | 5.4 nA | - |

| Our work | Multipurpose pressure sensor | LIG–silicone rubber | 1.13 cm2 | Contact–separation | 1.2 µA | 139.8 mW/m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamilya, T.; Han, D.; Shin, J.; Kwon, S.; Park, J. An Ultrasensitive Laser-Induced Graphene Electrode-Based Triboelectric Sensor Utilizing Trapped Air as Effective Dielectric Layer. Polymers 2024, 16, 26. https://doi.org/10.3390/polym16010026

Kamilya T, Han D, Shin J, Kwon S, Park J. An Ultrasensitive Laser-Induced Graphene Electrode-Based Triboelectric Sensor Utilizing Trapped Air as Effective Dielectric Layer. Polymers. 2024; 16(1):26. https://doi.org/10.3390/polym16010026

Chicago/Turabian StyleKamilya, Tapas, Doohyun Han, Jaehee Shin, Soongeun Kwon, and Jinhyoung Park. 2024. "An Ultrasensitive Laser-Induced Graphene Electrode-Based Triboelectric Sensor Utilizing Trapped Air as Effective Dielectric Layer" Polymers 16, no. 1: 26. https://doi.org/10.3390/polym16010026